Circulating water management device, circulating system and management method based on cooling tower

A technology for managing equipment and cooling towers, applied in heat exchange equipment, water shower coolers, lighting and heating equipment, etc., it can solve the problems of increasing water quality concentration of cooling circulating water, waste of electricity and deterioration of water resources, and achieve a good signal Transmission stability and control convenience, the effect of reducing high power consumption and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

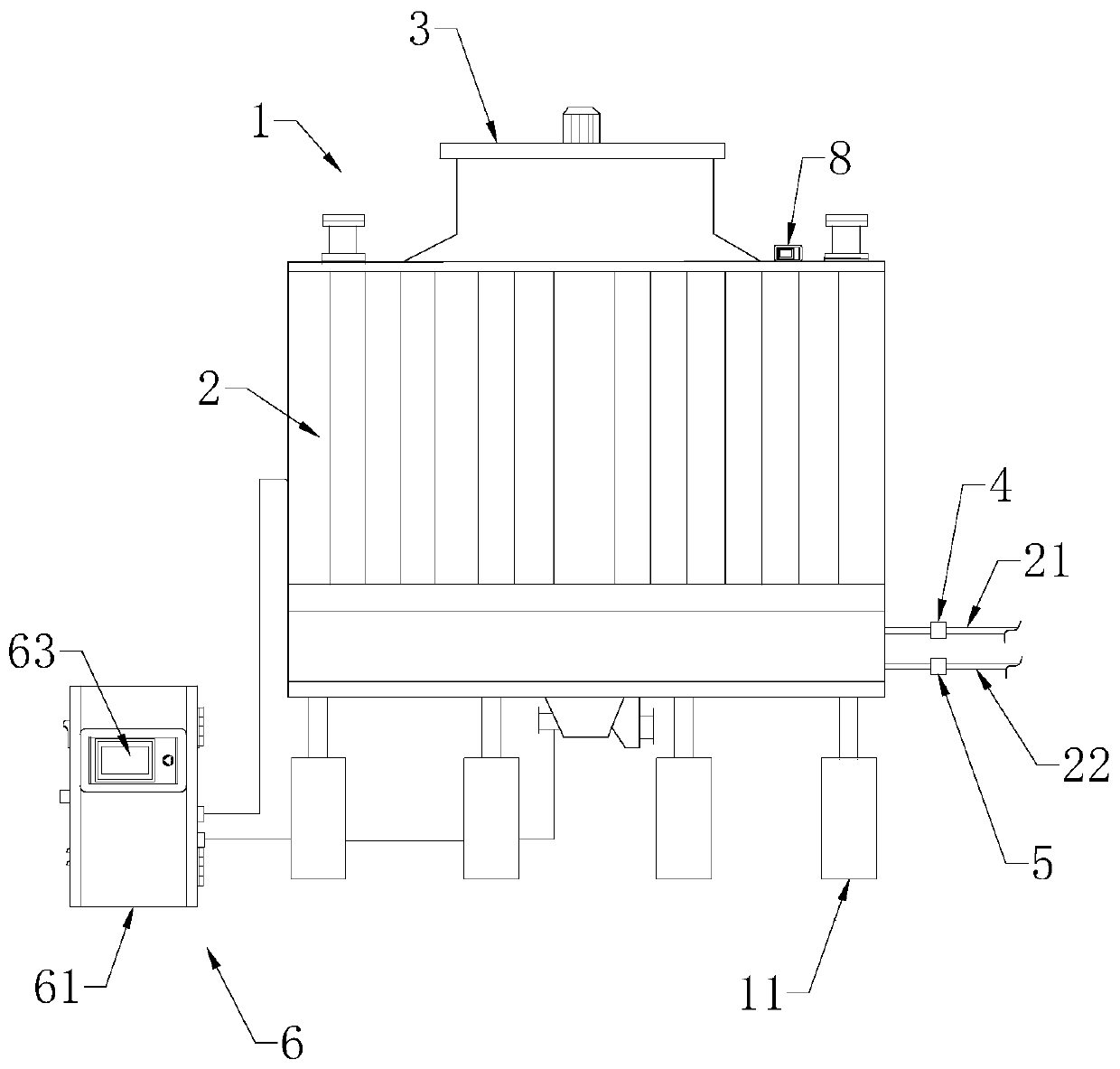

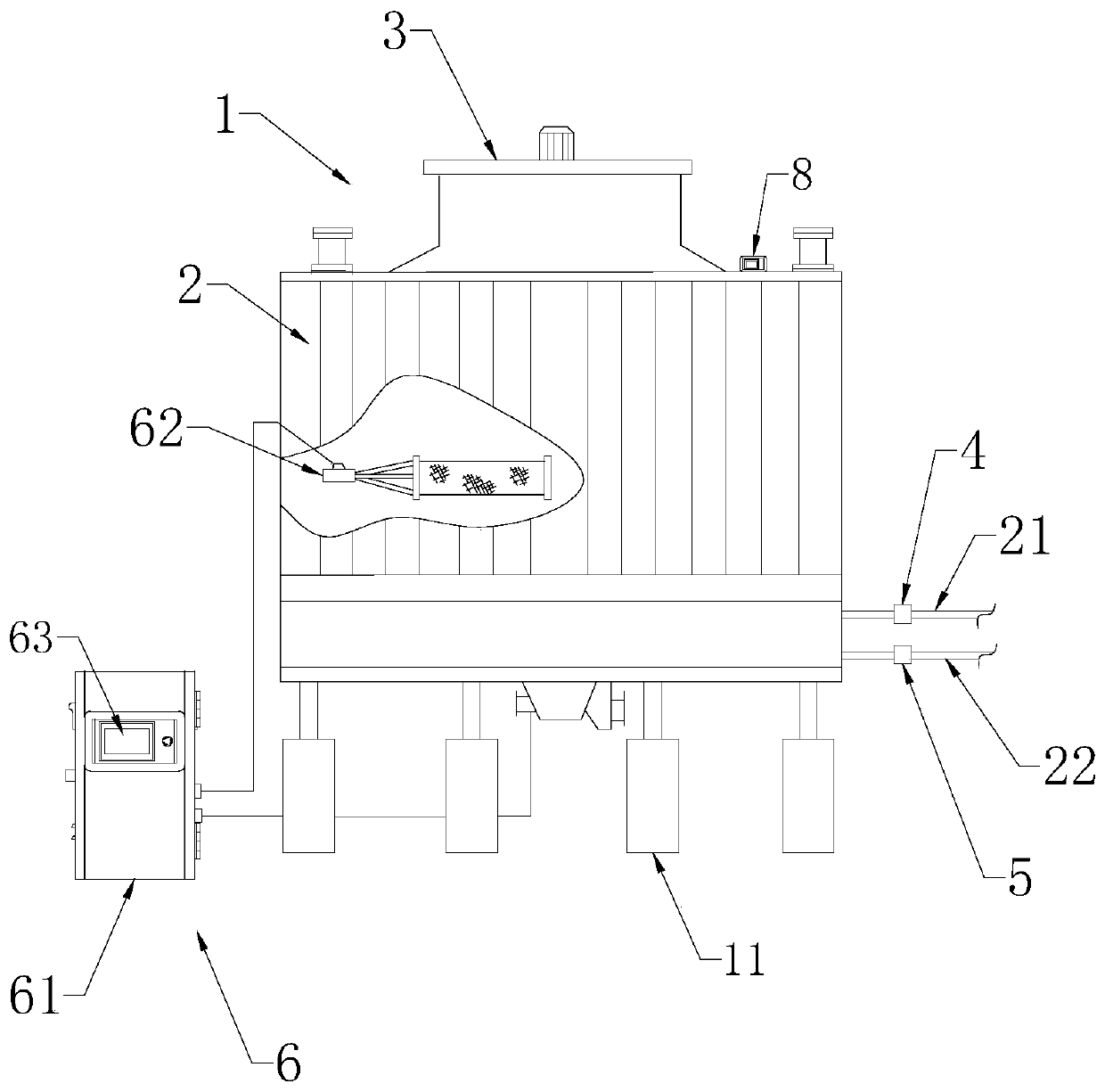

[0040] combine figure 1 and figure 2 As shown, a circulating water management device based on a cooling tower is installed based on a cooling tower 1. The cooling tower 1 includes a frame 11 and a cooling tower main body 2 installed and fixed on the frame 11. The cooling tower main body 2 is usually set It is a square structure, and a frequency conversion fan 3 is installed on the top of the main body 2 of the cooling tower. The cooling tower main body 2 is equipped with a descaling device 6 for adsorbing and removing scale. The descaling device 6 is used to adsorb and remove microorganisms, algae and scale in the cooling tower main body 2, so as to ensure the refrigeration or process equipment connected to the cooling tower 1. of normal operation. The main body 2 of the cooling tower is connected with the water inlet pipe 21 and the water outlet pipe 22. The water inlet pipe 21 and the water outlet pipe 22 are respectively connected with the external circulation pipeline 7...

Embodiment 2

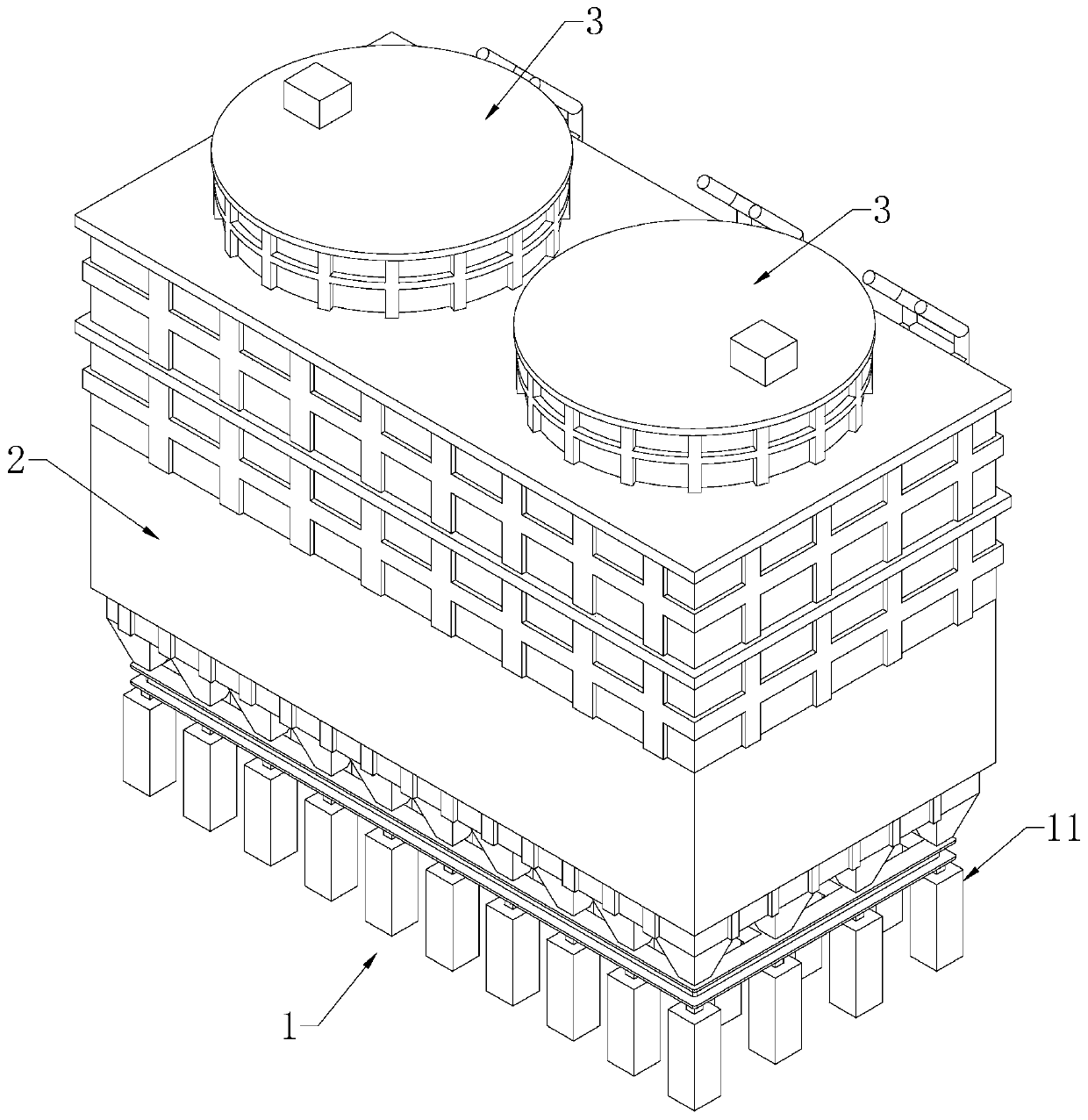

[0048] combine Figure 5 and Figure 6 As shown, a cooling tower-based circulation system differs from Embodiment 1 in that a complete cooling circulation system is constructed based on multiple cooling towers 1 . A plurality of cooling towers 1 are commonly connected to the circulation pipeline 7, and the circulation pipeline 7 includes a water inlet main pipe 71 and a water return main pipe 72 that circulate and communicate with the user and the cooling tower 1, and the water outlet pipes 22 of each cooling tower 1 are connected to the water inlet The main pipe 71, and the water inlet pipe 21 of each cooling tower 1 is connected to the return water main pipe 72 to realize the pipeline circulation of circulating water, that is, the waste heat generated by the user is distributed to each cooling tower 1 by the circulating water through the return water main pipe 72 The heat exchange is completed inside, and the cooled circulating water is then distributed to each user via the...

Embodiment 3

[0050] combine Figure 7 As shown, a cooling tower-based management method differs from Embodiment 1 in that it provides a method of adjusting the actual working power of the cooling tower 1 frequency conversion fan 3 based on the amount of heat transfer of circulating water that actually flows into the cooling tower 1 . The specific adjustment steps are as follows: firstly, the water inlet temperature value T1 of the water inlet pipe 21 and the water outlet temperature value T2 of the water outlet pipe 22 are detected by the water inlet temperature detection device 4 and the water outlet temperature detection device 5 at the water inlet pipe 21 and the water outlet pipe 22. , and then calculate the actual temperature difference ΔT between the inlet water temperature value T1 and the outlet water temperature value T2, and compare the actual temperature difference ΔT with the theoretical temperature difference ΔT, and finally control the scale collector 61 and the motor of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com