Metal/polycrystal surface Cu2O composite adjustable photocatalyst and preparation method thereof

A polycrystalline surface and light-regulating technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of photocatalytic efficiency discount and achieve low cost , less pollution, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Preparation of polycrystalline Cu by chemical precipitation method 2 O particles;

[0047] 1.1) Add 20mmol CuSO 4 ·5H 2 O was added to 50ml of deionized water and heated to 70°C to obtain solution I;

[0048] 1.2) Add 20ml of 0.18g / ml aqueous sodium hydroxide solution dropwise to the copper salt solution obtained in step 1.1), and stir for 5min to obtain suspension II;

[0049] 1.3) Add 0.6 g of glucose to the suspension II obtained in step 1.2), and react for 1 hour to obtain

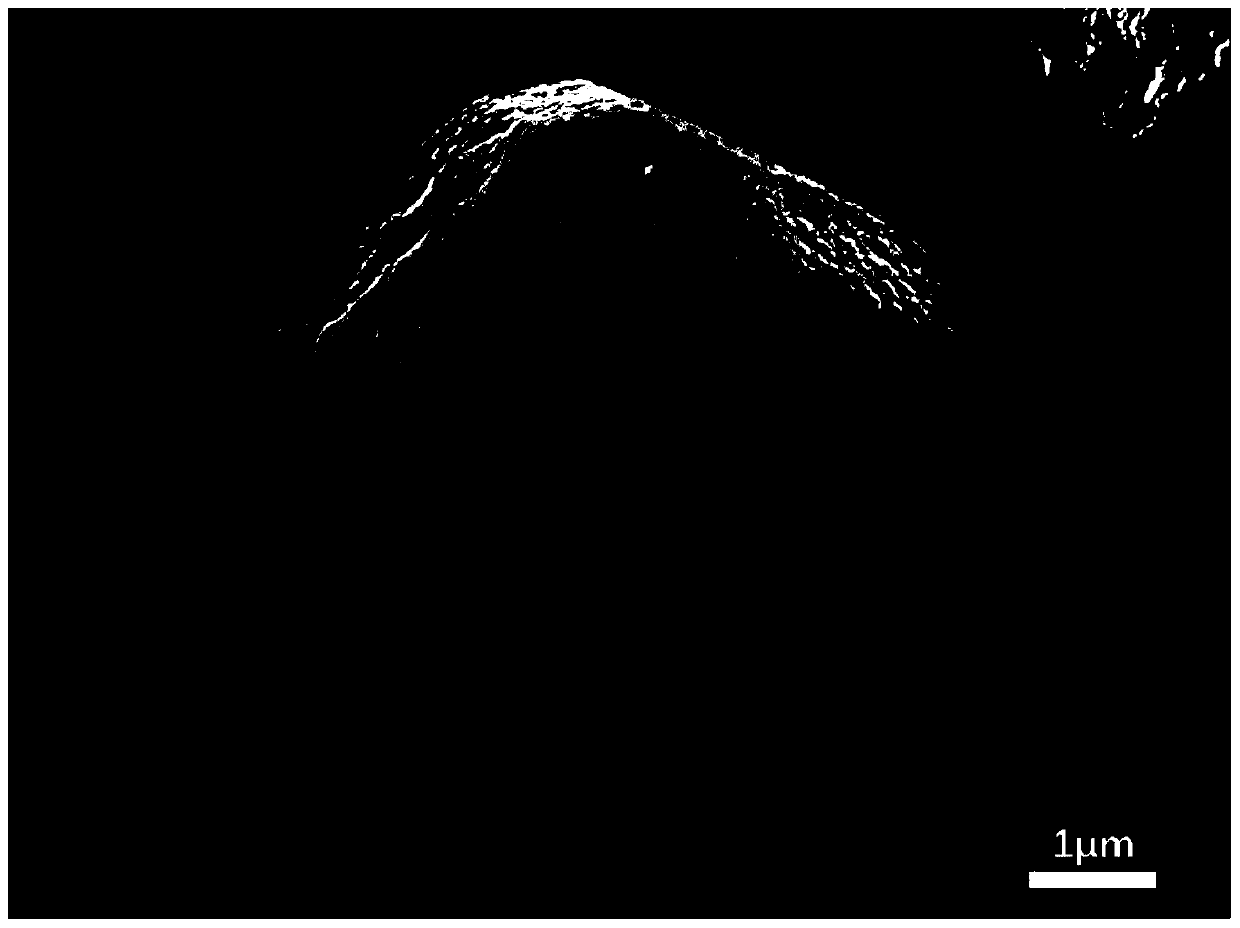

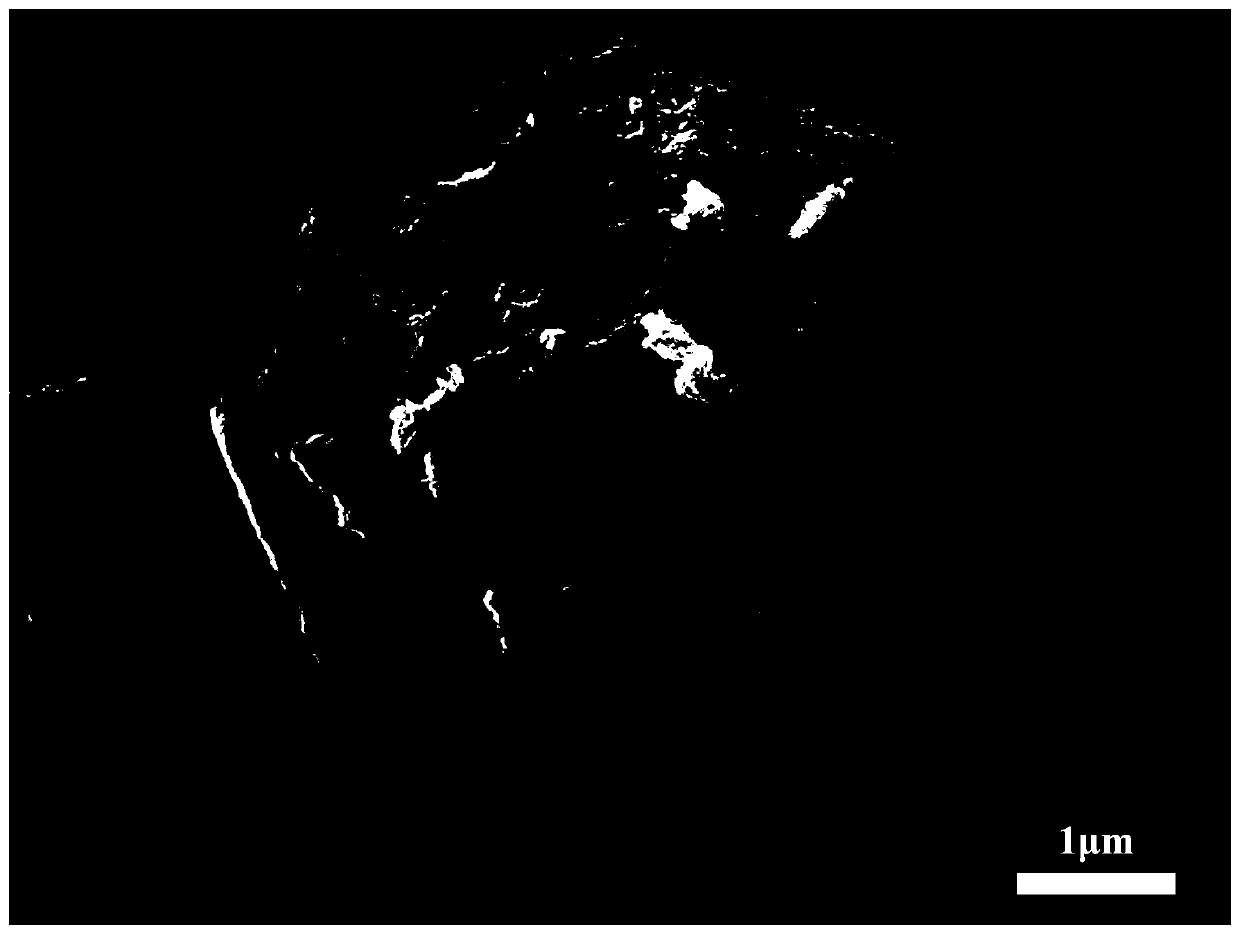

[0050] The suspension of copper precipitation is taken out and aged for 1 hour, separated, washed, and dried in vacuum at 70°C for 12 hours to obtain polycrystalline Cu 2 O particles. It was confirmed by scanning electron microscope (SEM) observation that the polycrystalline Cu 2 The O particle is a 26-hedron. According to the common knowledge of the prior art, the polycrystalline Cu 2 The crystal faces of O particles are divided into three types: {100}, {110}, and {111} according to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com