Anti-deviation device for pre-cleaning waste lithium battery

A waste lithium battery, pre-cleaning technology, used in secondary batteries, battery recycling, cleaning methods and utensils, etc. problems, to avoid deviation, facilitate recycling, and avoid splashing around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

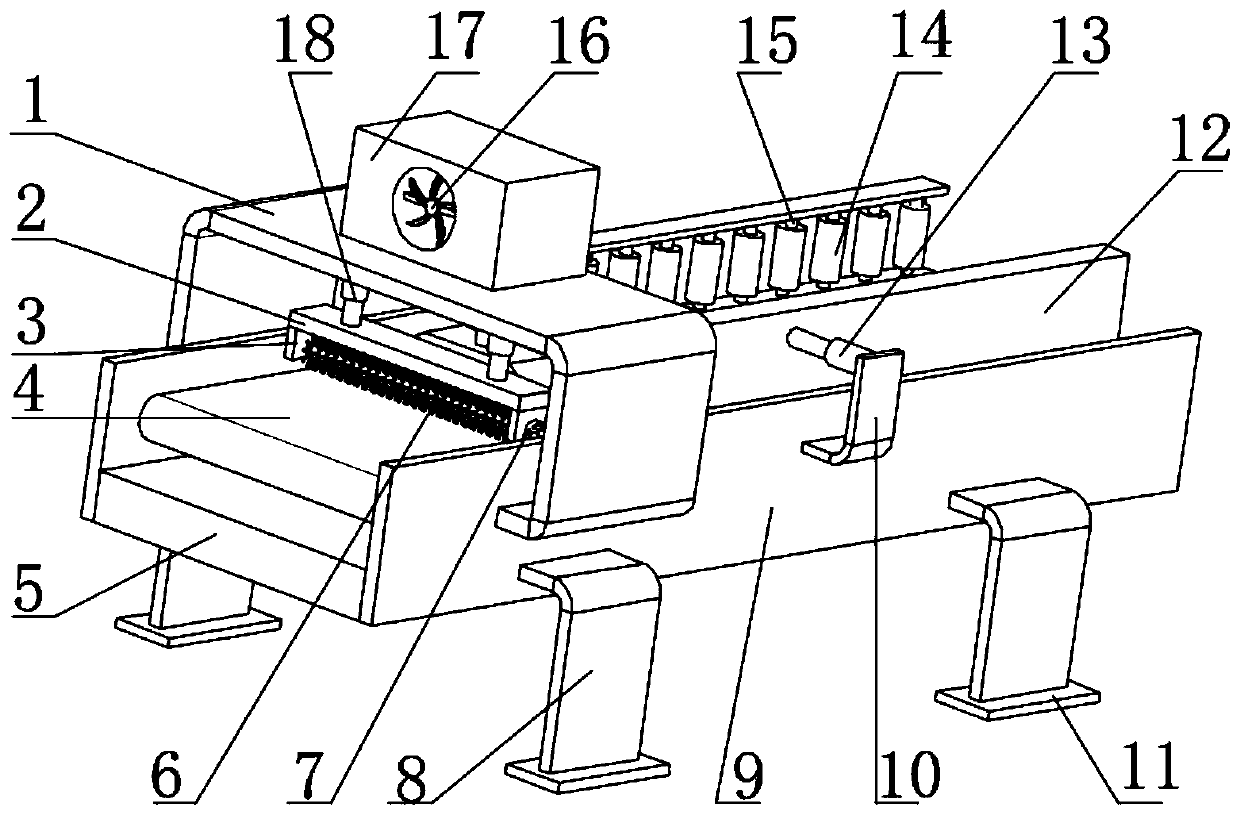

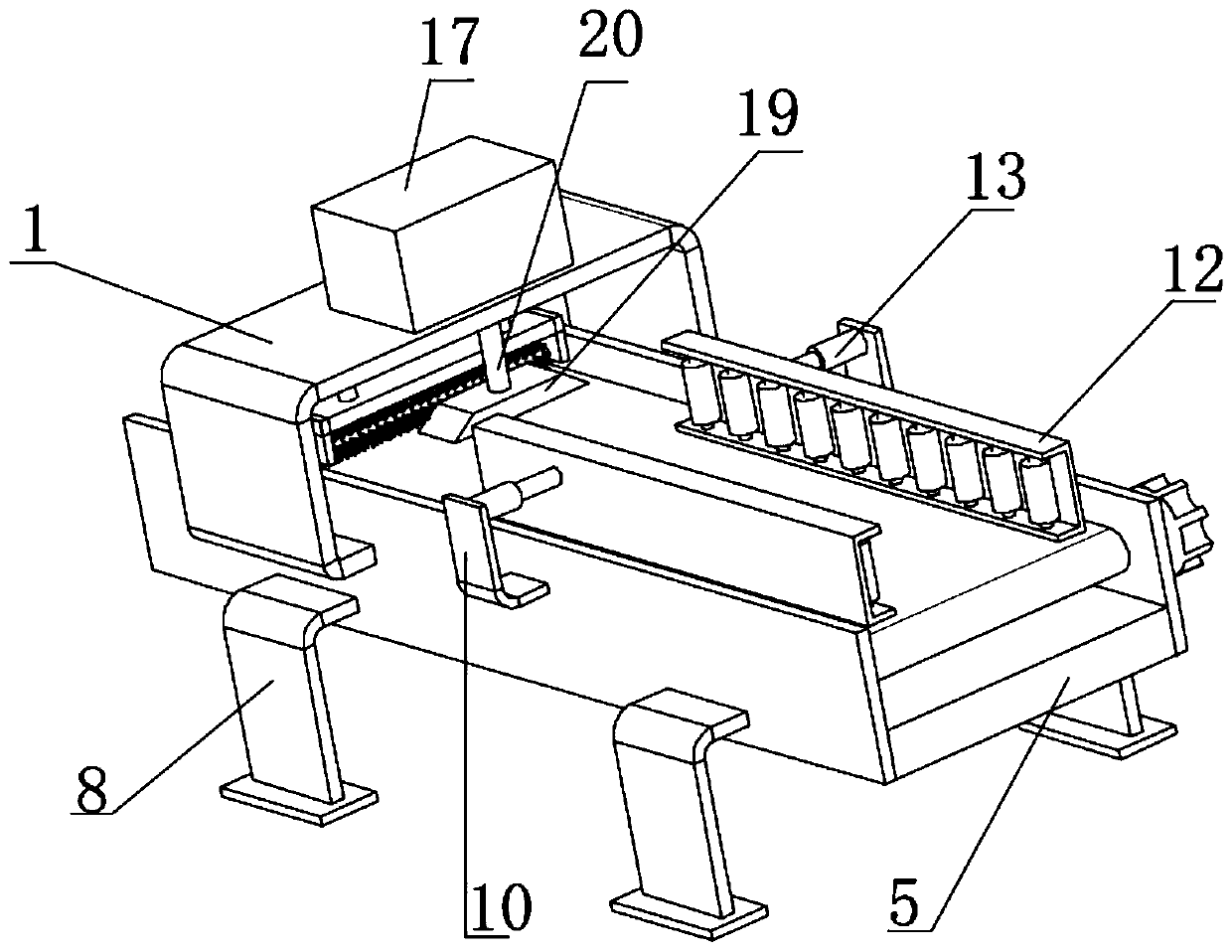

[0028] An anti-deviation device for pre-cleaning waste lithium batteries, such as Figure 1-3 As shown, including the base 5, the two ends of the outer wall of the top of the base 5 are equipped with a fixed plate 9, and the two opposite ends of the outer wall of the two fixed plates 9 are rotationally connected with two rotating shafts, and the outer walls of the circumference of the two rotating shafts are sleeved with the same A conveyor belt 4, the outer wall of one end of the two fixed plates 9 away from each other is equipped with a mounting plate 10, and the outer wall of the opposite end of the two mounting plates 10 is equipped with an electric telescopic rod 13, and one end of the two electric telescopic rods 13 is close to each other The outer wall is equipped with a mounting block 12, and the outer wall of one end of the mounting block 12 is provided with a rectangular groove.

[0029] The four corners of the outer wall at the bottom of the base 5 are equipped with...

Embodiment 2

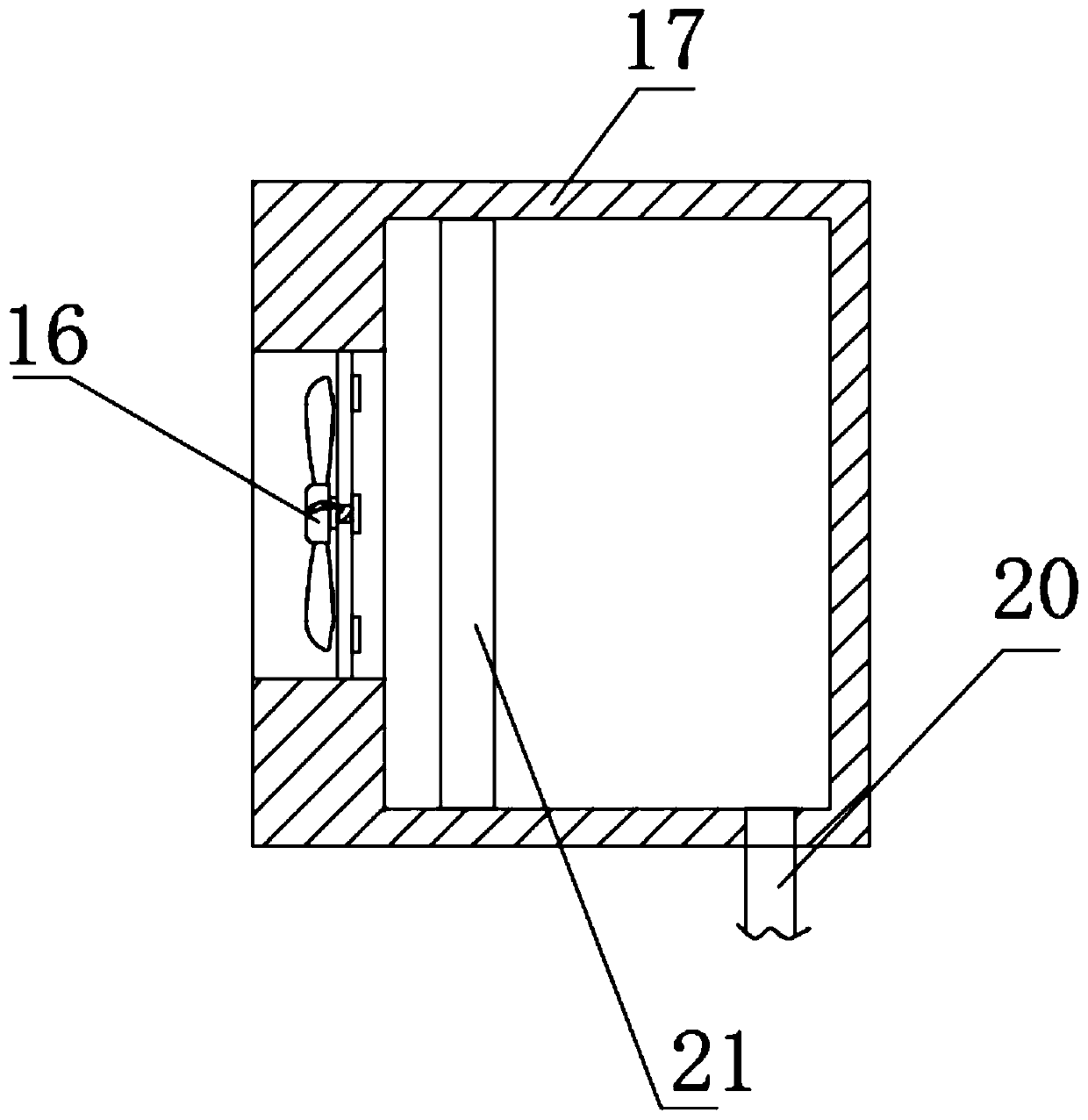

[0032] An anti-deviation device for pre-cleaning waste lithium batteries, such as Figure 1-4 As shown, the top outer wall of the storage housing 17 is provided with an opening, and a door panel 22 is installed on the inner wall at one end of the opening, and a handle is installed on the top outer wall of the door panel 22 .

[0033] When this embodiment is in use, the dust generated by the collection can be collected and processed by being provided with the door panel 22 and the handle, so as to prevent the dust from accumulating in the storage housing 17 and ensure the filtration quality and filtration efficiency of the filter screen 21 for air dust. , to ensure the filtering function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com