High-elasticity temperature-sensing underwear chest ring

A high-elasticity underwear technology, applied in corsets, clothing, brassieres, etc., can solve the problems of respiratory impact, poor blood circulation, etc., and achieve the effect of good resilience, good fixation and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

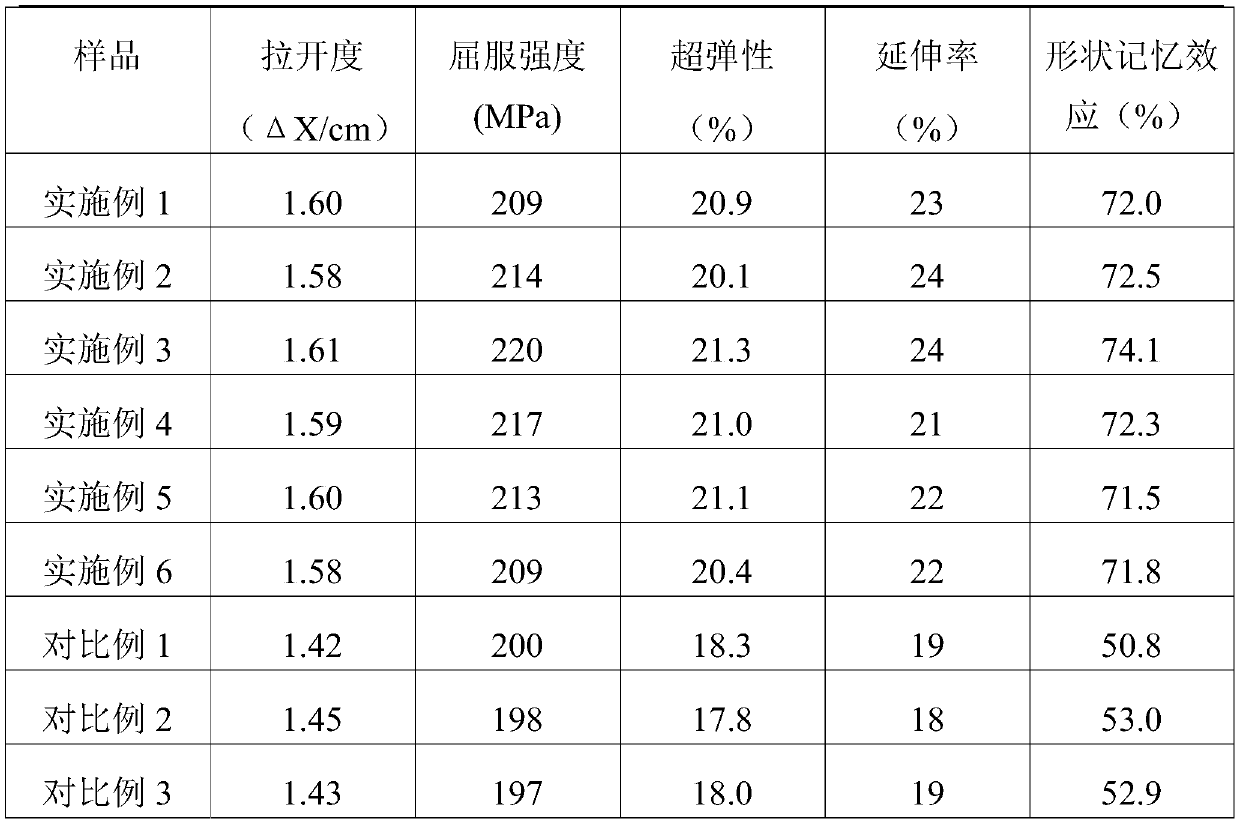

Embodiment 1

[0018] A high-elastic temperature-sensing underwear chest ring: including the following raw materials in parts by weight: 30 parts of quartz ore, 25 parts of nickel-titanium alloy, 12 parts of nano-titanium dioxide, and 12 parts of composite fiber; the composite fiber is composed of pineapple fiber, mushroom fiber, corn fiber Composition by mass ratio of 1:0.5:0.8;

Embodiment 2

[0020] A high-elastic temperature-sensing underwear chest ring: including the following raw materials in parts by weight: 50 parts of quartz ore, 34 parts of nickel-titanium alloy, 24 parts of nano-titanium dioxide, and 20 parts of composite fiber; the composite fiber is composed of pineapple fiber, mushroom fiber, corn fiber Composition by mass ratio of 3:1.6:2;

Embodiment 3

[0022] A high-elastic temperature-sensing underwear chest ring: including the following raw materials in parts by weight: 40 parts of quartz ore, 30 parts of nickel-titanium alloy, 18 parts of nano-titanium dioxide, and 16 parts of composite fiber; the composite fiber is composed of pineapple fiber, mushroom fiber, corn fiber Composed of 2:1:1.4 by mass ratio;

[0023] The above-mentioned embodiment 1-3 is a preparation method of a high-elastic temperature-sensitive underwear bra ring, comprising the following steps:

[0024] S1. Soak the composite fiber in propyl gallate solution for 5 hours according to the volume ratio of 1:3,

[0025] S2, grinding quartz ore and nano-titanium dioxide into powder, passing through a 160-mesh sieve;

[0026] S3. Heating the composite fiber to 60°C, pulverizing it, and passing it through a 400-mesh sieve;

[0027] S4. Mix the powders prepared by the above S1 and S2, and stir evenly to form a mixed powder. The stirring rate is 400r / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com