Preparation method of organic silicon foaming gasket for power battery box body packaging

A box packaging and power battery technology, applied in applications, household components, household appliances, etc., can solve the problems of poor deformation, poor sealing, poor waterproof and anti-aging performance, and achieve good waterproof performance, small permanent compression deformation, Good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

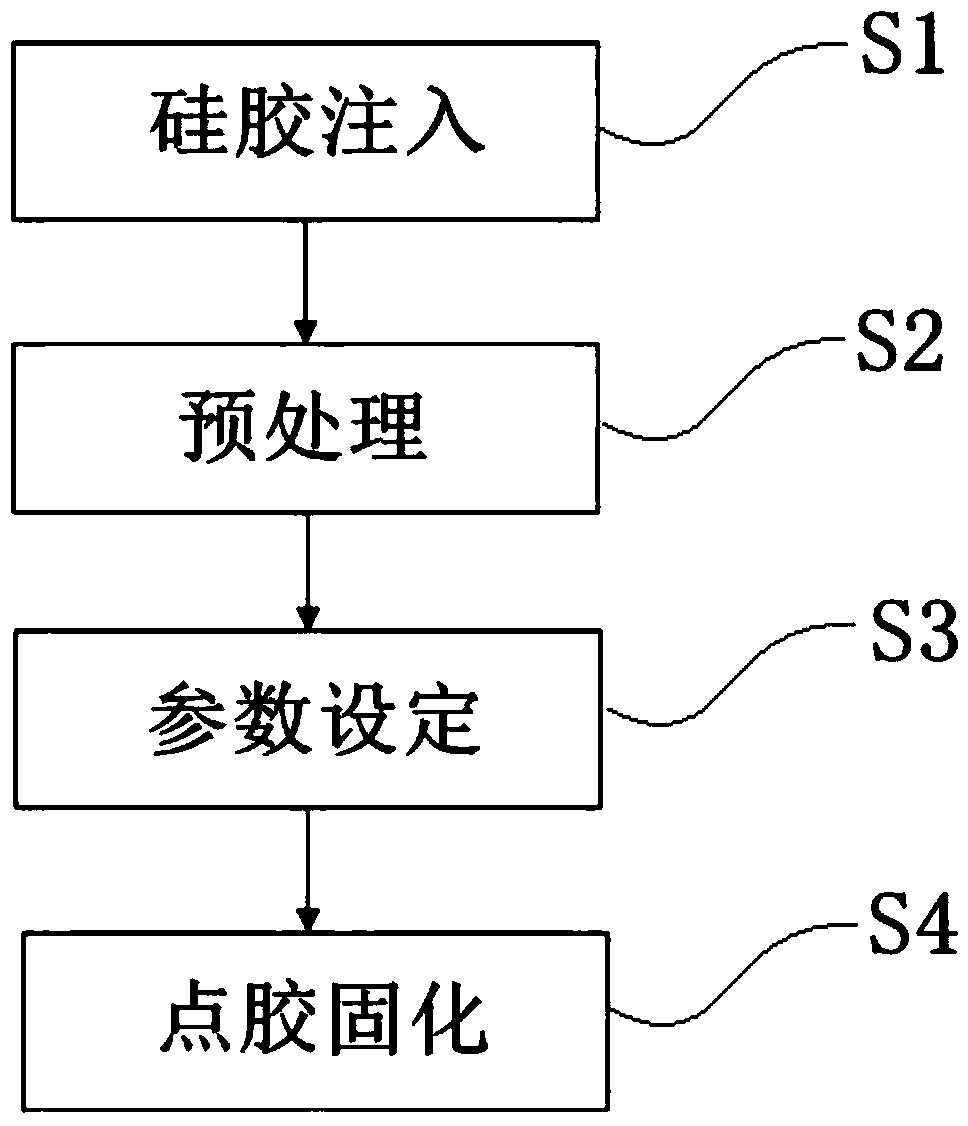

[0031] A kind of preparation method of the organosilicon foam gasket that is used for power battery case packaging of the present invention, such as figure 1 shown, including the following steps:

[0032] S1, silicone injection;

[0033] S2, pretreatment;

[0034] S3, parameter setting;

[0035] S4, dispensing and curing.

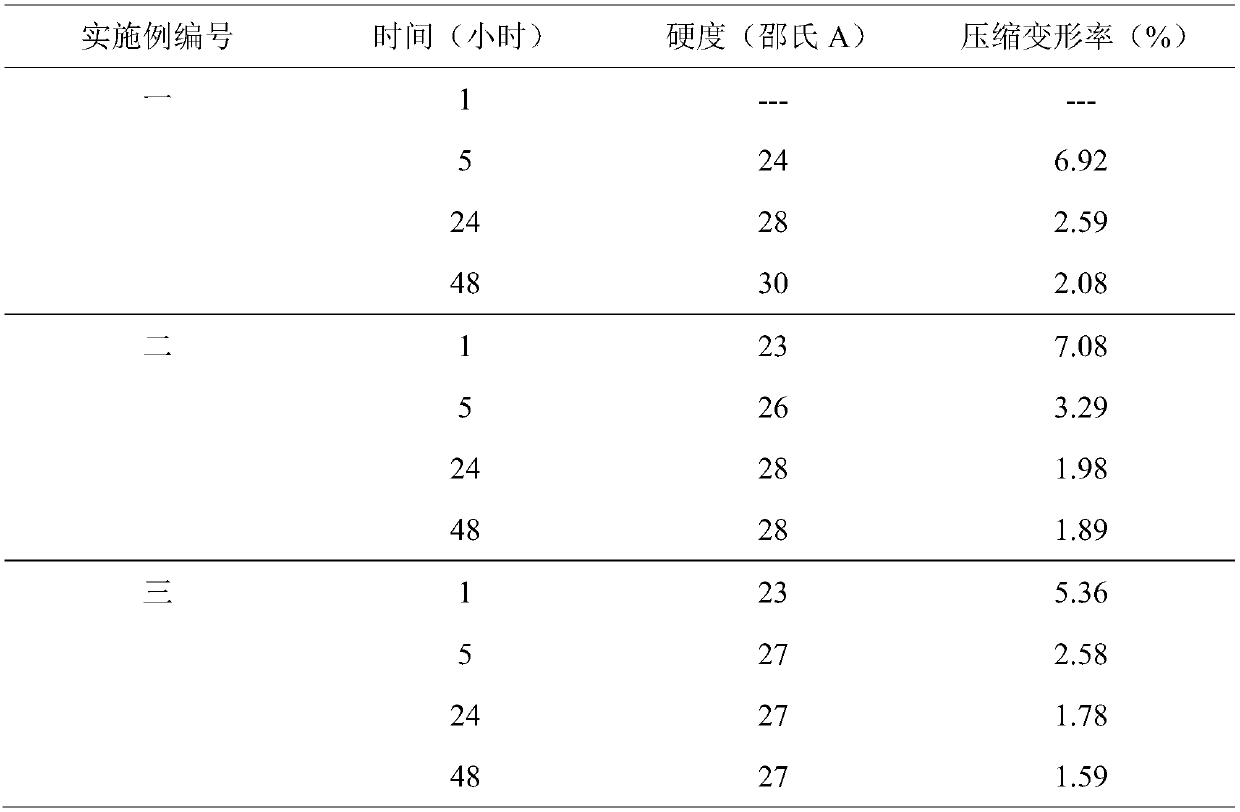

Embodiment 1

[0037] Embodiment 1, a method for preparing a silicone foam gasket used for encapsulation of a power battery box includes the following steps:

[0038] S1. Put the battery box to be packaged on the workbench; transport the prepared organic silica gel A and organic silica gel B to channel A and channel B respectively, and the mass ratio of the two components is A:B=1 :20.

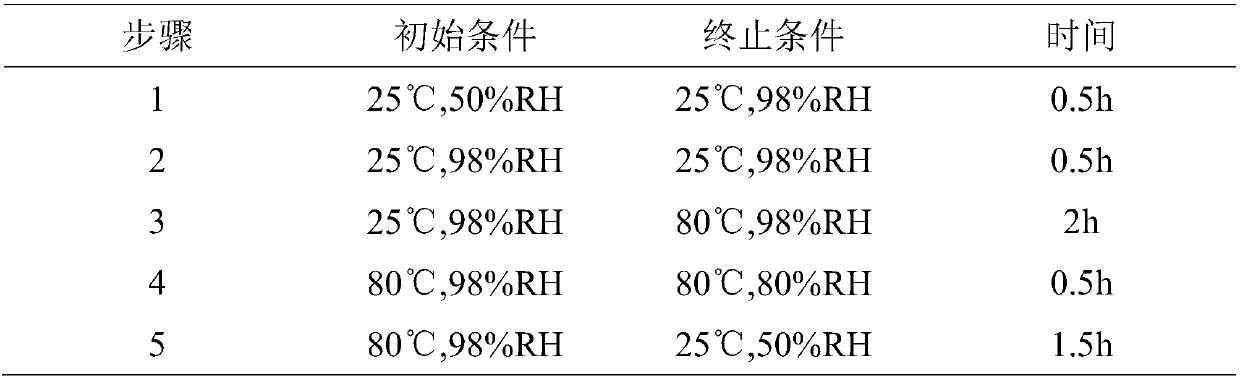

[0039] S2. Set the working temperature of the pretreatment to 10° C. for 2 hours.

[0040] S3. Set the glue dispensing parameters, wherein the walking speed is 0.5m / min, the glue dispensing temperature is 10°C, and the glue spouting amount of the machine head is 0.5g / s.

[0041] S4. Start the dispensing machine, and mix the organic silica gel A and the organic silica gel B at a speed of 500rpm, so that the two components of the organic silica gel are fully mixed, and the glue mixing process is completed; the mixed glue is extruded from the machine head, along the Glue is dispensed at the junction of the ba...

Embodiment 2

[0042] Embodiment 2, a method for preparing a silicone foam gasket used for encapsulation of a power battery box includes the following steps:

[0043] S1. Put the battery box to be packaged on the workbench;

[0044] Transport the prepared silicone silica gel A and silicone silica gel B to channel A and channel B respectively, wherein the mass ratio of the two components is A:B=1:1.

[0045] S2. Set the working temperature of the pretreatment to 20° C. for 2 hours.

[0046] S3. Set the dispensing parameters, wherein, the walking speed is 6m / min, the dispensing temperature is 25°C, and the dispensing amount of the machine head is 2g / s.

[0047] S4. Start the dispensing machine, and mix the organic silica gel A and the organic silica gel B at a speed of 1800rpm, so that the two components of the organic silica gel are fully mixed, and the glue mixing process is completed; the mixed glue is extruded from the machine head, along the Glue is dispensed at the junction of the batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com