Simulation calculation method for evaluating service life of cylindrical anode layer Hall thruster

A technology of Hall thruster and life evaluation, applied in the field of simulation, can solve the problems of inapplicability, high cost and long time of thruster life evaluation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

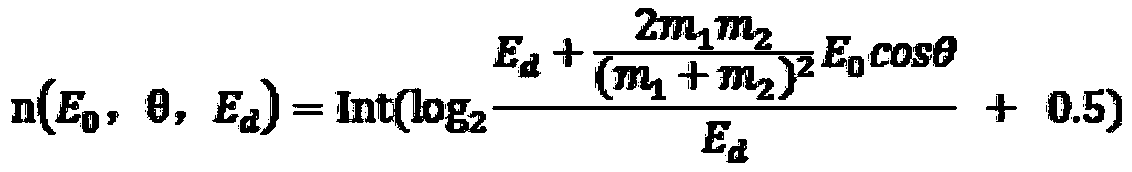

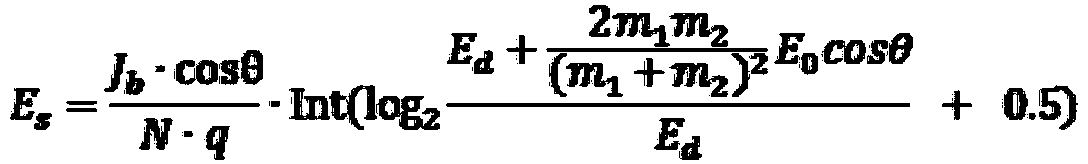

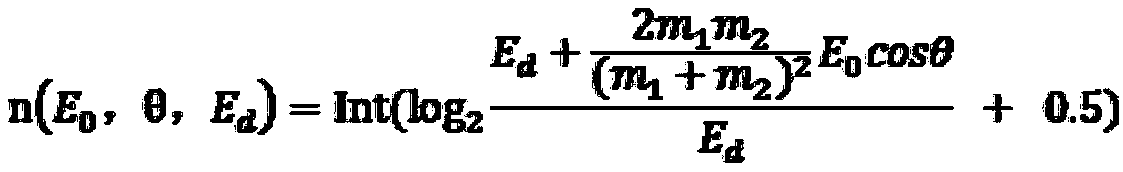

[0034] The present invention adopts the numerical simulation simulation method, based on the VORPAL simulation software developed by Tech-X Company of the United States, conducts a comprehensive and accurate modeling analysis of the behavior of electrons and ions in the discharge process, and obtains the ion position, energy and The distribution of the incident angle, and then use the sputtering coefficient formula and the etching rate formula to evaluate the life of the thruster. Specific implementation methods include:

[0035] (1) Use the 3D drawing software AutoCAD or VariCAD to model the 3D geometric structure, obtain the meshed geometric structure model, and save it in STP and STL formats for future use. And the mesh repair is performed on the exported meshed geometric model in STL format.

[0036] (2) Import the 3D geometric model in STP format saved in the first step into the infolytic Magnetic magnetic field simulation software for magnetic field simulation, and obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com