Ultrafine diamond micropowder synthesis method

A technology of diamond micropowder and synthesis method, which is applied in the direction of diamond, etc., which can solve the problems of high cost, low purity and low diamond yield of ultrafine micropowder, and achieve narrow grain size distribution range, high purity and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for synthesizing ultrafine diamond powder, comprising the following steps:

[0038] Step 1. Sample pre-compression: use a tablet press to press the precursor to a density of 1.1-1.35g / m 3 , the precursors include naphthalene, anthracene, nitrogen anthracene, phenanthroline;

[0039] Step 2. Pressurization: Boost the pressure from normal pressure to the target pressure, keep the pressure under the target pressure, heat during the pressure keeping stage, and after the pressure keeping is completed, reduce the pressure to normal pressure to obtain ultrafine diamond powder.

[0040] In the step 2, the target pressure is 10Gpa-13Gpa, and the pressure is maintained at the target pressure for 100min-300min. The holding time is slightly longer than the total heating time.

[0041] Further, the heating process in the pressure holding stage in the step 2 is as follows: firstly, the temperature is raised to 620°C-650°C, the heating rate is 10-20°C / s, and the temperature...

Embodiment 2

[0048] Naphthalene synthetic ultrafine diamond powder:

[0049] Press the precursor naphthalene to a density of 1.23 g / m using a tablet press 3, first increase the pressure from normal pressure to the target pressure of 13Gpa, and heat at the target pressure. , the heating rate is 0.5°C / min, and the temperature is kept at 680°C for 120 minutes; then the temperature is raised to 720°C, and the heating rate is 0.5°C / min; finally, the temperature is raised to the target temperature of 1680°C at 10°C / s, and annealed after holding at the target temperature for 5s , after the pressure holding is completed, the pressure is reduced to normal pressure to obtain diamond powder.

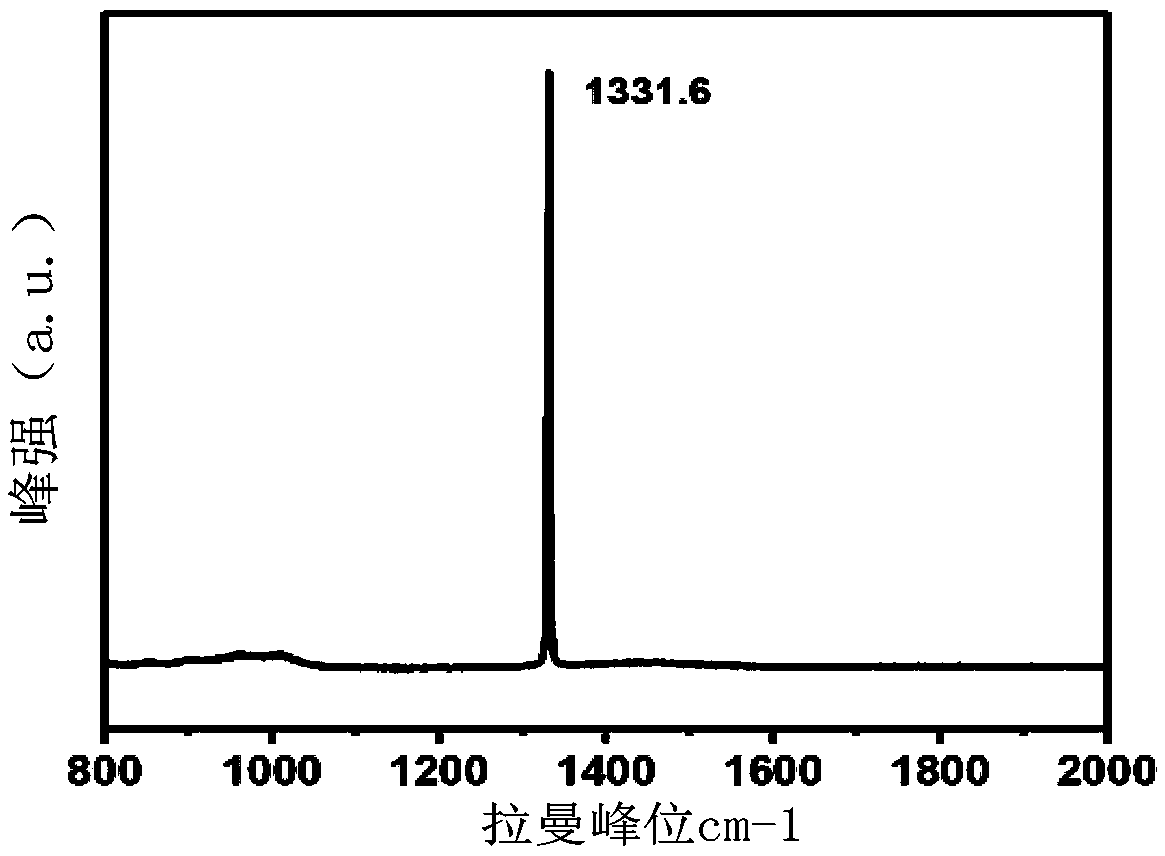

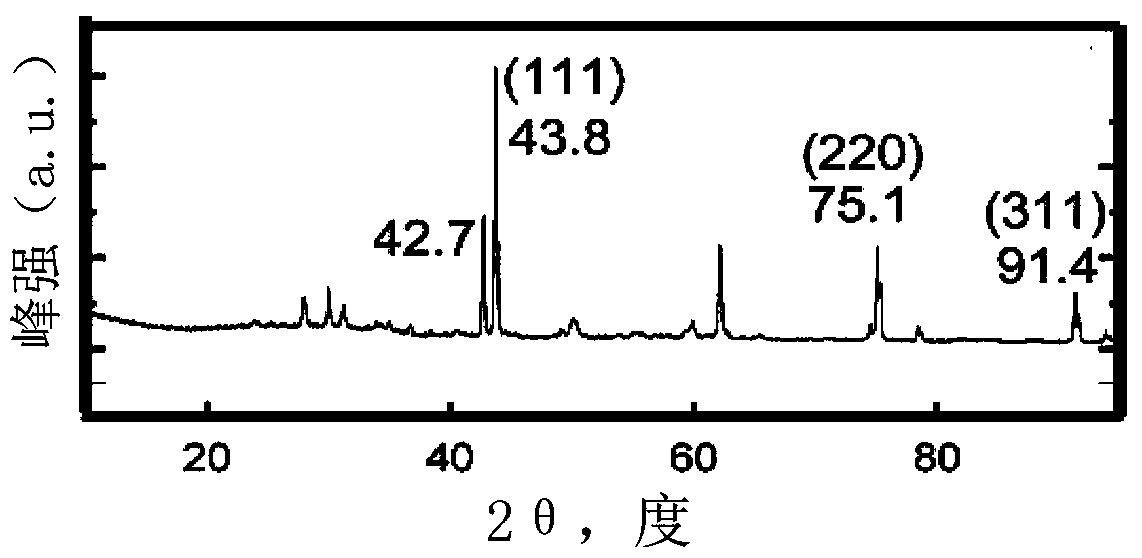

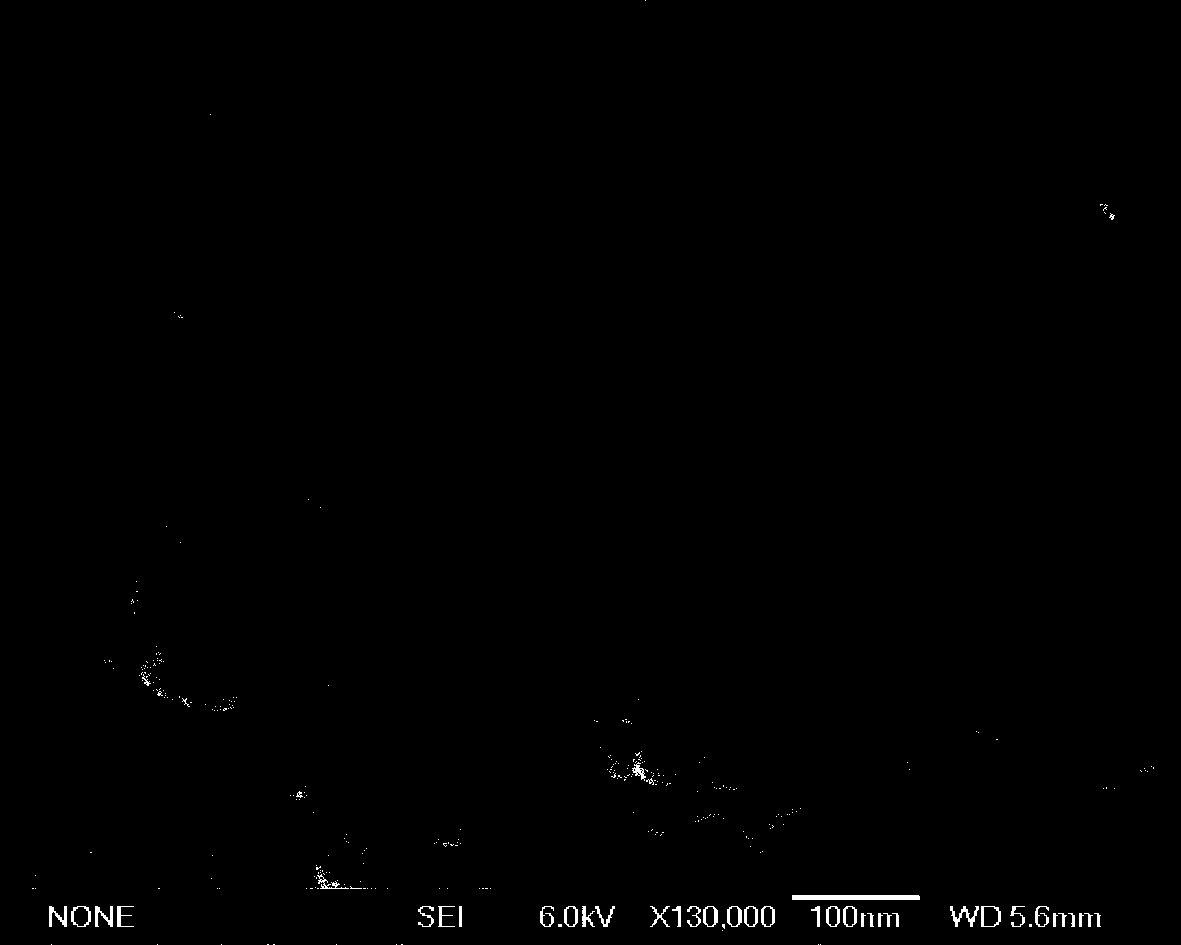

[0050] Carry out Raman, XRD, FE-SEM characterization to the material synthesized in above-mentioned embodiment 2, obtain its basic experiment characterization data figure respectively as follows figure 1 , figure 2 , image 3 shown, from figure 1 Raman Peak is located at 1331.6cm -1 , figure 2 The XRD ...

Embodiment 3

[0052] Naphthalene synthetic ultrafine diamond powder:

[0053] Press the precursor naphthalene to a density of 1.18 g / m using a tablet press 3 , from normal pressure to the target pressure of 12.5Gpa, heating at the target pressure, the heating process is as follows: first raise the temperature to 640°C, the heating rate is 10°C / s, keep the temperature at 640°C for 18 minutes; then raise the temperature to 690°C ℃, the heating rate is 0.8°C / min, and the temperature is kept at 690°C for 100 minutes; then the temperature is raised to 730°C, and the heating rate is 0.6°C / min; finally, the temperature is raised to the target temperature of 1800°C at 25°C / s, and the temperature is kept at the target temperature for 300s. After the fire, after the pressure holding is completed, the pressure is reduced to normal pressure to obtain diamond powder.

[0054] The FE-SEM scanning image of the product of embodiment 3 is as Figure 4 shown, and the appearance characterized by FE-SEM Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com