Gear PSN curve drawing method considering material inclusions and residual stress

A technology of PSN curve and residual stress, applied in instrumentation, geometric CAD, design optimization/simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Select gears such as Figure 5 Shown are the gears of the gearbox of a 2-megawatt wind turbine in service. This gear is an intermediate gear pair pinion, and the fatigue failure probability of this gear pair is significantly greater than other gears. Figure 5 On the right is the situation when fatigue failure occurs. The gear material is 18CrNiMo7-6 steel, which has been carburized, quenched and ground.

[0047] The material parameters of this material are as follows:

[0048]

[0049] The main parameters of the gear pair are as follows:

[0050]

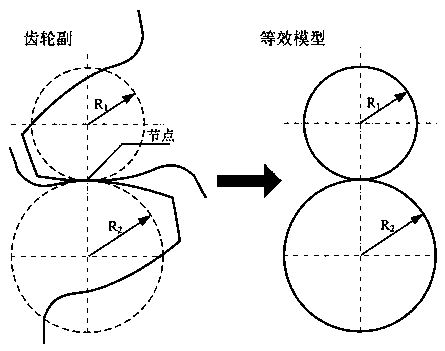

[0051] Step 1. According to formula (1) and the main parameters of the gear pair, the radius of curvature in the two-dimensional circular contact model can be calculated as: pinion r 1 =50mm, big gear r 2 = 250.3mm, according to the radius of curvature, a two-dimensional circle contact model is established.

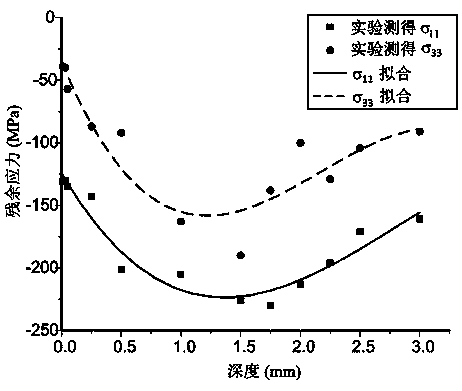

[0052] Step 2. Use the X-ray diffractometer to obtain the residual stress distribution of the gear along the depth direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com