Backbone prosthesis with supination-type expansion tube structure handle and using method thereof

A tube expansion and backbone technology, applied in the direction of prosthesis, femur, femoral head, etc., can solve the problems of increased trauma, increased operation difficulty and operation time, postoperative stress concentration, etc., to improve rigid confrontation, increase surgical trauma, local The effect of diameter increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

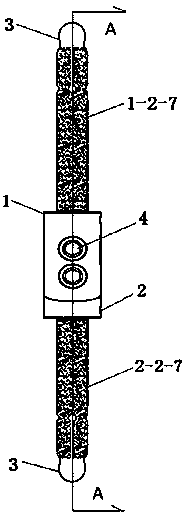

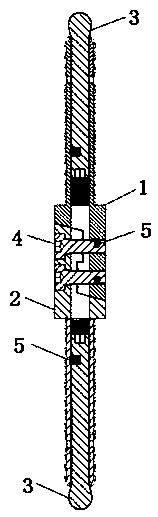

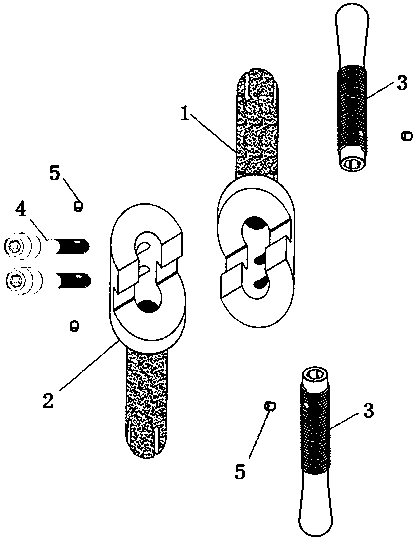

[0051] like Figure 1 to Figure 10 As shown, a backbone prosthesis of a supination type expansion tube structure handle, including a proximal part 1, a distal part 2, an expansion bolt 3, a connecting bolt 4 and an anti-rotation plunger 5;

[0052] The proximal part 1 is composed of a reconstructed part I1-1 with an integral structure and a hollow handle part I1-2;

[0053] The distal part 2 is composed of a reconstructed part II2-1 with an integral structure and a hollow handle part II2-2.

[0054] The base end of the reconstruction part I1-1 is a cylinder I1-1-1, the connecting end is a semi-cylindrical I1-1-2, and a semicircular groove I1-1 is vertically arranged on the plane of the semi-cylindrical I1-1-2 -3, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com