Functional color reducing agent, and method for stabilizing color number of diisocyanate product

A technology of diisocyanate and toluene diisocyanate, which is used in the purification/separation of isocyanate derivatives, organic chemistry, etc., can solve the problems of increased color number, yellow-green color, and high color number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

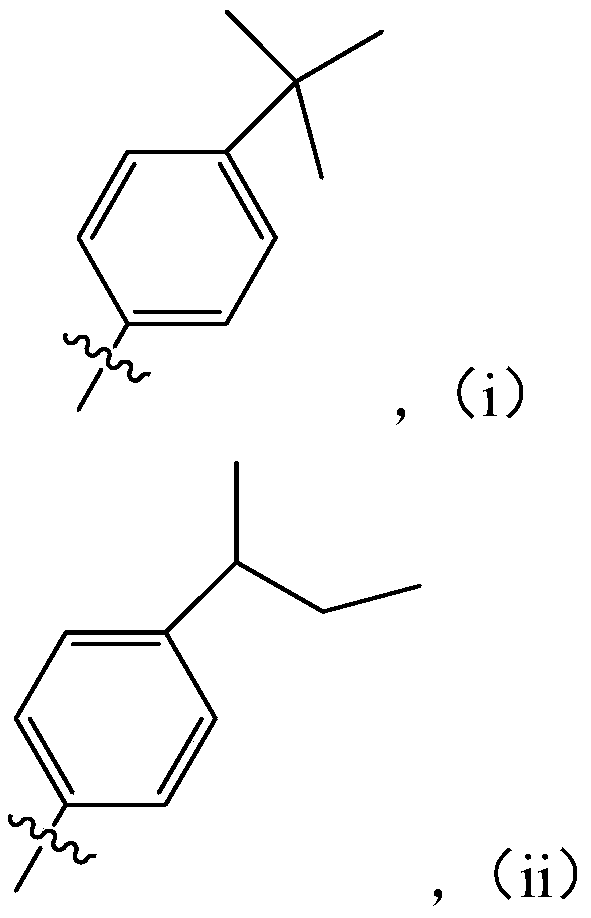

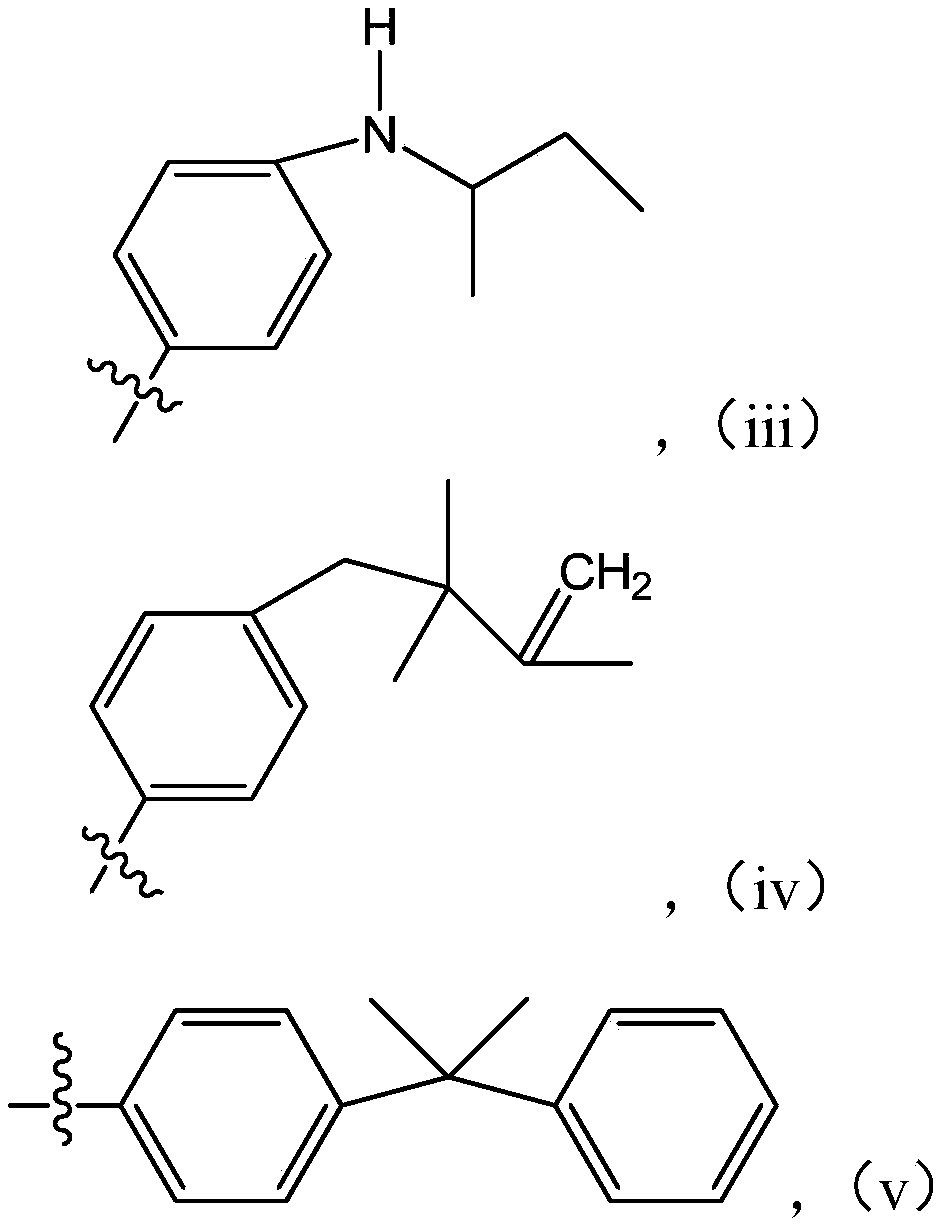

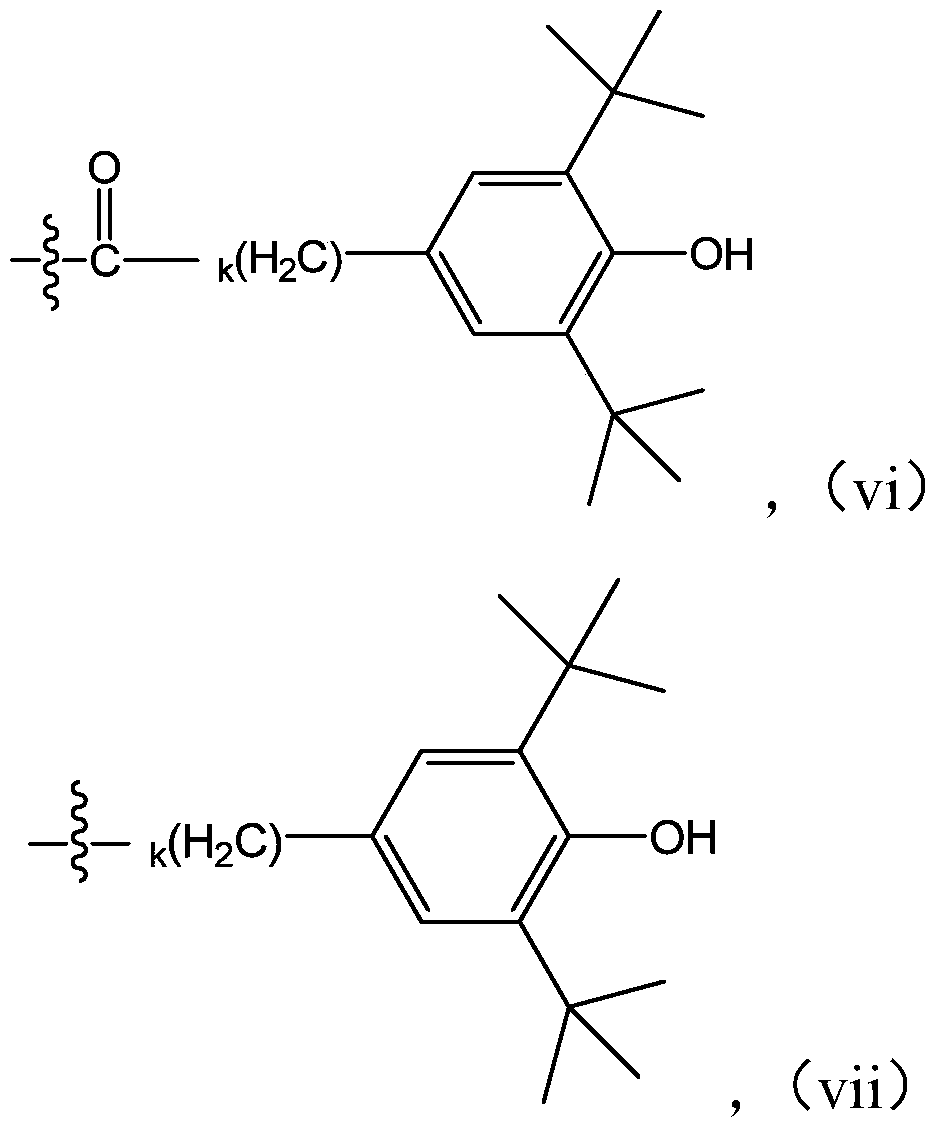

Method used

Image

Examples

Embodiment 1

[0078] The method for the color number of stable diisocyanate product, comprises the steps:

[0079] (1) Prepare a closed galvanized barrel (volume of 210L) filled with toluene diisocyanate TDI-80 industrial products. After testing, the APHA color number of TDI-80 industrial products is 7#;

[0080] (2) Preparation of 4,4'-bis-(2,3,3-trimethyl-1-butenyl)diphenylamine and bis(1,2,2,6,6-pentamethyl-4-piper The mixture of pyridyl) sebacate, the mass ratio of the two in the mixture is 2:1, and the mixture is stirred and mixed for 30 minutes according to the rotating speed of 200 rev / min, and the functional color reducing agent is prepared. The obtained functional color reducer has a viscosity of 1325 Pa·s (at 25° C.).

[0081] (3) Add the above-mentioned functional color reducer to the closed galvanized barrel that is equipped with toluene diisocyanate TDI-80 industrialized product, the addition of the functional color reducer is 0.0300% of TDI-80 quality %; After shaking with a...

Embodiment 2

[0085] The method for the color number of stable diisocyanate product, comprises the steps:

[0086] (1) Prepare a closed galvanized barrel (volume 210L) filled with toluene diisocyanate TDI-80 industrial products. After testing, the APHA color number of TDI-80 industrial products is 5#;

[0087] (2) Preparation of 4,4'-di(phenylisopropyl)diphenylamine and N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexyl The mixture of diamines, the mass ratio of the two in the mixture is 4:1, is stirred and mixed at a speed of 200 rpm for 30 minutes, and a functional color reducer is prepared. The obtained functional color reducer has a viscosity of 1200 Pa·s (at 25° C.).

[0088] (3) Add the above-mentioned functional type color reducer to the closed galvanized barrel that is equipped with toluene diisocyanate TDI-80 industrialized product, the addition of the functional type color reducer is 0.0200% of TDI-80 quality %; after shaking with a bucket shaker, store it in a -30°C...

Embodiment 3

[0092] The method for the color number of stable diisocyanate product, comprises the steps:

[0093] (1) Prepare a closed galvanized barrel (volume 210L) filled with diphenylmethane diisocyanate MDI-50 industrialized product. After testing, the APHA color number of MDI-50 industrialized product is 9#;

[0094] (2) Preparation of a mixture of 4,4'-di(phenylisopropyl)diphenylamine and bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate, the mixture The mass ratio of the two is 2.5:1, and the mixture is stirred and mixed for 30 minutes at a speed of 200 rpm to prepare a functional color reducer. The obtained functional color reducer has a viscosity of 1287 Pa·s (at 25° C.).

[0095] (3) Add the above-mentioned functional type color reducer prepared to the closed galvanized barrel that diphenylmethane diisocyanate MDI-50 industrialized product is housed, the addition of functional type color reducer is MDI-50 0.0250% by mass; after shaking with a bucket shaker, store in a -10°C fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com