Energy-saving high-efficiency nano mixed liquid sectional radiator

A mixed liquid and radiator technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of simple structure, poor heat exchange effect, and single function of radiators, and achieve high heat exchange efficiency and high heat dissipation efficiency. , the effect of strong liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

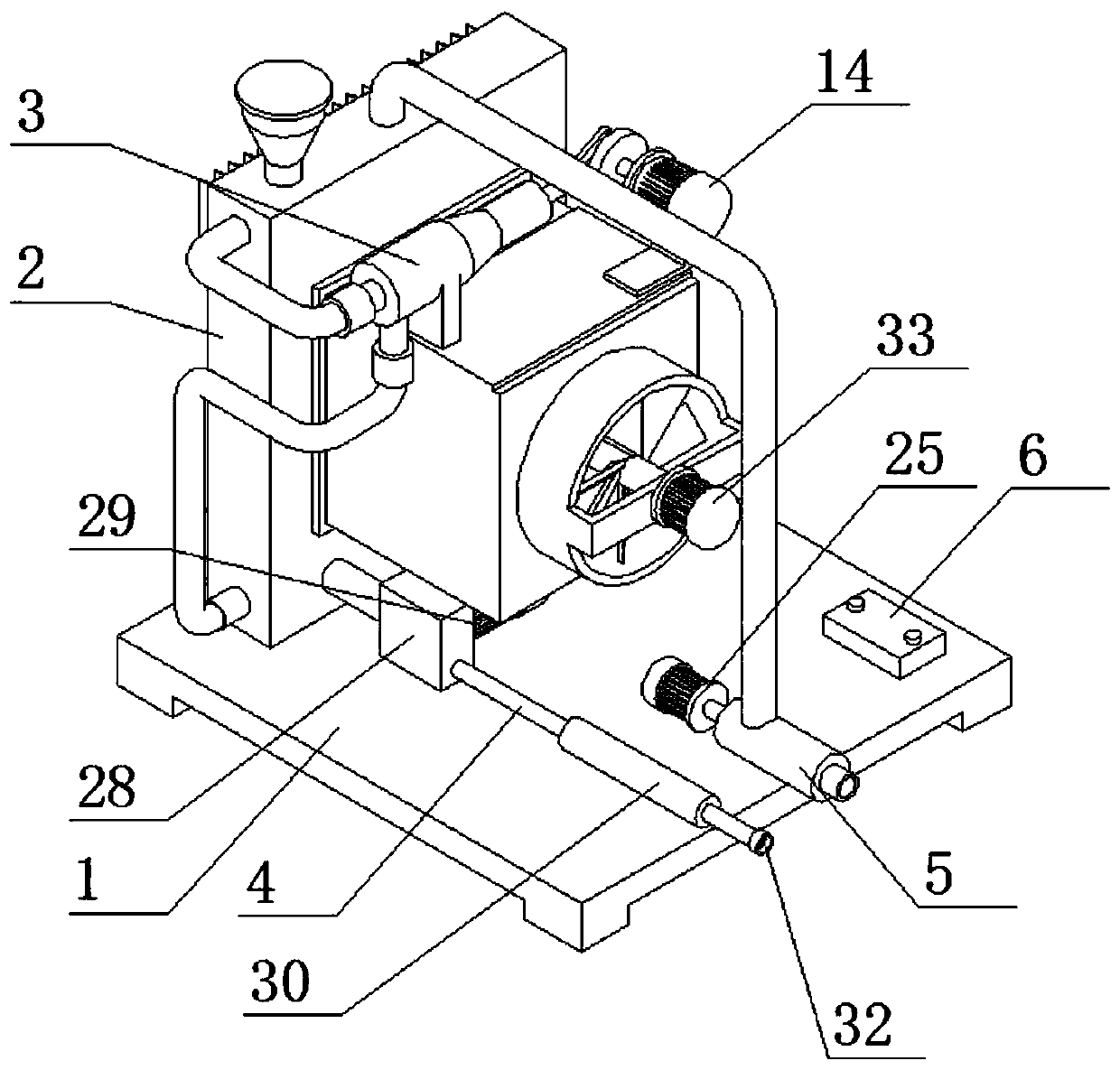

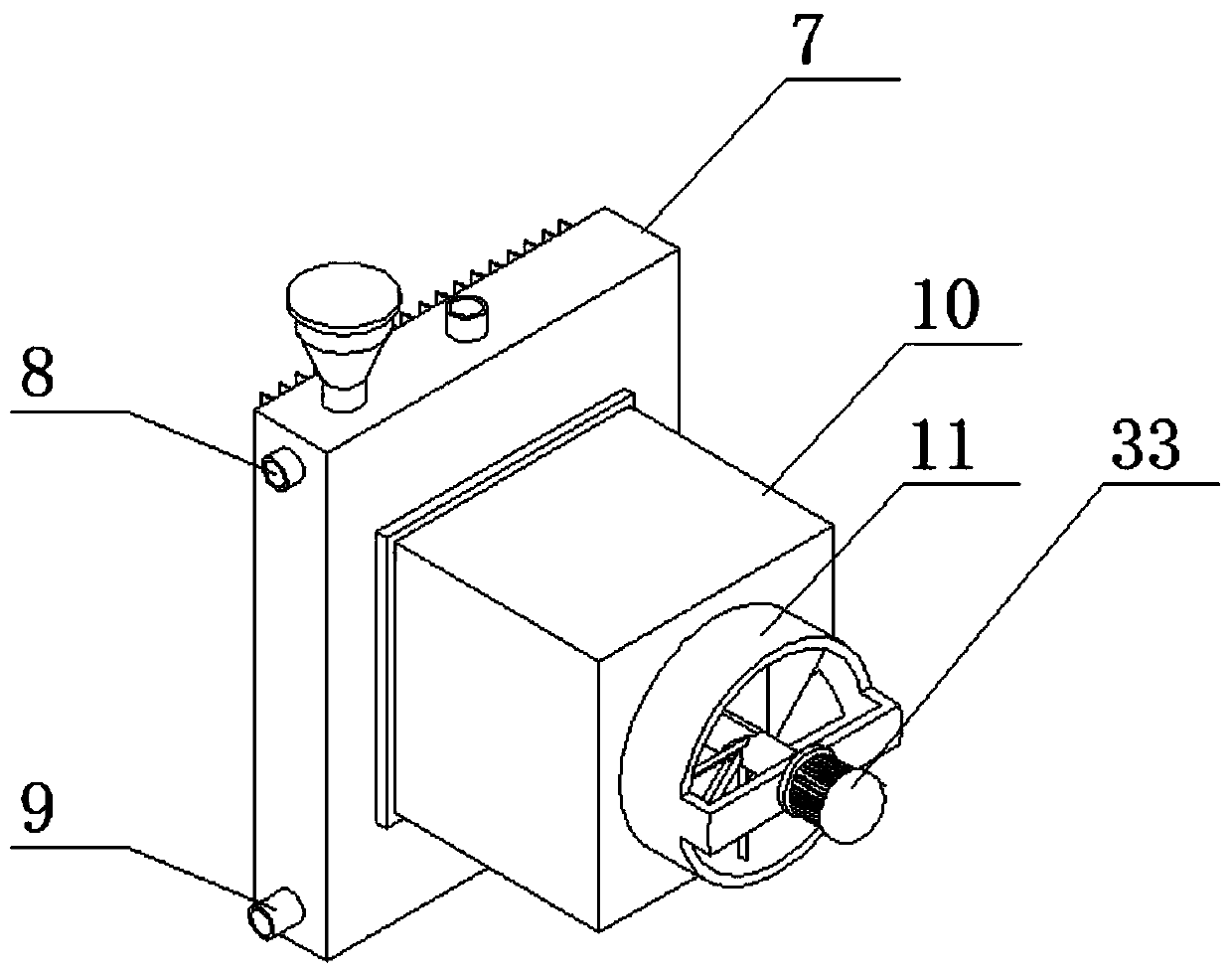

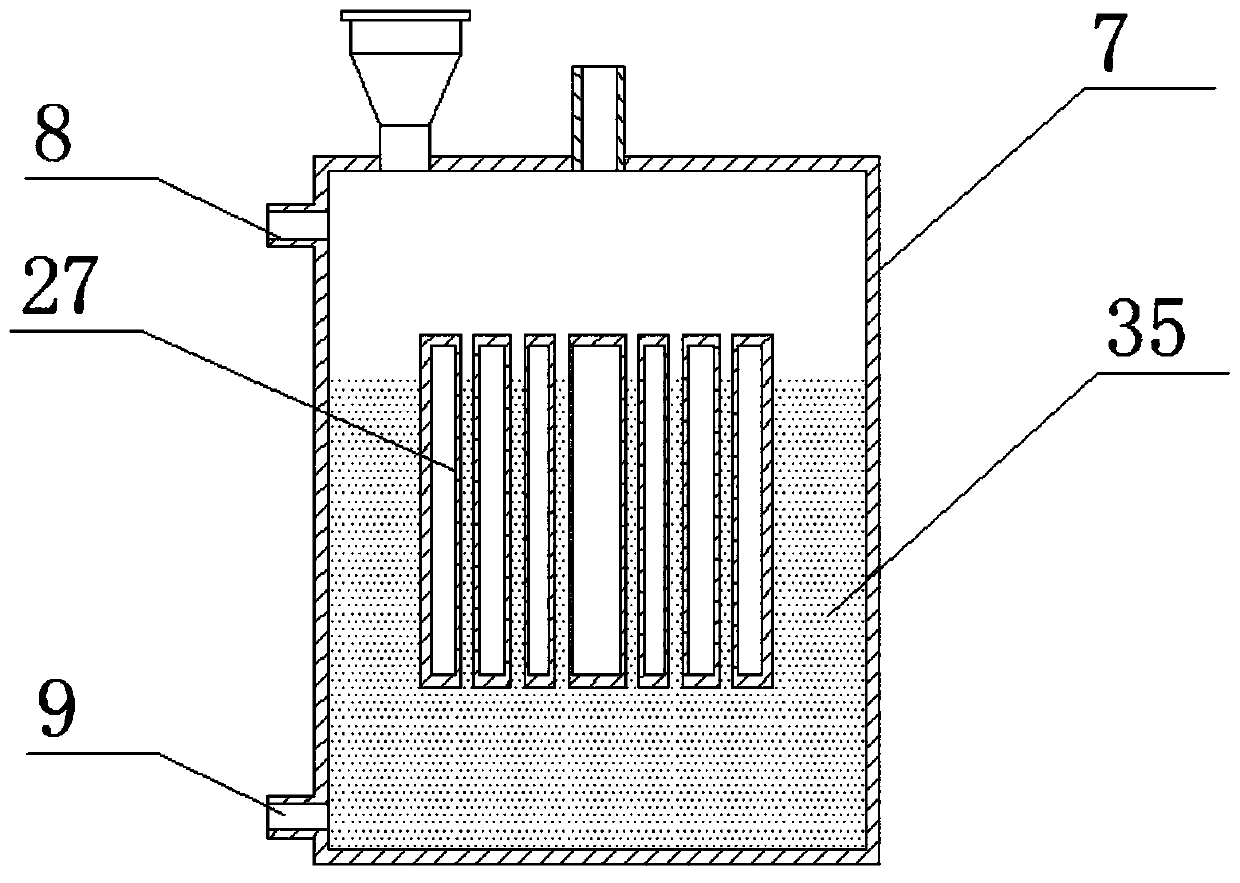

[0031]As a preferred embodiment of the present invention, the delivery pump combination 4 is composed of a water supply pump 28, a water supply motor 29 and a speed increasing tube 30, the water supply motor 29 is arranged on one side of the water supply pump 28, and the mixing tank 7 One side of the windshield 10 on the side wall is provided with a suction pipe, the water supply pump 28 is provided with a suction port and a water discharge port, the water suction port is connected with the water suction pipe through a pipeline, and the water discharge port is connected with a pipeline and a booster. One end of speed pipe 30 is connected.

[0032] As a preferred embodiment of the present invention, a spiral guide plate 31 is arranged inside the speed increasing pipe 30 , and a water inlet joint 32 is disposed at the other end of the speed increasing pipe 30 .

[0033] As a preferred embodiment of the present invention, one side of the filter turntable 24 and the filter plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com