Method for preparing carbon nanotube film reticular structure for reinforcing water vapor condensation

A carbon nanotube film, network structure technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of small range of enhanced heat transfer subcooling, poor stability of condensation surface, complex processing technology, etc. Achieving good water vapor condensation strengthening effect, reducing the separation diameter and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

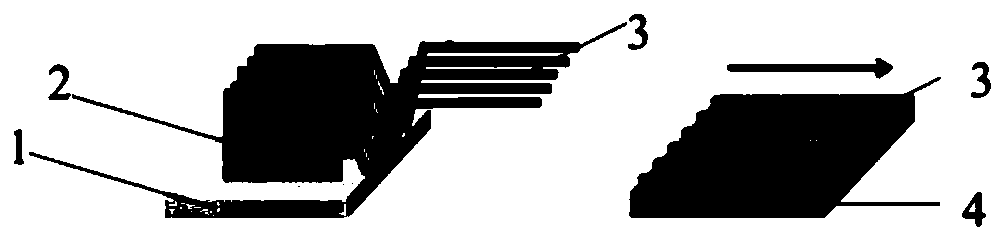

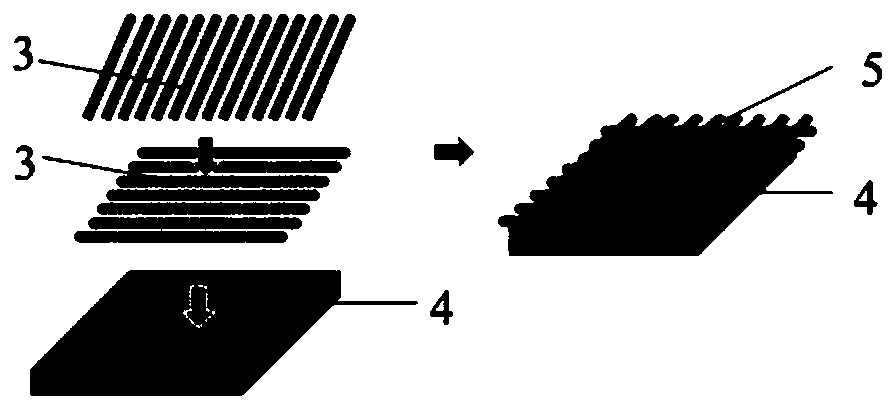

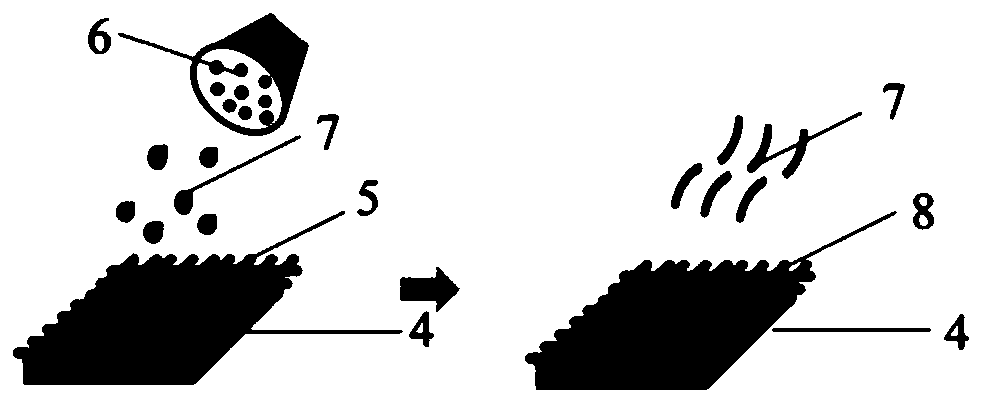

[0031] A three-dimensional carbon nanotube film network structure and a preparation method thereof for enhanced water vapor condensation. By constructing a three-dimensional carbon nanotube film network structure 5 on the surface of the substrate 4, the purpose of strengthening water vapor condensation is achieved. The carbon nanotube thin film network structure 5 material can be covered on various types of material substrates 4 , and the effect of strengthening water vapor condensation and heat transfer can be achieved after simple treatment. The preparation steps of the three-dimensional carbon nanotube film network structure 5 are as follows:

[0032] (1) preparing a single-layer carbon nanotube film 3;

[0033] (2) spreading a pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com