Experimental method for desulfurizing and deashing coal by utilizing permeation and dissolution capacity of supercritical fluid

A technology of supercritical fluid and solvency, applied in separation methods, solid solvent extraction, chemical instruments and methods, etc., to achieve the effects of easy temperature and pressure control, good mass transfer, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

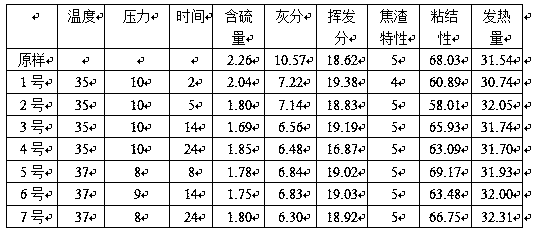

[0020] The present invention will be further described below in conjunction with specific examples.

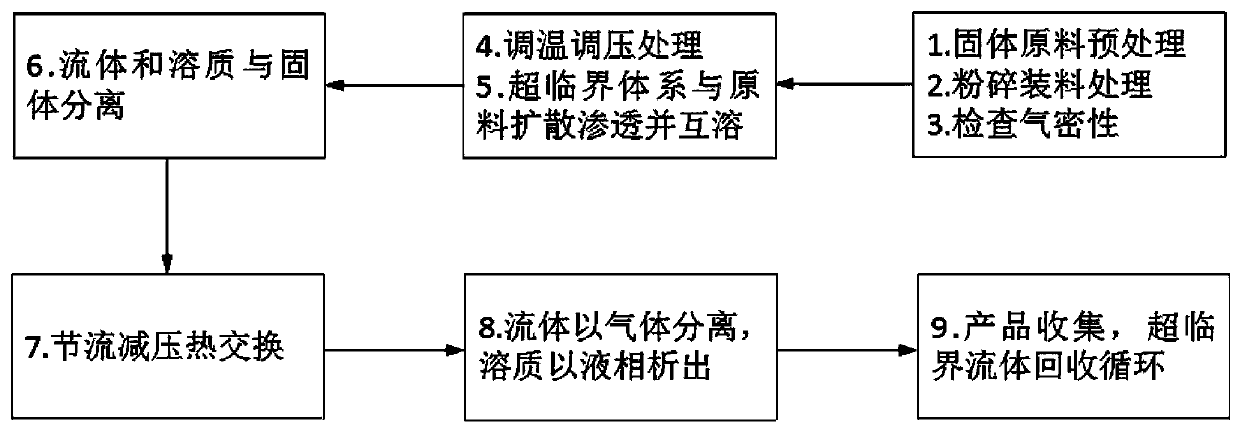

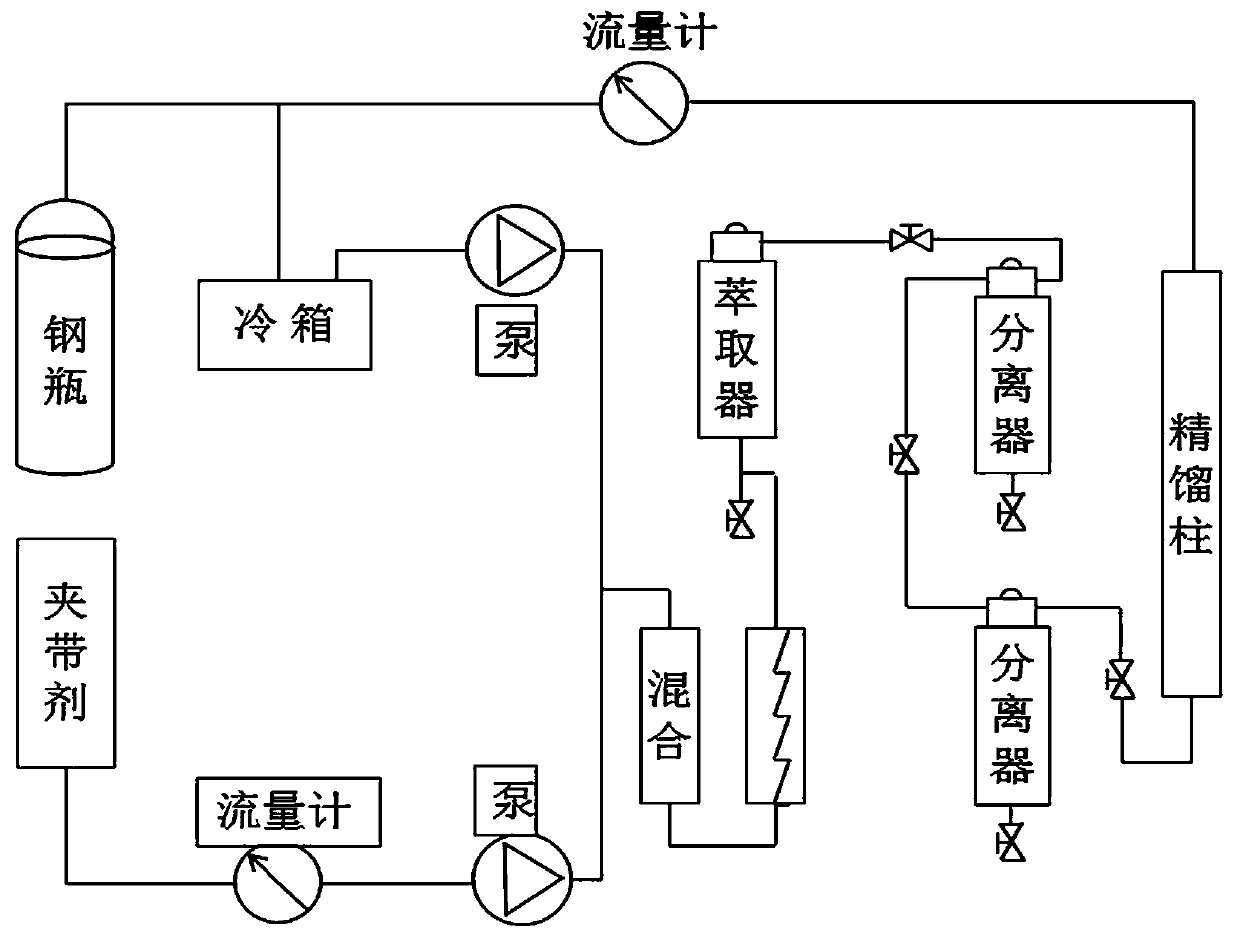

[0021] An experimental method for desulfurization and deashing of coal by using the infiltration and dissolution ability of supercritical fluid, such as figure 1 , figure 2 shown, including the following steps:

[0022] (1) Pretreatment as it is: crush the coal sample to a certain particle size, and the particle size of the coal sample is 1-3mm or 3-6mm;

[0023] (2) Exclude the air and impurities in the kettle body: use a full-boring quick-opening reactor, open the inlet and outlet valves of the extraction kettle to connect with the supercritical fluid storage container, and use supercritical CO 2 The fluid circulates through the entire closed-circuit system, and the auxiliary pump carries ethanol to clean the pipeline, and closes the outlet valve of the extraction kettle to ensure that the airtightness is intact;

[0024] (3) Material canning: put the coal sample in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com