Large-capacity longitudinal corner tube boiler

A corner tube boiler and vertical installation technology, which is applied to water tube type steam boilers, steam boilers, boiler support/positioning devices, etc., can solve the problems of being limited to a small range and difficult to ensure sealing, and achieves reduction of expansion gaps and earthquake resistance. Good sex and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

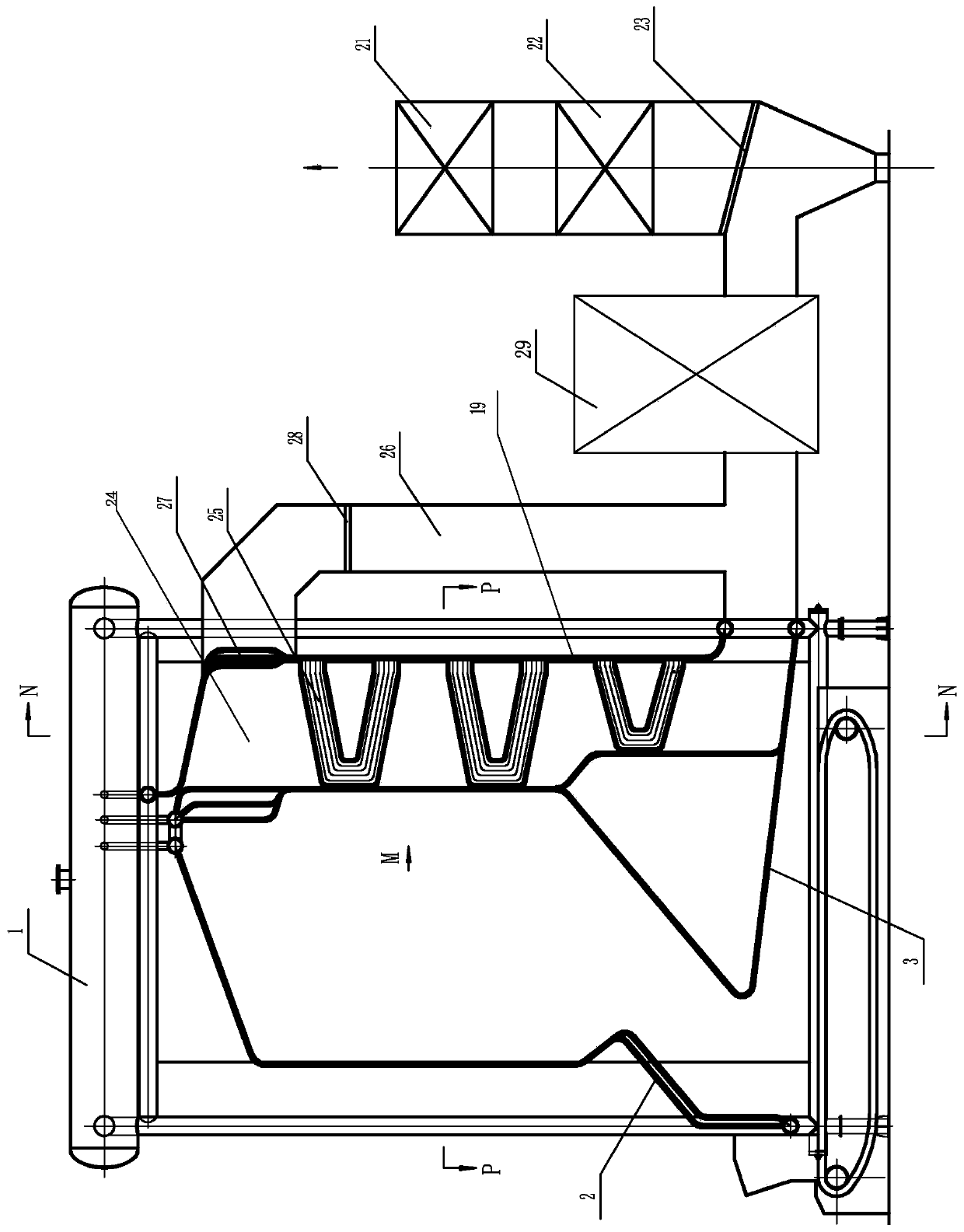

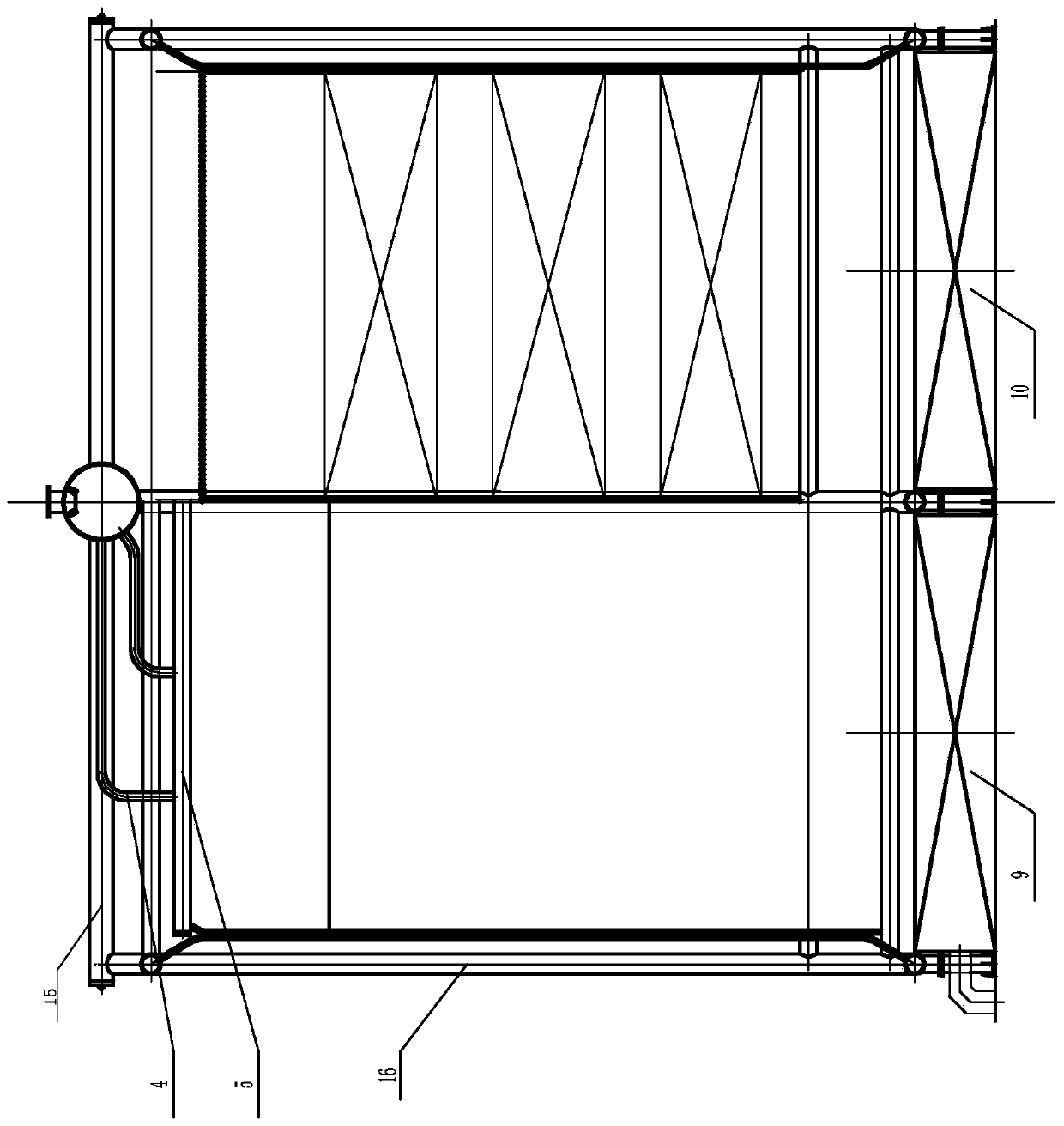

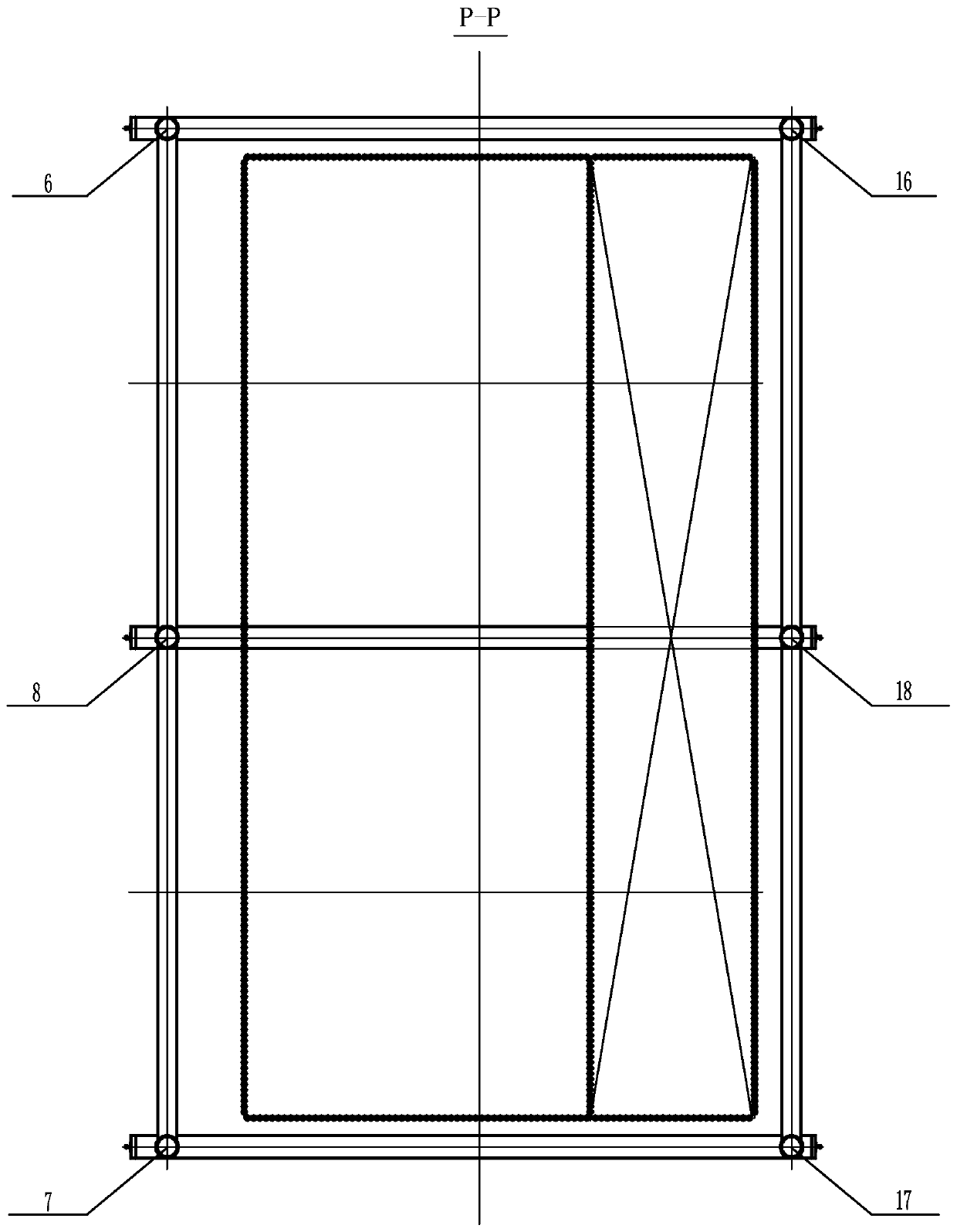

[0017] Specific implementation mode one: combine Figure 1-Figure 9 Describe the present embodiment. The large-capacity vertical corner tube boiler described in this embodiment includes a boiler body, a smoke exhaust mechanism and a rear heating surface. The boiler body and the tail heating surface are connected by a smoke exhaust mechanism. The boiler body includes a boiler Tube 1, front arch water wall 2, rear arch water wall 3, side water wall, flue water wall 19, outlet pipe 4, steam collection pipe 5, connecting pipe 15, ember chamber 24, flag type convection screen 25, convection Flue, left grate 9, right grate 10, support seat assembly, upper header, lower header, front left descending pipe 6, front middle descending pipe 8, front right descending pipe 7, rear left descending pipe 16, rear The middle descending pipe 18 and the rear right descending pipe 17; the front left descending pipe 6, the front middle descending pipe 8 and the front right descending pipe 7 are arr...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, a large-capacity vertical corner tube boiler described in this embodiment, the drum 1 is installed above the front middle downcomer 8 and the rear middle downcomer 18 through the upper header, and the whole boiler does not have an independent The supporting steel frame greatly reduces the weight of the traditional steel frame structure boiler, and the vertical arrangement of the drum also reduces the length of the drum, thereby reducing the weight and water volume, and reducing the load of the entire boiler. Other structures and methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 1-Figure 9 Describe this embodiment, a large-capacity vertical corner tube boiler described in this embodiment, the support base assembly includes a fixed support base 31, two multi-directional support bases 32 and three unidirectional support bases 33; the fixed support base 31 is installed below the front middle drop tube 8, a one-way support seat 33 is respectively installed under the front left drop tube 6, the front right drop tube 7 and the rear middle drop tube 18, the rear left drop tube 16 and the rear right drop tube 17 A multi-directional support base 32 is installed respectively below the bottom. The support seat assembly is provided with six fulcrums in total. The load is transferred to the boiler foundation through the corresponding support. The one-way support seat 33 relies on the limitation of the limit channel steel. The front right support allows free expansion to the right, the front left supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com