Brushed DC torque motor stator magnetic steel protection structure and forming method thereof

A protective structure and torque motor technology, applied in the direction of magnetic circuit shape/style/structure, manufacturing motor generators, manufacturing stator/rotor body, etc., can solve problems such as unretrieved technical solutions, achieve simple structure, less process, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

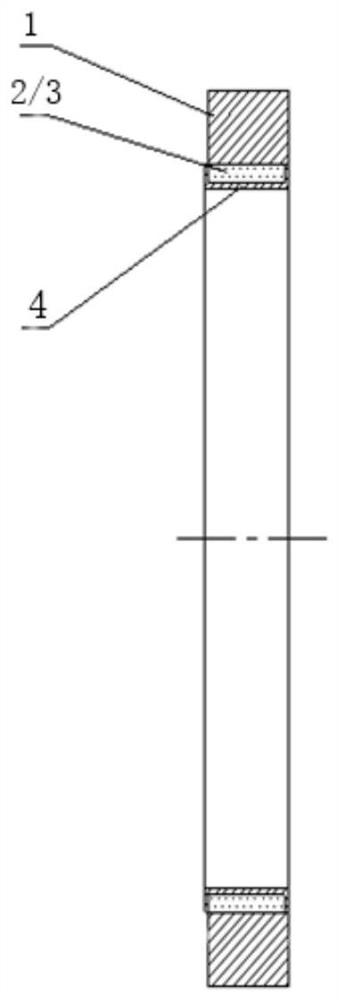

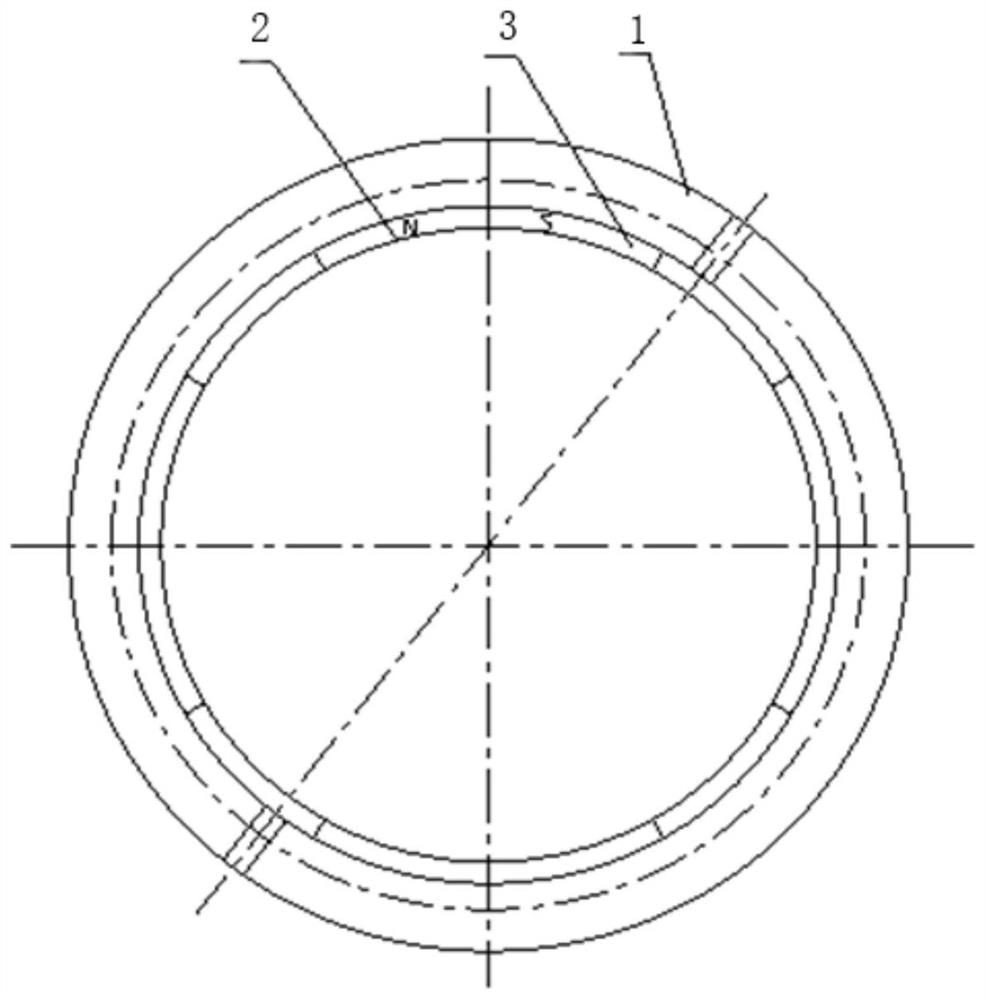

[0021] A brush DC torque motor stator magnetic steel protection structure, please refer to figure 1 and 2 , and its invention points are: comprising a plurality of first magnetic steel blocks 2 and a plurality of second magnetic steel blocks 3 with opposite polarities, a magnetic permeable ring 1 and a magnetic steel cover 4, wherein the first magnetic steel blocks and the second magnetic steel blocks The blocks are all made of NdFeB material. The magnetic conduction ring is a ring structure with a rectangular cross section, and the magnetic steel cover is composed of a cylindrical steel cover main body and a first outer flange part and a second outer flange connecting the two ends of the steel cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com