Numerical control device and information processing device

A technology of information processing device and numerical control device, applied in digital control, program control, comprehensive factory control, etc., can solve problems such as mechanical interference and poor processing, and achieve the effect of reducing abnormalities and suppressing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

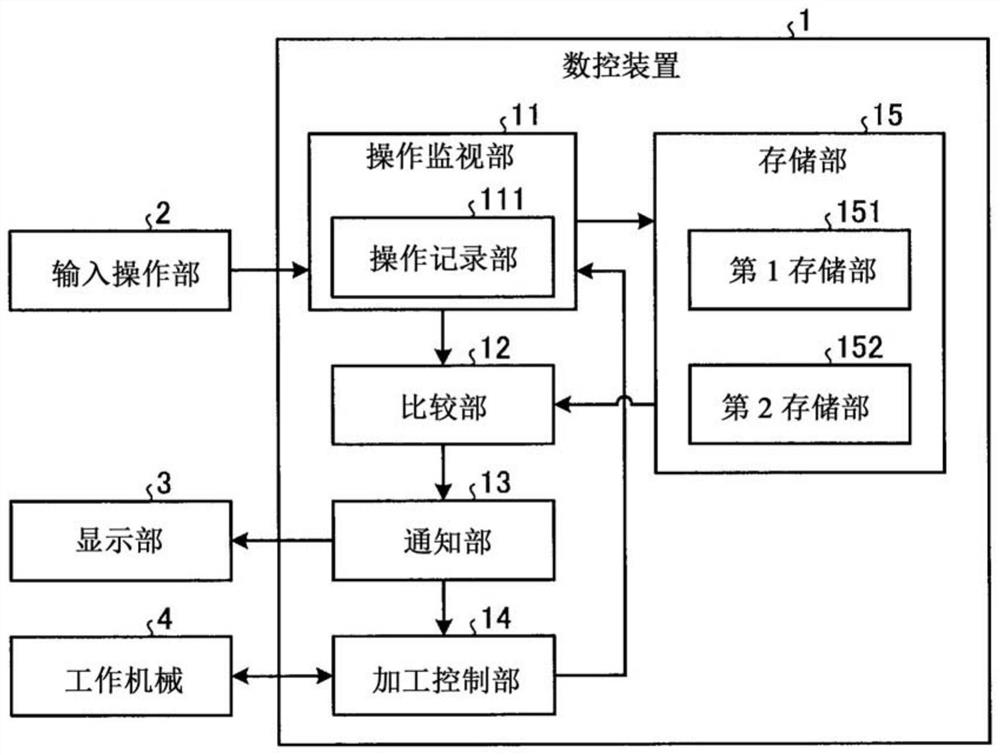

[0023] figure 1 It is a figure which shows the functional structure of the numerical control device 1 concerning Embodiment 1 of this invention. The numerical control device 1 has functional units such as an operation monitoring unit 11 , a comparison unit 12 , a notification unit 13 , a machining control unit 14 , and a storage unit 15 . The operation monitoring unit 11 has an operation recording unit 111 . The storage unit 15 has a first storage unit 151 and a second storage unit 152 . The numerical control device 1 is connected to an input operation unit 2 for an operator to perform an input operation, and a display unit 3 capable of outputting a display screen to the operator.

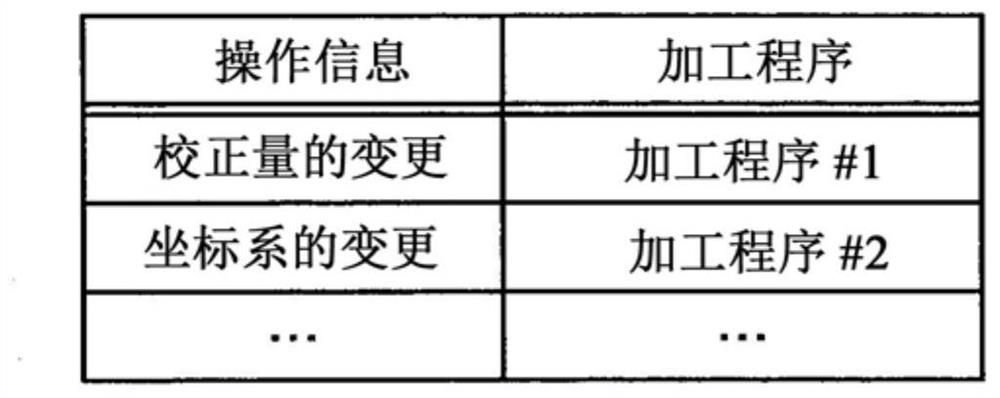

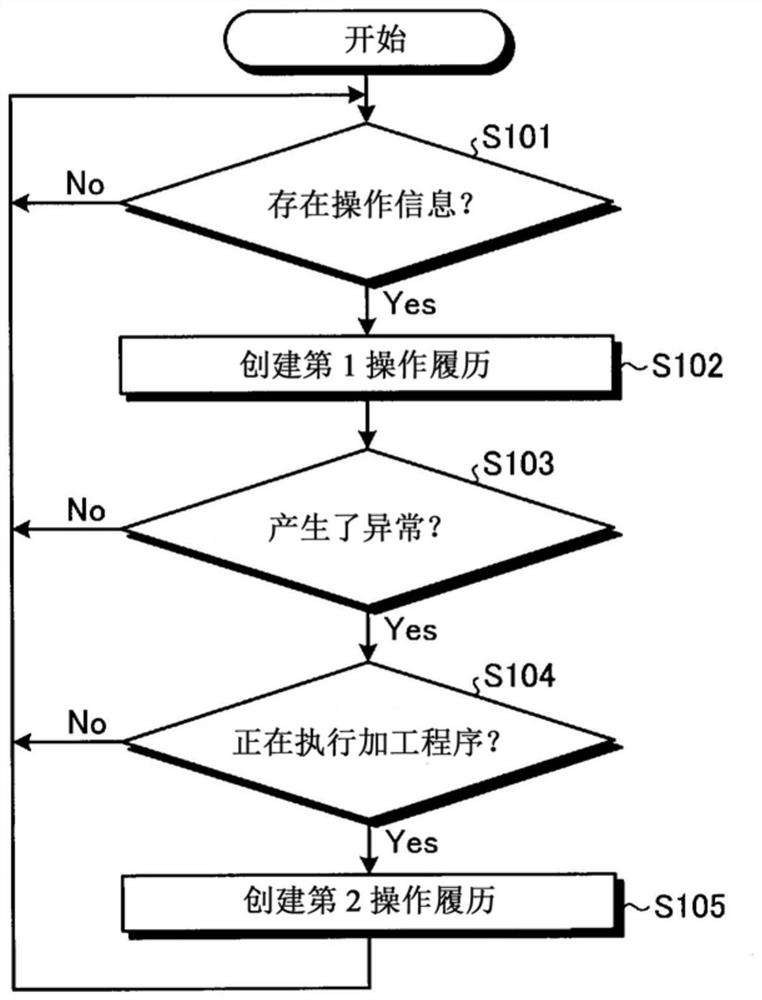

[0024] The operation monitoring unit 11 receives operation information indicating the content of the input operation from the input operation unit 2 , and monitors the content of the input operation. Specifically, the operation monitoring unit 11 inputs the operation information to the compariso...

Embodiment approach 2

[0041] Image 6 It is a figure which shows the structure of the control system 100 of the numerical control device 1a-1, 1a-2 concerning Embodiment 2 of this invention. The control system 100 includes numerical control devices 1 a - 1 , 1 a - 2 , and an information processing device 7 connected to the numerical control devices 1 a - 1 , 1 a - 2 via a network 8 . Numerical control devices 1a - 1 and 1a - 2 each have an operation monitoring unit 11 , a notification unit 13 , a machining control unit 14 , and a communication unit 16 . The information processing device 7 has a comparison unit 72 , a storage unit 75 , and a communication unit 76 . The storage unit 75 has a first storage unit 751 and a second storage unit 752 . In the following, when there is no need to distinguish the numerical control devices 1a-1 and 1a-2, the numerical control devices 1a-1 and 1a-2 are simply referred to as the numerical control device 1a respectively.

[0042] The difference between the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com