A kind of all-glazed Jun porcelain spherical glaze beads and preparation method thereof

A spherical and Jun porcelain technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as the difficulty in producing spherical glaze beads with full glaze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

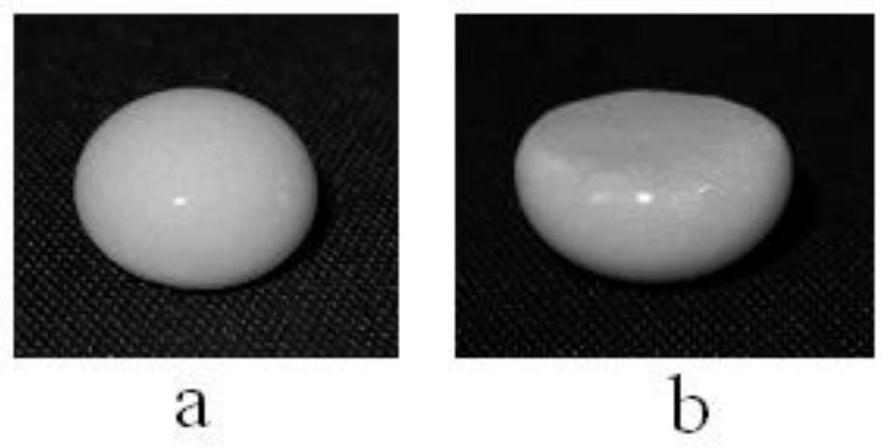

[0021] The invention provides a preparation method of full-glazed Jun porcelain spherical glaze beads, comprising the following steps:

[0022] a) In parts by weight, mix 42 to 48 parts of yellow feldspar, 18 to 22 parts of potassium feldspar, 13 to 18 parts of quartz, 4 to 6 parts of talc and 13 to 18 parts of calcite, ball mill to obtain a glaze slurry, pass 120 Mesh sieve, after drying, grind into powder, add water, and make the glaze mud into balls to obtain glaze balls;

[0023] b) Place a corundum plate covered with ultra-fine alumina micropowder on the shed plate as the setter plate, disperse the glaze balls on the setter plate, and use the method of first oxidation and then reduction for glaze firing, the temperature of glaze firing The temperature is 1260~1300℃, and the spherical glaze beads of full-glazed Jun porcelain are obtained.

[0024] The method provided by the present invention uses the above-mentioned amount of raw materials to directly prepare glaze balls,...

Embodiment 1

[0044] 1. Bottom glaze: Mix 45 parts by weight of yellow feldspar, 20 parts by weight of potassium feldspar, 15 parts by weight of quartz, 5 parts by weight of talc, and 15 parts by weight of calcite according to the proportion, add an appropriate amount of water, and place Mill in a ball mill for 12 hours, then pass the glaze slurry through a 120-mesh sieve, and the sieve balance is less than 0.5%; dry the glaze slurry that has been ball-milled naturally in the sun, and grind it into powder; directly add a small amount of water to moisten the glaze mud. Process it into a glaze ball with a diameter of 2 cm and let it dry.

[0045] 2. Glaze firing device: use a smooth and flat corundum plate as the firing plate, and spread a layer of ultrafine alumina powder with a thickness of 0.5 mm on it, and disperse the glaze balls on the alumina powder.

[0046] 3. Glaze firing: firing with the firing system of first oxidation and then reduction, the firing temperature is 1260-1300°C, an...

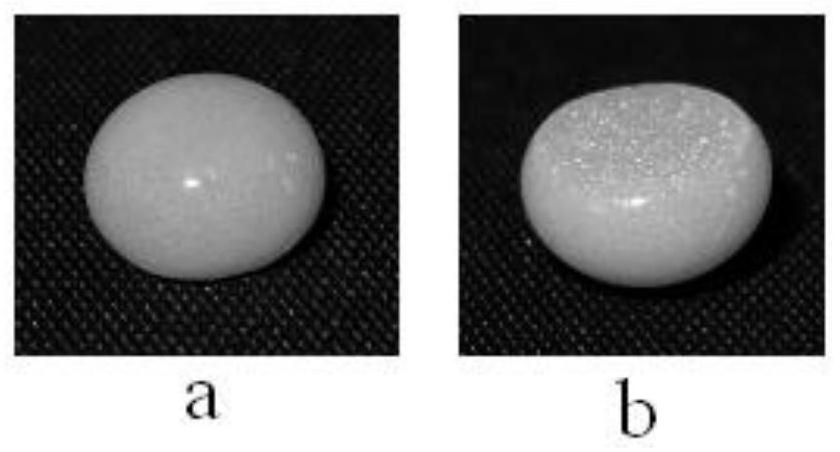

Embodiment 2

[0049] 1. Bottom glaze: Mix 45 parts by weight of yellow feldspar, 20 parts by weight of potassium feldspar, 15 parts by weight of quartz, 5 parts by weight of talc, and 15 parts by weight of calcite according to the proportion, add an appropriate amount of water, and place Mill it in a ball mill for 12 hours, then pass the glaze slurry through a 120-mesh sieve, and the sieve residue is less than 0.5%. Dry the glaze slurry that has been ball-milled naturally in the sun, and grind it into powder; directly add a small amount of water to the glaze powder to wet it into glaze mud; process the glaze mud into a glaze ball with a diameter of 2cm, to dry.

[0050] 2. Top glaze configuration: The top glaze is sky blue colored top glaze. Mix 55 parts by weight of feldspar, 15 parts by weight of quartz, 14 parts by weight of kaolin, 15 parts by weight of calcite and 1 part by weight of iron ore according to the proportion, add an appropriate amount of water, and place in a planetary bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com