Raw material crushing device for pure vegetable oil refining

A raw material crushing and vegetable oil technology, which is applied in the direction of drying solid materials, static material dryers, mixers with rotating stirring devices, etc., can solve the problems of raw materials that cannot be crushed quickly and efficiently, and the crushing accuracy and quality are low, and achieve Improved accuracy and uniformity, high speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

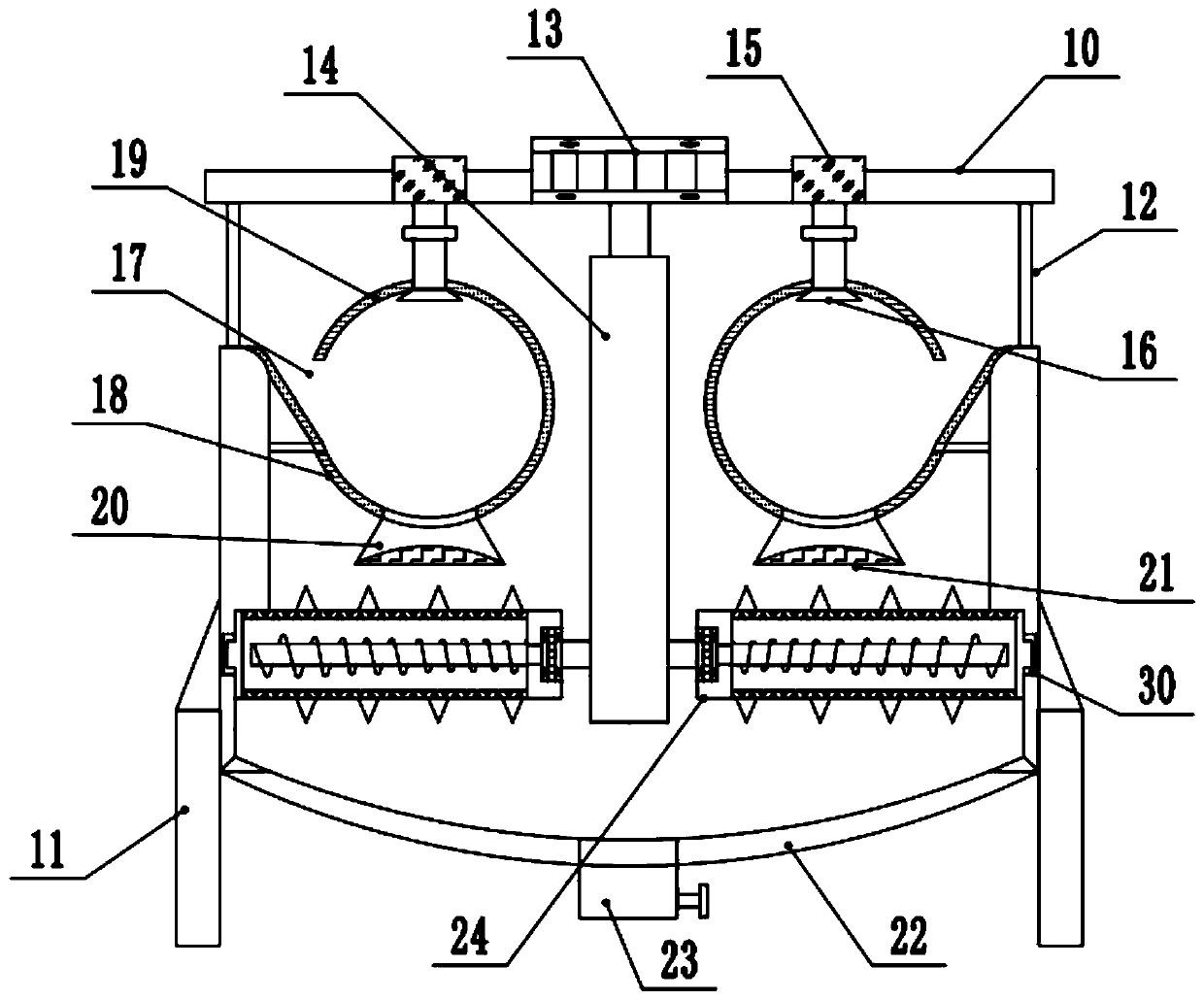

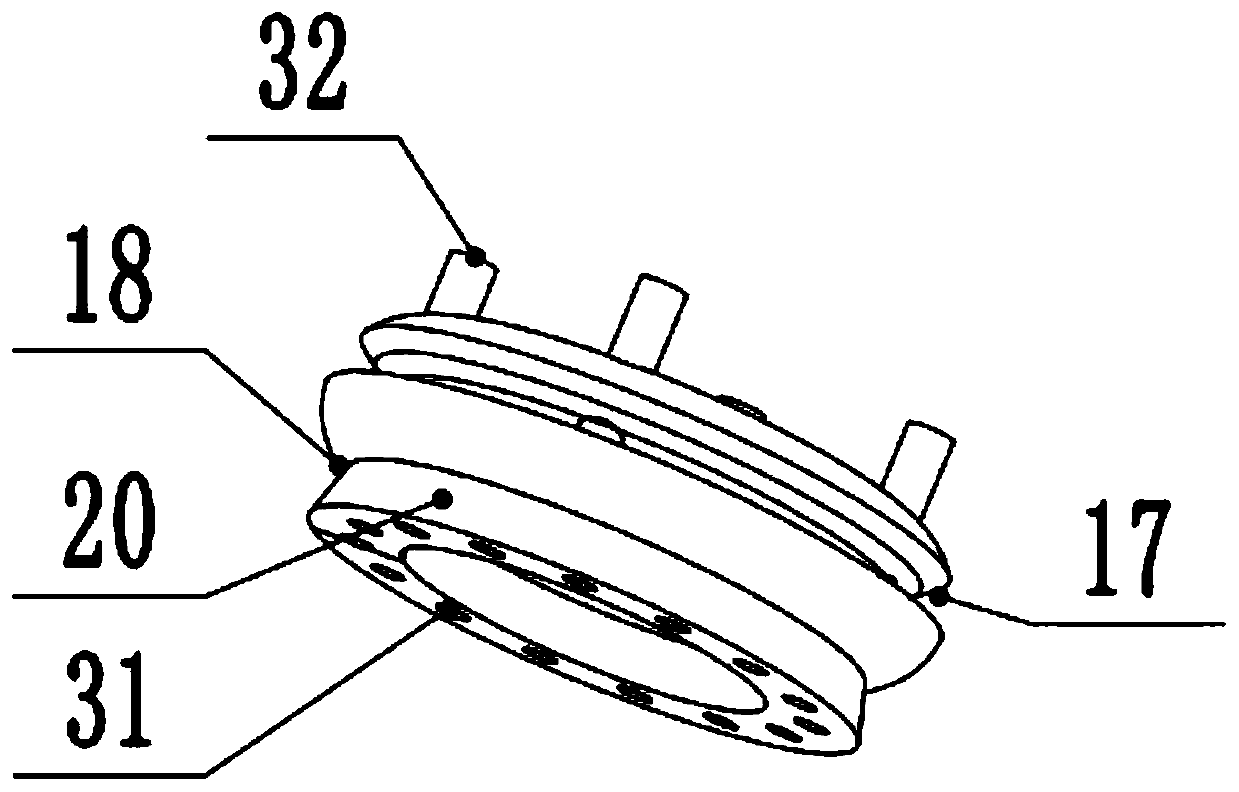

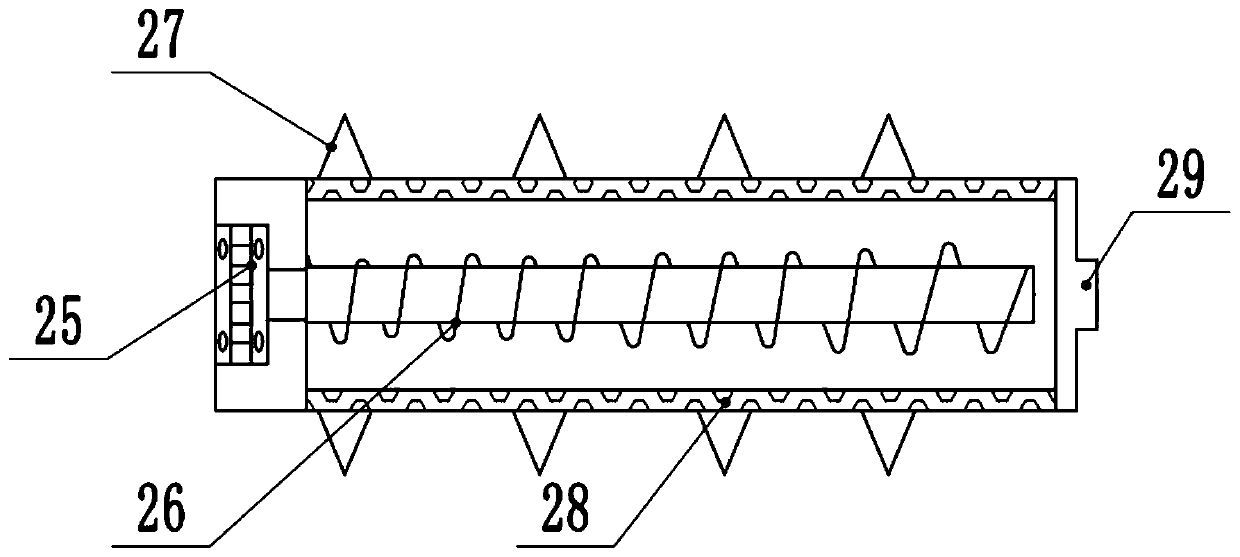

[0020] see Figure 1-3 , a raw material crushing device for refining pure vegetable oil, comprising a top plate 10, a leg 11, a first motor 13, a crushing chamber 22, and a crushing mechanism 24; The bottom of the machine is set as an arc structure to facilitate the output of raw materials. The center of the bottom of the crushing chamber 22 communicates downward with a discharge port 23, and a control valve is arranged on the discharge port 23. The top of the crushing chamber 22 is set as an open structure, and the four corners of the top surface of the crushing chamber 22 are fixedly supported by four sets of support rods 12 to have a set of horizontal top plates 10, and a set of first motors 13 are arranged at the center of the top plate 10. The lower output end of 13 passes through the top plate 10 and is rotatably connected with a rotating shaft 14, a group of drying chambers 18 pass through the middle of the rotating shaft 14, and four sets of crushing mechanisms 24 are...

Embodiment 2

[0024] On the basis of Embodiment 1, the inner side wall of the drying chamber 18 is provided with thermal insulation cotton 19 used to prevent the internal temperature of the drying chamber 18 from dropping too quickly. Input to the rapid drying of raw materials inside the drying chamber 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com