PCB copper foil side cutting and board separating integrated equipment and PCB process line

A technology of splitting and cutting, which is applied in metal processing and other directions, can solve the problems of restricting production efficiency, high labor intensity, waste of resources, etc., and achieve the effects of reducing labor intensity, improving automation procedures, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the drawings and specific embodiments.

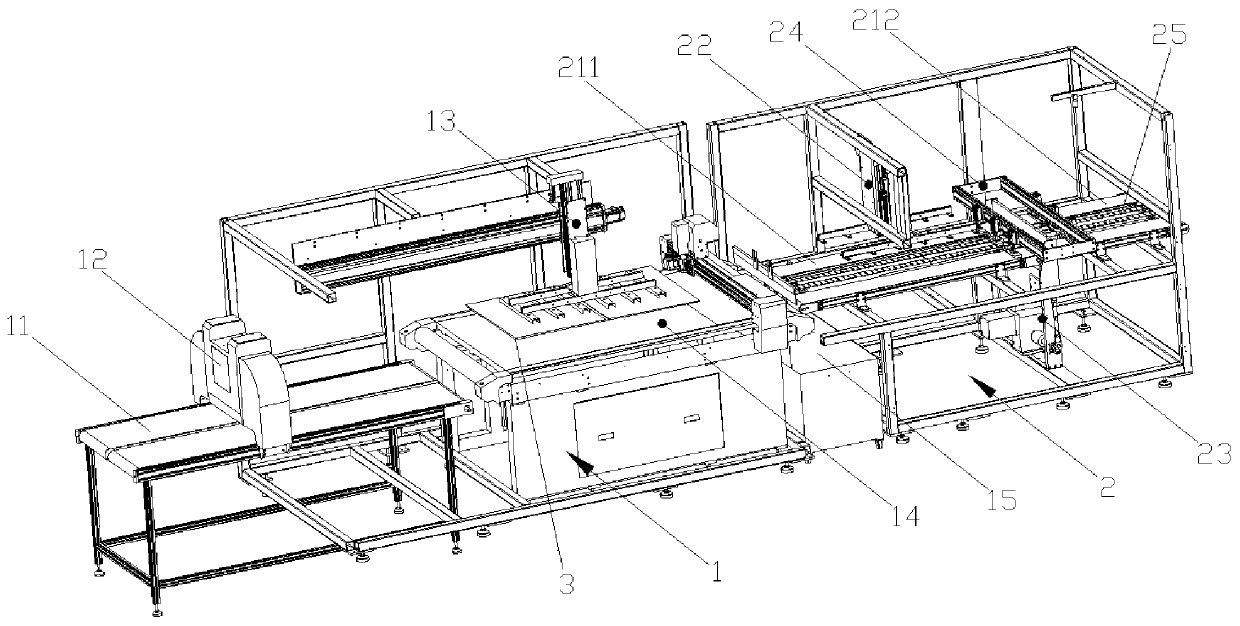

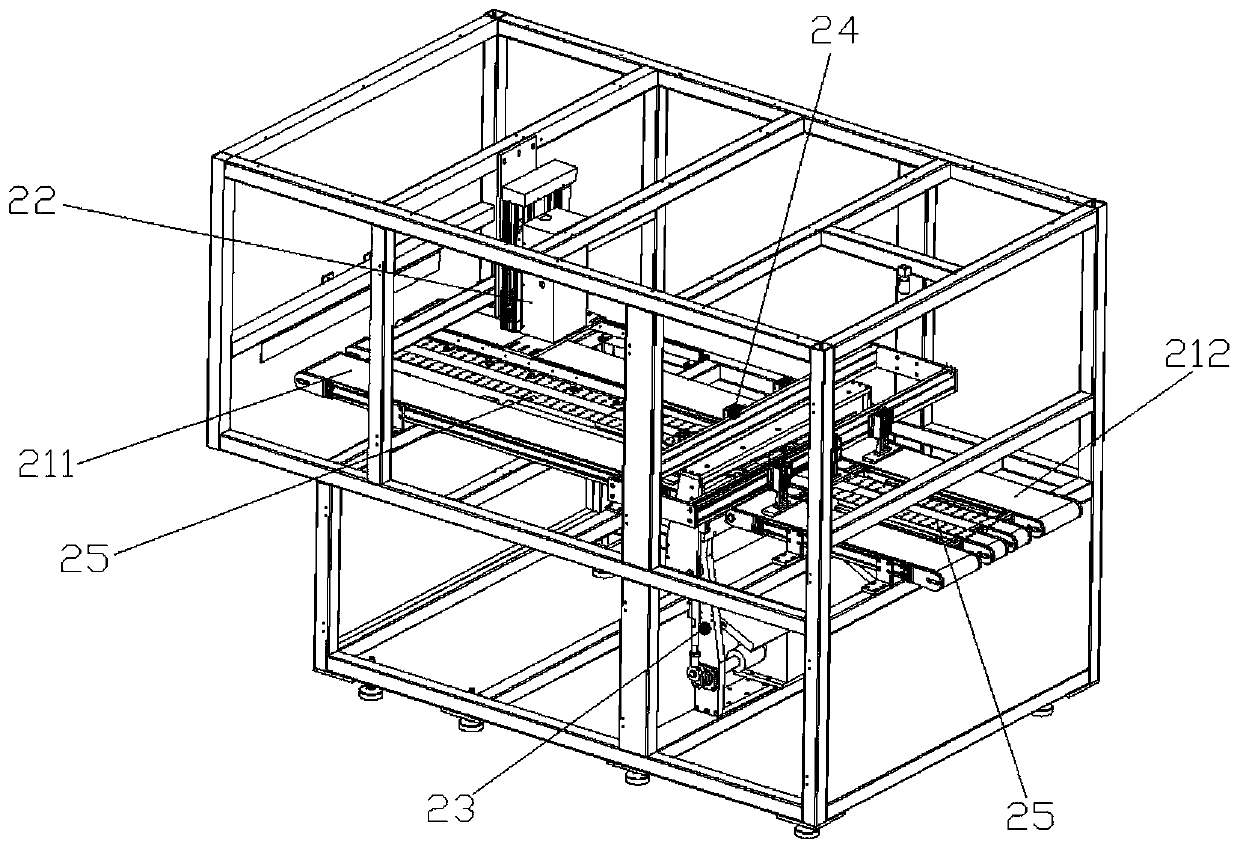

[0042] Such as figure 1 This embodiment provides an integrated device for cutting and separating PCB copper foil trims, including a PCB copper foil trim cutting and recycling device 1 and a PCB board automatic separation device 2. The PCB copper foil trim cutting and The recycling device is the front station, and the PCB board automatic dividing device is the rear station.

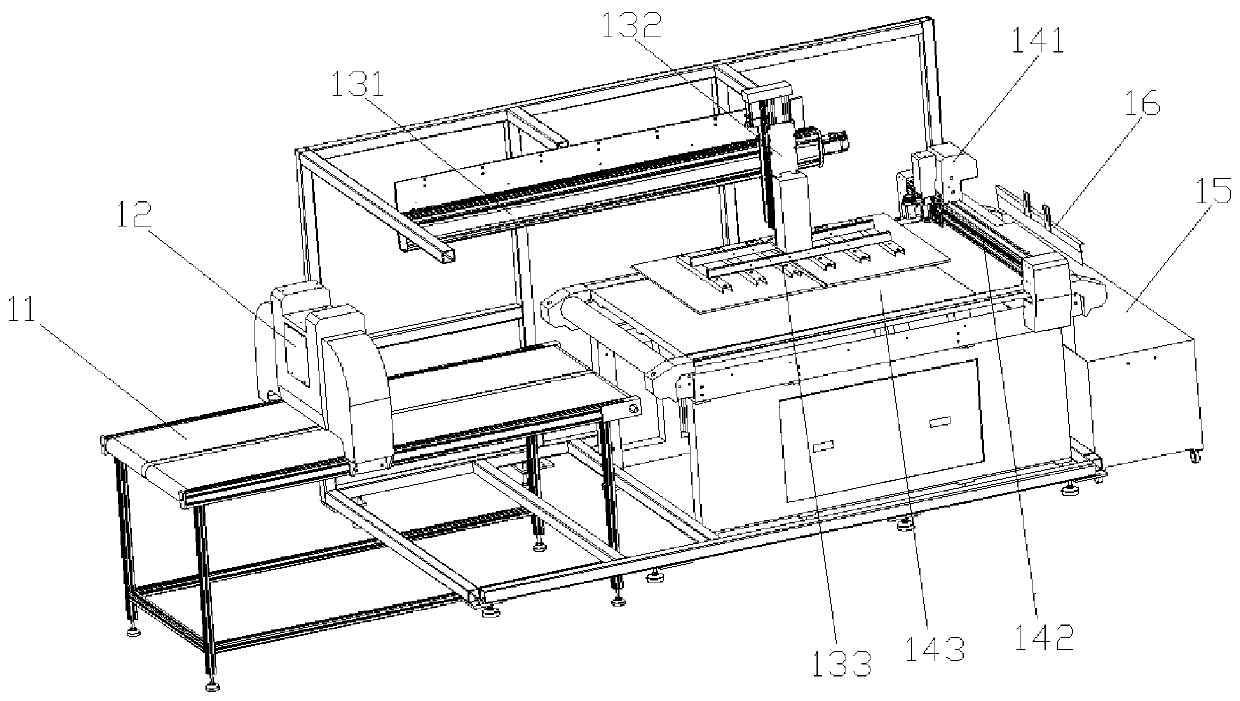

[0043] Such as figure 1 with figure 2 , The PCB copper foil trim cutting and recycling device includes: a feeding conveyor belt 11, a visual inspection device 12, a feeding manipulator, a cutting device, and a copper foil recovery box 15. The visual inspection device 12 is located on the feeding conveyor belt 11 Above, the cutting device is located on the side of the feeding conveyor belt 11, the feeding manipulator is located above the cutting device, and the copper foil recovery box 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com