Recycled plastic assembled sidewalk panel based on arch-shaped combined structure and a paving method thereof

A technology of combined structure and recycled plastic, applied in the direction of paving, road, pavement, etc. paved with prefabricated blocks, can solve the problems of affecting pedestrian travel and safety, low laying efficiency, uneven road surface, etc., to ensure strength and stability. performance requirements, simple installation and maintenance process, and good surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

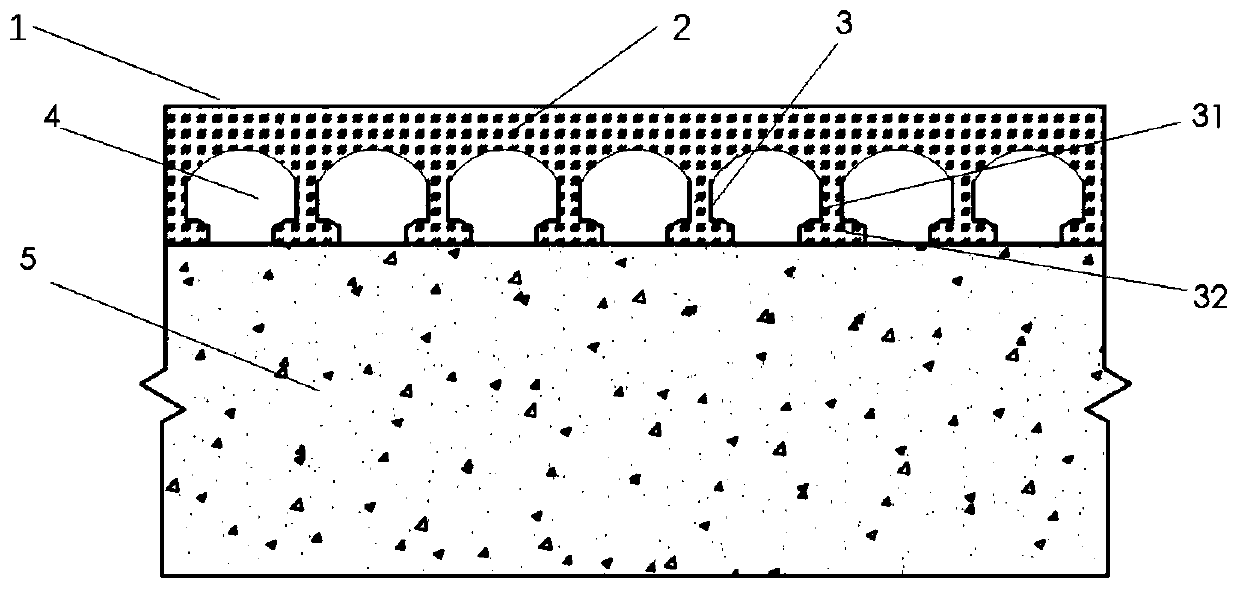

[0033] The recycled plastic assembled sidewalk panel based on the arched composite structure of the present embodiment has 7 panel structures 1, and the modulus of elasticity of the panel structure 1 is 903Mpa, the length of the panel structure 1 is 120cm, and the transverse direction of the arch groove 2 The span is 25m, the arch height is 8cm, the distance from the vault to the upper end surface of the panel structure 1 is 15cm, and the distance between the central axes of adjacent arched grooves 2 is 40cm; the width of the support column 31 is 2.5cm, and the height is 40cm. The height of the supporting base 32 is 6cm, and the width is 10cm; the groove width of the anti-skid groove is 2mm, and the groove depth is 8mm, and the interval between the anti-skid grooves along the width direction is 2.5cm. The modulus of resilience of the subgrade 5 is 40Mpa; the modulus of elasticity of the recycled plastic is 3000Mpa.

[0034] The method for paving the sidewalk surface is realize...

Embodiment 2

[0040] The difference from Example 1 is that the recycled plastic assembled sidewalk panels based on the arch composite structure in this example have 6 panel structures 1, and the modulus of elasticity is 822Mpa, the length of the panel structure 1 is 100cm, and the arch The horizontal span of the shaped groove 2 is 30m, the arch height is 5cm, the distance from the vault to the upper end surface of the panel structure 1 is 10cm, and the distance between the central axes of the adjacent arched grooves 2 is 50cm; the width of the support column 31 is 3cm , height is 25cm, and the height of support base 32 is 6cm, and width is 5cm of support column width; The modulus of resilience of the subgrade 5 is 35Mpa, and the modulus of elasticity of the recycled plastic is 3500Mpa.

Embodiment 3

[0042]Different from Embodiment 1 and Embodiment 2, the recycled plastic assembled sidewalk panels based on the arched composite structure of this embodiment have 10 panel structures 1, and their elastic modulus is 1016Mpa, and the length of the panel structure 1 80cm, the transverse span of the arched groove 2 is 20m, the arch height is 10cm, the distance from the vault to the upper end surface of the panel structure 1 is 20cm, and the distance between the central axes of adjacent arched grooves 2 is 30cm; Width is 2cm, and height is 30cm, and the height of supporting base 32 is 10cm, and width is 5cm of support column width; The modulus of resilience of the subgrade 5 is 60Mpa, and the modulus of elasticity of the recycled plastic is 3800Mpa.

[0043] The panel structure 1 of Embodiment 1, Embodiment 2 and Embodiment 3 is prefabricated in a plastic prefabrication factory. The prefabrication process is as follows: the temperature of the prefabricated factory building is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com