Overhead shielding door of electric furnace

A screen door and electric furnace technology, applied in the field of metallurgical machinery, can solve the problems of serious environmental pollution, exhaust gas cannot be collected, deformation of the doghouse door, etc., to achieve the effect of reducing environmental pollution and avoiding deformation of the doghouse door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

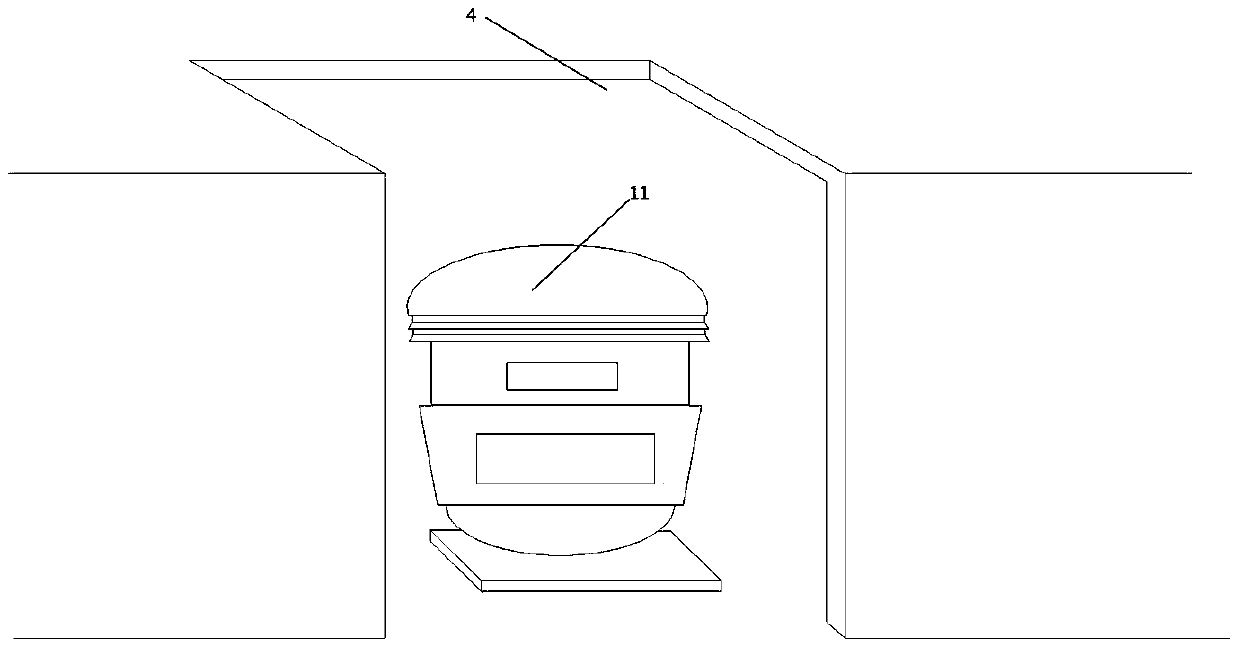

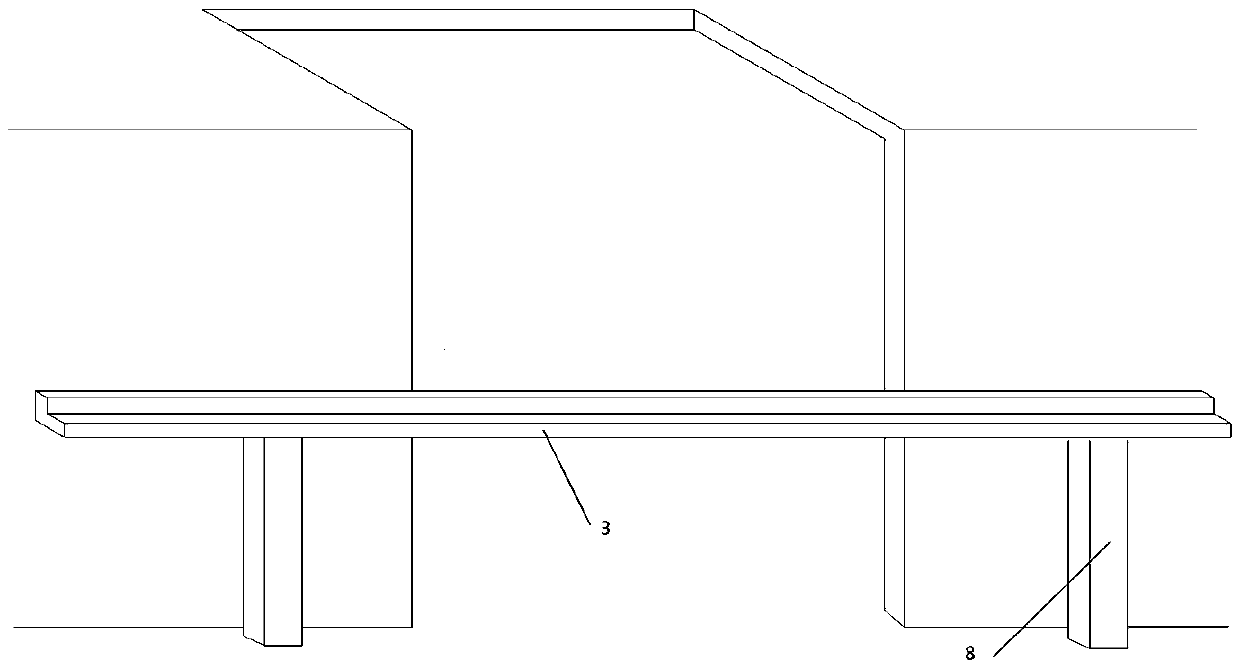

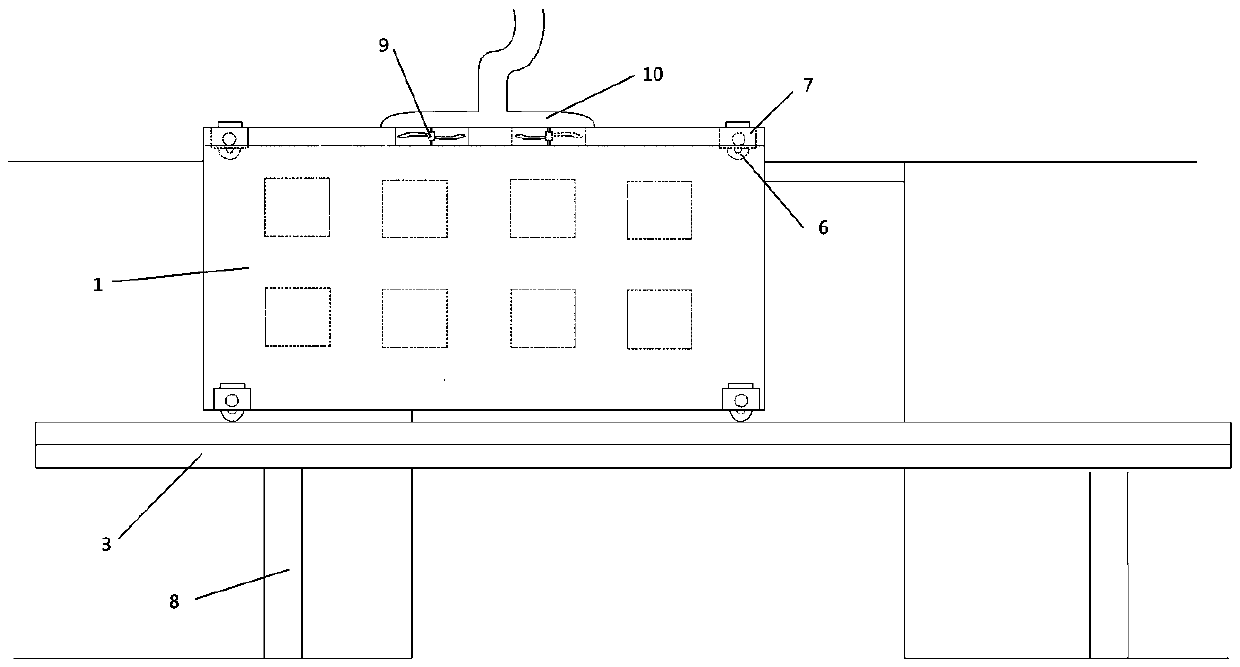

[0022] Such as Figure 1-5 As shown, the present invention provides an electric furnace elevated screen door, including an upper screen sliding door 1, a lower screen sliding door 2 and a beam 3; the longitudinal sections of the upper and lower screen sliding doors are both inverted "L" shape, the longitudinal section of the beam is "L" shape, between the lower surface of the horizontal structure of the upper screen sliding door and the top wall 4 of the electric furnace steelmaking workshop, and the lower part of the vertical structure of the upper screen sliding door Between the surface and the upper surface of the longitudinal structure of the beam, and between the upper surface of the transverse structure of the beam and the lower surface of the longitudinal structure of the lower screen sliding door, a walking mechanism is respectively provided. The two traveling wheels 6 in the track and the traveling electrodes 7 connected to the traveling wheels are respectively provide...

Embodiment 2

[0025] Such as Image 6 As shown, the present invention provides an electric furnace elevated screen door, which includes 2 upper screen sliding doors 1, 2 lower screen sliding doors 2 and beam 3; the longitudinal sections of the upper and lower screen sliding doors are both Inverted "L" shape, the longitudinal section of the beam is "L" shape, the vertical structure of the upper screen sliding door between the lower surface of the horizontal structure of the upper screen sliding door and the top wall 4 of the electric furnace steelmaking workshop Between the lower surface of the beam and the upper surface of the longitudinal structure of the beam, the upper surface of the transverse structure of the beam and the lower surface of the longitudinal structure of the lower screen sliding door are respectively provided with a walking mechanism, the walking mechanism includes a walking rail 5, a device On the two traveling wheels 6 and the traveling electrodes 7 connected with the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com