Copper-zirconium-aluminum ternary amorphous alloy thin film and preparation method thereof

An amorphous alloy film, copper zirconium aluminum technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of high price and increased cost of zirconium-copper-nickel ternary amorphous alloy film, etc. Achieve the effect of low cost, excellent practical application performance, and accurate control of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

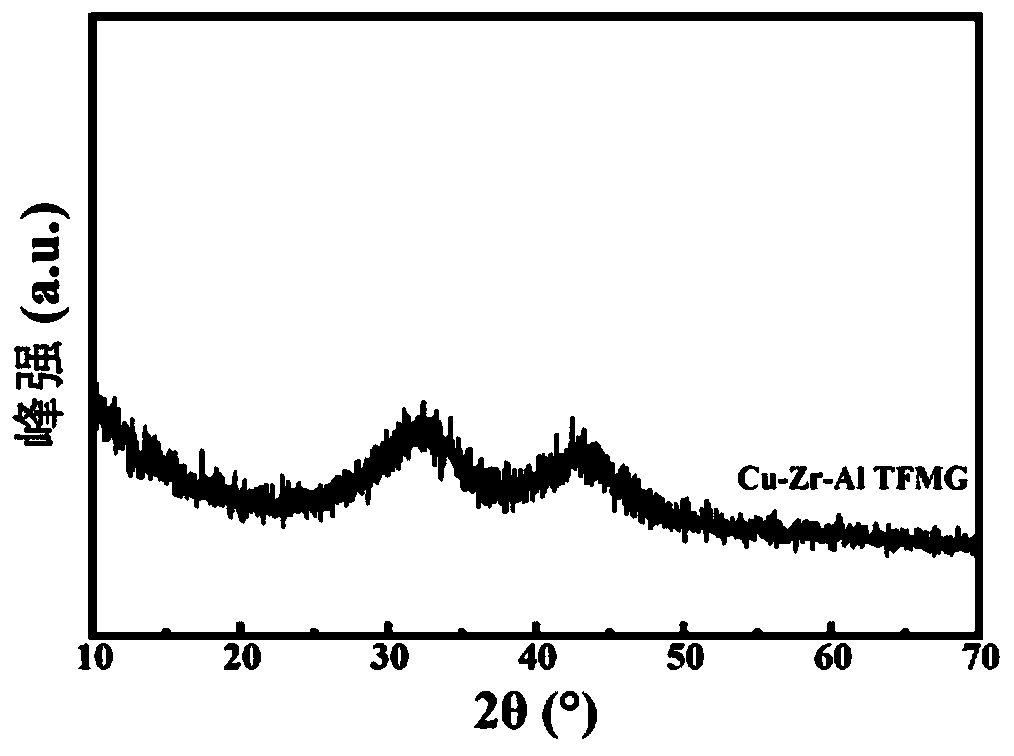

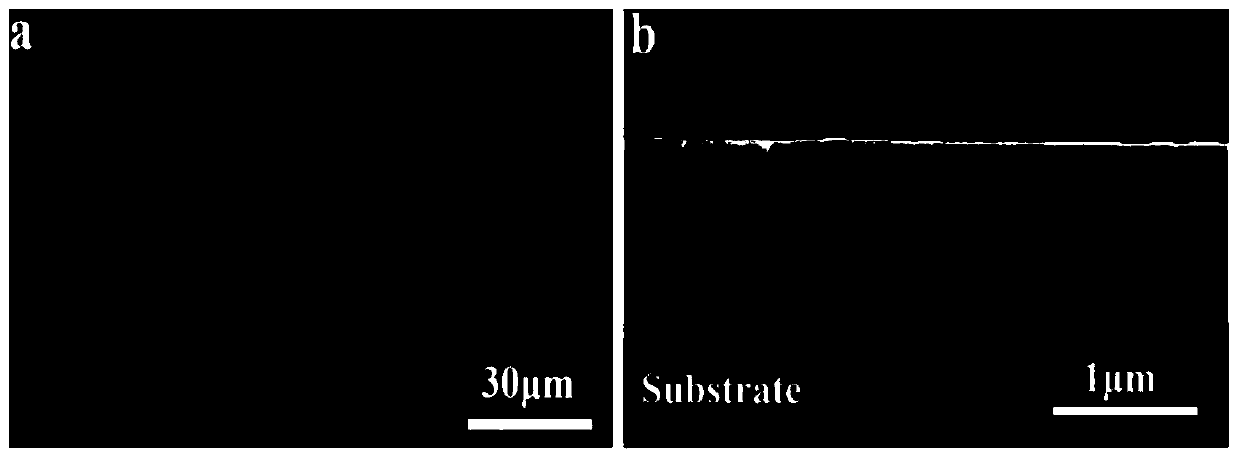

Image

Examples

Embodiment 1

[0033] The main components of the copper-based amorphous alloy film in this embodiment are Cu, Zr, and Al, and the percentage (at.%) contents of each element are: Cu 49, Zr 38, and Al 13, respectively.

[0034] Its preparation method is:

[0035] S1: Prepare the target: Melt the raw materials Cu, Zr, and Al elements in proportion to form a single alloy target, the target size is Ф60mm×3mm, and put the prepared alloy target into the sputtering target position;

[0036] S2: Substrate treatment: select monocrystalline silicon (10mm×10mm) as the substrate material, put the monocrystalline silicon into the ultrasonic cleaning equipment for deionized water cleaning for 10 minutes, take it out and clean it with alcohol, and then put it into the ultrasonic cleaning equipment again for cleaning with acetone for 10 minutes , take it out and clean it with deionized water and alcohol, and dry it with warm air after cleaning.

[0037] S3: Carry out magnetron sputtering: first evacuate, so...

Embodiment 2

[0040] The main components of the copper-based amorphous alloy film in this embodiment are Cu, Zr, and Al, and the percentage (at.%) contents of each element are: Cu 49, Zr 38, and Al 13, respectively.

[0041] Its preparation method is:

[0042] S1: Prepare the target: Melt the raw materials Cu, Zr, and Al elements in proportion to form a single alloy target, the target size is Ф60mm×3mm, and put the prepared alloy target into the sputtering target position;

[0043] S2: Substrate treatment: choose 304 stainless steel (10mm×10mm) as the substrate material, put the stainless steel into the ultrasonic cleaning equipment for deionized water to clean for 10 minutes, take it out and clean it with alcohol, then put it into the ultrasonic cleaning equipment again for cleaning with acetone for 10 minutes, after taking it out Clean with deionized water and alcohol, dry with warm air after cleaning, and use stainless steel as the substrate for sputtering.

[0044] S3: Carry out magnet...

Embodiment 3

[0047] The main components of the copper-based amorphous alloy film in this embodiment are Cu, Zr, and Al, and the percentage (at.%) contents of each element are: Cu 51, Zr 38, and Al 11, respectively.

[0048] Its preparation method is:

[0049] S1: Prepare the target: Melt the raw materials Cu, Zr, and Al elements in proportion to form a single alloy target, the target size is Ф60mm×3mm, and put the prepared alloy target into the sputtering target position;

[0050] S2: Substrate treatment: choose 304 stainless steel (10mm×10mm) as the substrate material, put the stainless steel into the ultrasonic cleaning equipment for deionized water to clean for 10 minutes, take it out and clean it with alcohol, then put it into the ultrasonic cleaning equipment again for cleaning with acetone for 10 minutes, after taking it out Clean with deionized water and alcohol, dry with warm air after cleaning, and use stainless steel as the substrate for sputtering.

[0051] S3: Carry out magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com