Method of manufacturing film having low oxygen transmission rate values

A calendering and web technology, applied in the field of film manufacturing, can solve problems such as non-profit cost structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Trials were carried out on pilot paper machines running at 15 m / min and 9 m / min to produce MFC membranes from softwood (B) and hardwood (C) kraft pulp, respectively. In addition to MFC, a variety of processing and performance chemicals are added, including any of the following: retention aids, wet strength chemicals, optical agents, drainage chemicals, biocides, lubricants, defoamers, etc. Table 1 summarizes the samples.

[0087] Table 1. Sample Example 1

[0088] B C Fiber source, % MFC (coniferous wood) MFC (hardwood) Gram weight, g / m 2

30.8 27.4

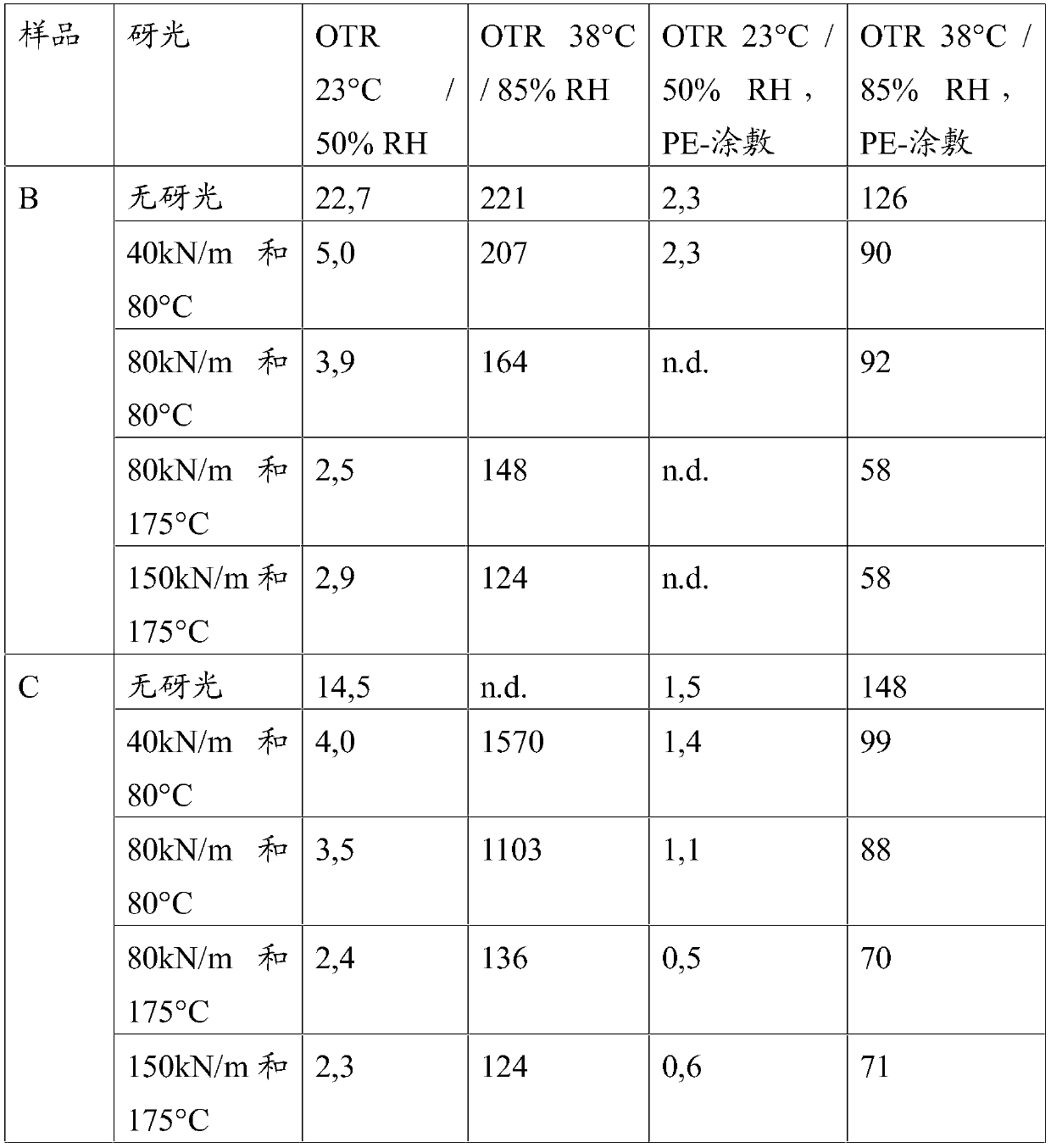

[0089] MFC webs B and C produced on the pilot paper machine were calendered using a soft gap laboratory calender. The results of the tests performed are disclosed in Table 2, which discloses the measured oxygen transmission rate (OTR) of the treated samples (ie the formed films).

[0090] In order to evaluate the effect of calendering of MFC films on PE-coatings, 25 g / m 2 The calender...

Embodiment 2

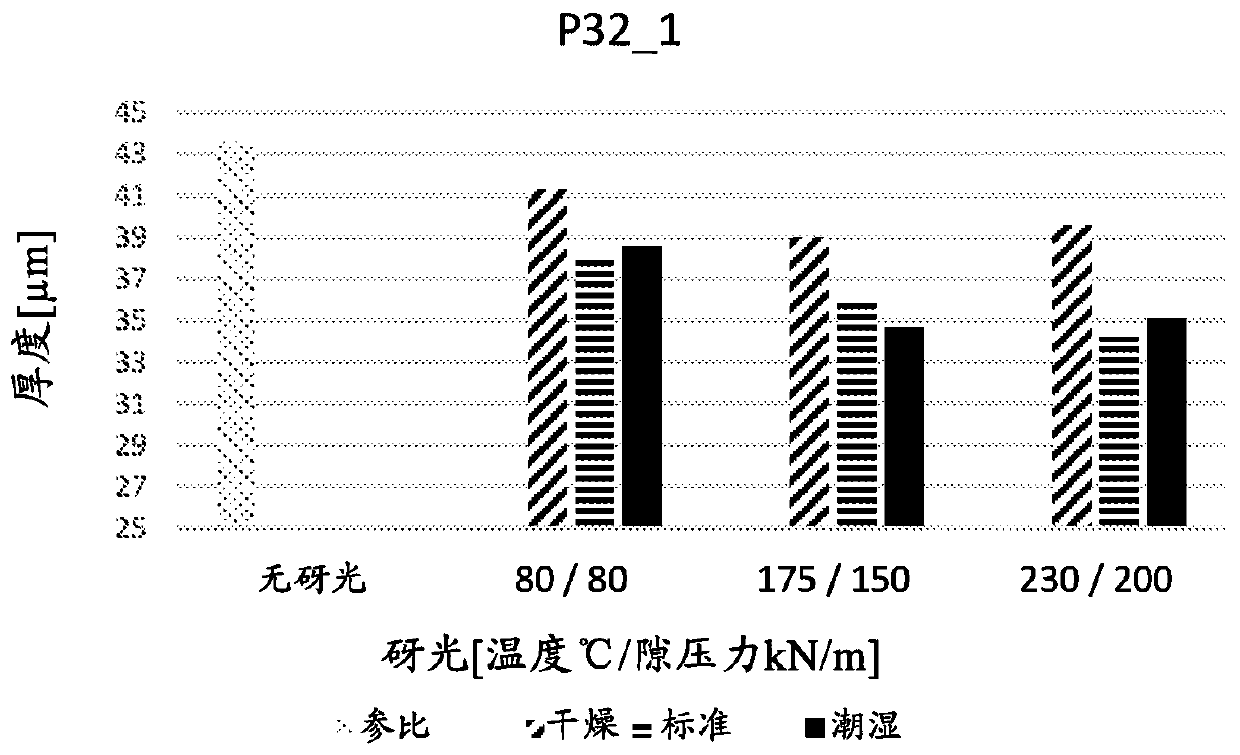

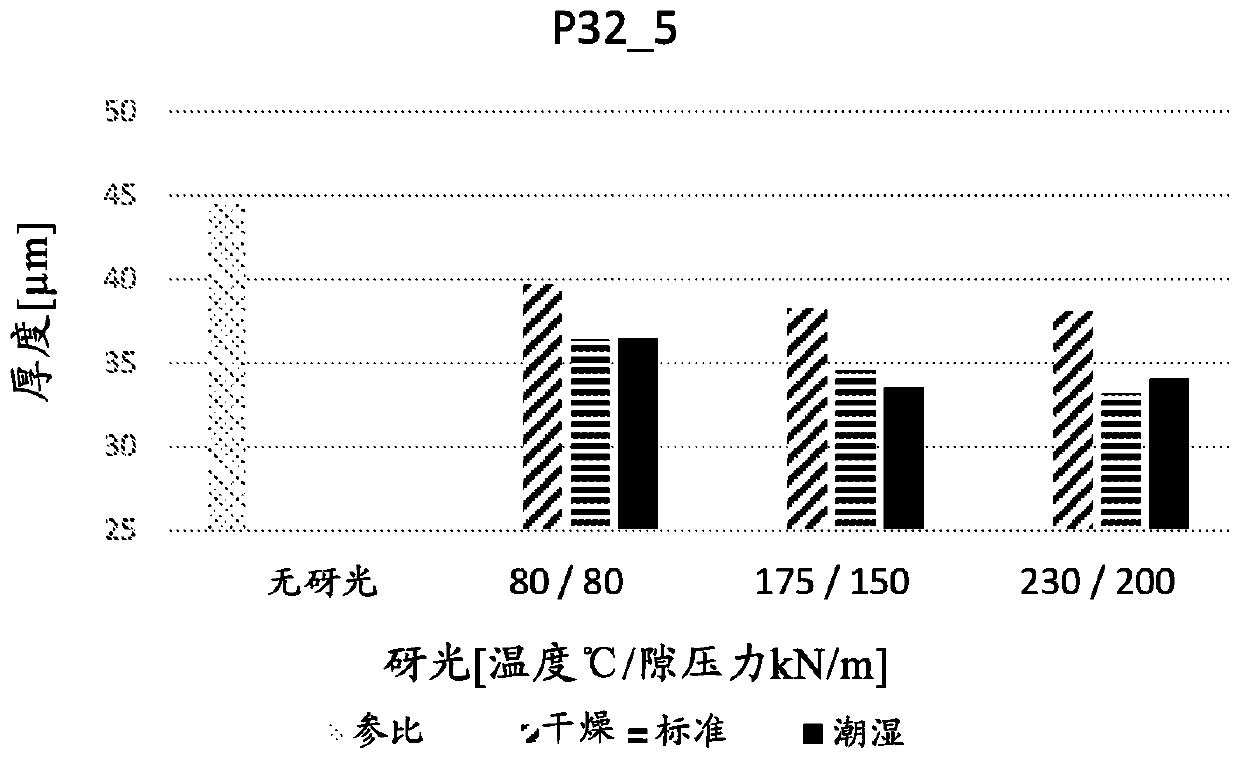

[0095] A surface sized MFC web sample made according to Sample B in Example 1 with a medium oxygen transmission rate was calendered using a soft gap laboratory calender. Different temperatures and pore pressures were used during the experiments and some test points were run through the calender several times. The samples were characterized for light transmittance, Bendtsen and PPS roughness and thickness values. For selected samples, the oxygen transmission rate was also recorded at 65% relative humidity. OTR values were determined at elevated relative humidity as it is believed to better reveal possible differences between samples.

[0096] The results compiled in Table 3 reveal that depending on the calendering conditions, the light transmission can be increased and the thickness, roughness and oxygen transmission rate of the MFC film can be reduced (ie oxygen barrier properties can be improved by calendering).

[0097] Therefore, the calendering conditions should be opt...

Embodiment 3

[0103] Trials were carried out on a pilot paper machine running at 15 m / min to produce MFC membranes from softwood kraft pulp with either hardwood or softwood kraft pulp added to the MFC. In addition to MFC, conventional wet-end chemicals such as wet-strength chemicals, fillers, sizing agents, etc. are added.

[0104] Test point P11_1 is the reference group containing 100% MFC as fiber source.

[0105] In test points P11_3, and P11_4, respectively, 30% by weight, and 50% by weight of hardwood fibers were mixed with MFC in a pulper, followed by mixing the fibers and MFC with a fiberizer. In test points P11_5 and P11_6, 15% by weight of softwood fibers were mixed with MFC in a pulper, followed by mixing of fibers and MFC with a fiberizer.

[0106] Table 4 summarizes the test points.

[0107] Table 4. Test points.

[0108]

[0109] * Add long fiber to pulper, mix with MFC with fiberizer

[0110]The MFC webs produced on the pilot paper machine were calendered using a soft g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com