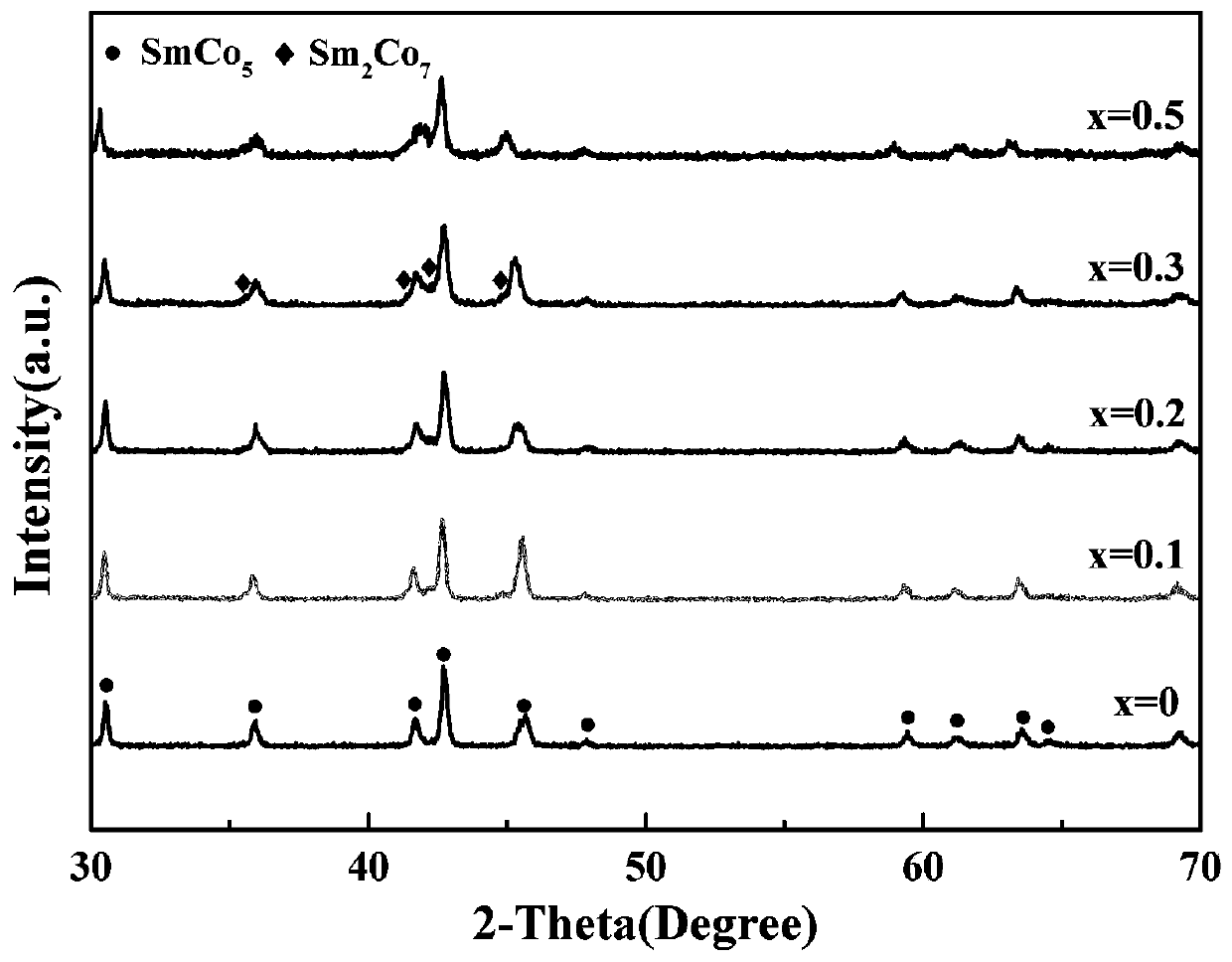

Sm(Co, Mn) 5 type rare earth permanent magnet material and preparation method thereof

A rare earth permanent magnet and annealing technology, used in magnetic materials, inductance/transformer/magnet manufacturing, furnace types, etc., can solve the problems of insufficient fast quenching performance, affecting saturation magnetization and anisotropy field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

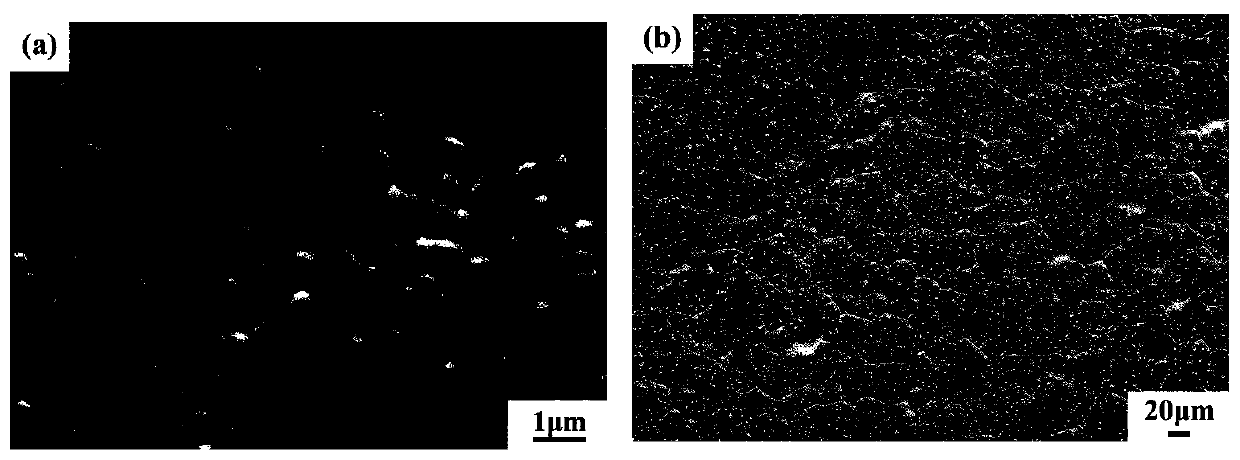

Image

Examples

preparation example Construction

[0037] The present invention provides the Sm(Co,Mn) described in the above scheme 5 The preparation method of type rare earth permanent magnet material comprises the following steps:

[0038] Melting the mixture comprising Sm, Co and Mn to obtain an ingot;

[0039] performing rapid quenching of the ingot to obtain a quenched strip;

[0040] Annealing and quenching are performed sequentially on the quenched strip to obtain Sm(Co,Mn) 5 Type rare earth permanent magnet materials;

[0041] The quality of the Co corresponds to the theoretical quality of Co in Formula 1, and the quality of the Sm is increased by 1 to 5% on the basis of the theoretical Sm quality calculated according to Formula 1; the quality of the Mn corresponds to the theoretical quality of Mn in the Formula 1 .

[0042] In the invention, the mixed material including Sm, Co and Mn is smelted to obtain an ingot.

[0043] In the present invention, the mass of Co corresponds to the theoretical mass of Co in Form...

Embodiment 1

[0055] 1) According to the stoichiometric ratio of SmCo 4.9 mn 0.1 Proportioning, wherein the mass of Sm is the same as that according to the general formula SmCo 4.9 mn 0.1 5% increase compared to the calculated mass;

[0056] 2) Put Sm, Co, and Mn with a purity higher than 99% in the crucible of the induction melting furnace, and vacuumize so that the vacuum degree reaches 2×10 -2 Pa; then fill the cavity with high-purity argon to make the furnace pressure reach 90kPa. Power on; heat up to 1600°C to melt the sample, and stop after 70 seconds of melting; repeat the melting 4 times, and take it out of the furnace for use after the sample is completely cooled;

[0057] 3) Break the alloy ingot and put it into a quartz tube with a nozzle diameter of 20mm and a bottom nozzle diameter of 2mm; put the quartz tube into a melt quenching furnace so that the bottom of the quartz tube is 4mm away from the copper roller; close the cavity, and Vacuumize the cavity of the quick quench...

Embodiment 2

[0060] 1) According to the stoichiometric ratio of SmCo 4.8 mn 0.2 Proportioning, wherein the quality of Sm increases by 5% compared with the quality calculated according to the general formula;

[0061] 2) Put Sm, Co, and Mn with a purity higher than 99% in the crucible of the induction melting furnace, and vacuumize so that the vacuum degree reaches 6×10 -2 Pa; then fill the cavity with high-purity argon to make the furnace pressure reach 80kPa. Power on; heat up to 1500°C to melt the sample, stop after 80 seconds of melting; repeat the melting 5 times, after the sample is completely cooled, take it out of the furnace for use;

[0062] 3) Break the alloy ingot and put it into a quartz tube with a nozzle diameter of 20mm and a bottom nozzle diameter of 1mm; put the quartz tube into the melt quenching furnace so that the bottom of the quartz tube is 2mm away from the copper roller; close the cavity, and Vacuumize the cavity of the quick quenching furnace so that the vacuum ...

PUM

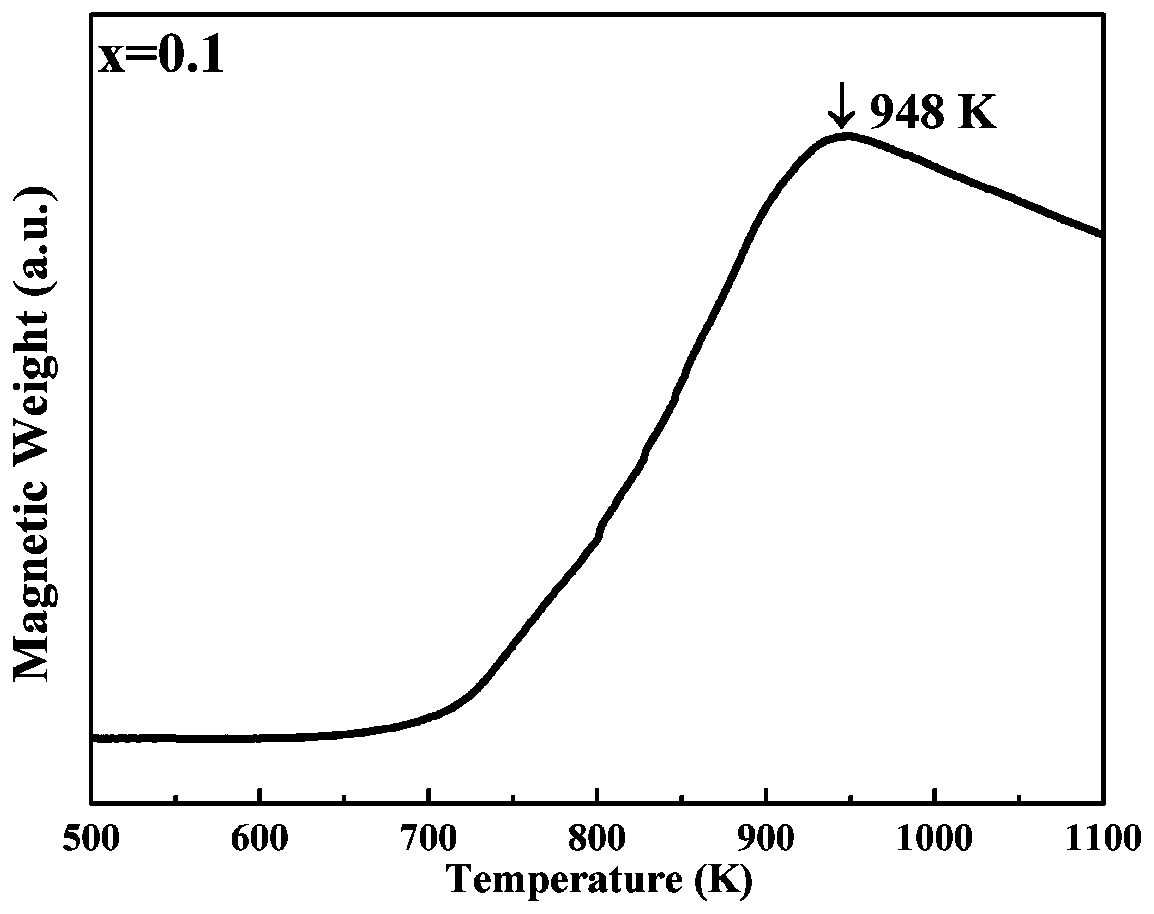

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com