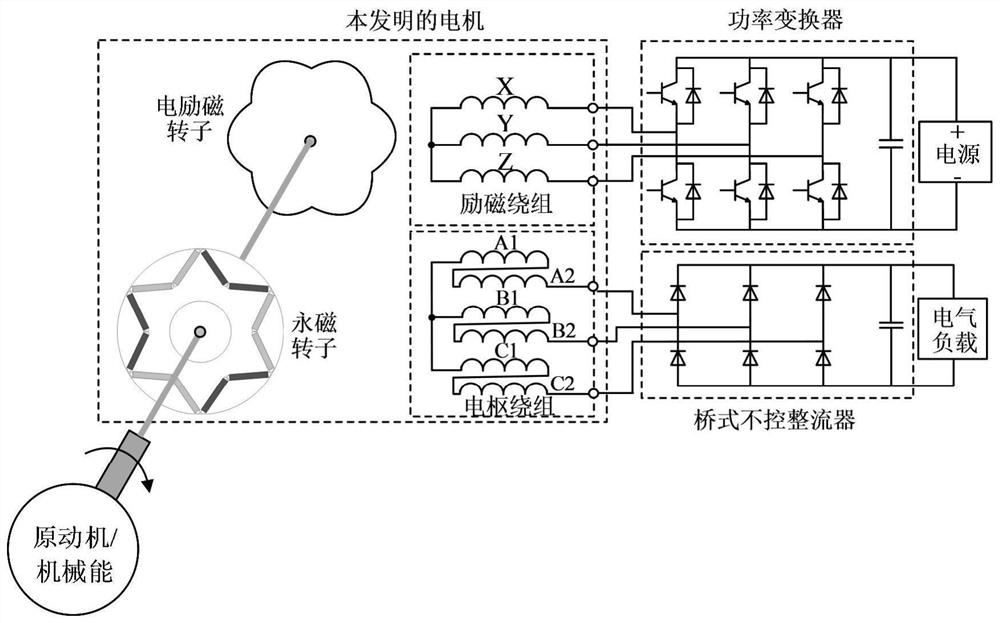

A parallel structure hybrid excitation brushless motor and its power generation system

A hybrid excitation and brushless motor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous generators, magnetic circuit shape/style/structure, etc., can solve the problem of reducing system reliability and failing to generate rotating excitation Magnetic field, unable to achieve excitation and other problems, to achieve the effect of reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

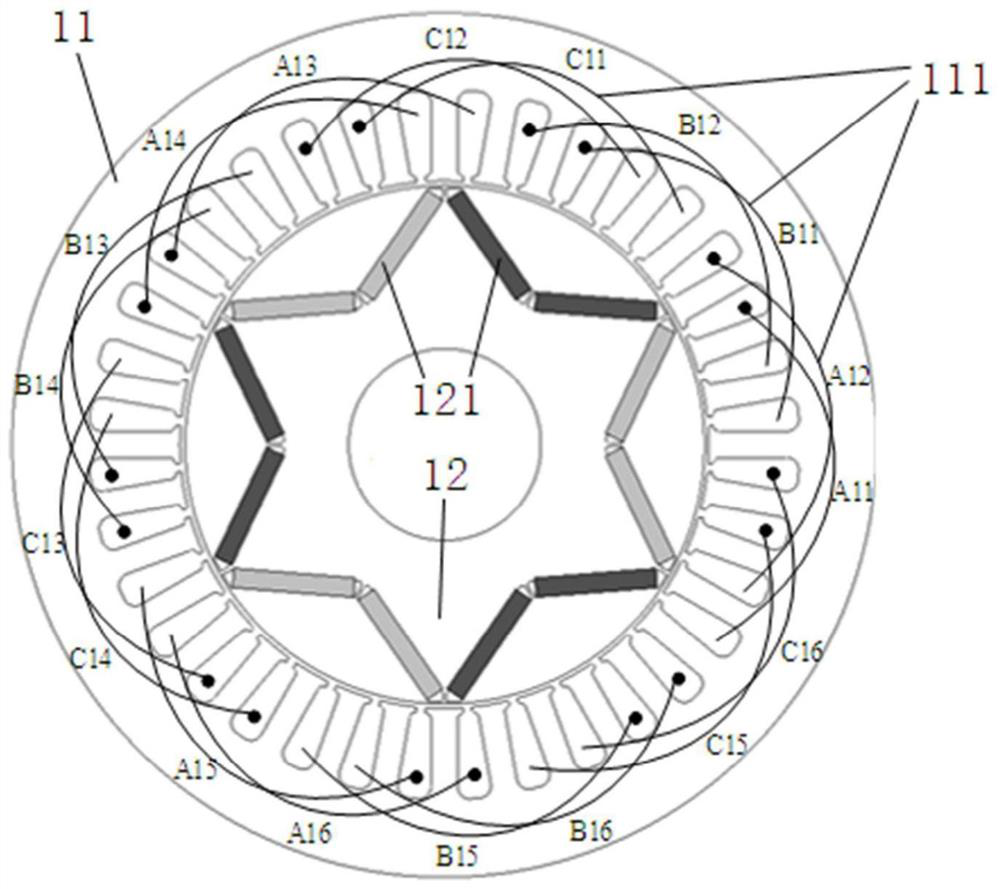

Embodiment 1

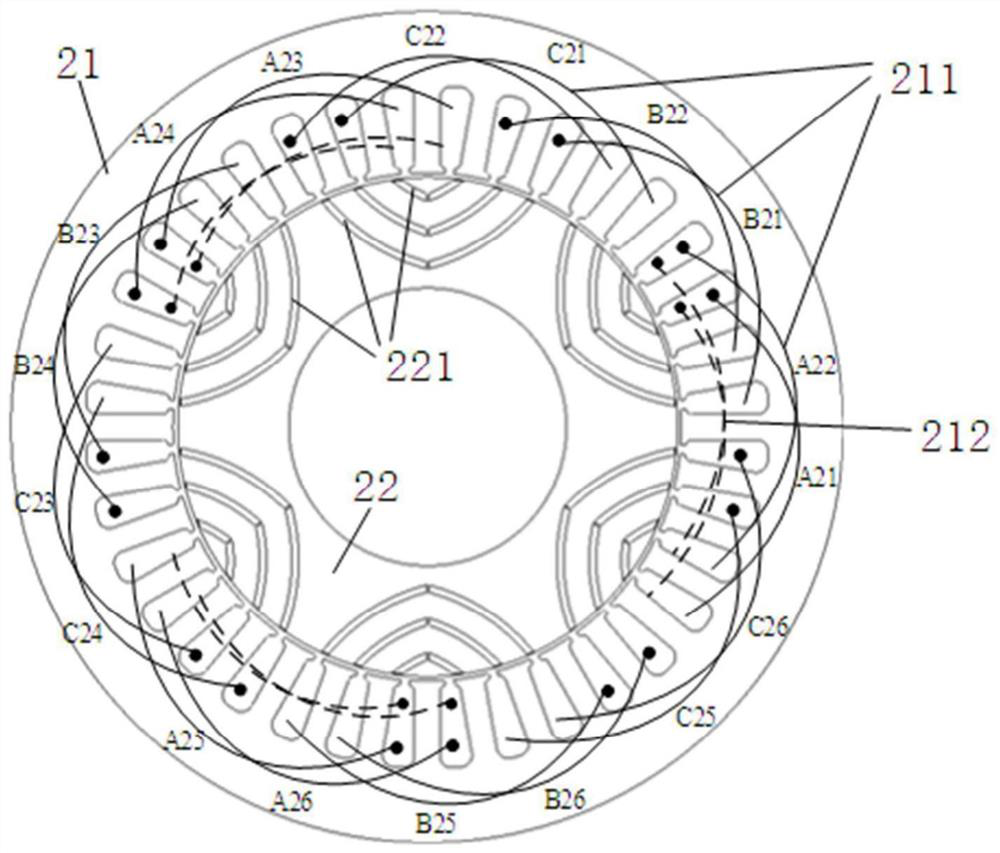

[0066] Embodiment 1 The reluctance rotor is a magnetic barrier rotor

[0067] Such as image 3 As shown, the magnetic barrier rotor includes 2p magnetic barrier groups uniformly distributed along the rotor circumference, and each magnetic barrier group includes one or more than two magnetic barriers 221 stacked. The shape of each layer of magnetic barrier is preferably arc, V-shape or strip, etc., and in this embodiment, it is preferably arc.

[0068] The direct axis is the center line of the two sets of magnetic barriers 221 , the quadrature axis is the center line of the magnetic barriers 221 , and the quadrature axis lags the direct axis by 90 electrical degrees, that is, the lagging mechanical angle is 360 / (4*p).

[0069] further, such as Figure 5 As shown, the magnetic barrier rotor also includes a bar-shaped tangential magnetic barrier 222, and a bar-shaped tangential magnetic barrier arranged in the radial direction is arranged between two adjacent magnetic barrier g...

Embodiment 2

[0070] Embodiment 2 The reluctance rotor is a salient pole rotor

[0071] Such as Image 6 As shown, the direct axis is the center line of the rotor salient pole 223, and the orthogonal axis is the center line of the two salient poles 223 in the salient pole rotor.

Embodiment 3

[0072] Embodiment 3 The reluctance rotor is a mixed pole rotor

[0073] Such as Figure 7 As shown, the reluctance rotor is a hybrid rotor with a mixture of salient poles and magnetic barriers. The hybrid rotor includes 2p salient poles and 2p magnetic barrier groups, and the 2p magnetic barrier groups are arranged in the rotor core between two adjacent salient poles , that is, on the straight axis. The quadrature-axis magnetic barrier is to reduce the reluctance of the quadrature-axis magnetic circuit, and at the same time, it does not affect the direct-axis magnetic circuit: because the direct-axis magnetic circuit is a low reluctance path for the excitation flux, which is conducive to excitation regulation.

[0074] Each magnetic barrier group is a single-layer magnetic barrier or a multi-layer magnetic barrier. The shape of each magnetic barrier is preferably arc-shaped, V-shaped, or strip-shaped. In this embodiment, it is preferably arc-shaped. The function of the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com