Anti-floating reinforcement structure of in-operation subway tunnel and construction method

A technology for strengthening structures and construction methods, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of insufficient bearing capacity of anti-floating reinforcement construction structures for operating subway tunnels and weak construction integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

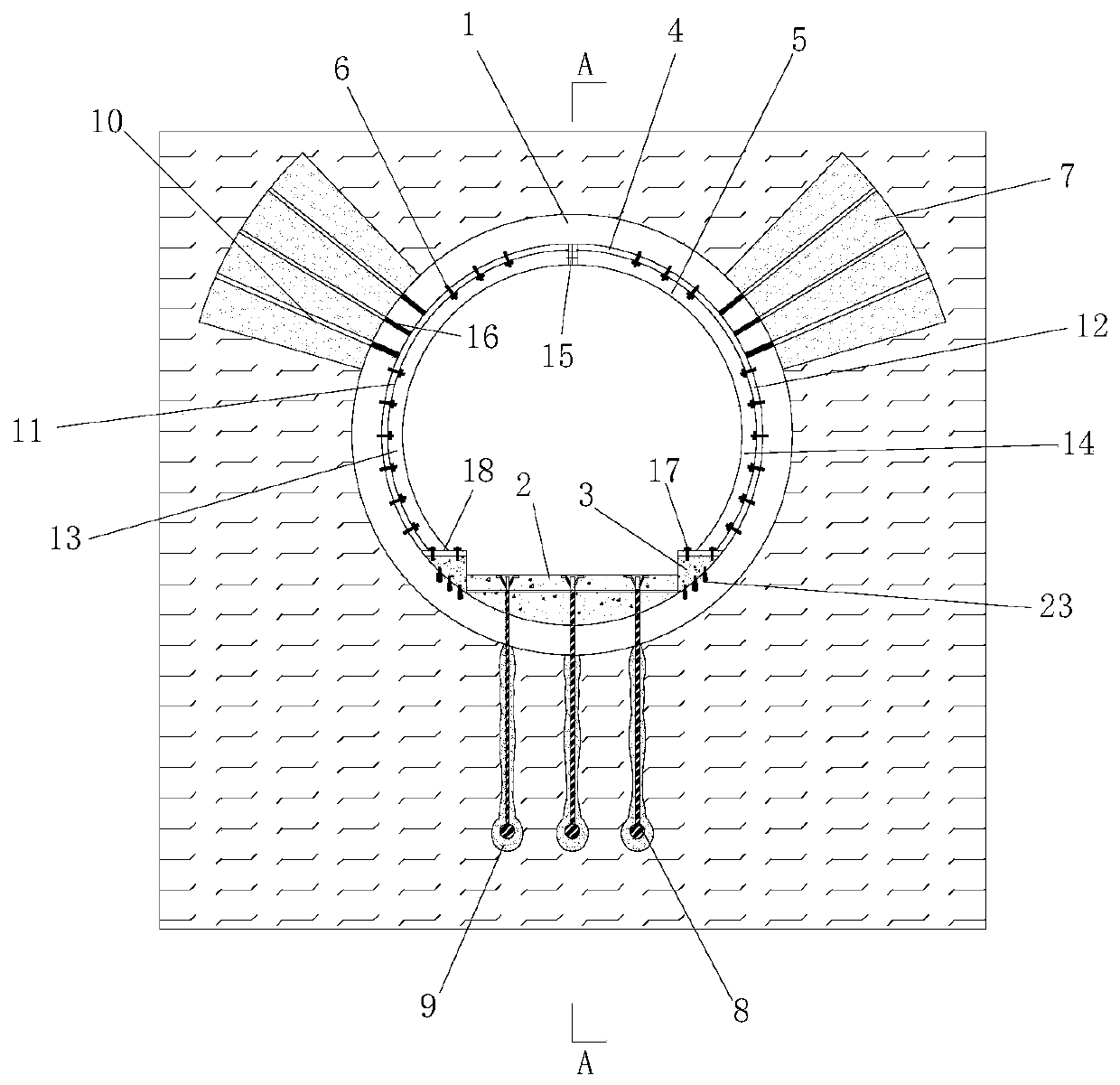

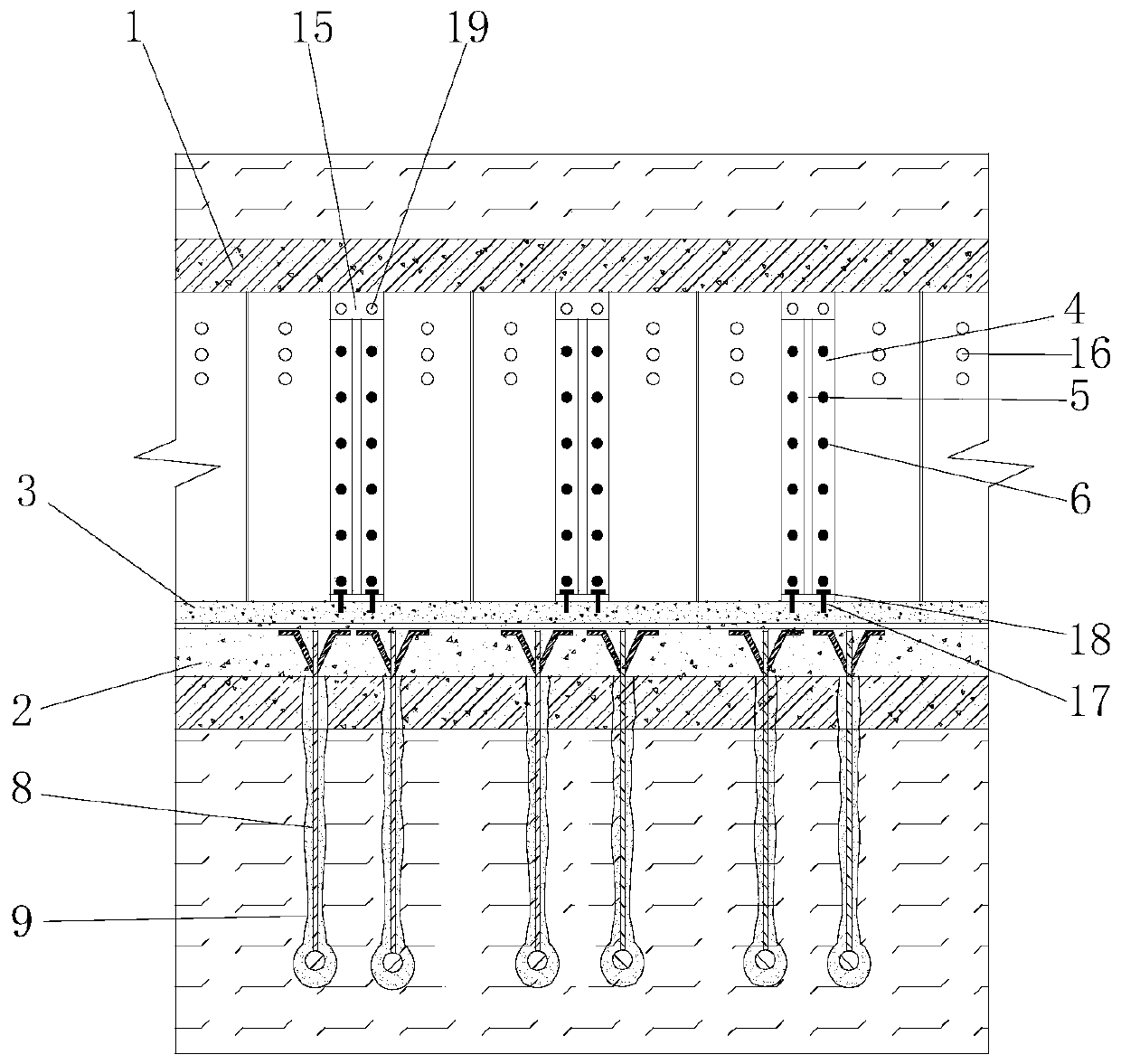

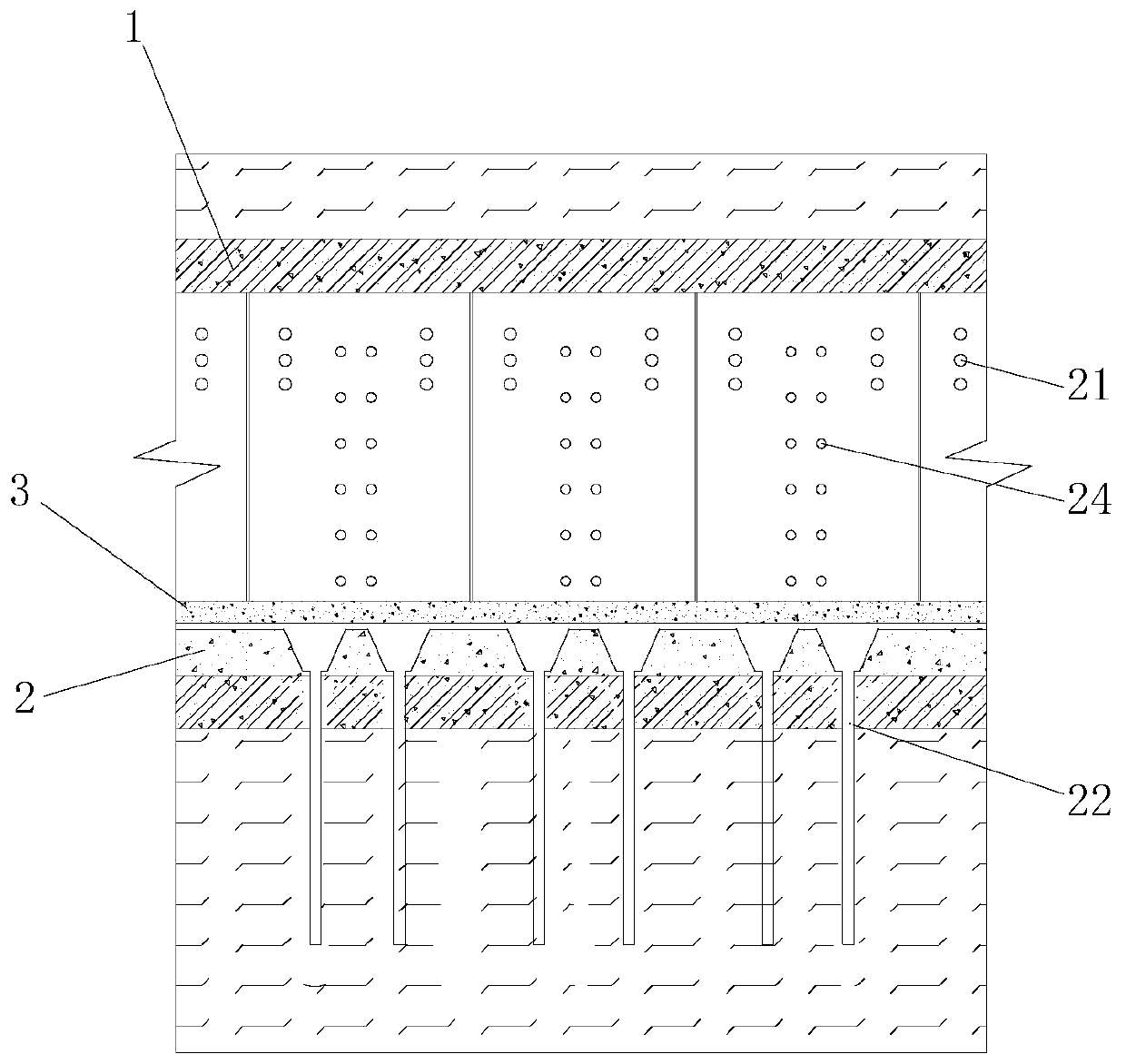

[0084] combined with Figure 1~4 As shown, the present invention relates to an anti-floating reinforcement structure of subway tunnels in operation, which is used to solve the problem of tunnel floating caused by rising water level or unloading above the tunnel. The structure includes tunnel lining 1, and tunnel lining 1 is equipped with The ballast bed 2 and the inner reinforcement structure, the outer reinforcement structure and the anti-floating structure are provided on the outside of the tunnel lining 1, and caps 3 are provided on both sides of the ballast bed 2, and the caps 3 are connected to the tunnel lining 1 through a number of expansion bolts 23.

[0085] combined with Figure 1~4 As shown, the internal reinforcement structure includes steel ferrules 4 and stiffeners 5 arranged at intervals, the stiffeners 5 are welded to the steel ferrules 4, the steel ferrules 4 include left arc-shaped steel plates 11 and right arc-shaped steel plates 12, and the stiffeners The ...

Embodiment 2

[0089] When the operating subway tunnel is raised due to rising water level, the following steps shall be adopted for construction:

[0090] 1) According to the construction environment such as the limit of the operating line, the minimum radius of the line, and the maximum slope, select the manipulator and flatbed truck for construction; etc., to provide an effective site for construction; then cut and chisel the ballast bed 2 and water ditches on both sides of the subway track until the shield segment is exposed, and after cutting, the side of the ballast bed 2 is roughened, and, using The high-pressure water gun cleans the surface of the tunnel lining 1, and treats loose objects such as collapse and calcification on the surface of the segment.

[0091] 2) Construction cap 3 at the position where the ballast bed is cut and chiseled on both sides of the subway track: according to the cutting size of the ballast bed 2, the cap 3 is processed on site, transported to the site by...

Embodiment 3

[0128] When the operating subway tunnel is lifted due to the unloading above the tunnel, the following steps shall be adopted for construction:

[0129] 1) According to the construction environment such as the limit of the operating line, the minimum radius of the line, and the maximum slope, select the manipulator and flatbed truck for construction; etc., to provide an effective site for construction; then cut and chisel the ballast bed 2 and water ditches on both sides of the subway track until the shield segment is exposed, and after cutting, the side of the ballast bed 2 is roughened, and, using The high-pressure water gun cleans the surface of the tunnel lining 1, and treats loose objects such as collapse and calcification on the surface of the segment.

[0130] 2) Construction cap 3 at the position where the ballast bed is cut and chiseled on both sides of the subway track: according to the cutting size of the ballast bed 2, the cap 3 is processed on site, transported to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com