Heavy-load fast railway freight car bogie with mechanically suspended type secondary suspension device and stiffness calculation method

A secondary suspension device, the technology of railway freight cars, which is applied in the direction of bogies, railway car body parts, devices for lateral relative movement between the underframe and the bogies, etc., can solve the problems of train running stability, safety, service life, Increase operation and maintenance costs, aggravated wheel and rail wear, etc., to achieve the effect of reducing operation and maintenance costs, good running stability, and reducing wheel and rail wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

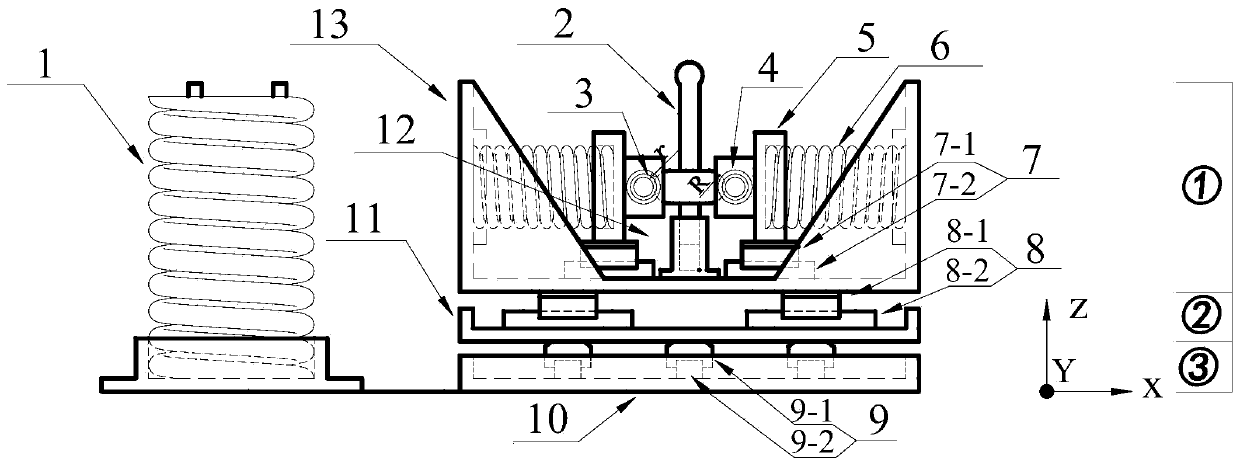

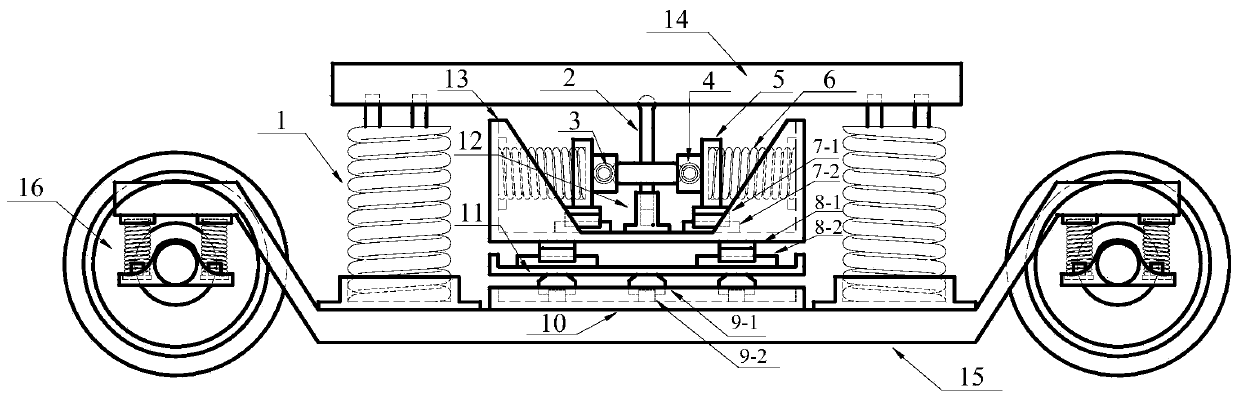

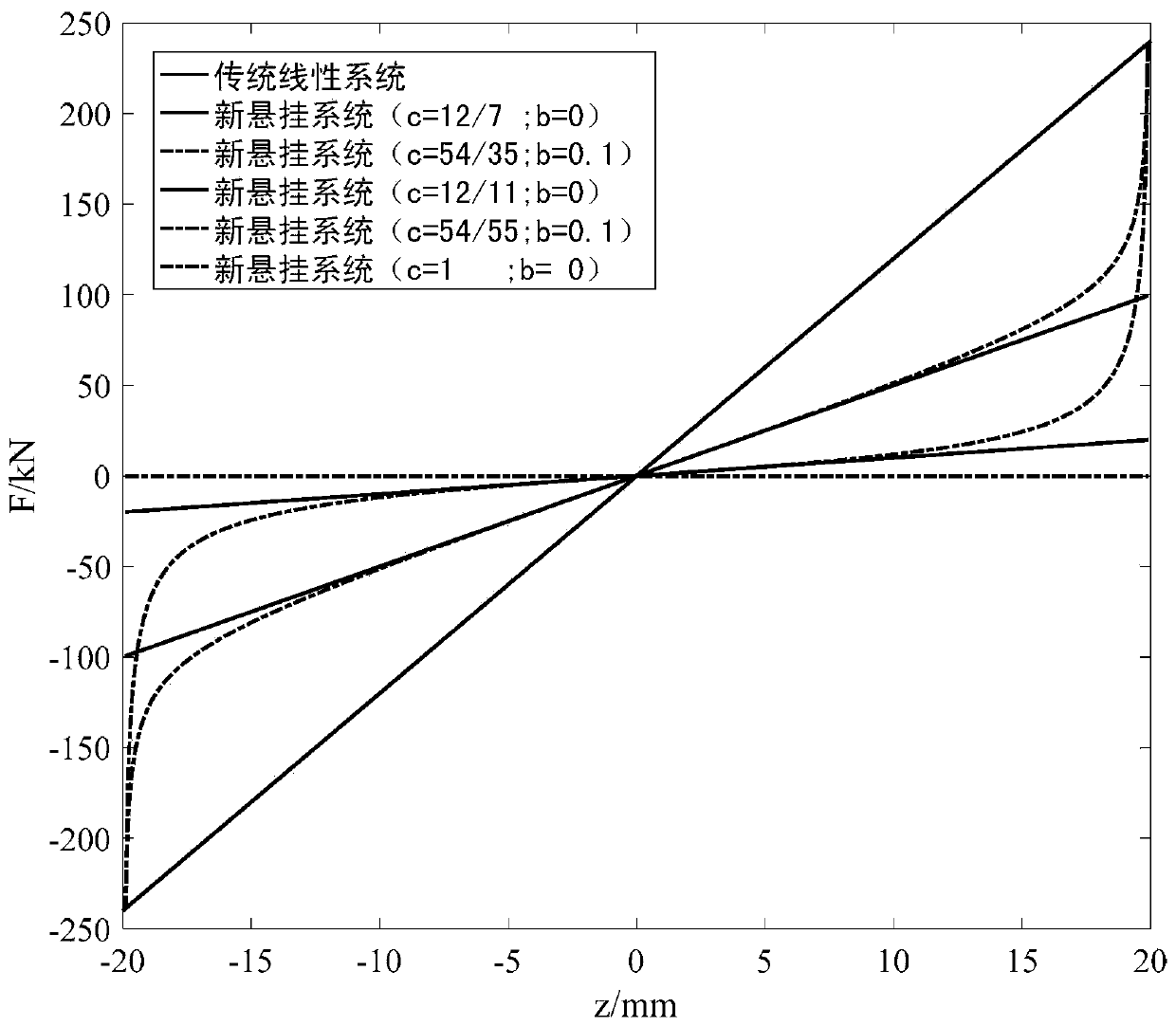

[0051] In order to make the technical scheme and advantages of the present invention clearer, the following in conjunction with the attached Figures 1 to 7 The technical solution of the present invention is described in more detail. The preferred embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation process and specific operation process and corresponding simulation results are provided, but the scope of protection of the present invention is not limited to the following examples, and it cannot be understood as the implementation of the present invention. limit. All other embodiments obtained by those skilled in the art using the concept of the present invention belong to the protection of the present invention.

[0052] The specific implementation plan is as follows:

[0053] A heavy-duty express railway freight car bogie with mechanical suspension secondary suspension is designed. The mechanical suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com