Reaction kettle

A technology for reactors and kettle lids, applied in the field of reactors, can solve the problems of reducing maintenance costs, not being able to control activated alumina well, and generating static electricity, so as to reduce maintenance costs, eliminate potential safety hazards, and protect reaction equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

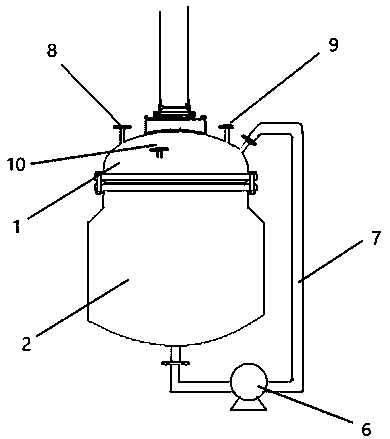

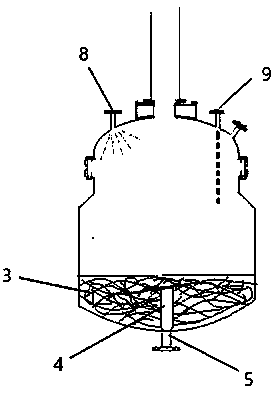

[0020] like figure 1 , 2 As shown, the reactor of the present invention comprises a still cover 1 and a still body 2, the still cover 1 is provided with a feed inlet, and the bottom of the still body 2 is provided with a discharge port 5, and the reactor also includes a filtering device and a circulation device, The filter device is arranged at the bottom of the inner cavity of the kettle body 2. Specifically, the filter device includes a first filter part and a second filter part. The first filter part is a number of porcelain rings 3 laid randomly on the bottom of the reactor cavity. The filter part is an enamel channel 4 vertically arranged at the bottom of the inner cavity of the reaction kettle, and all walls of the enamel channel 4 are provided with filter holes; the bottom of the enamel channel 4 covers the discharge port 5 . The circulation device is specifically a circulation pump 6, which is arranged outside the reaction kettle and connected to the kettle cover 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com