System for simultaneously carrying out confining pressure and back pressure to realize high pressure in micro-fluidic chip

A microfluidic chip, medium and high pressure technology, applied in the field of multiphase flow, can solve the problems such as the pressure difference cannot be too large, the loss is strong, and the realization of the confining pressure is small, and the system is simple, the operability is strong, and the system is reduced. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

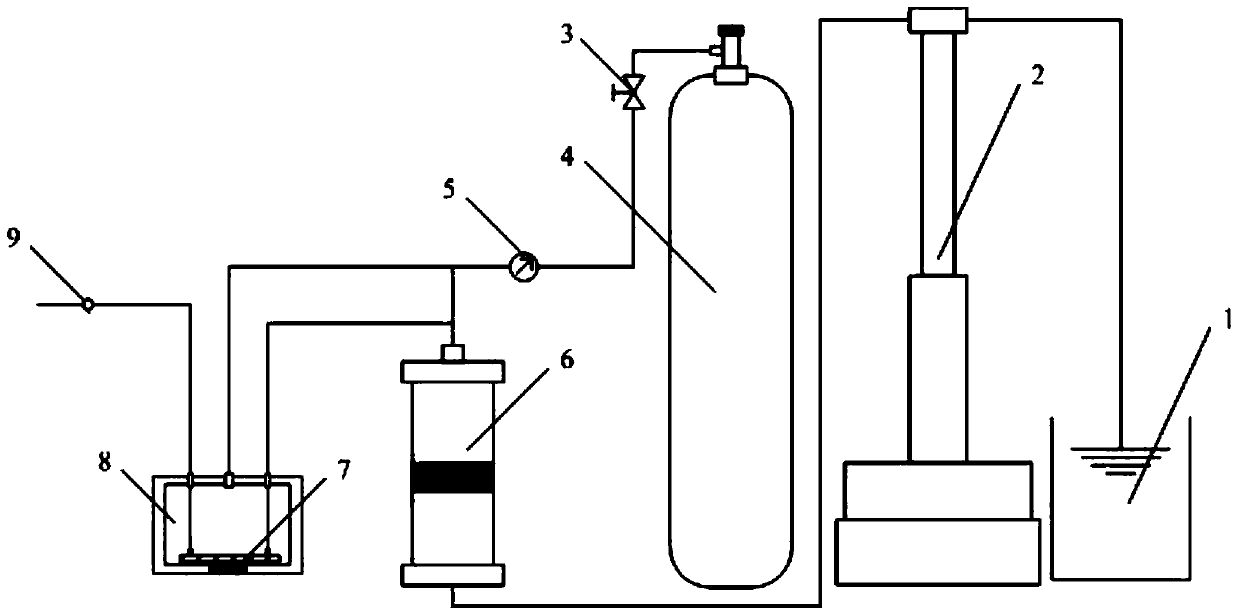

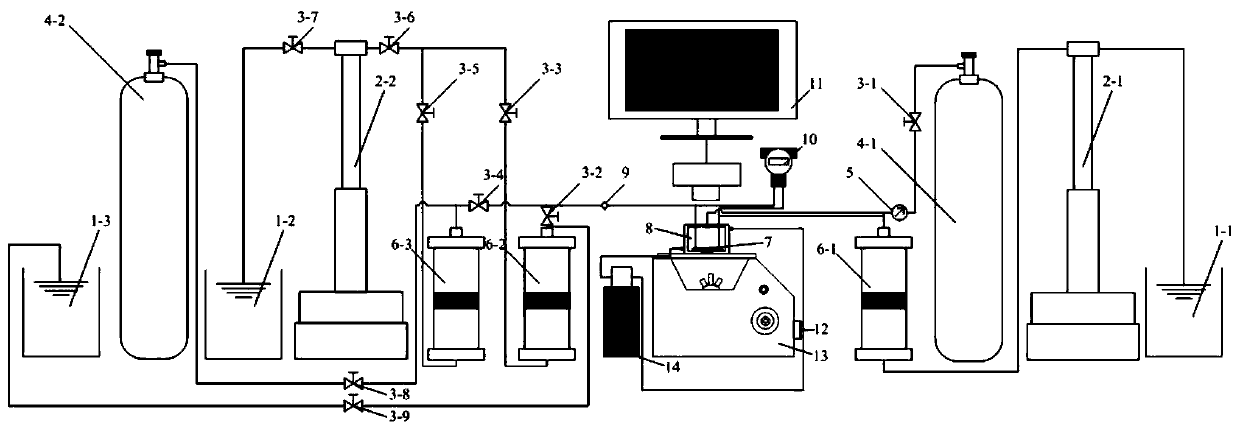

[0018] In order to make the purpose, technical solution and advantages of the system of the present invention clearer, the system of the present invention will be further described in detail below in conjunction with the specific example "Microcosmic visualization system for CO2 displacement of brine under high temperature and high pressure". It should be understood that the specific embodiments described here are only used to explain the system of the present invention, and are not intended to limit the system of the present invention.

[0019] attached figure 2 in the attached figure 1 The injection system is added on the basis of the experiment, and all valves are closed by default before the experiment starts. When the valve g3-7 is opened, the plunger pump a2-1 and plunger pump b2-2 will suck the liquid container a1-1 and the liquid container Release the liquid in the container b1-2 for pressurization, then close the valve g3-7. Turn on the circulating water bath 14 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com