Multifunctional numerical control system debugging and troubleshooting practical training platform capable of rapidly recovering

A numerical control system and fast recovery technology, applied in the simulation devices, instruments, simulators and other directions of space navigation conditions, can solve the problems of complicated sorting work, machine tool damage, easy to find faults, etc., to achieve convenient and concealed fault setting, and reduce complexity. work and save hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

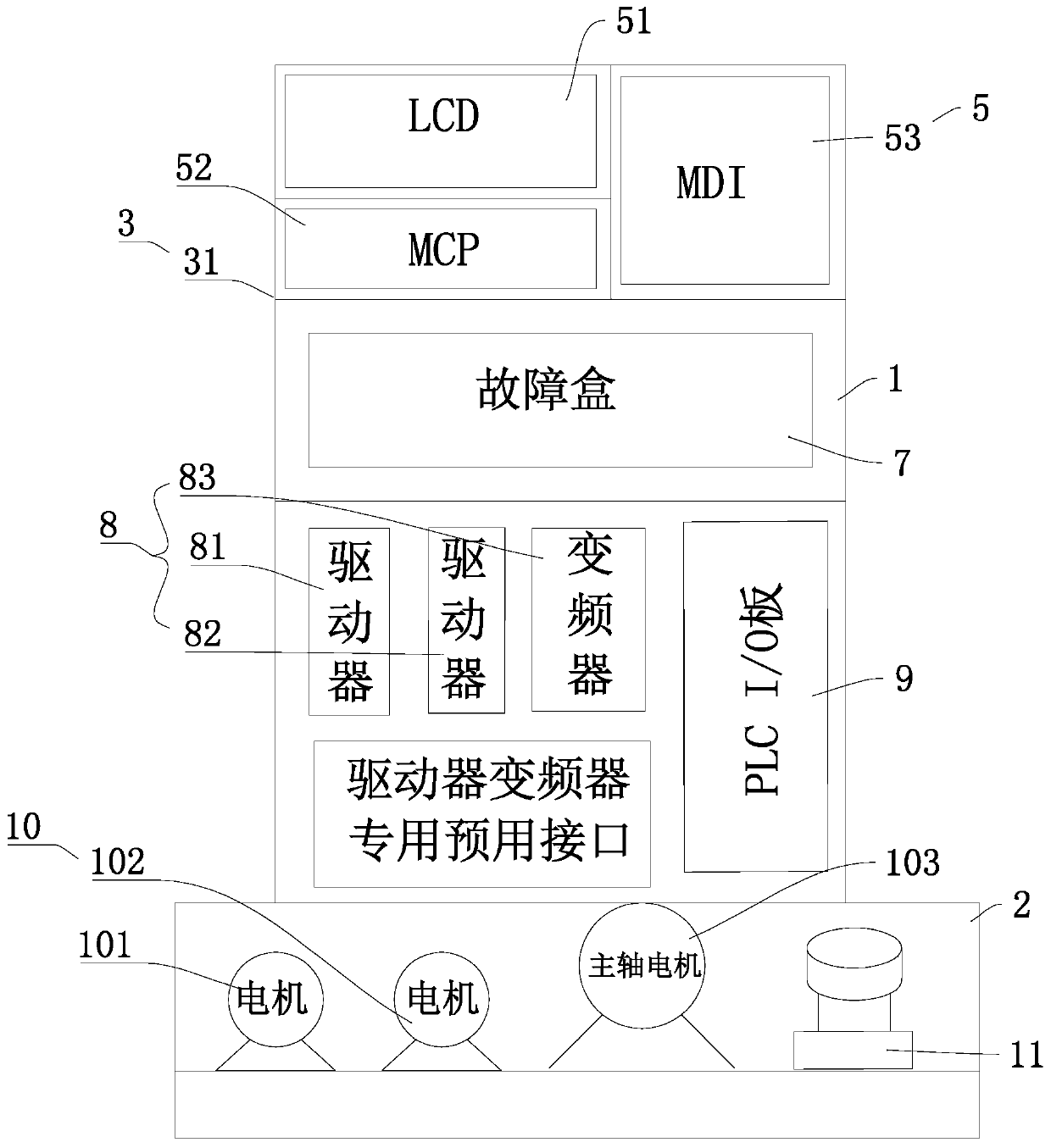

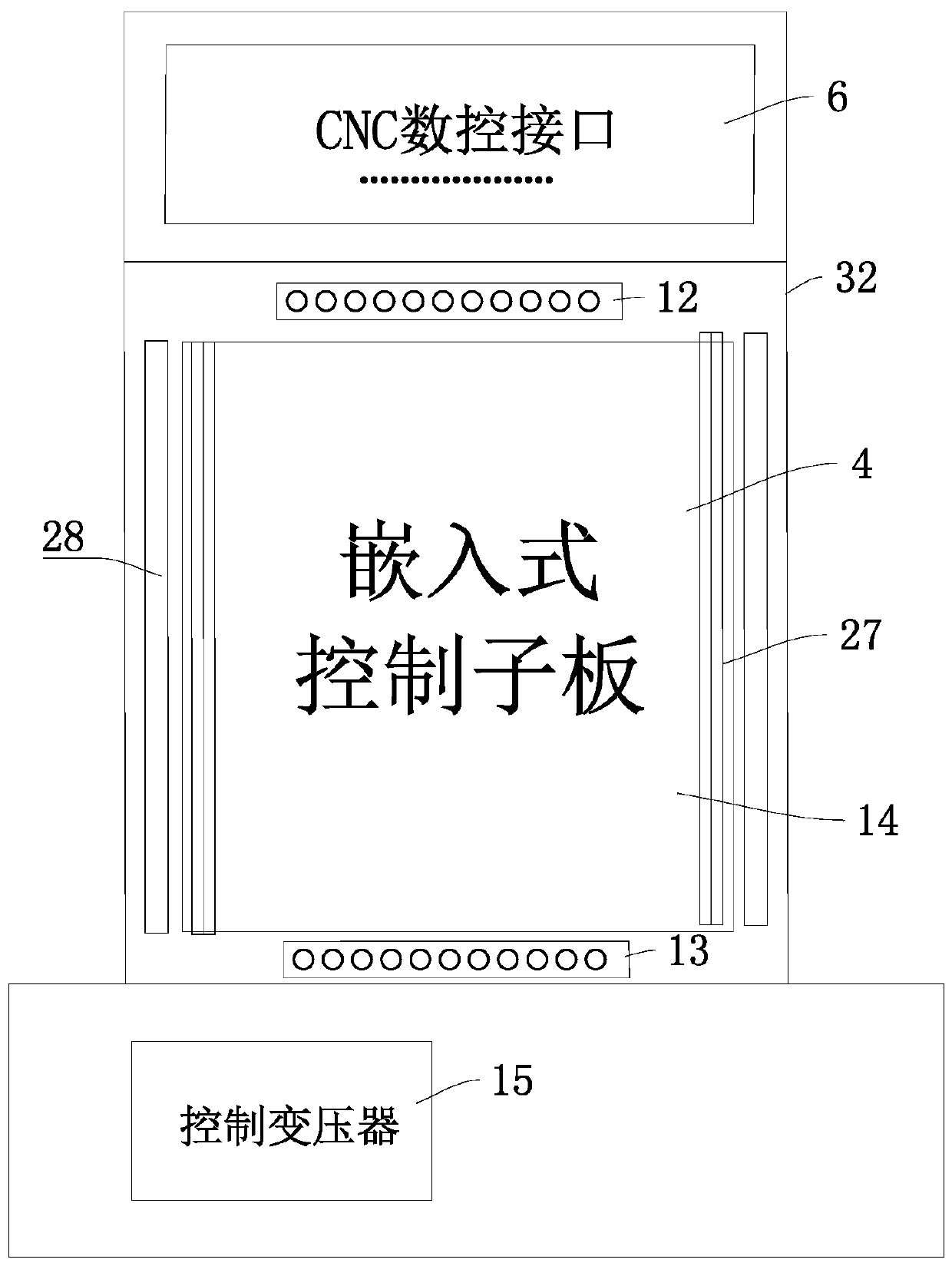

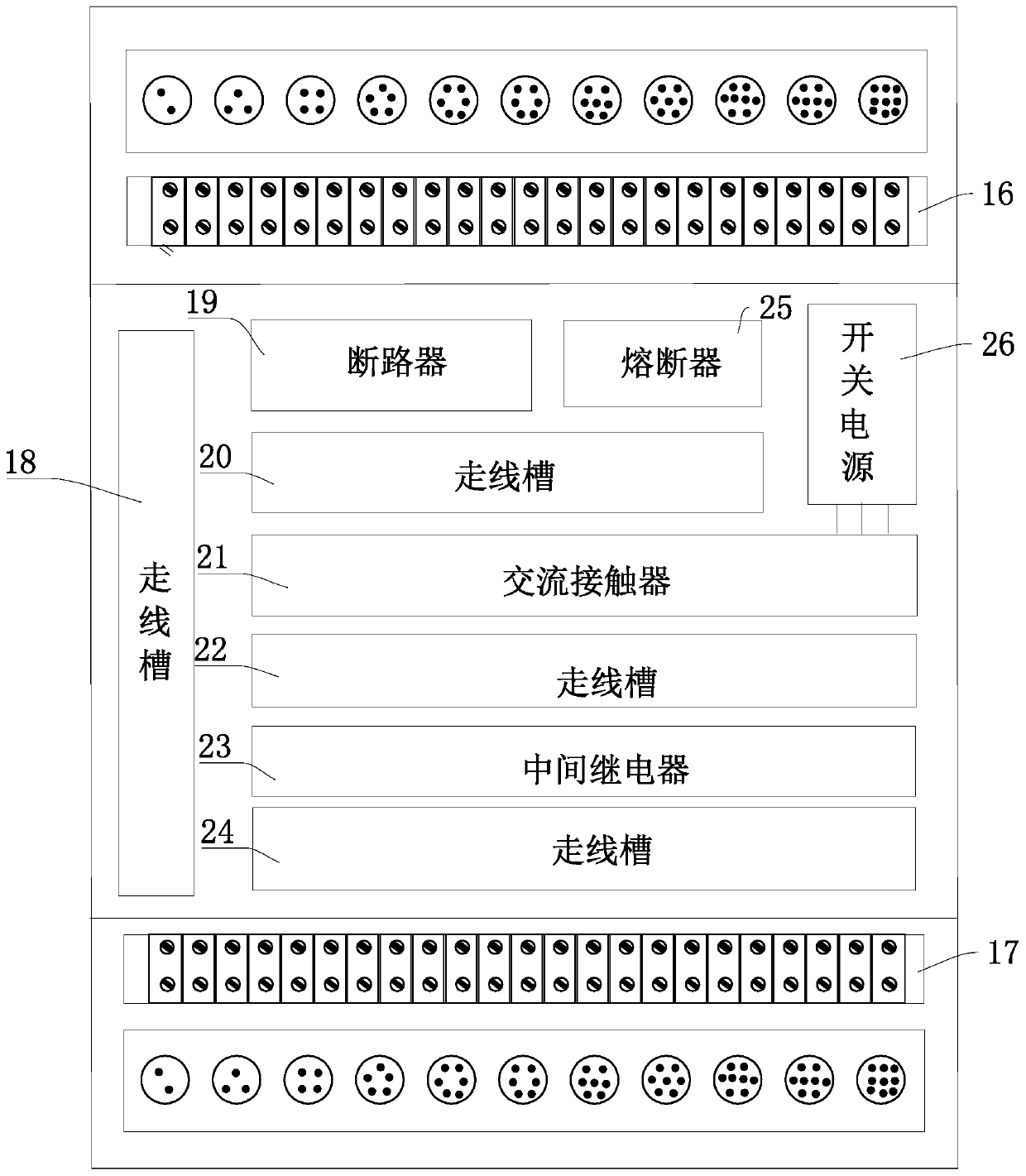

[0032] Embodiment 1: as Figure 1 to Figure 4 As shown, a debugging and troubleshooting training platform for a multifunctional numerical control system 5 capable of rapid recovery, the bottom of the console 1 is fixedly connected with a base 2, the console 1 is mainly divided into a main part 3 and an embedded part 4, and the main part 3 It is further divided into a front end 31 and a back end 32,

[0033] Such as figure 1 As shown, it is the front end 31 of the console 1, and the upper part of the training platform is the numerical control system 5 of the whole device, including a liquid crystal display 51LCD, a machine tool control panel 52MCP and a manual input panel 53MDI, and the liquid crystal display 51 is located at the front end 31, the machine tool control panel 52 is located at the bottom of the liquid crystal display 51, and the manual input panel 53 is arranged at one side of the liquid crystal display 51 and the machine tool control panel 52.

[0034] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com