Processing method of stack-bonded wafer

A processing method and wafer technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as yield loss, and achieve the effects of avoiding yield loss, avoiding wafer edge reduction, and stabilizing the cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

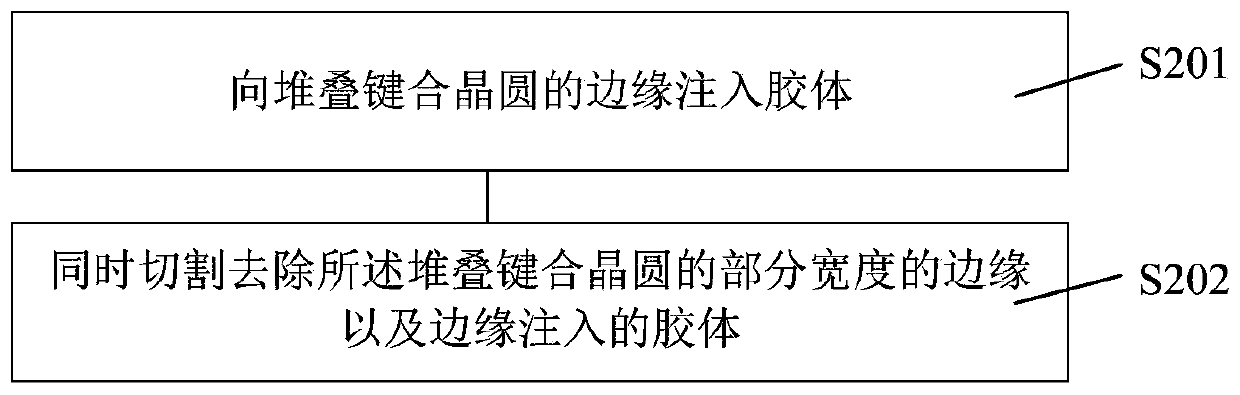

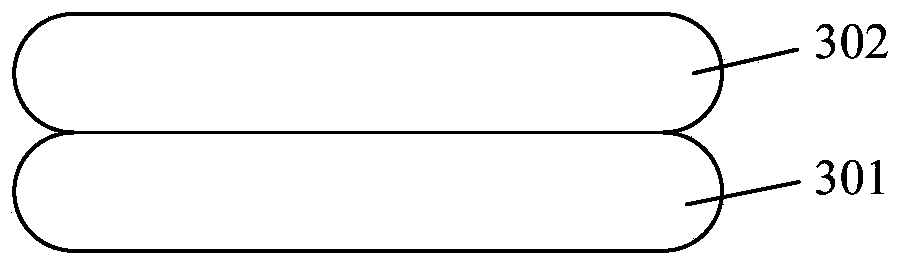

[0023] As mentioned in the background art, when conventional multi-layer wafers are stacked, the edge cuts will be considerable, resulting in a loss of yield.

[0024] The study found that when stacking multi-layer wafers, after each wafer stacking, the corresponding wafers must be thinned. After the thinning operation, an edge reduction process is required, so When stacking multi-layer wafers, multiple thinning operations and multiple trimming processes are required. Therefore, when multi-layer wafers are stacked, the edge trimming will be considerable, resulting in a loss of yield. And because defects such as cracks may spread to the center of the wafer every time the thinning is performed, the width to be cut will be wider when the edge is cut next time, which further increases the amount of cuts on the edge of the stacked wafer and further causes good rate loss. And the process has been cut many times, which reduces the production efficiency.

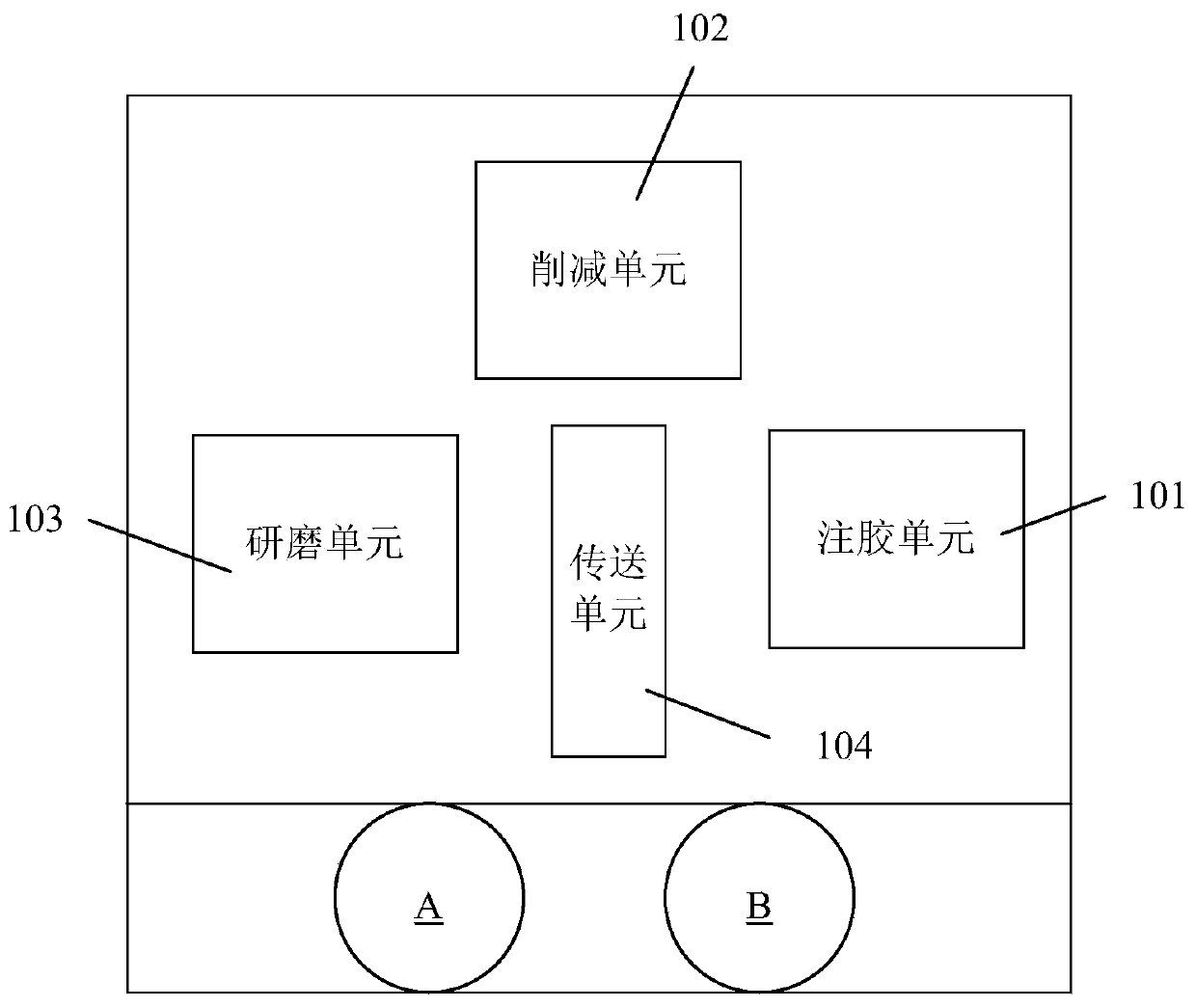

[0025] To this end, the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap