Rail type in-situ purification system for water discharge pipeline

A technology for drainage pipelines and purification systems, applied in waterway systems, water supply devices, water treatment sites, etc., can solve problems such as affecting normal drainage, black and odorous sewage, and easy to block pipelines, achieving easy implementation and promotion, small investment scale, The effect of less engineering measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

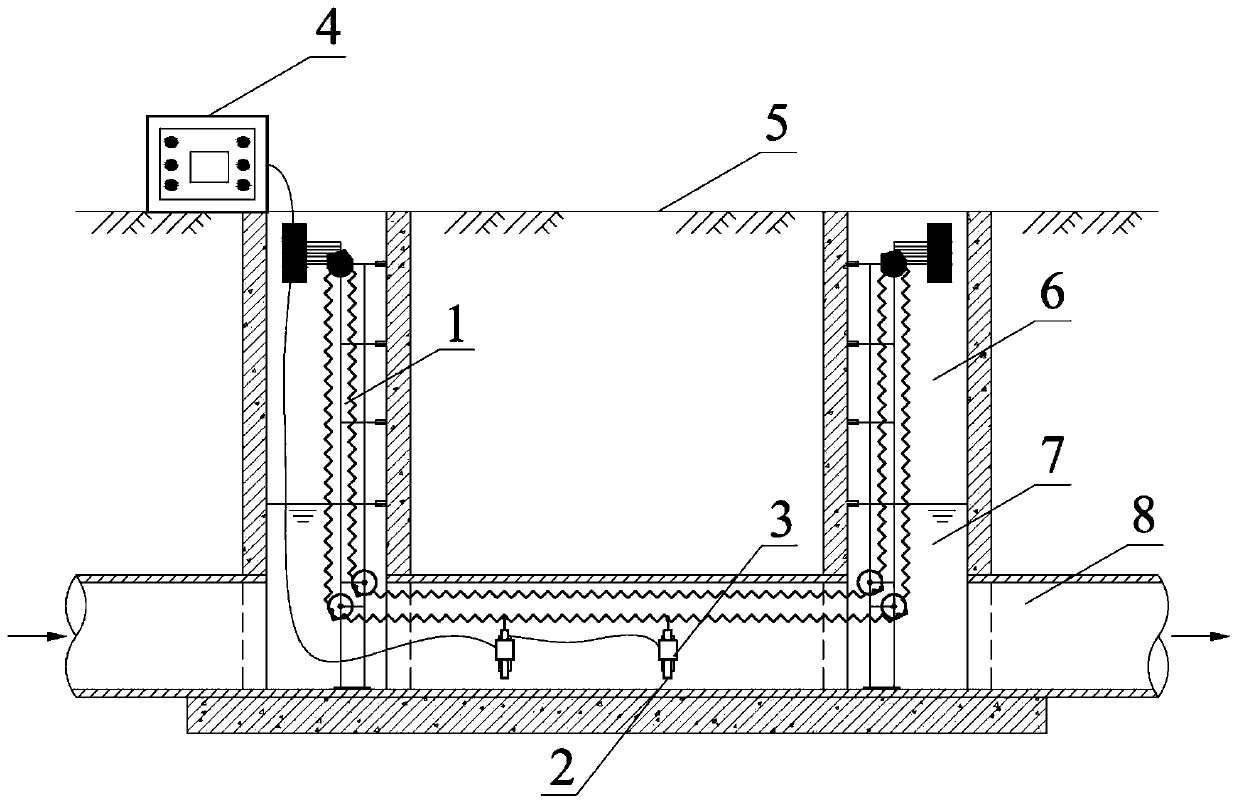

[0110] A track-type in-situ purification system for drainage pipes, the system specifically includes: a chain track 1, a suspension bracket 2, a processing unit 3 and an auxiliary unit 4; the chain track 1 is installed in the inspection well 6 and the drainage pipe 8 Inside, the suspension bracket 2 is suspended on the chain track 1 , and the processing unit 3 is nested in the suspension bracket 2 .

[0111] The suspension bracket 2 is composed of a hook 21, a frame body 22, a draw slot 23 and a counterweight 24; wherein, the hook 21 engages with the pin shaft of the chain 16, thereby limiting the frame body 22 and the The relative position of the chain 16; the hook 21 is set on the frame body 22, and the frame body 22 is provided with a card slot 23.

[0112] The processing unit 3 of the system selects an ultraviolet photodecomposer 31 , and correspondingly, the auxiliary unit 4 selects an ultraviolet sensing probe 41 .

[0113] The main body of the ultraviolet irradiation u...

Embodiment 2

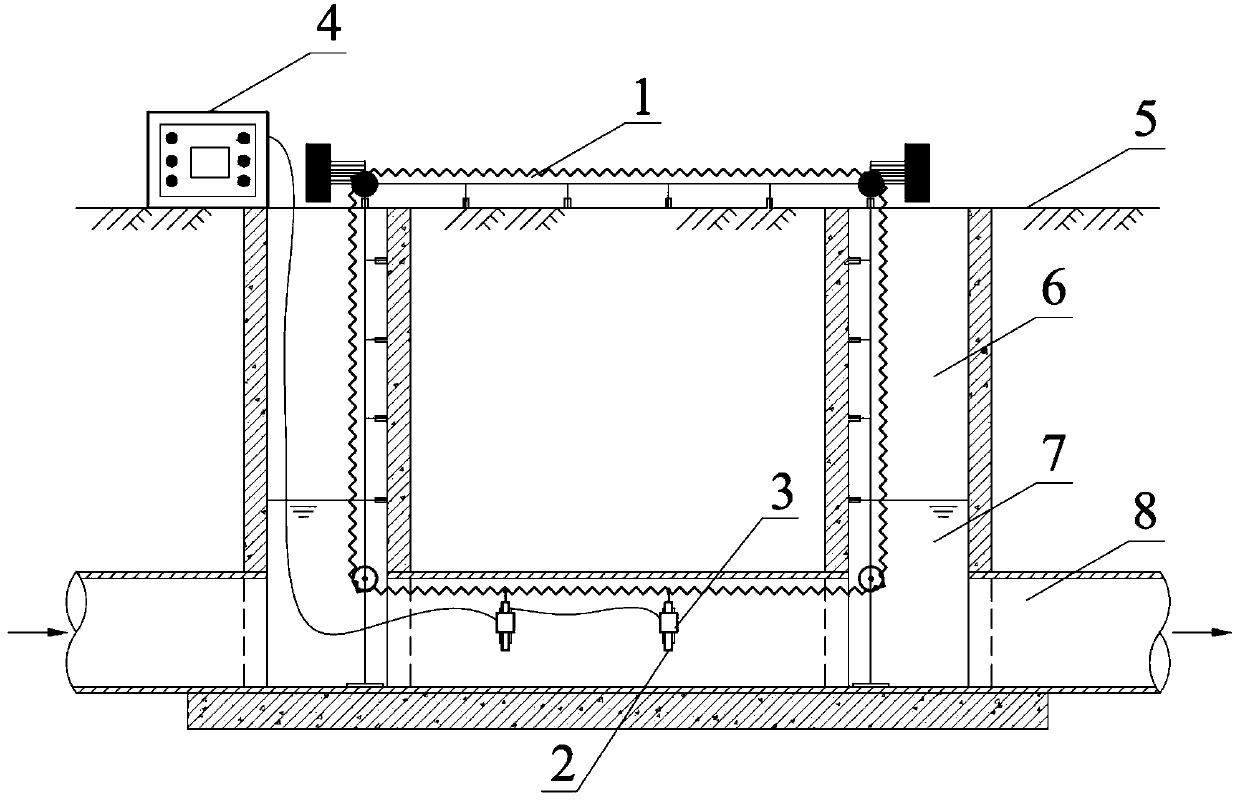

[0135] The track-type in-situ purification system used for drainage pipes has the same basic structure and water purification method as in Example 1, the processing unit 3 is a photocatalytic unit 32, and the auxiliary unit 4 supplies power to the photocatalytic unit and monitors its operation in real time. The implementation method is:

[0136] The suspension bracket 2 is composed of a hook 21, a frame body 22, a card slot 23, a snap-on grid and a counterweight 24; wherein, the hook 21 is engaged with the pin shaft of the chain 16, thereby limiting the The relative position of the frame body 22 and the chain; the hook 21 is arranged on the frame body 22, and the card slot 23 is arranged on the frame body 22; the card slot 23 is located on the surface of the frame body 22 for nesting the Photocatalytic unit 32; the main body of the photocatalytic unit 32 is an ultraviolet lamp tube, and the end of the ultraviolet lamp tube is waterproof through a waterproof coating; the draw-i...

Embodiment 3

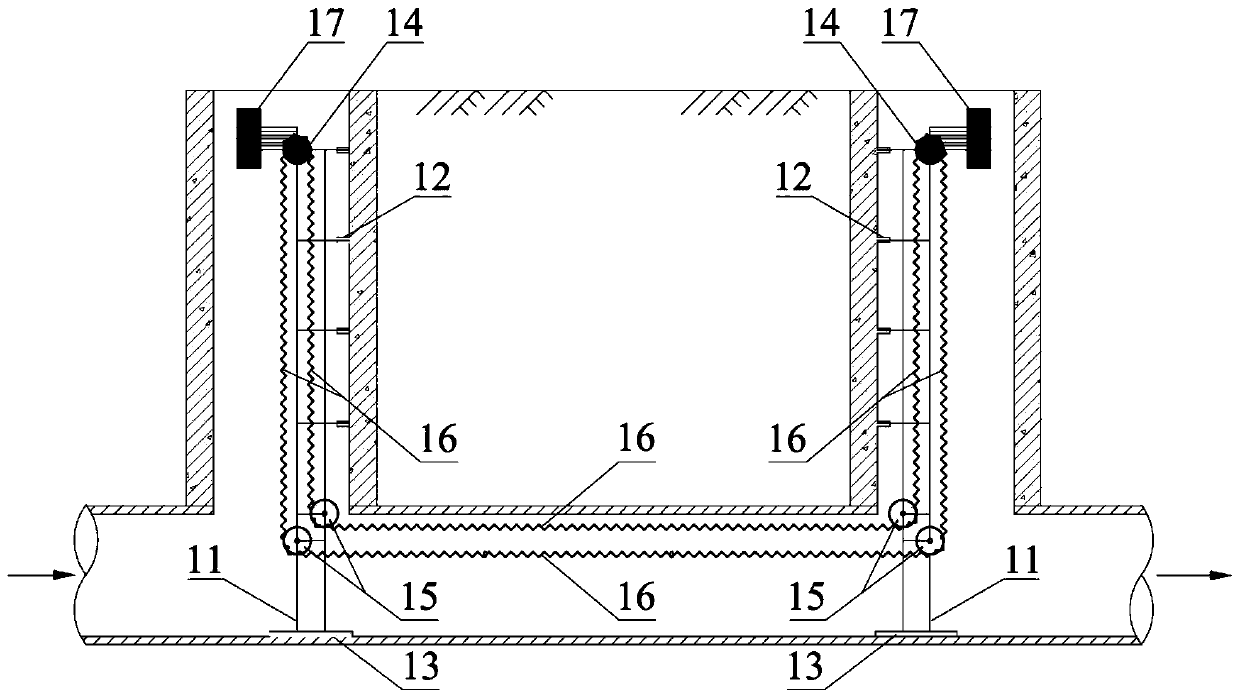

[0158] The track-type in-situ purification system for drainage pipes has the same basic structure and water purification method as in Embodiment 1, the processing unit 33 is an ultrasonic unit, and the auxiliary unit 4 is used to supply power to the ultrasonic unit 33 and regulate its vibration frequency and amplitude; Its specific implementation method is:

[0159]The suspension bracket is composed of a hook 21, a frame body 22, a draw-in groove 23 and a counterweight 24; wherein, the hook 21 passes through the pin shaft of the chain 16, thereby connecting the frame body 22 and the chain 16 Connected; the shape of the hook 21 is ring-shaped; the frame body 22 is connected to the hook 21, the card slot 23 is located on the surface of the frame body 22, and the ultrasonic unit 3 is embedded in the card slot 23; The counterweight 24 is located at the bottom of the frame body 22 and is used to increase the weight of the frame body 22 so that the suspension bracket 2 will not shak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com