A long-term water stability evaluation test device and method of asphalt mixture

A technology for asphalt mixture and water stability, which is applied in measurement devices, mechanical devices, analysis materials, etc., can solve the problems affecting the accuracy of evaluation, single evaluation method, and unfavorable development and progress of asphalt mixture water stability testing and other issues to achieve the effect of improving applicability and high reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

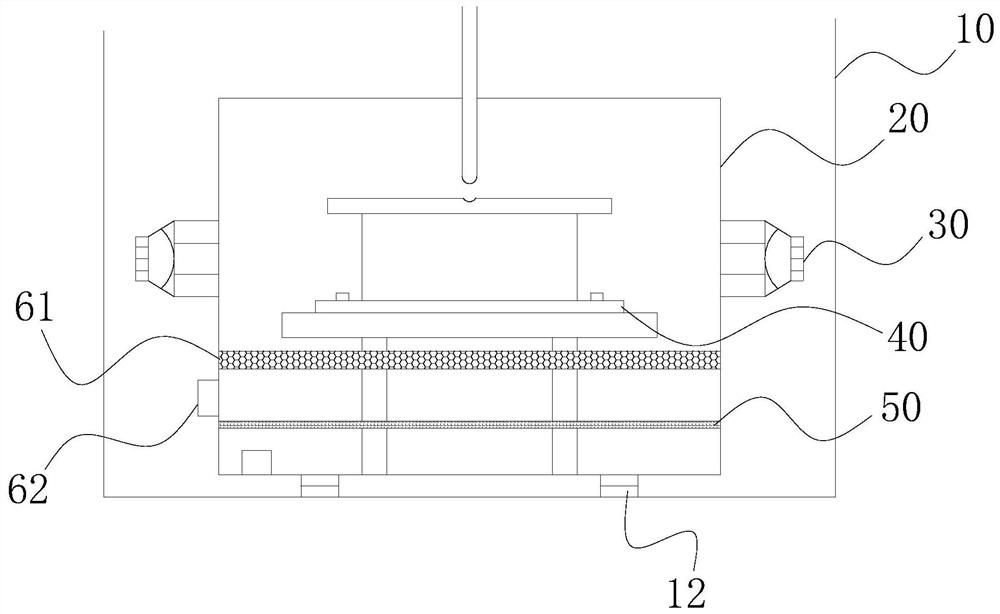

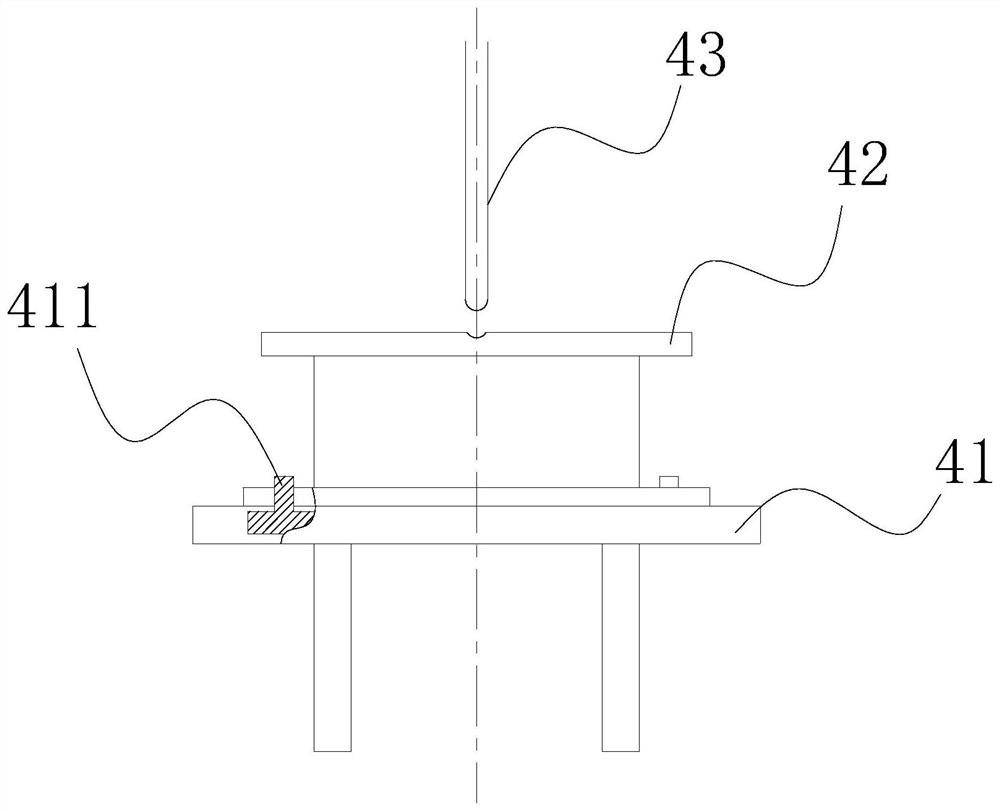

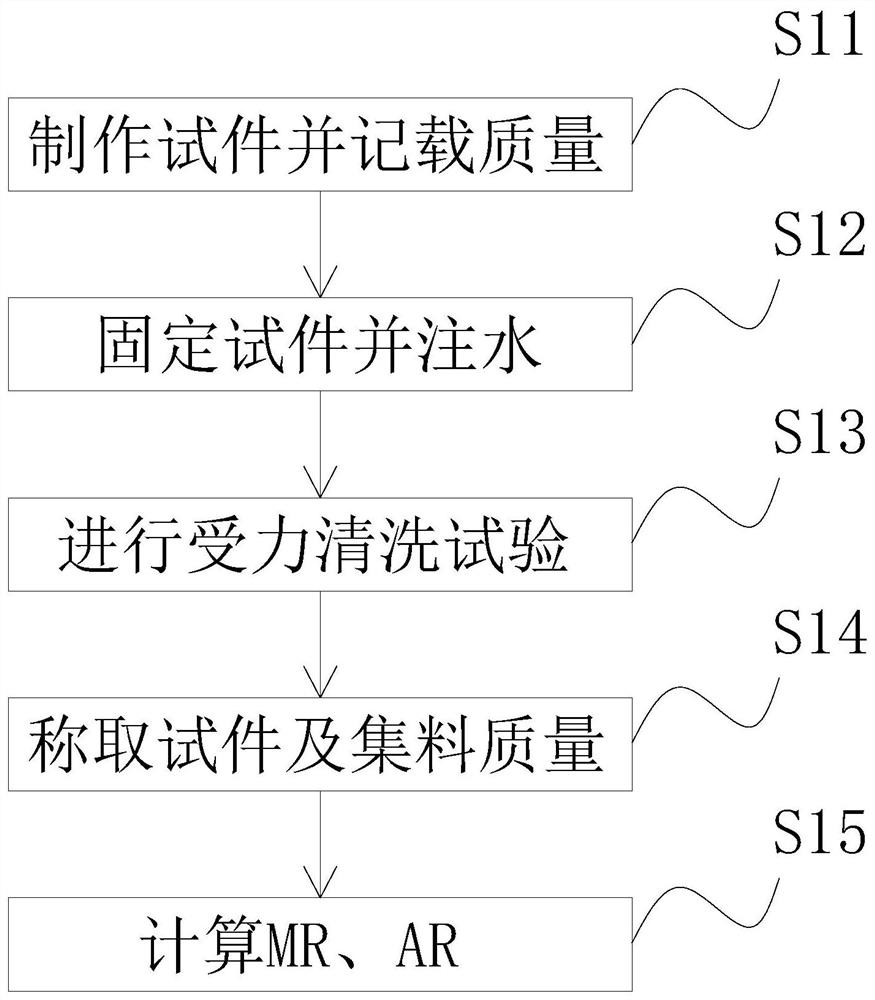

[0030] When the ultrasonic wave acts on the liquid, a large number of tiny bubbles will be continuously generated inside the liquid. When the generated bubbles pass from the high-pressure area to the low-pressure area in the liquid, the bubbles will burst, and the burst of each bubble will generate nearly a thousand atmospheric pressure. Shock wave, that is, "cavitation phenomenon", the shock wave generated by cavitation can impact and peel off the attachment on the surface of the object. At present, ultrasonic cleaning has been widely used in machinery, medical and other industries, but it has not been applied in the field of road engineering material testing. Therefore, the inventor considers placing the asphalt mixture specimen in an ultrasonic water tank, and uses the "cavitation effect" produced by ultrasonic waves on the liquid. When the bubbles burst, water will penetrate into the voids of the asphalt mixture specimen and further impact the asphalt binder. The bonding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com