Automatic powder feeding device and environment-friendly cement mixing pile ash feeding system

A cement mixing pile and automatic feeding technology, applied in the direction of selling raw material supply devices, etc., can solve the problems of low feeding efficiency, burnt out motor, high power consumption, etc., and achieve high feeding efficiency, cost saving, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

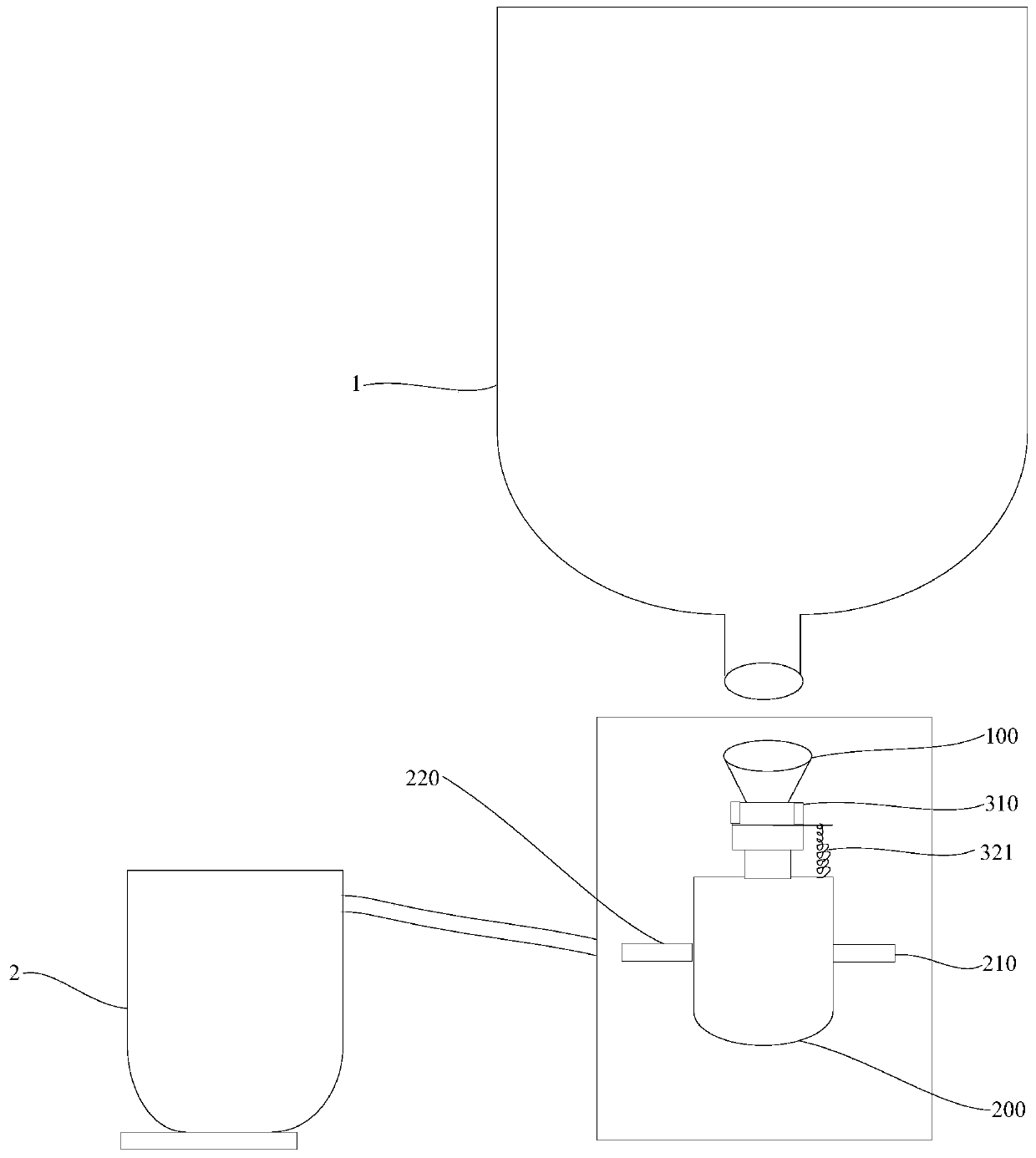

[0033] Please combine further figure 2 , this embodiment provides an automatic powder feeding device, including a receiving bin 100 and an automatic feeding mechanism.

[0034] In this embodiment, the material receiving bin 100 has a round platform structure as a whole, and the diameter of the feeding port is larger than that of the discharging port, which is convenient for discharging. The receiving bin 100 is preferably made of steel and other materials, and has high structural strength. Furthermore, the end where the feed port of the receiving bin 100 is located is also provided with a sealing sleeve that seals the docking area of the bulk powder tanks such as the bulk cement storage tank 1 and the receiving bin 100, so as to prevent leakage of the powder and is safe and environmentally friendly. Preferably, the sealing sleeve is an elastic ferrule, such as an elastic rubber sealing sleeve, which is wear-resistant, has good elasticity and has a long service life.

[00...

Embodiment 2

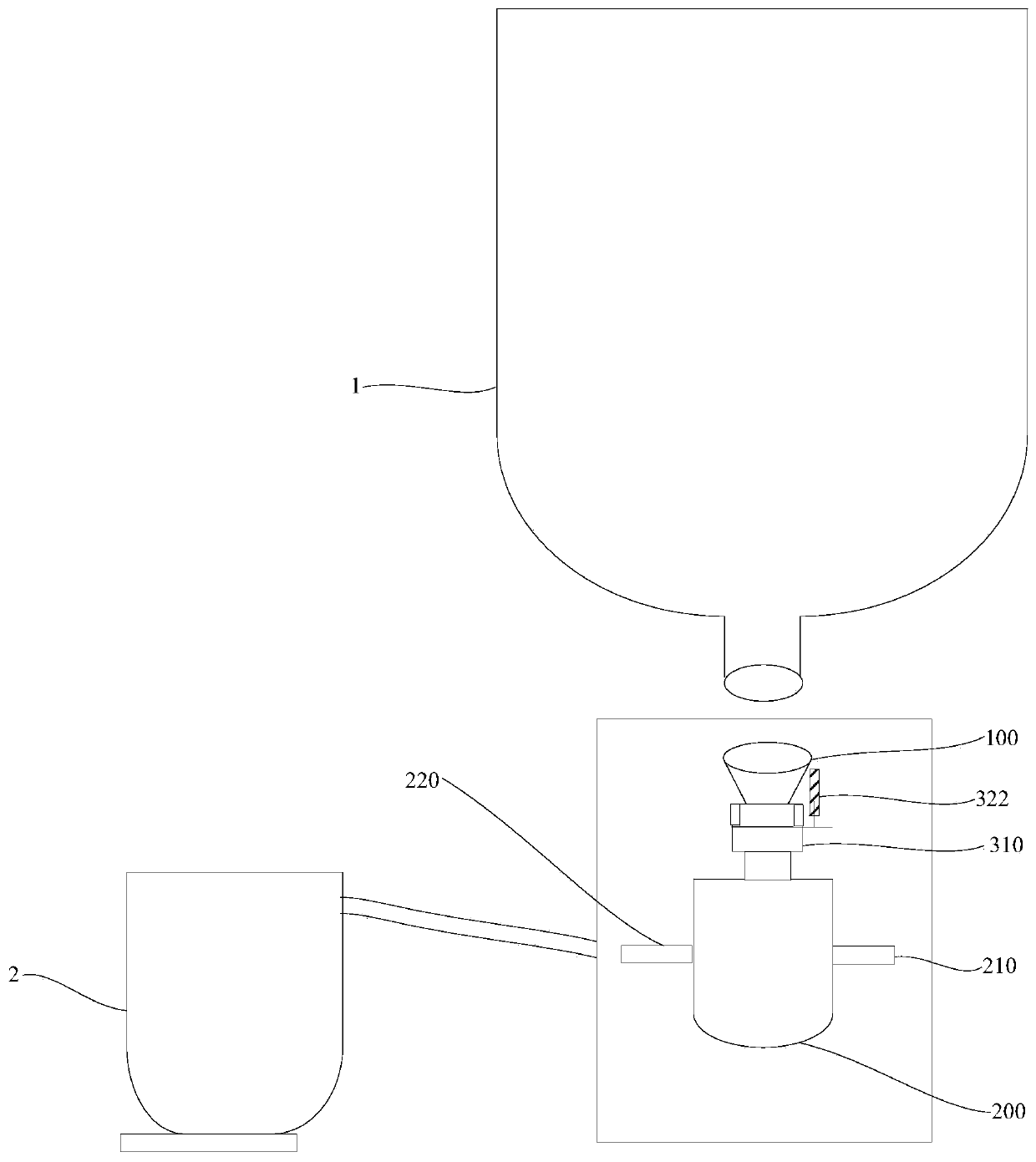

[0041] Please combine further image 3 , this embodiment provides an automatic powder feeding device, including a feeding bin 100 and an automatic feeding mechanism. One end of the cylinder is arranged on the outer wall of the material receiving bin 100, and the piston rod of the cylinder 322 is connected to the other end of the driving rod, which is used to drive the valve plate to automatically close the material through hole.

[0042] The automatic powder feeding device of this embodiment makes the cylinder 322 open the material through hole through the conversion of the cylinder to realize the automatic feeding of the powder into the buffer tank 200, and then adjusts the pressure in the buffer tank 200 by automatically supplying high-pressure gas to the buffer tank 200. The air pressure cooperates with the cylinder 322 to drive the piston rod, so that the valve plate automatically closes the material through hole, and at the same time relies on the air pressure in the buffer...

Embodiment 3

[0044] Please combine further Figure 4 , this embodiment provides an automatic powder feeding device, including a feeding bin 100 and an automatic feeding mechanism. Control the electromagnetic pneumatic butterfly valve that closes and opens the feeding channel.

[0045] The powder automatic feeding device in this embodiment automatically controls the opening of the material through hole through the electromagnetic pneumatic butterfly valve to realize the automatic feeding of the powder into the buffer tank 200, and then automatically closes the material through hole through the electromagnetic pneumatic butterfly valve, and then relies on the material in the buffer tank 200. The air pressure is adjusted to transport the powder to the feeding tank 2, and the automatic control of the powder feeding is realized as a whole.

[0046] In fact, the structure of the receiving bin 100 in the automatic powder feeding device of the present invention is not limited to the shape of a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com