Mobile bagging machine for fermented materials and bagging application method of mobile bagging machine

A technology for fermentation materials and bagging machines, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of restricting the bag fermentation technology process, reducing the oxygen permeability of organic materials, and directly falling to the ground. Fermentation efficiency and technical process level, fast water evaporation, and the effect of avoiding large-scale shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

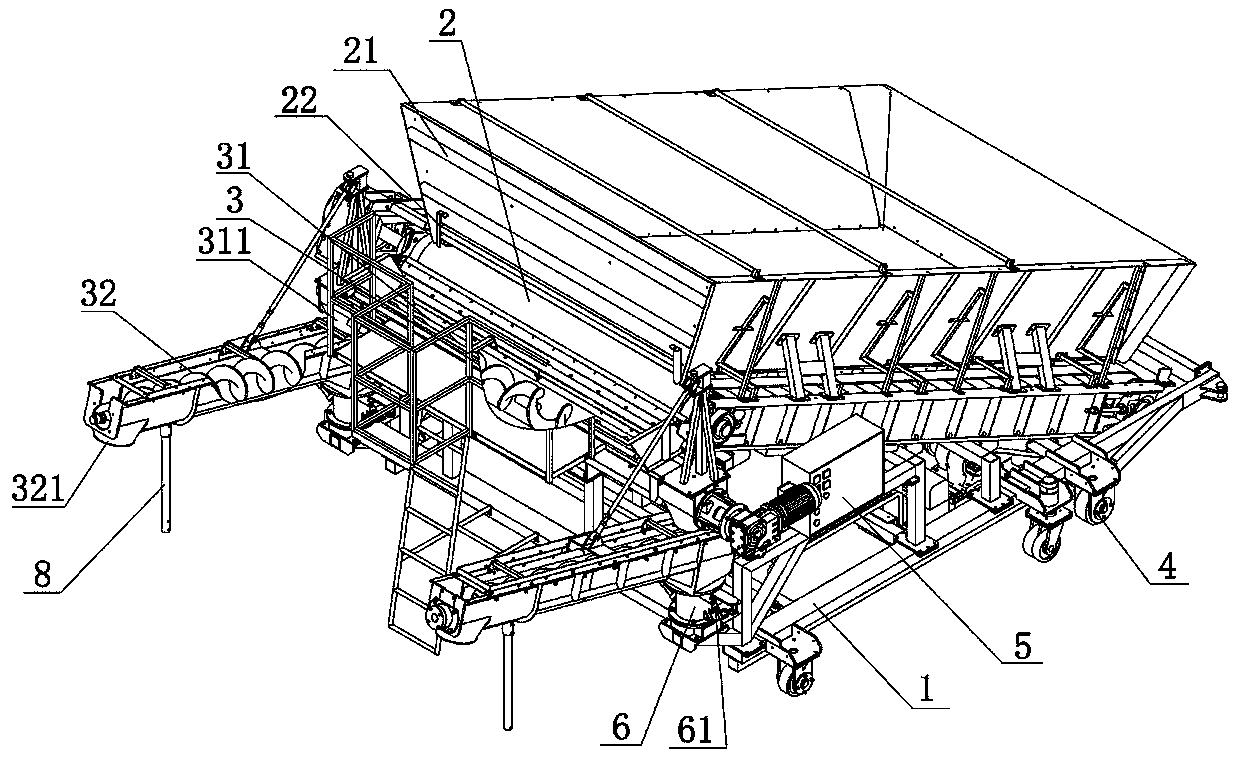

[0048] seefigure 1 As shown, the fermented material mobile bagging machine of the present invention is mainly composed of a frame 1, a main feeding conveyor 2, a bagging feeding device 3, a mobile walking device 4 and a controller 5; Machine 2, bagging feeding device 3, mobile walking device 4 and controller 5 are installed on the frame 1, the main feeding conveyor 2 is installed above the frame 1, and the bagging feeding device 3 is connected and installed in front of the output end of the main feeding conveyor 2, the mobile walking device 4 is installed under the frame 1, the main feeding conveyor 2, the bagging feeding device 3, The mobile walking device 4 is electrically connected to the controller 5 .

[0049] The bagging feeding device 3 is composed of a horizontal distribution conveyor 31 and a bagging feeding conveyor 32, wherein the horizontal distribution conveyor 31 is connected and installed on the front and lower side of the output end of the main feeding conveyor...

Embodiment 2

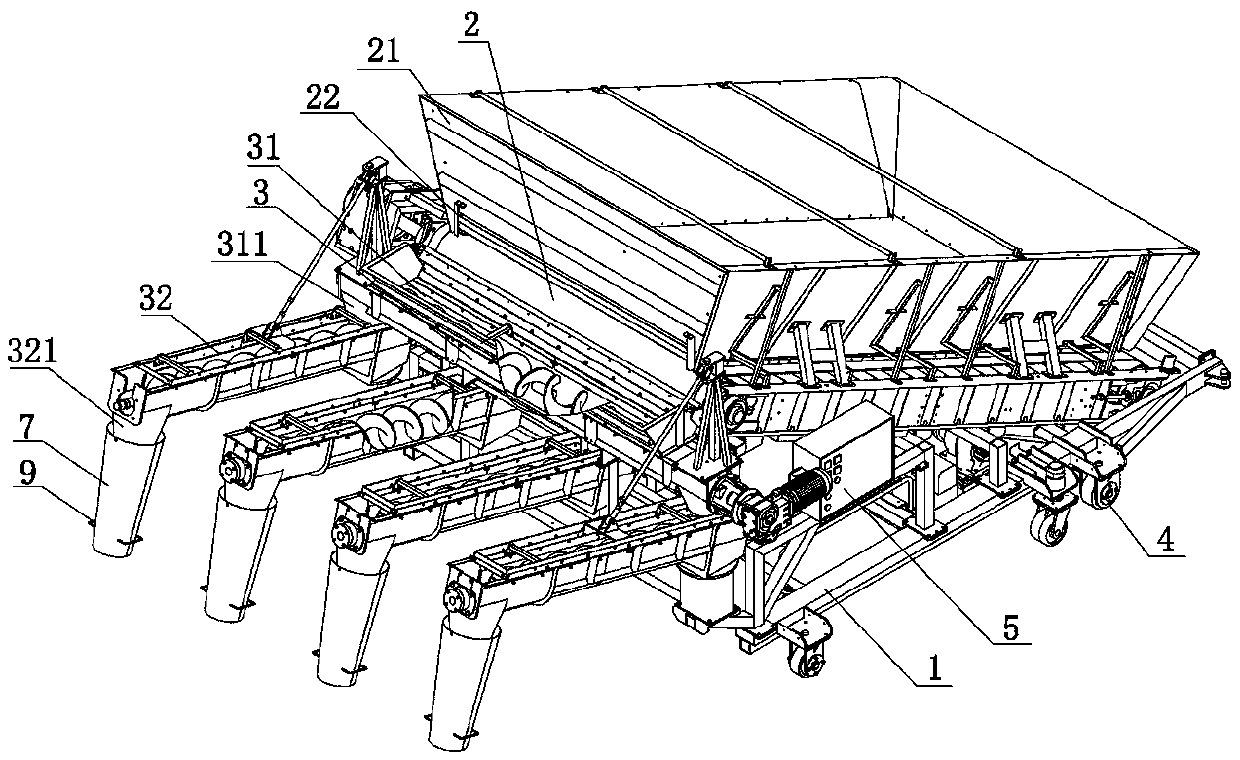

[0057] see figure 2 As shown, the fermented material mobile bagging machine of the second embodiment of the present invention is similar to the first embodiment, the only difference is:

[0058] The conveying surface width of the main feeding conveyor 2 is 4000mm.

[0059] The described horizontal material distribution conveyor 31 machine has four horizontal material distribution ports 311, and the corresponding bagging feeding conveyor 32 installed on the rear end of the horizontal material distribution port 311 has four sets; The screw of 31 is formed by connecting four blades with equal length and opposite screw directions. During operation, the fermentation material conveyed by the main feeding conveyor 2 is evenly and equally delivered to the four blades in opposite directions. The horizontal material distribution port 311 supplies material to the four bagging feed conveyors 32 below it.

[0060] Due to the increase of the quantity of the bagging feed conveyor 32, the ...

Embodiment 3

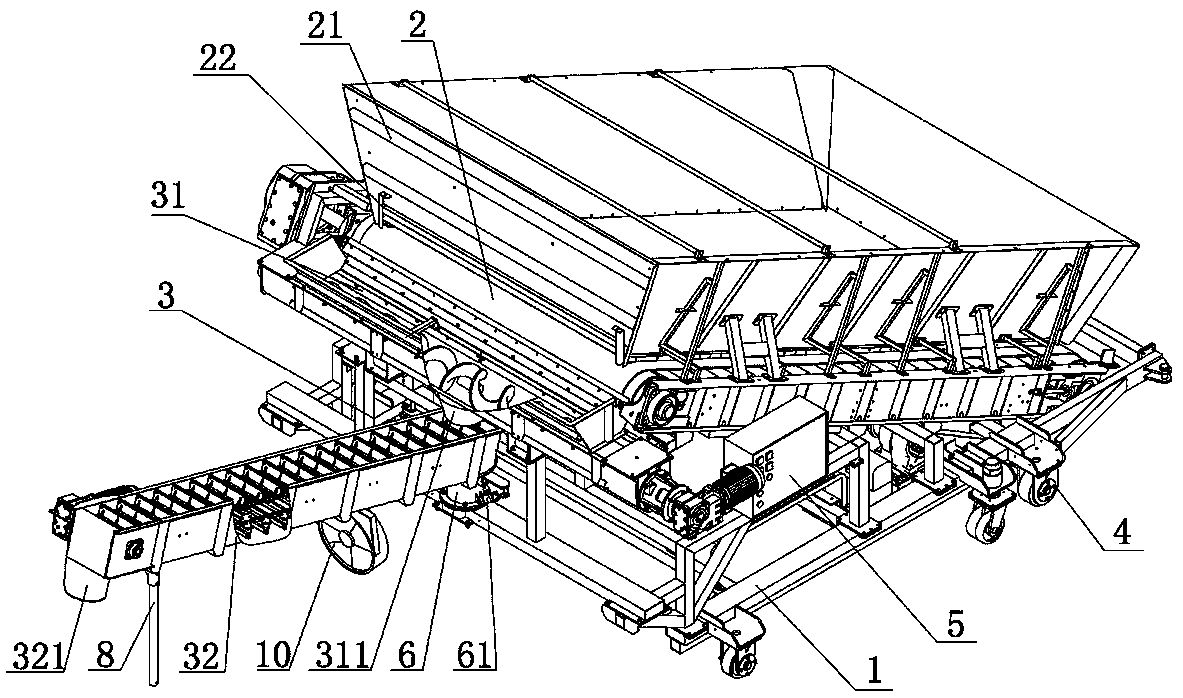

[0063] see image 3 As shown, the fermented material mobile bagging machine of the third embodiment of the present invention is similar to the first embodiment, the only difference being:

[0064] The conveying surface width of the main feeding conveyor 2 is 1000mm.

[0065] Described horizontal material distribution conveyor 31 machine has a horizontal material distribution port 311, and the described bagging feeding conveyor 32 that is installed in the described horizontal material distribution port 311 rear end correspondingly has one; Described horizontal material distribution conveyor 31 The screw is connected by two equal-length blades with opposite screw directions. During operation, the fermented material conveyed by the main feeding conveyor 2 is evenly and oppositely conveyed to the middle part of the horizontal distribution conveyor 31. The horizontal distributing port 311 is used to feed the bagging feed conveyor 32 below it.

[0066] The bagging feed conveyor 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com