Wireless charging coil and manufacturing method thereof

A technology of wireless charging and manufacturing method, which is applied in the direction of coil manufacturing, coil, transformer/inductor coil/winding/connection, etc. It can solve problems such as pollution, inability to realize coil miniaturization, and line oxidation, so as to reduce the difficulty of coating, The effect of realizing the miniaturization of the coil and reducing the risk of oxidation and contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

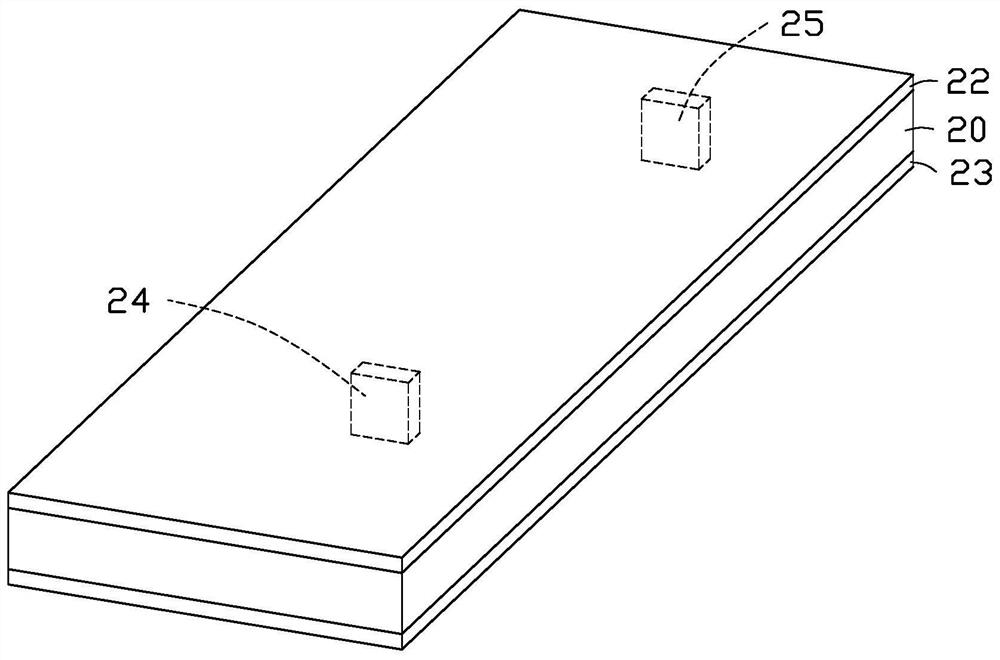

[0031] In order to further illustrate the technical means and effects that the present invention takes to reach the intended purpose of the invention, the following in conjunction with the appended Figure 1-13 And the preferred embodiment, the specific implementation, structure, features and effects of the wireless charging coil and its manufacturing method provided by the present invention are described in detail as follows.

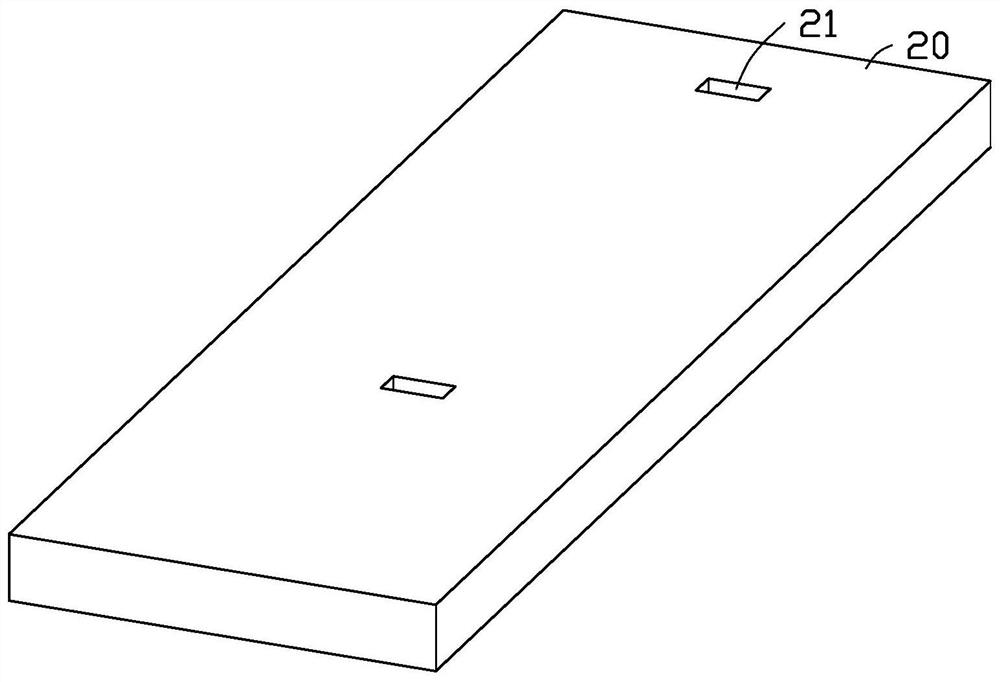

[0032] see Figure 1-10 , the first embodiment of the present invention provides a method for manufacturing a wireless charging coil 100, including the following steps:

[0033] For a first step, see figure 1 , providing a first elastic body 10 .

[0034] Wherein, the first elastic body 10 is stretchable.

[0035]Wherein, the first elastic body 10 may be a thermosetting elastomer or a thermoplastic elastomer. Specifically, the thermosetting elastomer is rubber, such as styrene-butadiene rubber, butadiene rubber, and silicone rubber. The thermoplas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com