Heat management system

A heat management system and heat medium technology, applied in the field of heat management systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

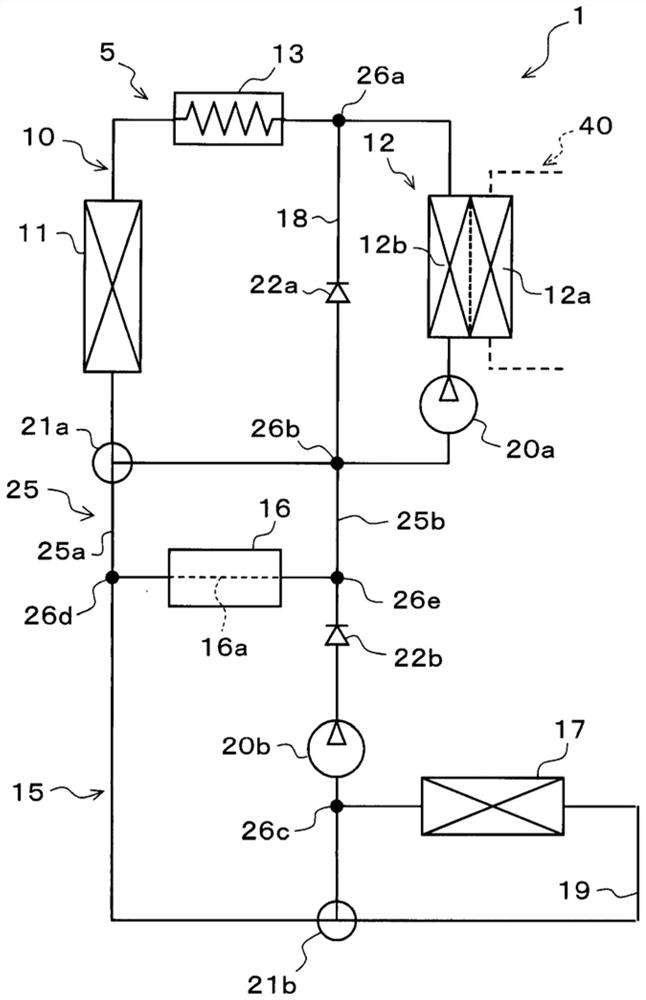

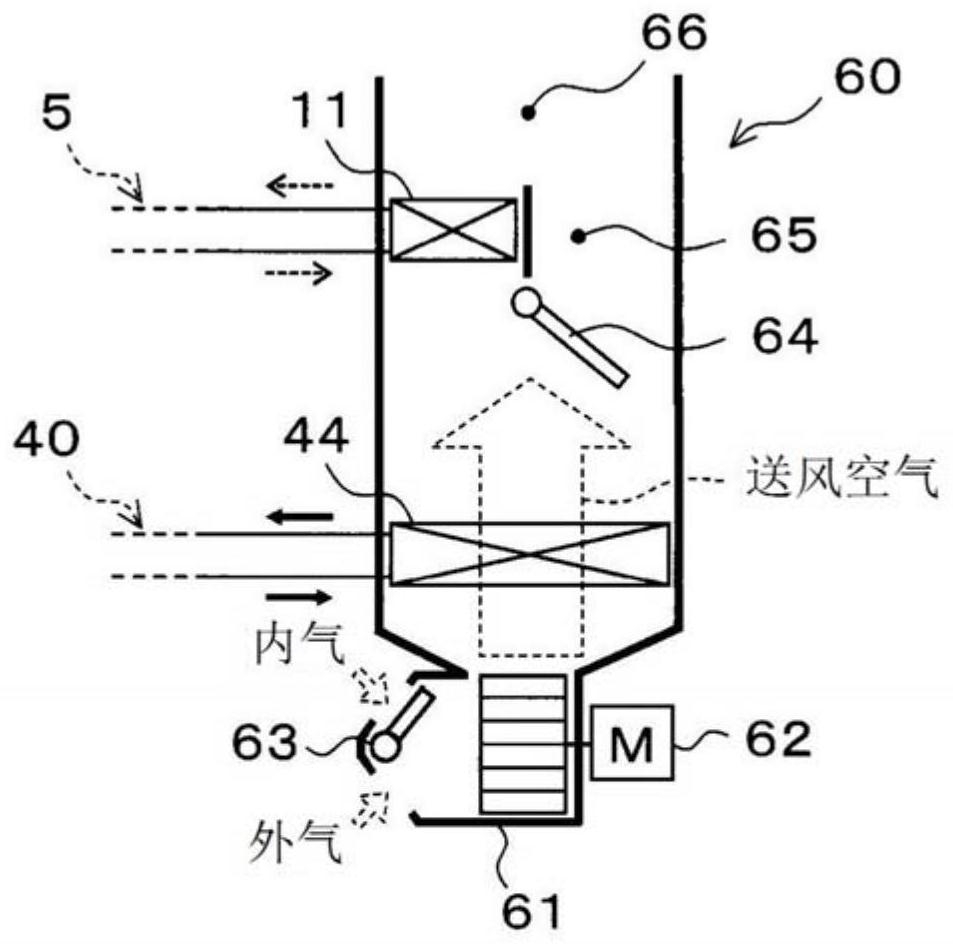

[0053] First, the schematic configuration of the thermal management system 1 according to the first embodiment will be described with reference to the drawings. The thermal management system 1 of the first embodiment is installed in an electric vehicle that obtains driving force for running from a motor generator.

[0054] The thermal management system 1 performs air conditioning of a vehicle interior as a space to be air-conditioned in an electric vehicle, and also performs temperature adjustment of an in-vehicle device (eg, heat generating device 16 ) as a temperature adjustment target. That is, the thermal management system 1 of the first embodiment is used as a vehicle air conditioner with a temperature adjustment function of an in-vehicle device in an electric vehicle.

[0055] In the thermal management system 1 in the first embodiment, the heat-generating device 16 that generates heat during operation is targeted for temperature adjustment. The heat generating device 16...

no. 2 approach

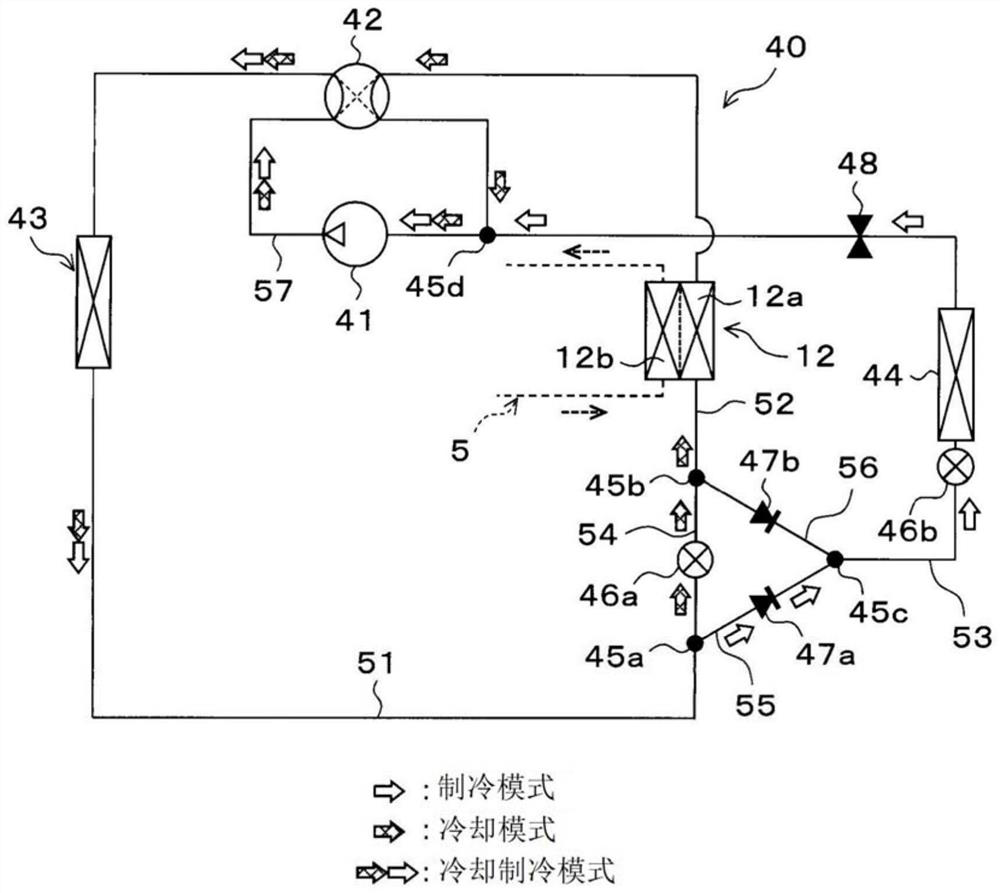

[0312] Next, refer to Figure 13 to Figure 23 , the thermal management system 1 of the second embodiment will be described. In the thermal management system 1 of the second embodiment, the configuration of the heat medium circuit 5 is changed from that of the first embodiment described above.

[0313] Therefore, in the thermal management system 1 of the second embodiment, the configurations of the refrigeration cycle 40, the indoor air-conditioning unit 60, and the control system of the control device 70 are the same as those of the first embodiment, and thus detailed description thereof will be omitted. In the following description of the second embodiment, differences from the first embodiment will be described.

[0314] Such as Figure 13 As shown, in the heat management system 1 of the second embodiment, the heat medium circuit 5 has: a battery 30 as a device to be adjusted in temperature, a third heat medium three-way valve 21c constituting a circuit switching unit, and...

no. 3 approach

[0540] Next, refer to Figure 24 , the thermal management system 1 of the third embodiment will be described. The thermal management system 1 of the third embodiment has the same basic structure as the thermal management system 1 of the second embodiment, and further includes a radiator on-off valve 28 .

[0541] Such as Figure 24 As shown, the radiator on-off valve 28 is disposed in the heat medium piping between the ninth connection portion 26 i and the heat medium inlet of the radiator 17 . The radiator on-off valve 28 opens and closes the heat medium passage between the ninth connection portion 26 i and the heat medium inlet of the radiator 17 , thereby switching whether or not the heat medium flows into and out of the radiator 17 .

[0542] The radiator on-off valve 28 is an electromagnetic valve whose operation is controlled by a control voltage output from the control device 70 . Therefore, in the third embodiment, the radiator on-off valve 28 constitutes a part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com