A chitosan microsphere-loaded nano-silver antibacterial polypropylene material, composite antibacterial agent and preparation method thereof

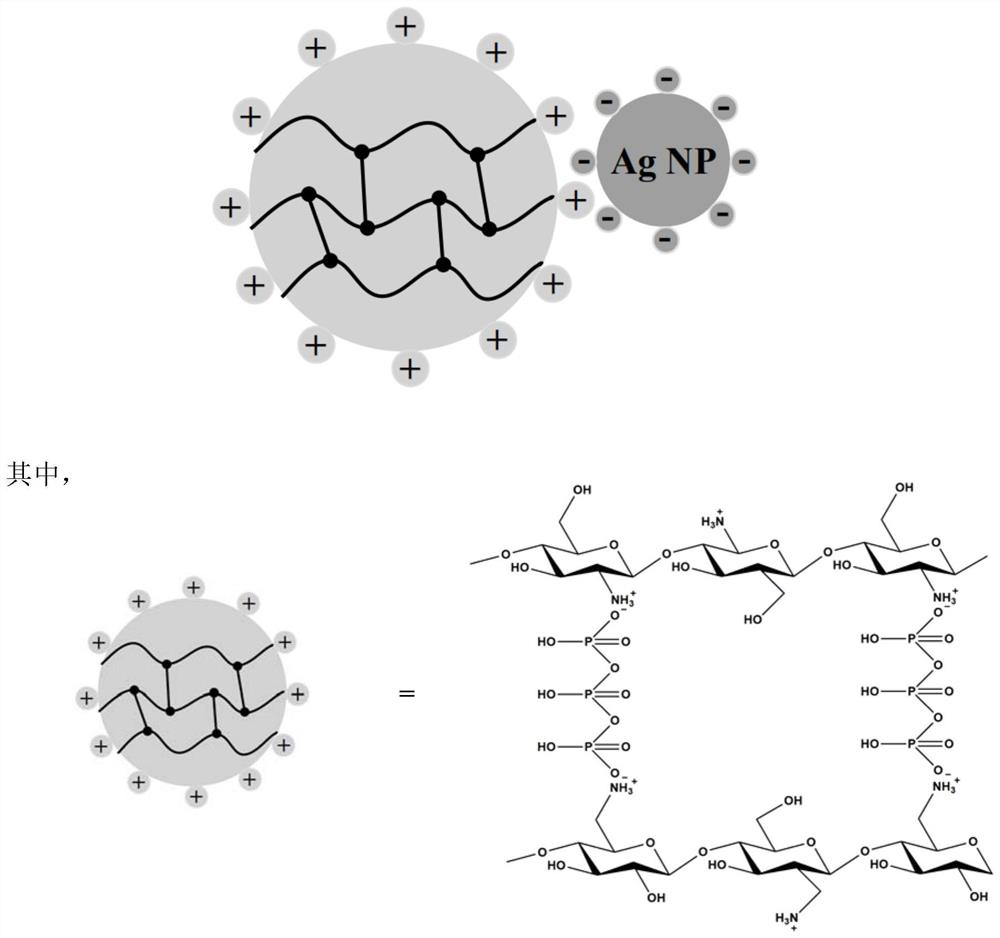

A technology of chitosan microspheres and polypropylene materials is applied in the field of composite antibacterial agents and their preparation. Chitosan microspheres are loaded with nano-silver antibacterial polypropylene materials, which can solve the problems of large specific surface area and high surface energy, and achieve the goal of preparing Simple process, good compatibility, and the effect of improving biosafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

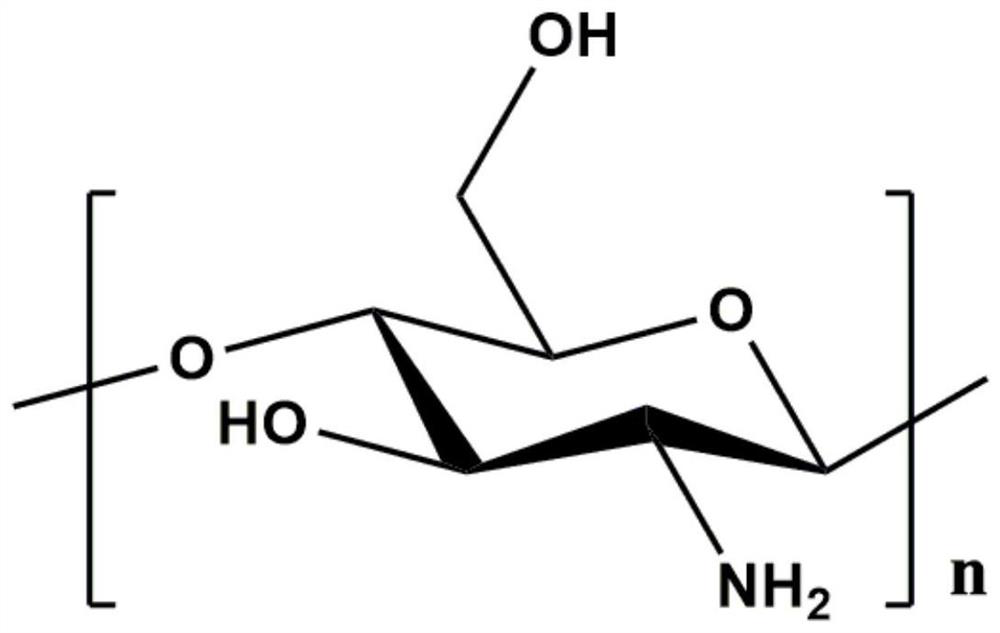

[0032] A chitosan microsphere load nano silver antibacterial polypropylene material, the feedstock composition comprises a polypropylene resin and a self-made chitosan microsphere / nano-silver composite antibacterial agent, wherein the polypropylene resin is 100 parts by weight, a composite antibacterial agent In 8 parts; the composite antibacterial agent is carried by chitosan microspheres, and nano silver is loaded on chitosan microspheres, and the mass ratio of nano silver and chitosan is 5 / 100.

[0033] The preparation method of the chitosan microsphere / nano silver composite antibacterial agent is:

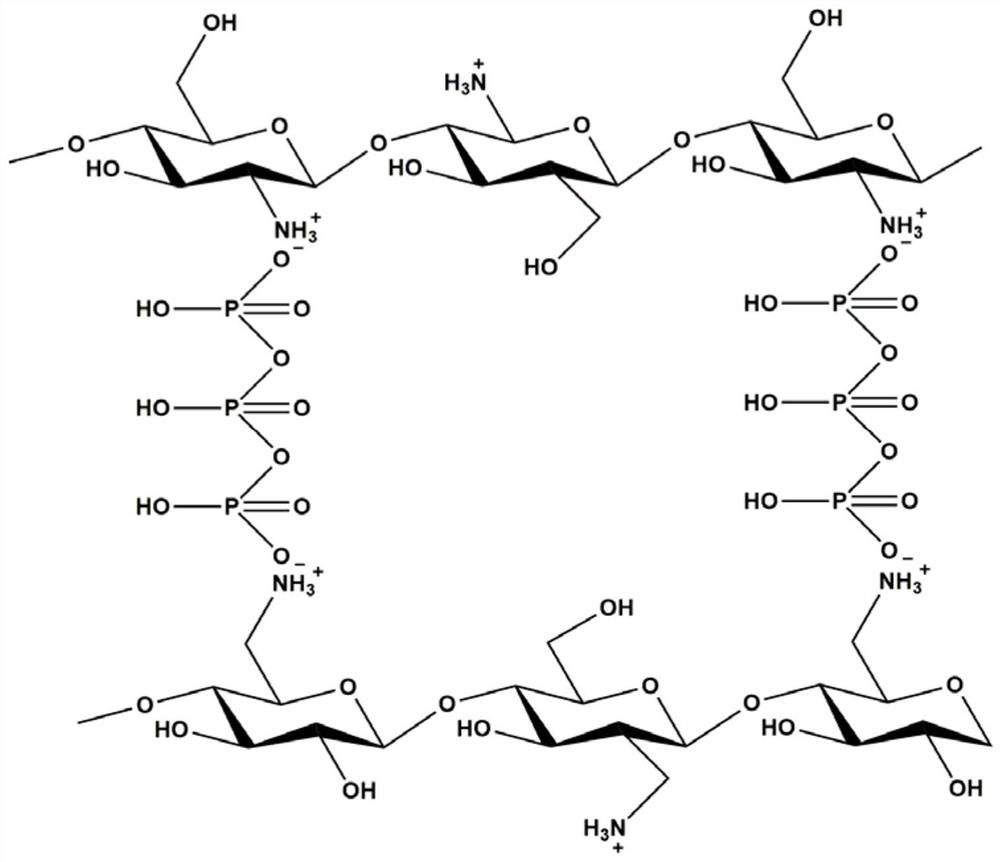

[0034](1) Preparation of chitosan microspheres: At room temperature, 100 mg of chitosan powder is dissolved in 50 ml of volume concentration (V / V) to 1% acetic acid solution, continuously stirred until completely dissolved, then use NaOH The pH of the solution regulation system was 5. Keeping the magnetic stirring state, a 20 ml concentration of 1 mg / ml of a tripolyphosphat...

Embodiment 2

[0039] Other process steps are the same as in Example 1 in addition to the second polyphosphate solution of 20 ml of a concentration of 1 mg / ml in addition to a 20 ml concentration of 1 mg / ml, in addition to the anionic gel of the preparation of the chitosan microsphere / nano silver composite antibacterial step (1). .

Embodiment 3

[0041] The other process steps were the same as those in Example 1 in addition to the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com