Film sealing tooling for lead-acid battery liquid storage bottle

A lead-acid battery and liquid storage bottle technology, applied in lead-acid batteries and other directions, achieves the effect of smooth bottle mouth film, simple structure, convenient processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

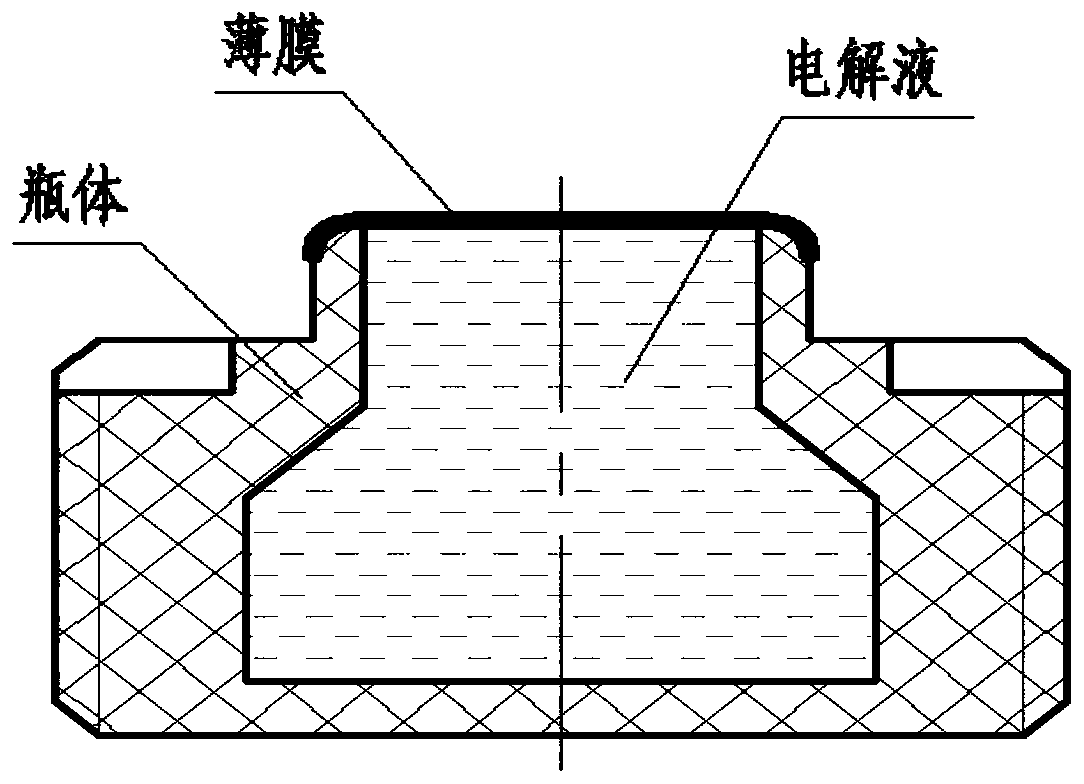

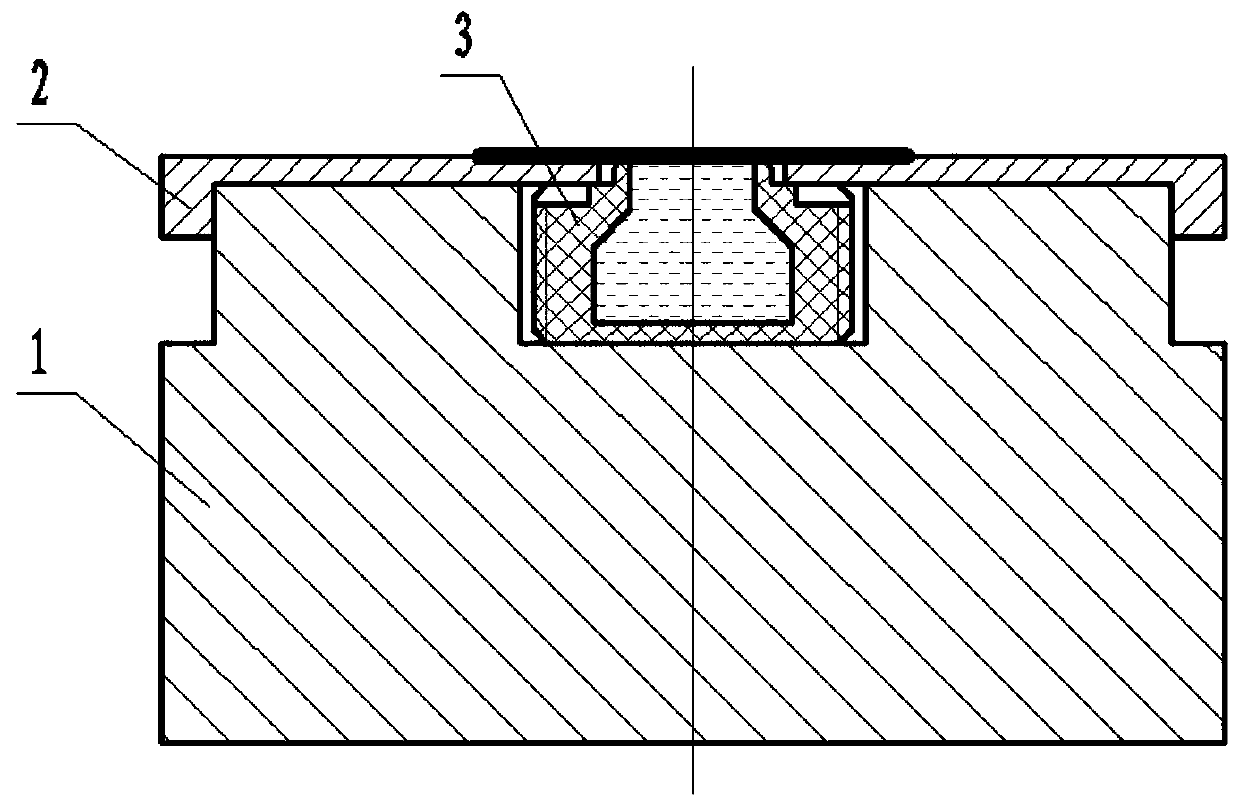

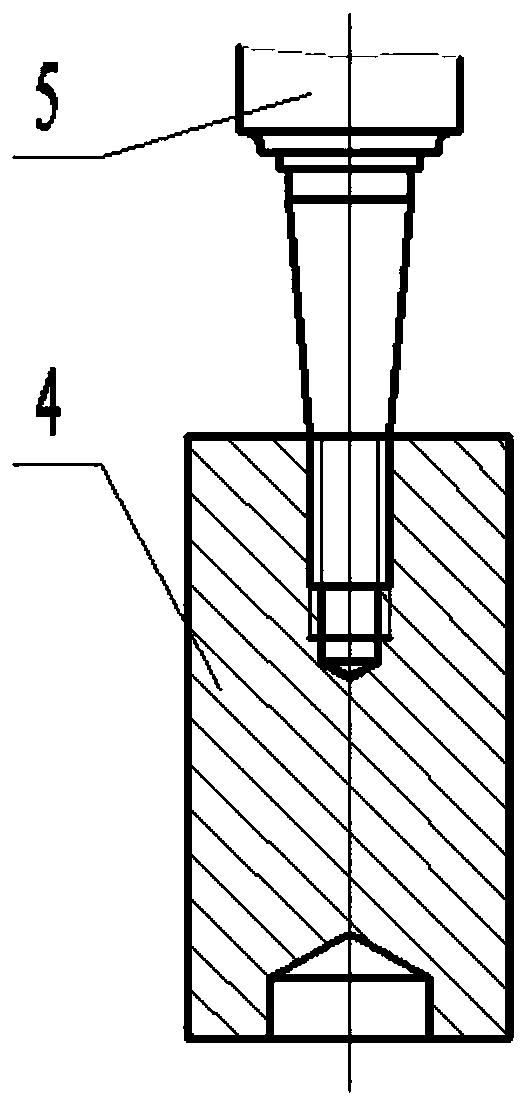

[0013] The film sealing tooling of the lead-acid battery liquid storage bottle involved in this embodiment, such as figure 1 , figure 2 , image 3 shown. The tooling is composed of a base 1, a cover plate 2, a soldering iron tip 4, and a reformed soldering iron tip 5. The reformed soldering iron tip 5 is made by threading the head of a waste general-purpose soldering iron tip, and the matching soldering iron tip 4 is made of a copper rod. Put the battery liquid storage bottle 3 into the hole 1 of the base, fix the battery liquid storage bottle 3 through the cover plate 2, and limit the height of the bottle mouth after welding; cover the bottle mouth of the battery liquid storage bottle 3 with PET / PE composite film, the soldering iron tip 4 is separated from the shoulder of the battery liquid storage bottle 3, heat seal the PE surface of the film and the bottle opening of the battery liquid storage bottle 3 with the soldering iron tip 4, then take out and cut off the excess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com