Manufacturing process of double-sided process sputtering film capacitive touch sensor

A double-sided process and capacitive touch technology, applied in the field of touch screens, can solve the problems of low process yield and process controllability, high vacuum requirements, large coating porosity, etc., to achieve process yield and process reliability The effect of high control degree, low vacuum requirement and small coating porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

[0022] Example:

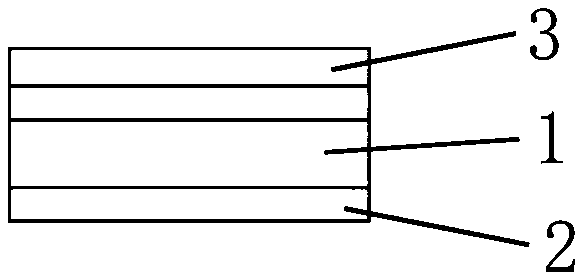

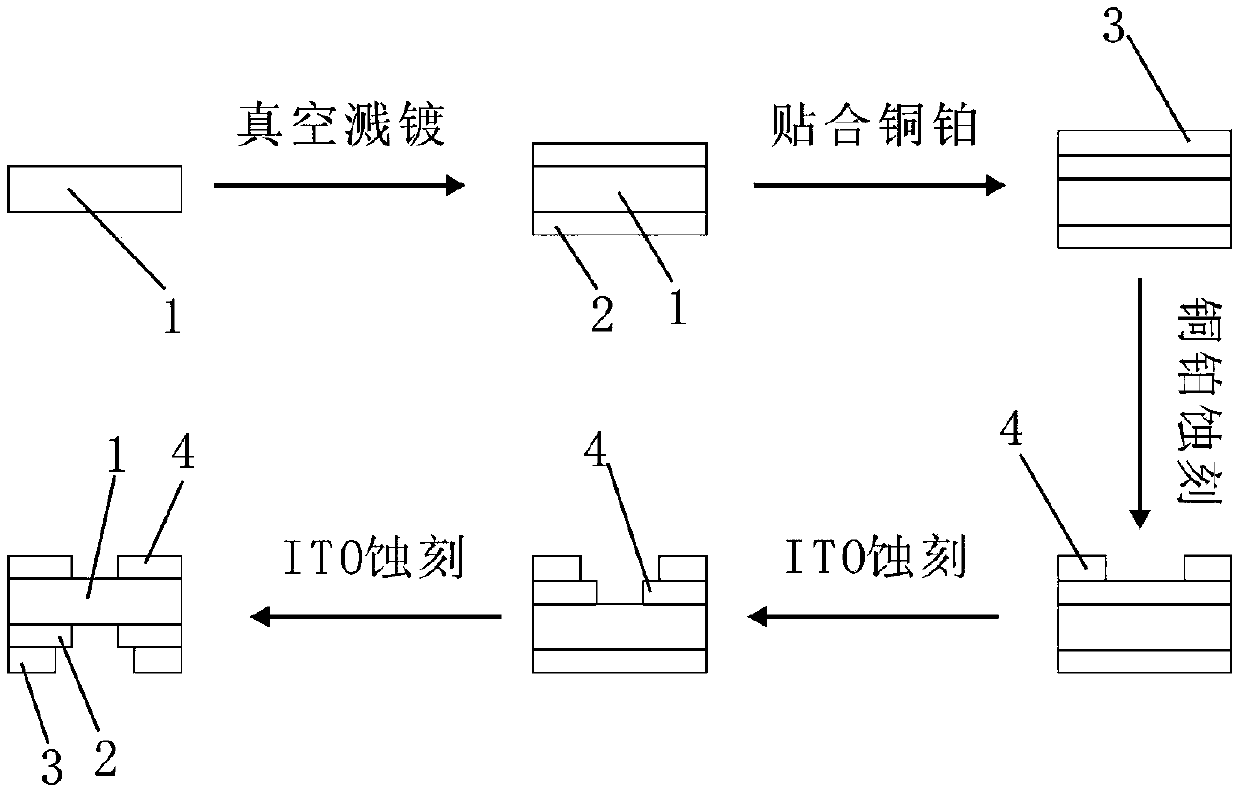

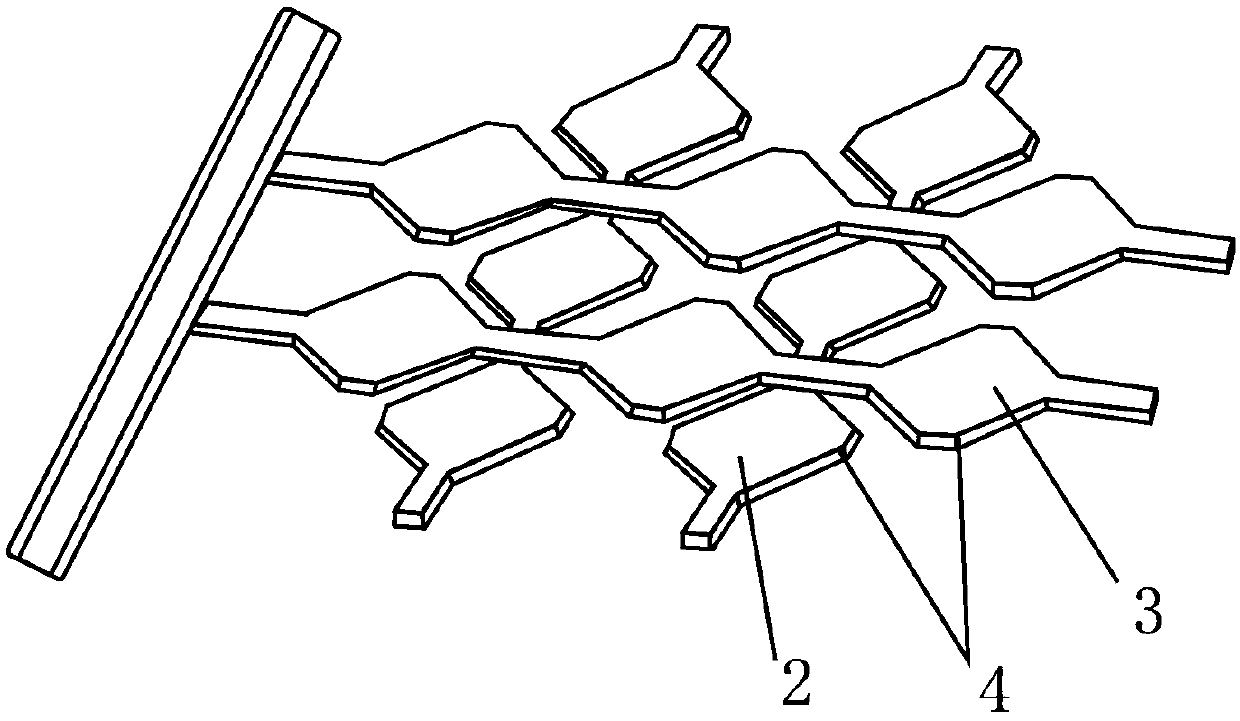

[0023] Such as Figure 1-3 The manufacturing process of a double-sided sputtering film capacitive touch sensor is shown, including a sputtering carrier plate 1, an ITO sputtering layer 2, a copper-platinum bonding layer 3, and a capacitive electrode 4. 1234

[0024] The manufacturing process of the double-sided process sputtering film capacitive touch sensor adopts that ITO sputtering layers 2 are respectively provided on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com