Mineralized keratin biomimetic material and preparation method thereof

A technology of bionic materials and keratin, which is applied in the field of biomedical materials, can solve the problems of unsatisfactory and stable promotion of DPSCs proliferation, and achieve the effect of promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Construction of mineralized keratin biomimetic material

[0034] A preparation method of mineralized keratin biomimetic material, which comprises the following steps:

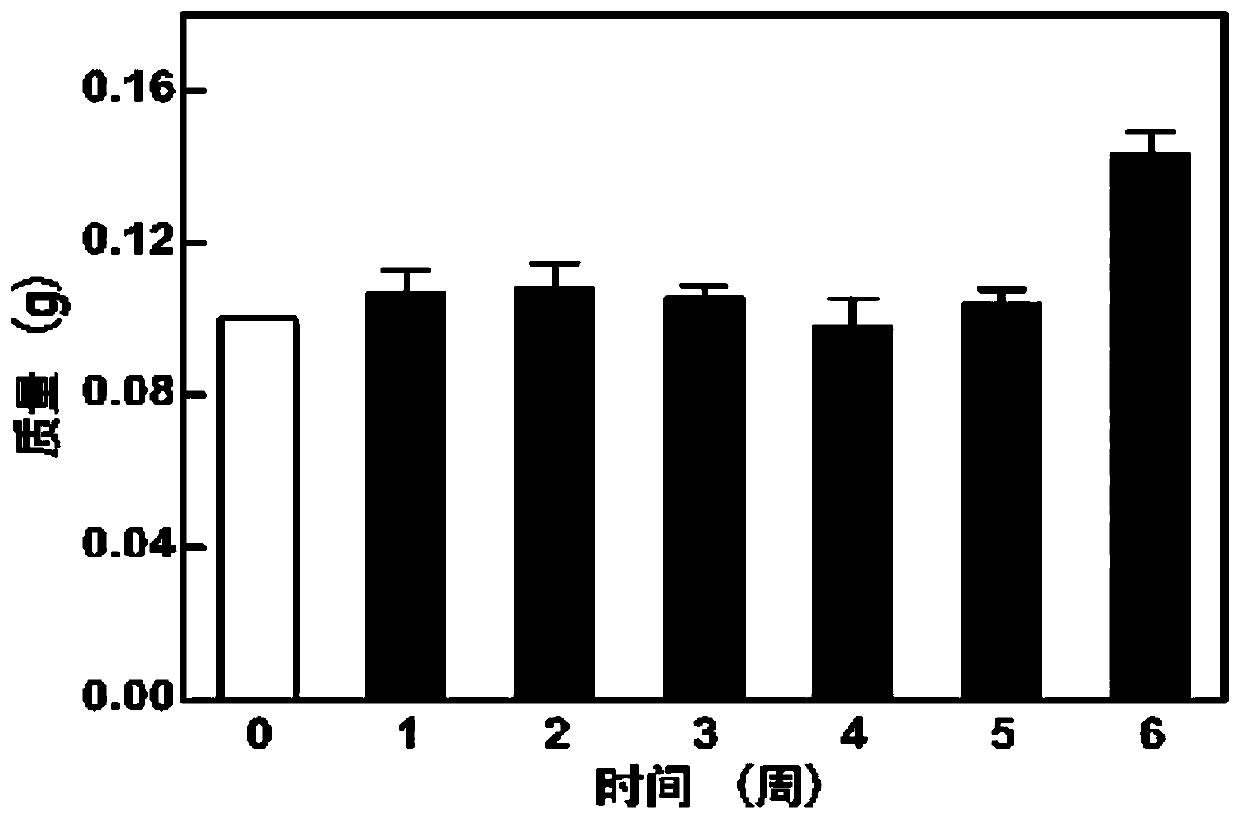

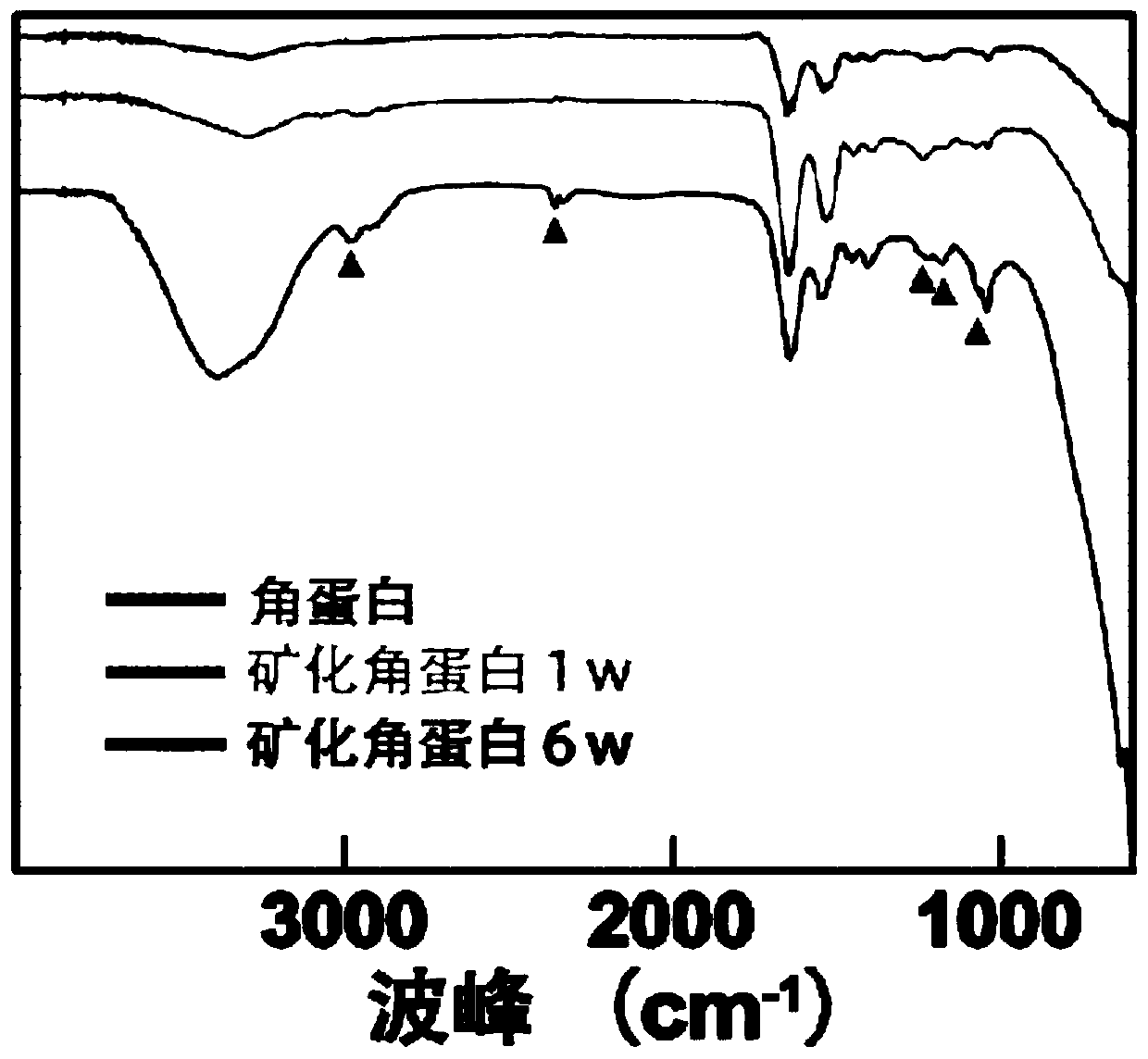

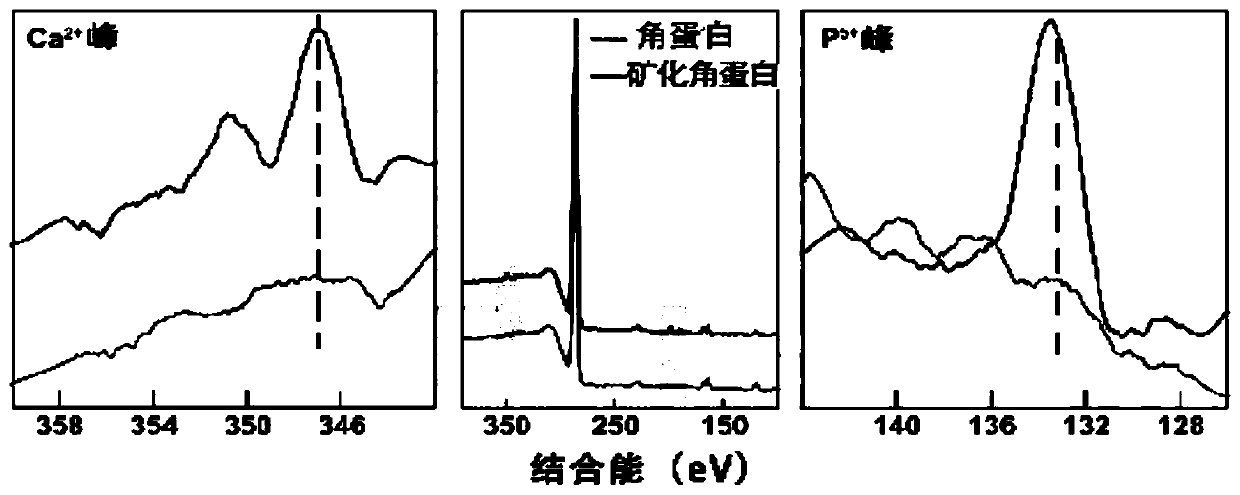

[0035] 1) Take nano-scale keratin powder and add it into a sterile simulated body fluid environment at a concentration of 100mg / ml, let it stand for mineralization treatment for 6 weeks, stir gently every 12 hours to disperse, and take a sample every other week as a sample. Put the mineralized keratin in a 1.5ml EP tube, centrifuge at 10,000rpm at room temperature for 15min, discard the supernatant, collect the precipitate, resuspend with deionized sterile water and wash 3 times, vacuum freeze-dry, and grind to a particle size of 50nm powder to obtain mineralized keratin particles that have been mineralized for 1 to 6 weeks and used for subsequent physical and chemical characterization experiments;

[0036] 2) The mineralized keratin particles obtained in step 1) that have been mineralized fo...

Embodiment 2

[0037] Example 2: Construction of mineralized keratin biomimetic material

[0038] A preparation method of mineralized keratin biomimetic material, which comprises the following steps:

[0039] 1) Take nano-scale keratin powder and add it into a sterile simulated body fluid environment at a concentration of 0.5 mg / ml, let it stand for mineralization treatment for 6 weeks, stir gently every 12 hours to disperse, take a sample when the mineralization is completed, and place the mineralized keratin In a 1.5ml EP tube, centrifuge at 15000rpm at room temperature for 1min, discard the supernatant, collect the precipitate, resuspend with deionized sterile water and wash 3 times, vacuum freeze-dry, and grind into a powder with a particle size of 20nm to obtain ore keratin particles;

[0040] 2) The mineralized keratin particles obtained in step 1) were resuspended at a concentration of 500mg / ml and poured into 24-well cell culture plates, and after they settled at the bottom of the 2...

Embodiment 3

[0041] Example 3: Construction of mineralized keratin biomimetic material

[0042] A preparation method of mineralized keratin biomimetic material, which comprises the following steps:

[0043] 1) Take nano-scale keratin powder and add it into a sterile simulated body fluid environment at a concentration of 500mg / ml, let it stand for mineralization treatment for 6 weeks, stir gently every 12 hours to disperse, take a sample when the mineralization is completed, and place the mineralized keratin in In a 1.5ml EP tube, centrifuge at 1000rpm for 30min at room temperature, discard the supernatant, collect the precipitate, resuspend with deionized sterile water and wash 3 times, vacuum freeze-dry, grind into a powder with a particle size of 80nm, and obtain mineralized Keratin particles;

[0044] 2) The mineralized keratin particles obtained in step 1) were resuspended at a concentration of 0.1 mg / ml and injected into a 24-well cell culture plate. After they settled at the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com