Functional urea for improving nitrogen fertilizer utilization rate, production apparatus and production method

A functional and high-utilization technology, applied in fertilization equipment, nitrogen fertilizer, urea compound fertilizer, etc., can solve the problems of manpower, material resources and time, reduce urea quality, affect the normal growth of crops, etc., and achieve convenient operation, simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

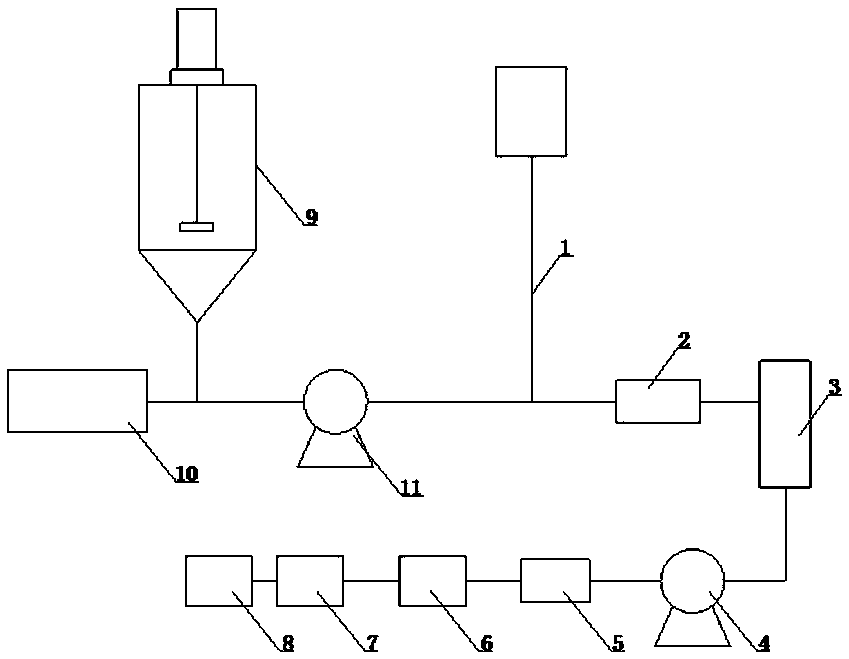

[0032] A method for preparing functional urea that improves the utilization rate of nitrogen fertilizers, comprising adding functional rare earth mineral powder and amino acid chelated trace elements through a mixing and feeding device, an air compressor 10 injection device and a powder pump 11 through a powder material adding port In the molten urea solution pipeline, it is merged with the molten urea solution with a concentration of more than 99.5%. After confluence, it is granulated by a granulation device 5. After granulation, it is sieved by a screening machine 6 in sequence, and an anti-caking agent wrapping machine 7 is used to wrap the oily anti-corrosion agent. Binder and urea packaging machine 8 can be packed.

[0033] Further, a kind of preparation method of the functional urea that improves nitrogen fertilizer utilization rate, comprises the steps:

[0034] Step 1: Put the functional rare earth mineral powder and amino acid chelated trace elements into the mixing f...

Embodiment 1

[0047] A functional urea production device that improves the utilization rate of nitrogen fertilizers, comprising a molten urea solution pipeline 1 connected to a urea flashing section, the molten urea solution pipeline 1 is provided with a powdery material adding unit connected to a powdery material adding unit mouth, the end of the molten urea solution pipeline 1 is connected successively through the pipeline mixer 2, the gas-liquid separator 3 and the urea solution pump 4, and the urea solution pump 4 passes through the granulation device 5 and the screening machine 6, the anticaking agent wrapping machine 7 and the urea solution The packaging machine 8 is connected; the powdery material adding unit includes a mixing feeding device 9 with a stirring device, the bottom material outlet of the mixing feeding device 9 is connected with a tee, and the second end of the tee is connected with the compressed gas outlet of the air compressor 10 The third end of the tee is connected t...

Embodiment 2

[0055] A functional urea production device that improves the utilization rate of nitrogen fertilizers, comprising a molten urea solution pipeline 1 connected to a urea flashing section, the molten urea solution pipeline 1 is provided with a powdery material adding unit connected to a powdery material adding unit mouth, the end of the molten urea solution pipeline 1 is connected successively through the pipeline mixer 2, the gas-liquid separator 3 and the urea solution pump 4, and the urea solution pump 4 passes through the granulation device 5 and the screening machine 6, the anticaking agent wrapping machine 7 and the urea solution The packaging machine 8 is connected; the powdery material adding unit includes a mixing feeding device 9 with a stirring device, the bottom material outlet of the mixing feeding device 9 is connected with a tee, and the second end of the tee is connected with the compressed gas outlet of the air compressor 10 The third end of the tee is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com