Water filter material and its preparation method and application

A technology of water filtration and melt blown, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as unsatisfactory sewage treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] According to one aspect of the present invention, the present invention also relates to the preparation method of the above water filter material, which comprises:

[0050] 1) prepare modified resin by A) or B) method:

[0051] A) Spray drying and assembling the graphene material liquid obtained by uniformly dispersing the modifier component and the graphene oxide component to obtain modified graphene;

[0052] Incorporating the modified graphene into the melt-blown resin matrix by physical blending;

[0053] B) Spray-drying the dispersion of the graphene oxide component to obtain a graphene assembly;

[0054] Incorporating the mixture of the modifier component and the graphene assembly into the melt-blown resin matrix by physical blending;

[0055] 2) Melt-spinning the modified resin, and further processing it into a desired shape.

[0056] In some embodiments, the spray drying temperature is 175°C-240°C, and can also be selected from 180°C-230°C, such as 190°C, 200...

Embodiment 1

[0062] 1) Preparation of raw material graphene: get the graphene oxide dispersion liquid that Hummers method makes, adjust its concentration to be diluted to 1g / L, add diethylenetriamine aqueous solution (its final concentration is 10wt% of graphene oxide), After adding ultrasonic treatment for 1 h, the modified graphene oxide was centrifuged and washed with deionized water to pH=7;

[0063] The modified graphene ultrafine powder was obtained by spray drying, the temperature was set at 200°C, the wind speed was adjusted, and the final output was 18g / h.

[0064] 2) Select a degradable PP melt-blown resin with a density of 0.88-0.91g / cm 3 , Melt index is 1500±100g / 10min. The graphene powder sample is added through the degradation process, and the addition amount is 0.02wt%, so as to obtain the graphene powder sample.

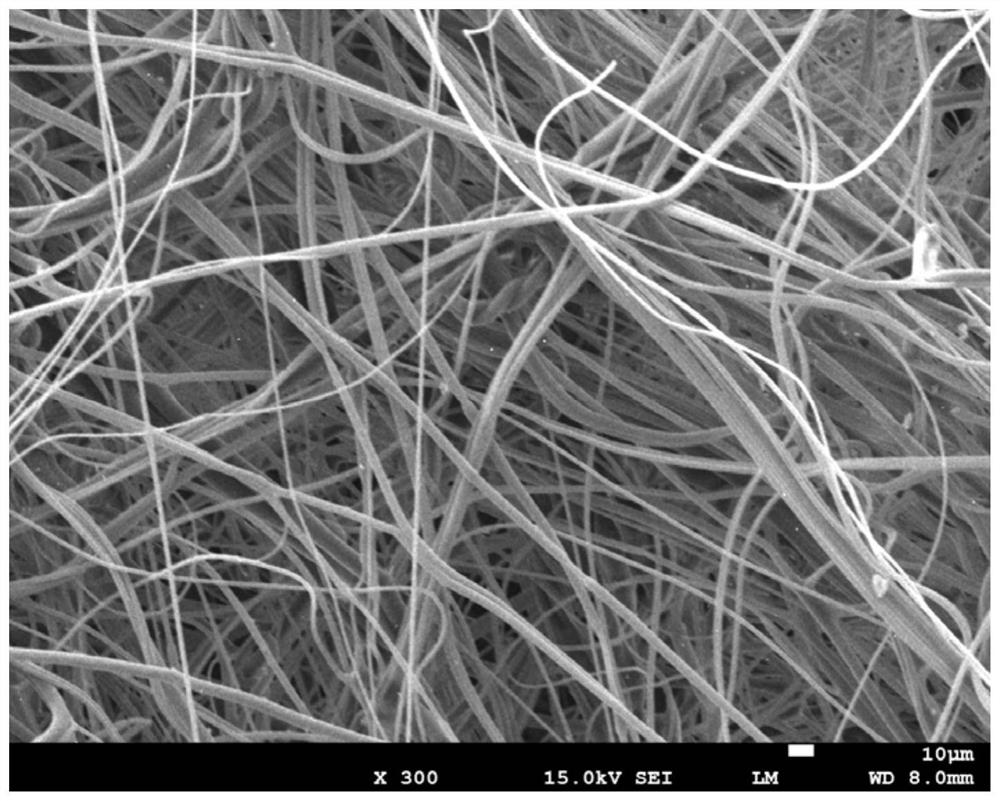

[0065] 3) Melt spinning through a 0.35mm aperture spinneret (Carson, Japan), the melt blowing temperature is 255-270°C, the feed rate is 6-15kg / h; the calender ...

Embodiment 2

[0068] 1) Preparation of raw material graphene: get the graphene oxide dispersion prepared by the Hummers method, adjust its concentration to be diluted to 1g / L, add triethylenetetramine aqueous solution (its final concentration is 20wt% of graphene oxide), add ultrasonic After 1 hour of treatment, the modified graphene oxide was centrifuged and washed with deionized water to pH=7;

[0069] The modified graphene ultrafine powder was obtained by spray drying, the temperature was set at 200°C, the wind speed was adjusted, and the final output was 18g / h to obtain a graphene powder sample.

[0070] 2) Select a degradable PP melt-blown resin with a density of 0.88-0.91g / cm 3 , the melt index is 1500±100g / 10min; the graphene powder sample is added through the degradation process, and the addition amount is 0.1wt%.

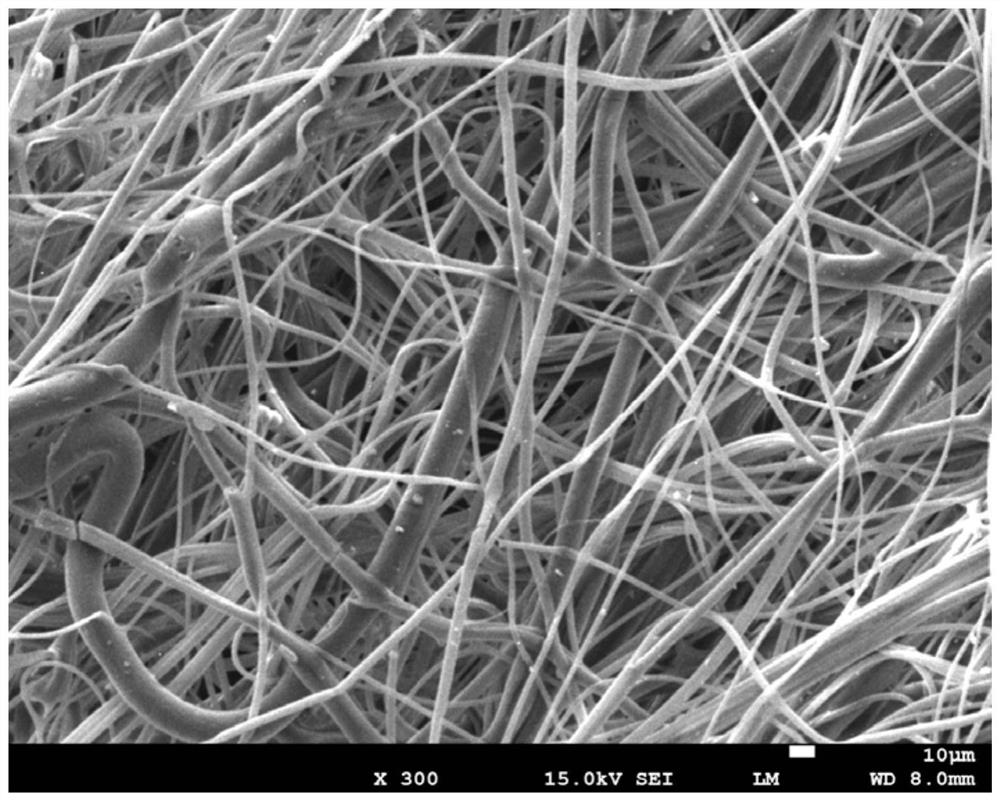

[0071] 3) Melt spinning through a 0.35mm aperture spinneret (Carson, Japan), the melt blowing temperature is 255-270°C, the feed rate is 6-15kg / h; the calender passes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com