Auxiliary heat source welding method for double-spindle friction stir welding

A friction stir welding and auxiliary heat source technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problem of easy adhesion and other problems, and achieve the effect of sufficient stirring needle, high feasibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

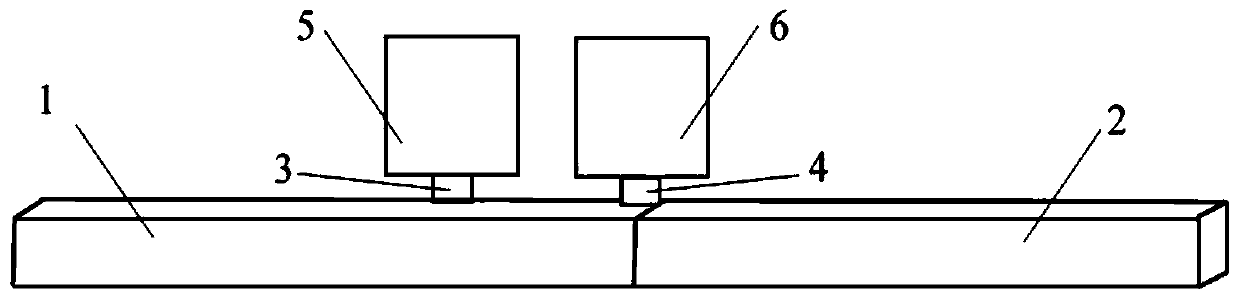

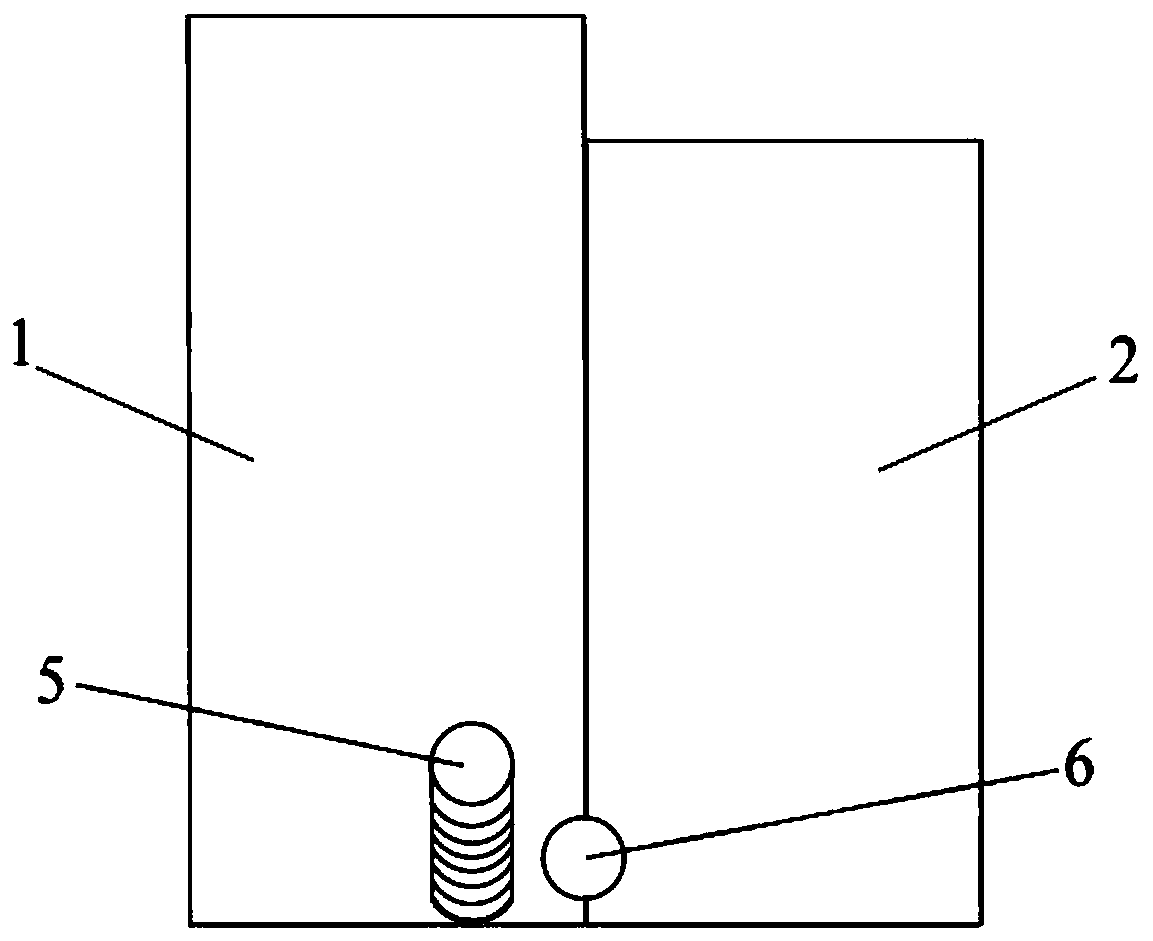

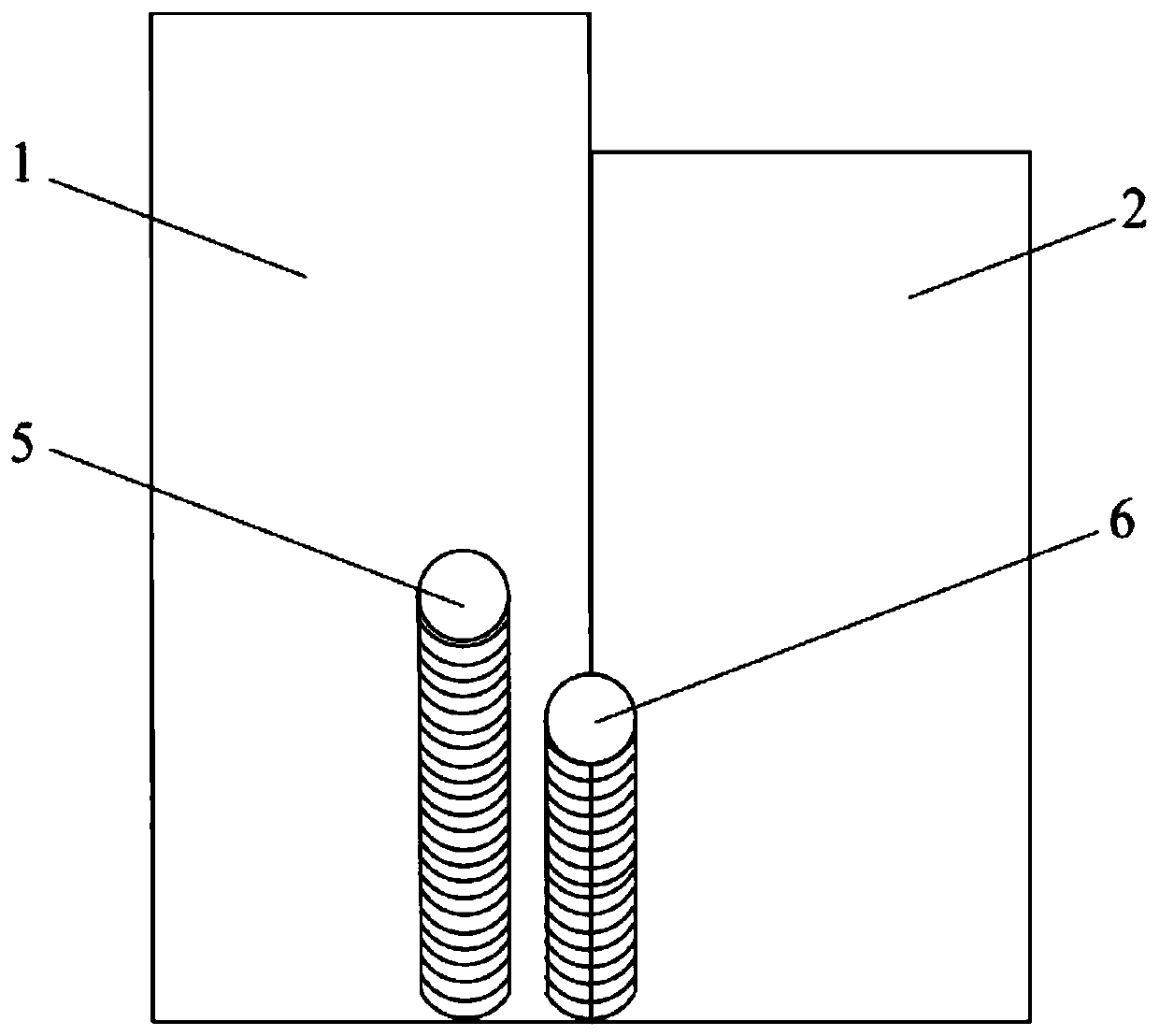

[0029] Below in conjunction with the present invention Figure 1-4 , to further illustrate the technical solutions in the embodiments of the present invention, but the present invention is not limited to these embodiments.

[0030] A heat source welding method assisted by dual-spindle friction stir welding, comprising the following steps:

[0031] Step 1, prepare the workpiece to be welded:

[0032] Clean the surface of the high-hardness metal plate 1 and the low-hardness metal plate 2, place them on the workbench by the method of butt joint, and fix and position them with a special tooling fixture to form the workpiece to be welded and the weld seam to be welded;

[0033] Step 2, the installation and positioning of the stirring head:

[0034] Install the auxiliary heat source stirring head 3 on the auxiliary heat source rotating main shaft 5 and fix it, install the welding seam stirring head 4 on the welding seam rotating main shaft 6 and fix it, then adjust the auxiliary h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com