Bi-cationic epoxy bactericide and preparation method thereof

A dicationic, epoxy-type technology, applied in the direction of botanical equipment and methods, biocides, chemical instruments and methods, etc., can solve the problems that the performance of fungicides cannot be achieved, achieve excellent killing effect, simple synthesis process, Good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

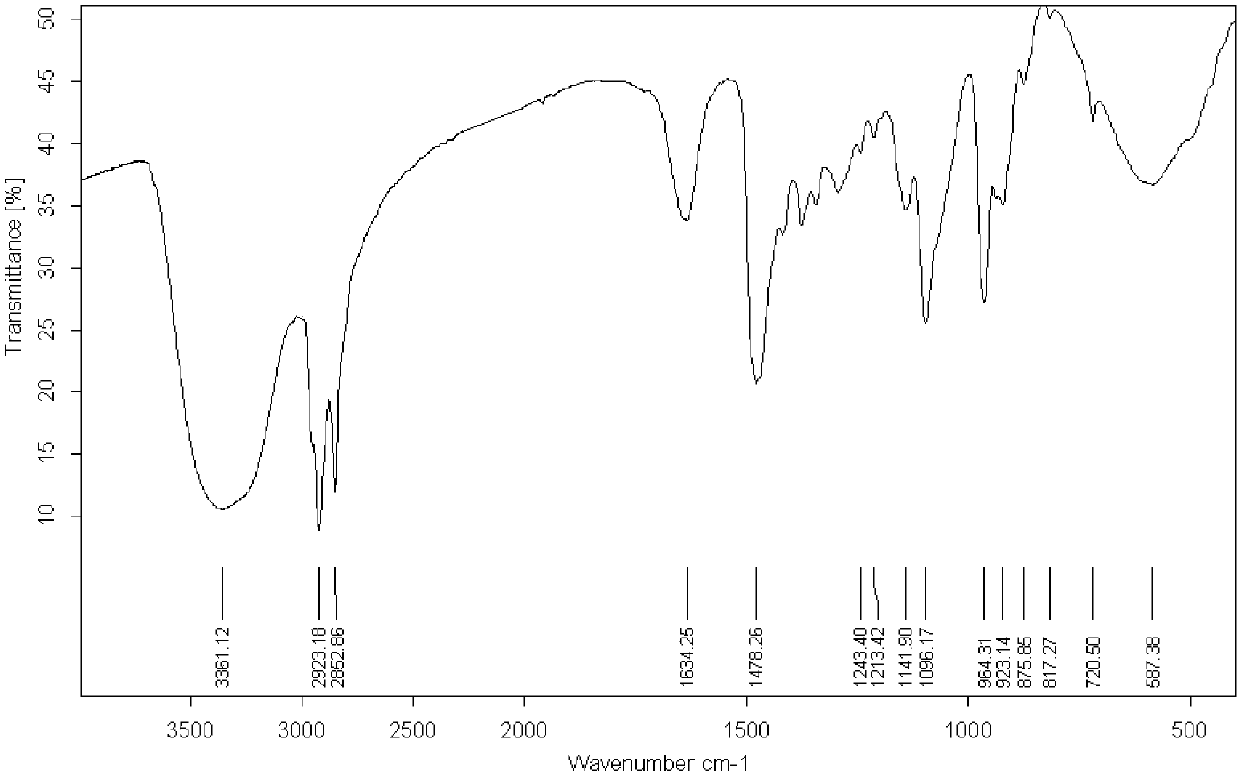

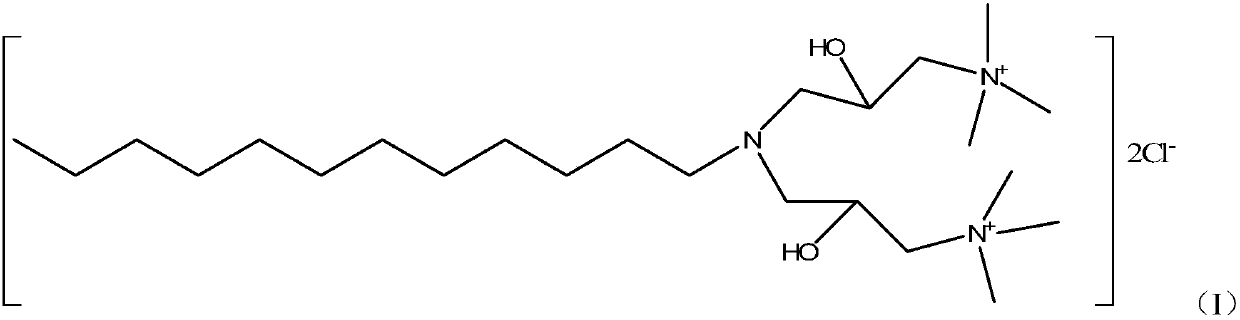

[0017] Add 40 g of dodecylamine and 20 g of isopropanol in a three-necked flask (250 ml), and heat in a water bath. At 70°C, 133 g of 2,3-epoxypropyltrimethylammonium chloride isopropanol solution with a mass fraction of 50% was slowly added dropwise. After the addition was completed, the temperature was raised and the reaction time was maintained for 10 hours. The reaction temperature was 90 Celsius, after the reaction process is over, let it cool naturally until it cools down to room temperature, take a part of the product to measure the structure of its active ingredients, recrystallize with a mixed solvent of petroleum ether / isopropanol, and dry to obtain a yellow solid, that is, a dication Type quaternary ammonium salt. Select the ATR method (infrared spectrum) to characterize the product structure, the characterization results are shown in figure 1 shown. Add water to the remaining product to form a solution with a mass percentage of 30% of the dicationic quaternary am...

Embodiment 2

[0019] Add 40 g of dodecylamine and 20 g of ethylene glycol in a three-necked flask (250 ml), and heat in a water bath. Slowly add 133 g of 2,3-epoxypropyltrimethylammonium chloride ethylene glycol solution with a mass fraction of 50% at 70°C. After the addition is completed, heat up and keep the reaction time for 8 hours. The reaction temperature is 90 Celsius, after the reaction process is finished, allow it to cool naturally until it is cooled to room temperature, continue to add water, and be mixed with a solution with a 52% mass fraction of a dicationic quaternary ammonium salt to obtain a dicationic epoxy fungicide N2.

[0020] Embodiment 3 bactericidal performance evaluation

[0021] The performance evaluation method of fungicide adopts the test bottle method of extinction dilution method, and the reference standard is "Fungicide Performance Evaluation Method" (SY / T 5890-1993), "Measurement Method for Bacteria and Algae in Industrial Circulating Cooling Water (GB / T14643...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com