Optical element, liquid crystal display device, and projection-type image display device

A technology of optical elements and compensating elements, which is applied in the direction of optical elements, optical elements, optics, etc., can solve the problems of insufficient space for configuring polarizing plates or phase difference compensation plates, problems in durability, and difficulty in adapting to miniaturization, etc., and achieve high suppression Effects of reducing costs, realizing reductions, and reducing adjustment man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0107] [Preparation method of polarizer]

[0108] The polarizer constituting the optical element of the present invention can be produced by going through a metal film forming step, a first dielectric film forming step, an absorbing film forming step, and an etching step.

[0109] In the metal film forming step, a metal film that becomes a linear metal layer in a subsequent etching step is formed on the entire substrate surface on one side of the transparent substrate. In the first dielectric film forming step, the first dielectric film that becomes the first dielectric layer through the subsequent etching step is laminated on the entire surface of the metal film formed in the metal film forming step. In the absorbing film forming step, an absorbing film to be an absorbing layer through the subsequent etching step is laminated on the entire surface of the first dielectric film formed in the first dielectric film forming step. In these respective formation steps, various films...

Embodiment 1

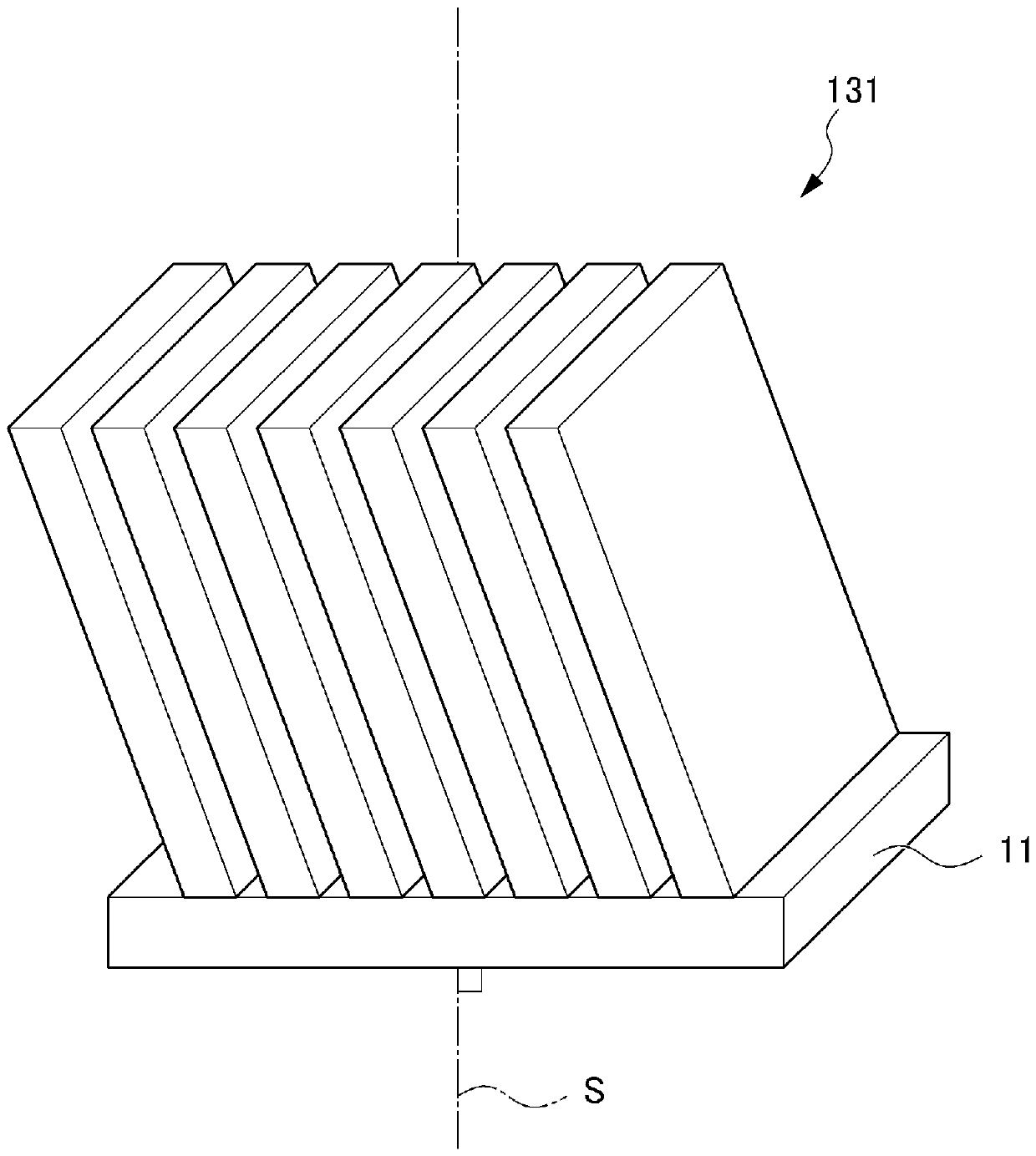

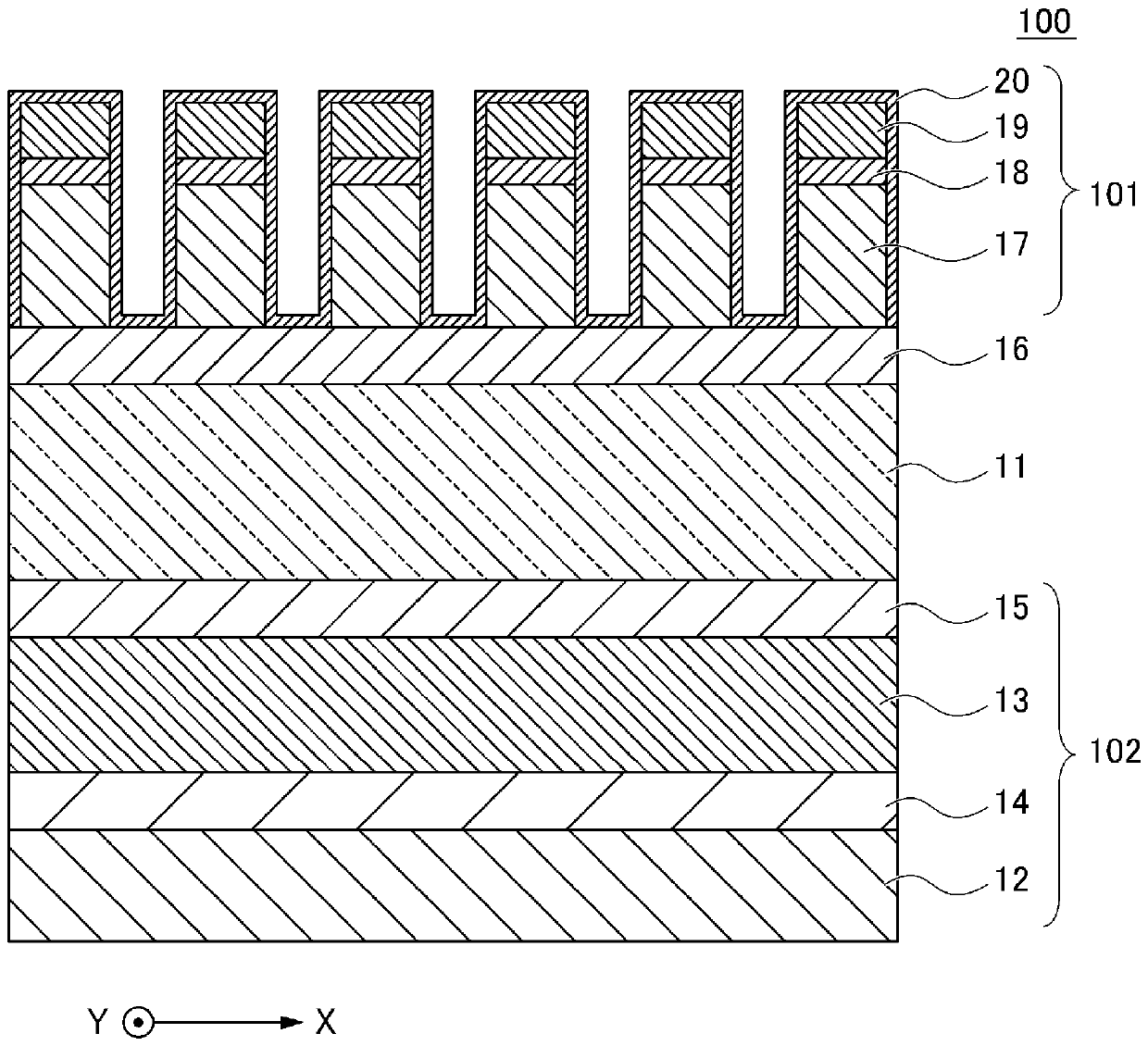

[0155] In Example 1, making figure 1 Optical elements of the composition shown.

[0156] [Production of polarizer]

[0157] (Formation of the third dielectric layer)

[0158] On one side of the glass substrate (average thickness 0.7 mm), SiO 2 Film formation, thereby forming the third dielectric layer ( figure 1 The third dielectric layer 16).

[0159] (formation of metal film)

[0160] Next, an Al film was formed on the third dielectric layer by a sputtering method to form a metal film.

[0161] (Formation of the first dielectric film)

[0162] Next, on the metal film, the SiO 2 The film is formed to form a first dielectric film.

[0163] (formation of absorbing film)

[0164] Next, Si is formed into a film by sputtering on the first dielectric film to form an absorption film.

[0165] (Formation of grid-like protrusions)

[0166] Next, a resist is applied on the absorbing film, followed by exposure and development to form a resist pattern. Then, etching is perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com