Adsorption enhanced methane water steam reforming hydrogen production device and method

A technology for reforming a hydrogen production device and methane steam, applied in chemical instruments and methods, through selective and reversible absorption of hydrogen separation, hydrogen, etc. The problem of high cost can reduce the cost and labor intensity, reduce the loss of activity and service life, and avoid the energy consumption of heating up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for adsorption enhanced methane steam reforming hydrogen production unit, comprising the following steps:

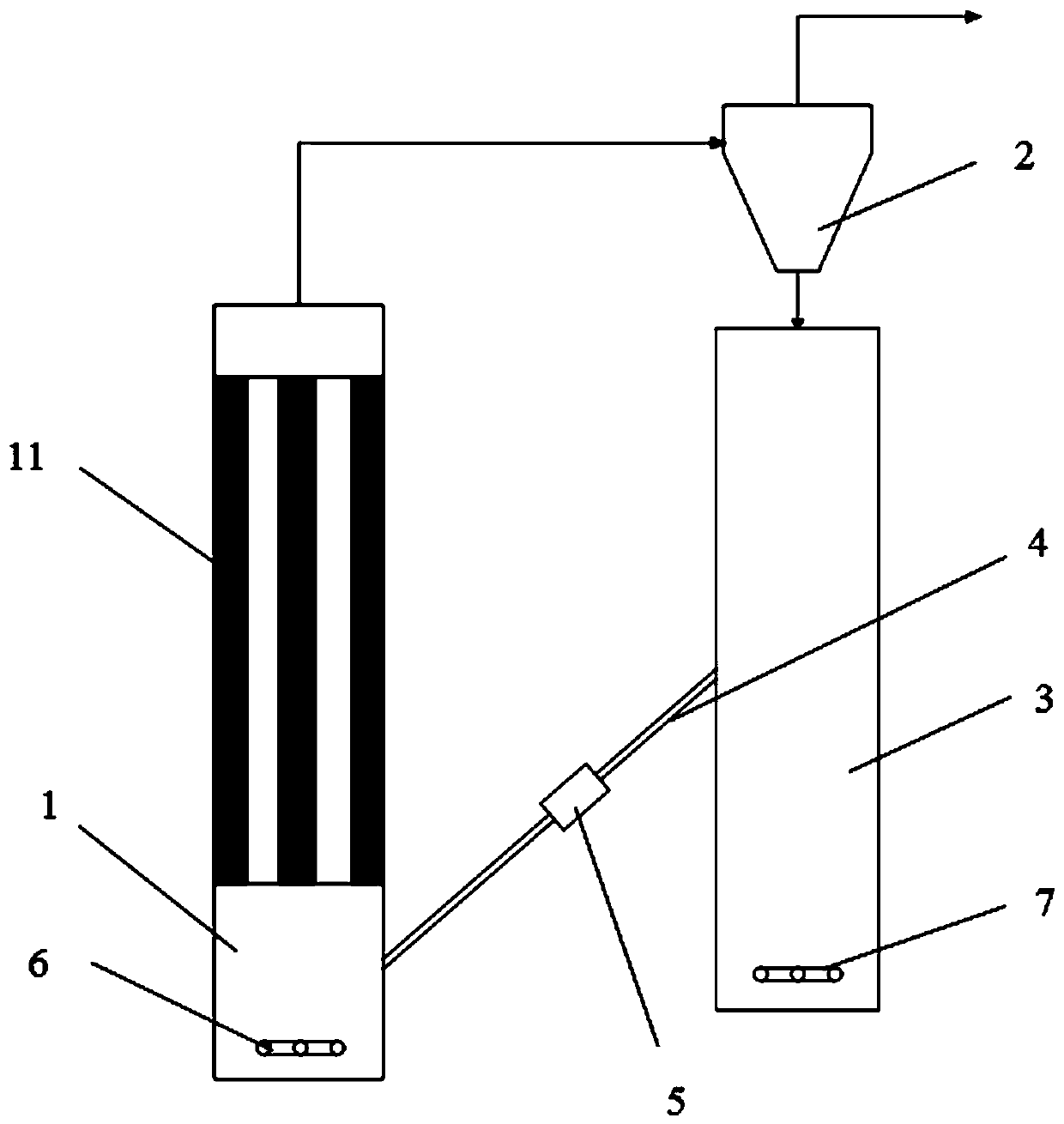

[0035] a, the mixed gas of water vapor and methane after preheating is passed in the grid type fluidized fixed reactor 1 together with the adsorbent that the regenerative reactor 3 comes over, and the catalyst inside the grid type fluidized fixed reactor 1 Coating 11 contacts to react, adsorb and strengthen reforming reaction; the molar ratio of water vapor and methane is 4:1; the operating pressure of the grid-type fluidized fixed reactor is 1 MPa; the reaction temperature is 500°C;

[0036] b. The gas-solid mixture coming out from the grid-type fluidized fixed reactor 1 enters the cyclone separator 2 for separation;

[0037] c. The adsorbent coming out of the cyclone separator 2 enters the regeneration reactor 3 to regenerate the adsorbent. The regenerated adsorbent passes through the feeding pipe 2 under the action of the regeneration gas, and enters t...

Embodiment 2

[0042] A method for adsorption enhanced methane steam reforming hydrogen production unit, comprising the following steps:

[0043] a, the mixed gas of water vapor and methane after preheating is passed in the grid type fluidized fixed reactor 1 together with the adsorbent that the regenerative reactor 3 comes over, and the catalyst inside the grid type fluidized fixed reactor 1 Coating 11 contacts to react, adsorb and strengthen reforming reaction; the molar ratio of water vapor to methane is 4:1; the operating pressure of the grid-type fluidized fixed reactor is 1.5MPa; the reaction temperature is 550°C;

[0044] b. The gas-solid mixture coming out from the grid-type fluidized fixed reactor 1 enters the cyclone separator 2 for separation;

[0045] c. The adsorbent coming out of the cyclone separator 2 enters the regeneration reactor 3 to regenerate the adsorbent. The regenerated adsorbent passes through the feeding pipe 2 under the action of the regeneration gas, and enters t...

Embodiment 3

[0050] A method for adsorption enhanced methane steam reforming hydrogen production unit, comprising the following steps:

[0051] a, the mixed gas of water vapor and methane after preheating is passed in the grid type fluidized fixed reactor 1 together with the adsorbent that the regenerative reactor 3 comes over, and the catalyst inside the grid type fluidized fixed reactor 1 Coating 11 contacts and reacts, adsorbs and strengthens reforming reaction; the molar ratio of water vapor and methane is 4:1; the operating pressure of the grid type fluidized fixed reactor is 1-2 MPa; the reaction temperature is 500-600 ℃;

[0052] b. The gas-solid mixture coming out from the grid-type fluidized fixed reactor 1 enters the cyclone separator 2 for separation;

[0053] c. The adsorbent coming out of the cyclone separator 2 enters the regeneration reactor 3 to regenerate the adsorbent. The regenerated adsorbent passes through the feeding pipe 2 under the action of the regeneration gas, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com