Liquid steel slag dry-process granulating device and sensible heat recovery method

A liquid steel slag and sensible heat recovery technology, which is applied in the field of iron and steel metallurgy, can solve the problems of low heat recovery efficiency, large granulator volume, and high energy consumption of the system, and achieve high heat recovery efficiency, complete recovery, and reduced height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

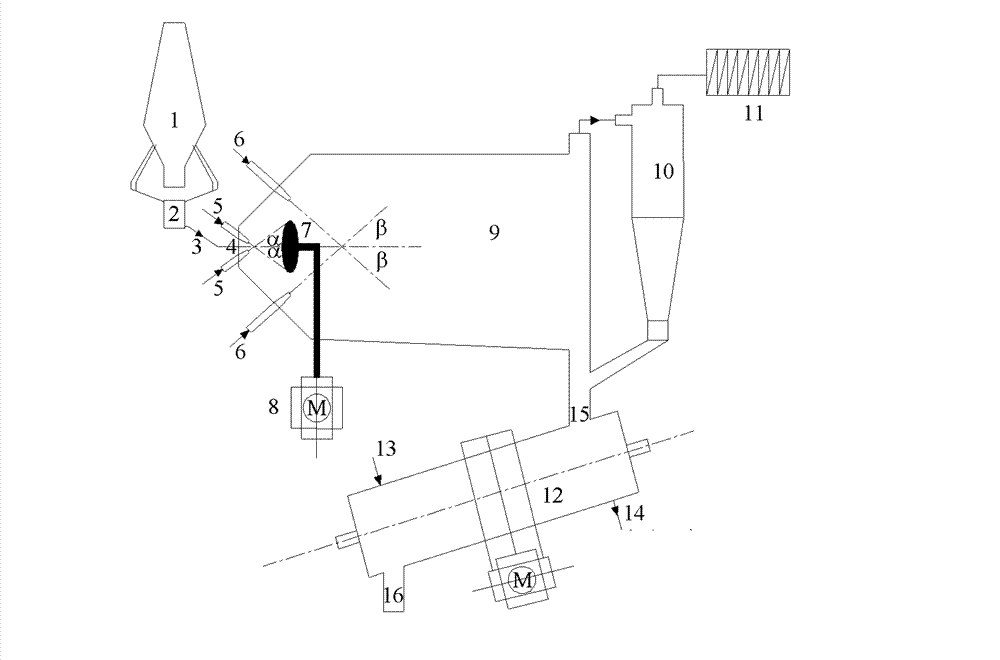

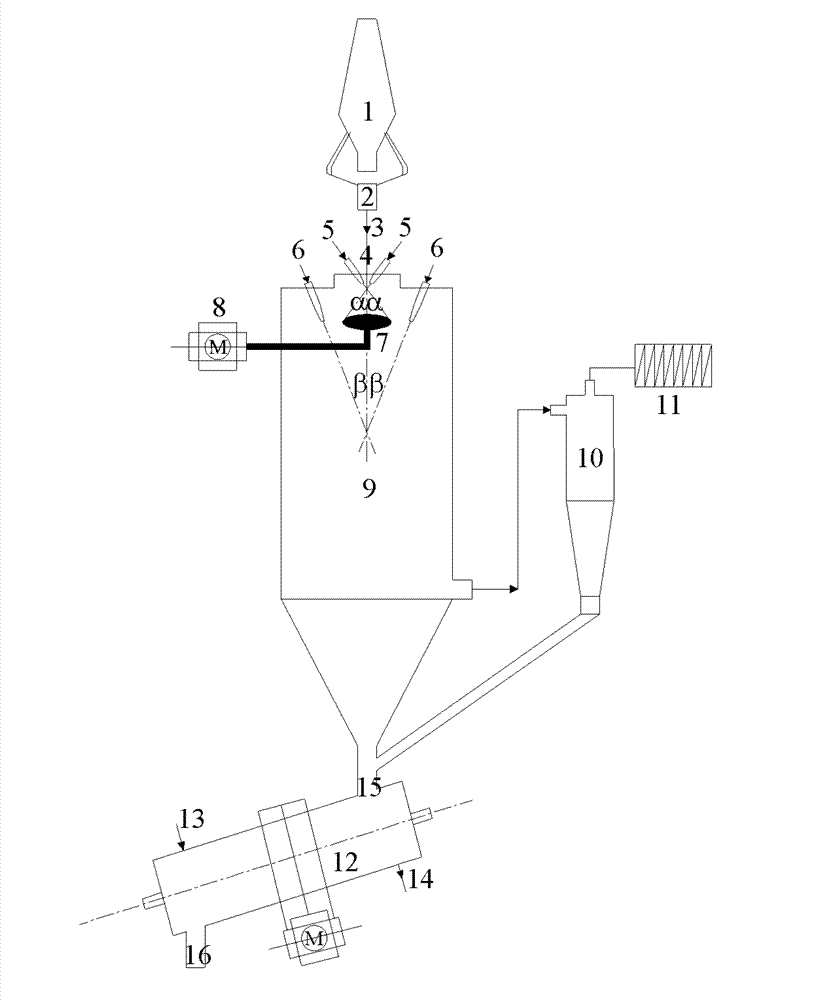

[0036] Embodiment 1: a liquid steel slag dry granulation device, such as figure 1 or figure 2 As shown, it includes a feed device, a dry granulator, a cyclone separator, a drum-type sensible heat recovery device, and a waste heat boiler connected to the upper part of the cyclone separator. The dry granulator, cyclone separator, and drum-type sensible heat recovery The heat recoverers communicate with each other.

[0037] Wherein, the feeding device includes a material storage container 2 and a diversion tank 3, both of which are made of refractory materials, and are arranged on the bottom or side of the slag discharge port of the blast furnace 1, and a liquid steel slag discharge port 4 is provided at the bottom of the diversion tank 3 and is connected with the The dry granulators 9 are connected, and the slag outlet 4 is round or flat and rectangular. The material storage container 2 mentioned above is 1m higher than the liquid steel slag drop outlet 4, and the diversion g...

Embodiment 2

[0044] Embodiment two: a kind of liquid steel slag dry granulation device, such as figure 1 or figure 2 As shown, the storage container 2 is 3m higher than the liquid steel slag drop outlet 4, and the diversion groove 3 forms an inclination angle of 20° with the horizontal plane; the bottom of the dry granulator 9 is parallel to the horizontal plane.

[0045] The angle α between the outlet axis of the low-pressure granulation nozzle and the horizontal line is 90°; the pressure of the sprayed low-pressure airflow is 0.05MPa. The angle β between the outlet axis of the high-pressure granulation nozzle 6 and the horizontal line is 25°. The particle size distribution of solid particles carried by the airflow is 0.01mm.

[0046] Described high-speed turntable 7 rotating speeds are 2000 rev / mins. The drum type sensible heat recovery device is 5° away from the ground. All the other are the same as embodiment one.

Embodiment 3

[0047] Embodiment three: a kind of liquid steel slag dry granulation device, such as figure 1 or figure 2 As shown, the storage container 2 is 1.5m higher than the liquid steel slag drop outlet 4, and the diversion tank 3 is at an angle of 50° to the horizontal plane; the bottom of the dry granulator 9 is at a 45° angle to the horizontal plane.

[0048] The angle between the outlet axis of the low-pressure granulation nozzle and the horizontal line α is 20°; the pressure of the sprayed low-pressure airflow is 0.5MPa. The angle β between the outlet axis of the high-pressure granulation nozzle 6 and the horizontal line is 90°. The particle size distribution of solid particles carried by the airflow is 0.08mm.

[0049] Described high-speed turntable 7 rotating speeds are 20000 rev / mins. The drum-type sensible heat recovery device is at 40° to the ground. All the other are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com