Dynamic precision detection method under complex motion state of five-axis machine tool based on double-ball-bar

A complex motion and dynamic precision technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve problems such as single evaluation index, single motion mode of machine tools, and inability to fully reflect the dynamic characteristics of machine tools, etc., to achieve comprehensive testing and evaluate, accurately reflect the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

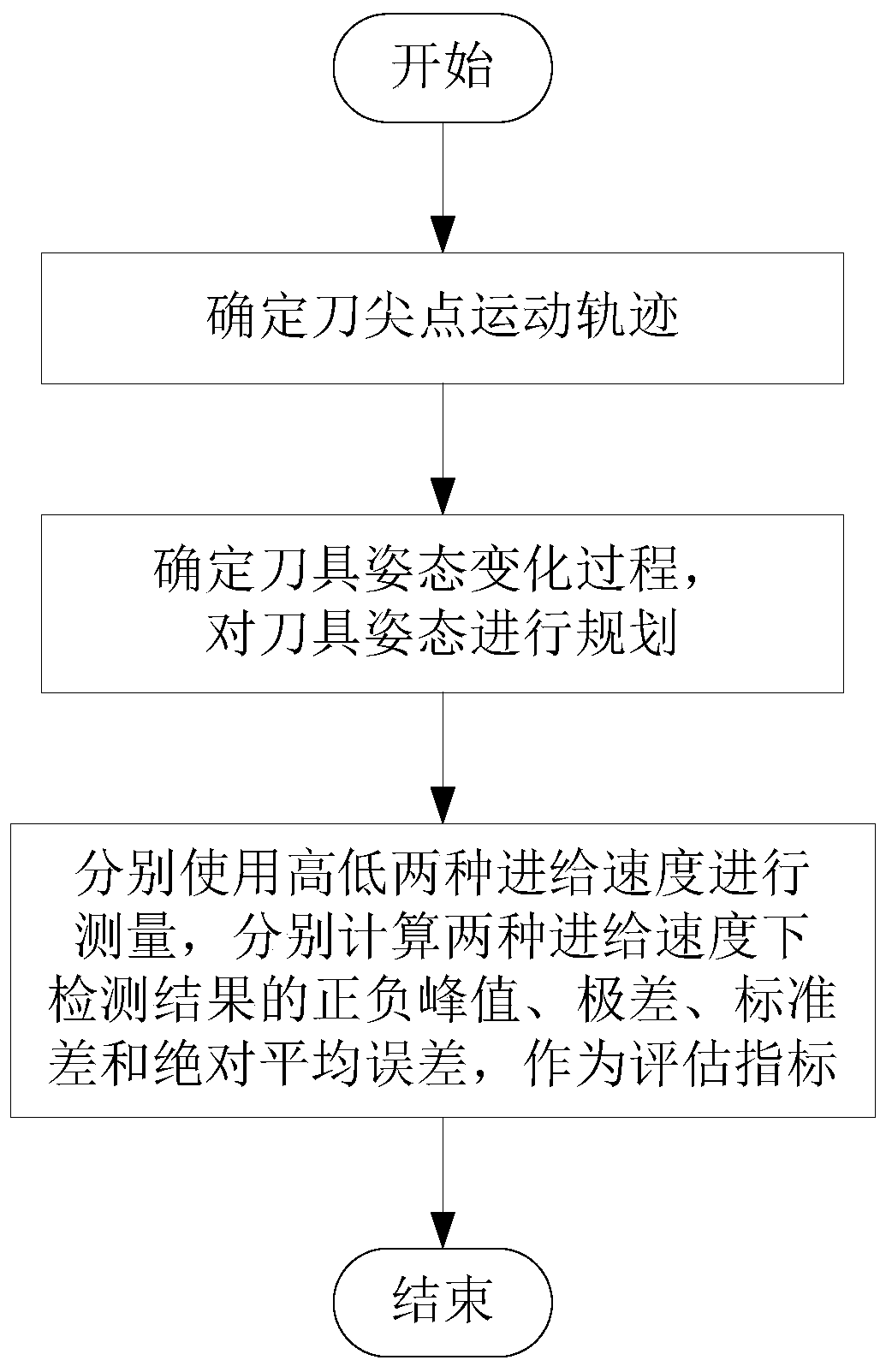

[0045] Such as figure 1 As shown, a ballbar-based five-axis machine tool dynamic accuracy detection method in a complex motion state of the present invention includes the following steps:

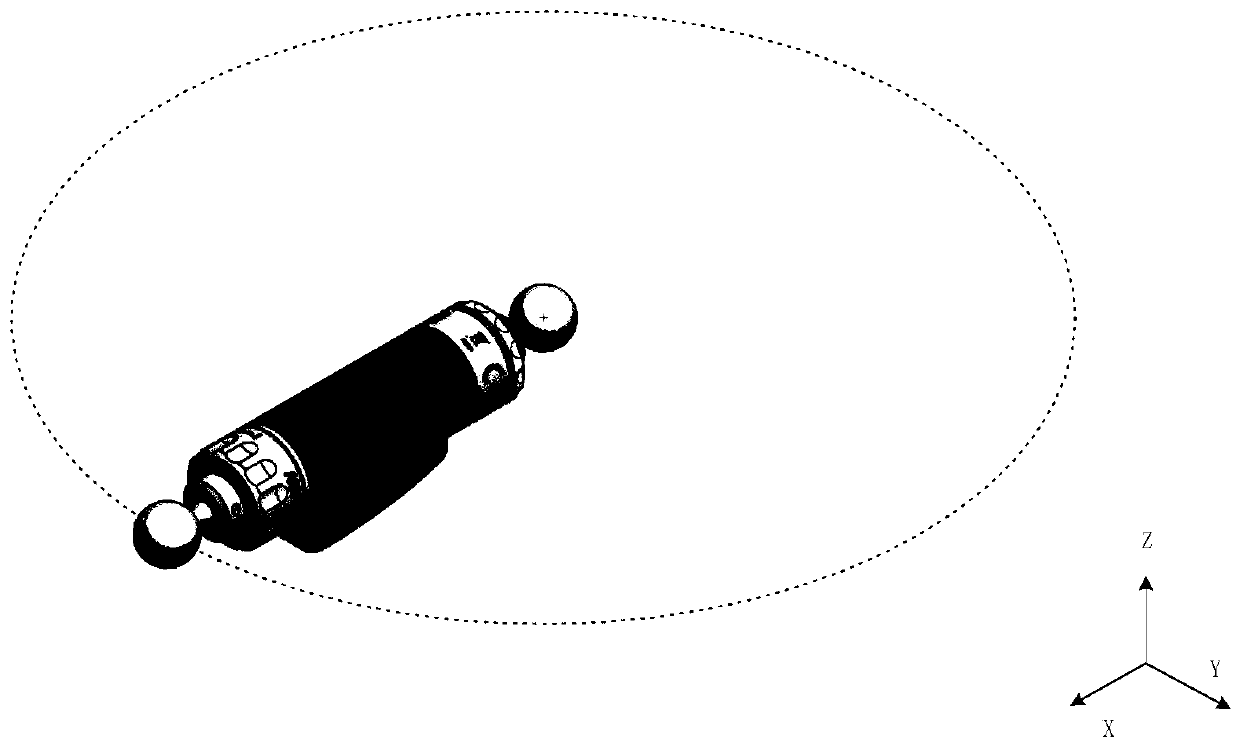

[0046] S1. Determine the motion trajectory of the tool tip point; for the planning of the tool tip point position, in order to ensure that the ideal distance between the two ballbars of the ballbar remains unchanged during measurement, set the tool tip point to perform circular interpolation movement, such as figure 2 As shown, the motion trajectory (X, Y, Z) of the tool nose point is obtained as:

[0047]

[0048] θ∈[0,2π]

[0049] Among them, R is the ideal distance between the two ball heads of the ballbar, (x 0 ,y 0 ,z 0 ) is the fixed position of the ball of the ballbar on one side of the table, θ is the rotation angle of the bar;

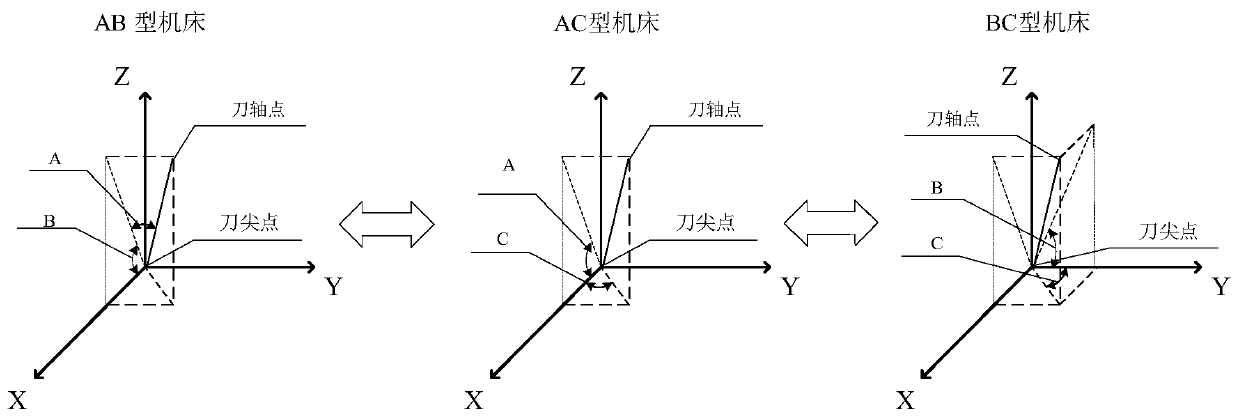

[0050] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com