Patents

Literature

40results about "Robotics systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

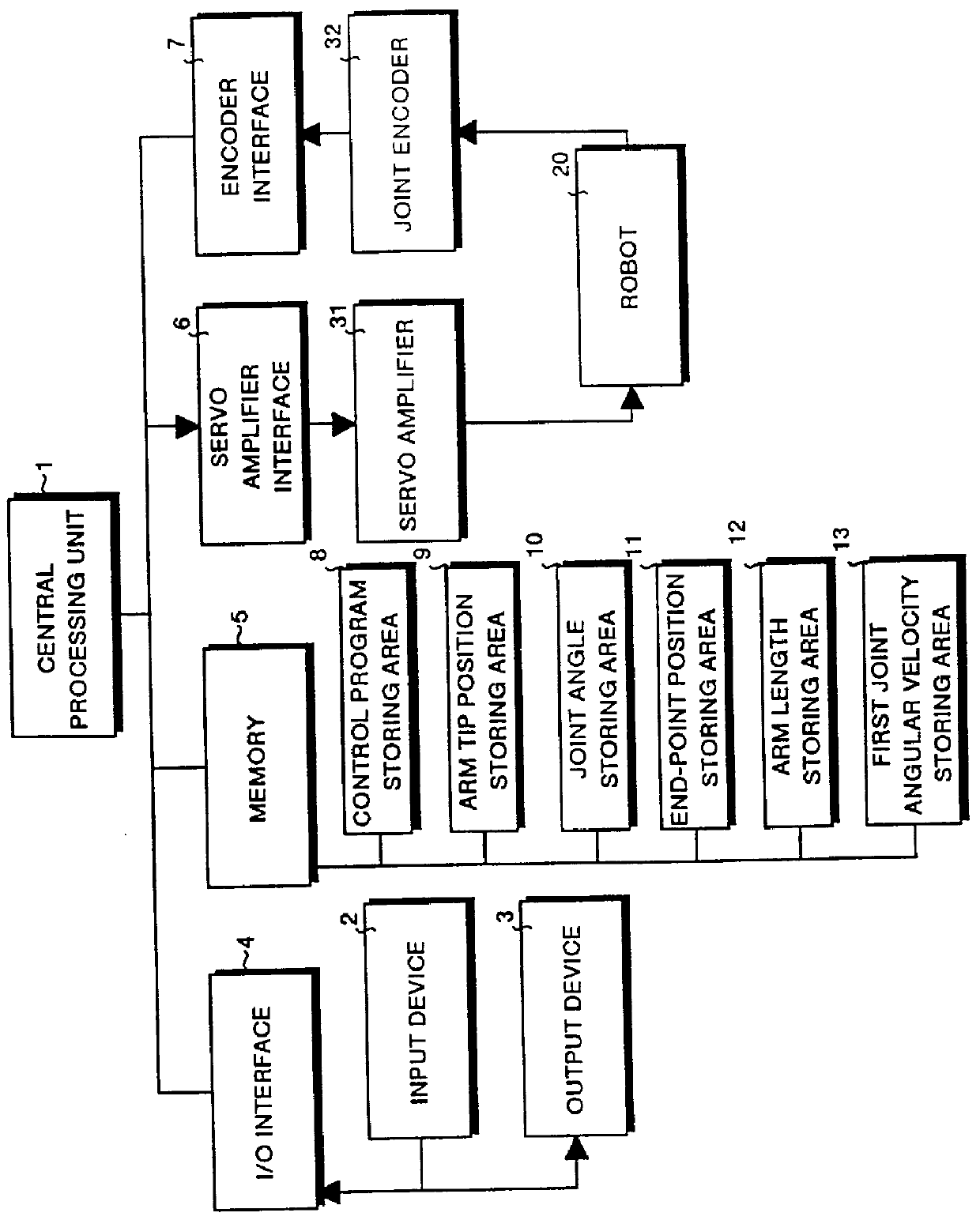

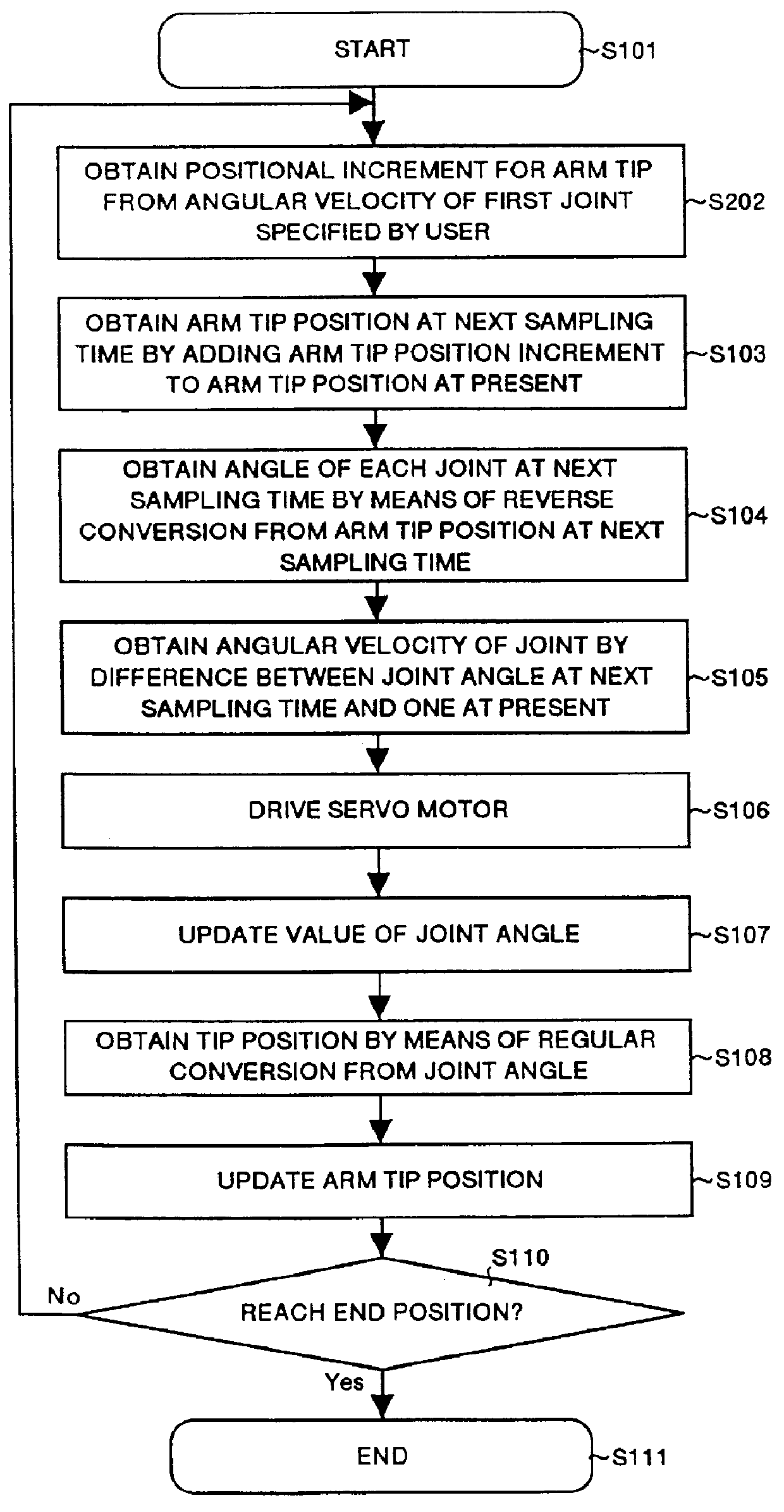

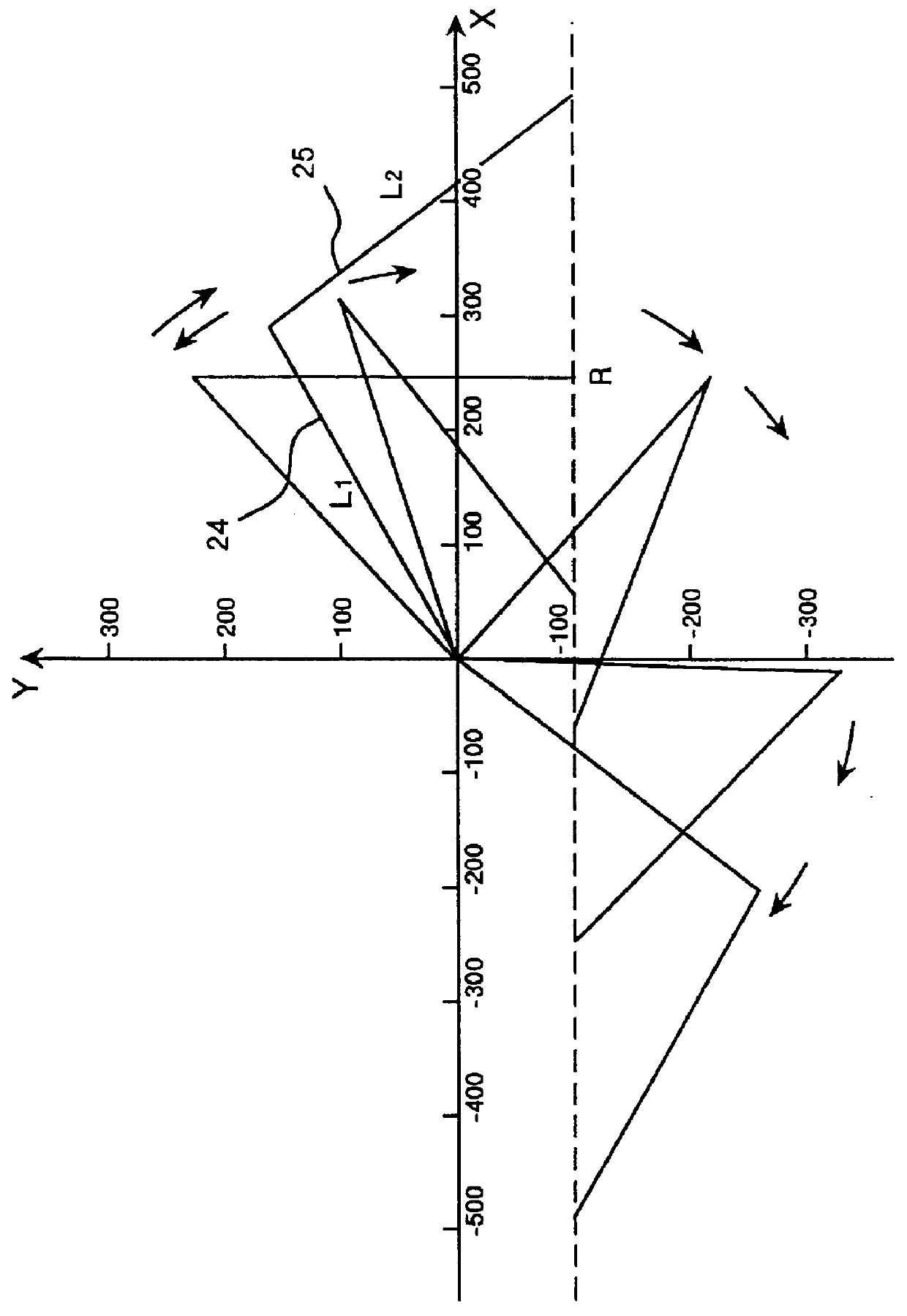

Trajectory control apparatus and trajectory control method for intra-planar multifreedom SCARA type of robot, and computer-readable recording medium with trajectory control program for intra-planar multifreedom SCARA type of robot stored therein

In a trajectory control method for an intra-planar multifreedom SCARA type of robot, a positional increment for an arm tip is computed for a linear interpolating operation through the expression described below. Namely, the expression is Vn=L.sub.1 .multidot.sin(.theta..sub.2).multidot.J.sub.1, wherein Vn indicates a positional increment of an arm tip; L.sub.1 indicates a length of a first arm; .theta..sub.2 indicates an angle of a second joint; and J.sub.1 indicates an angular velocity of a first joint (instructed angular velocity) specified by a user.

Owner:MITSUBISHI ELECTRIC CORP

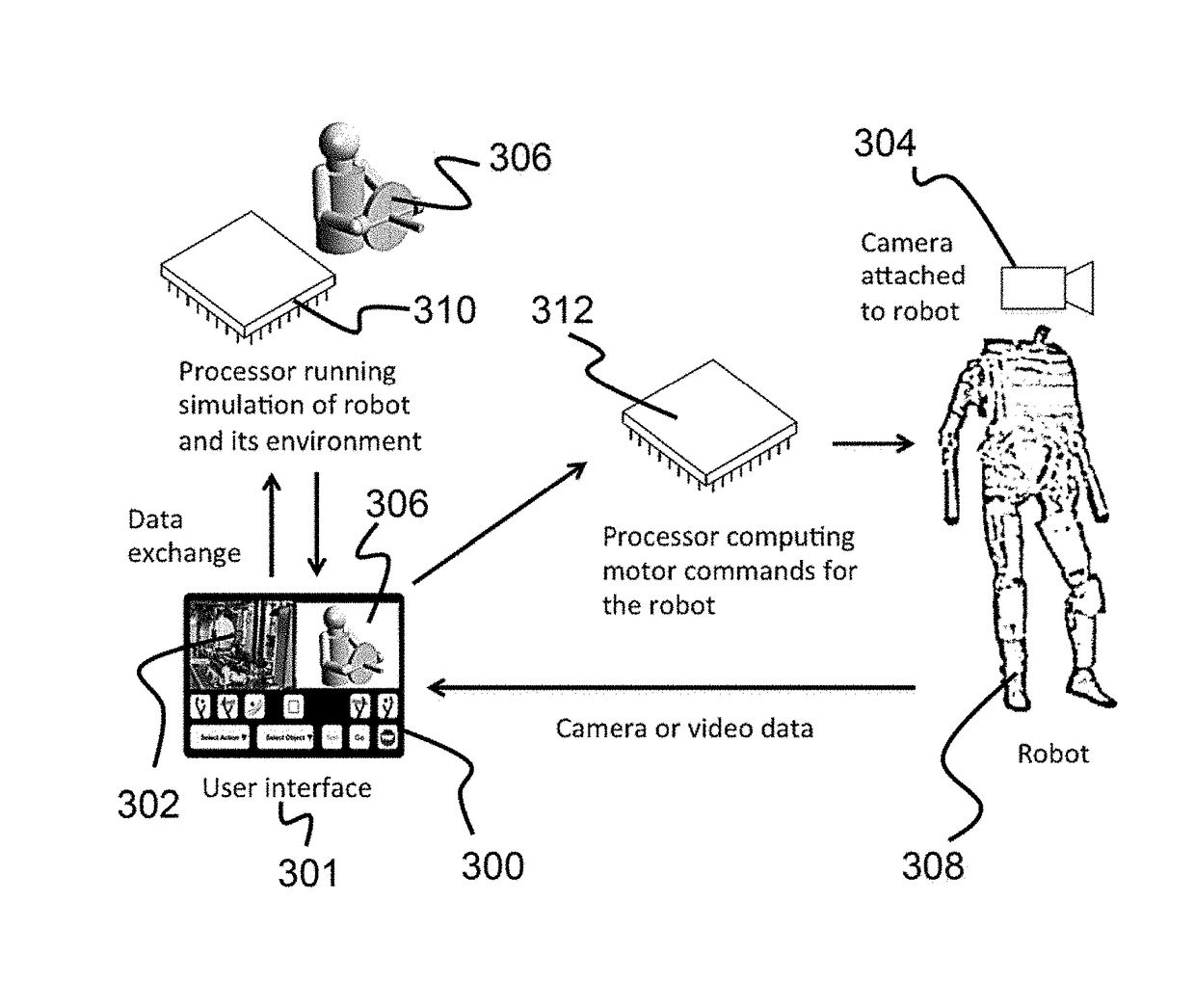

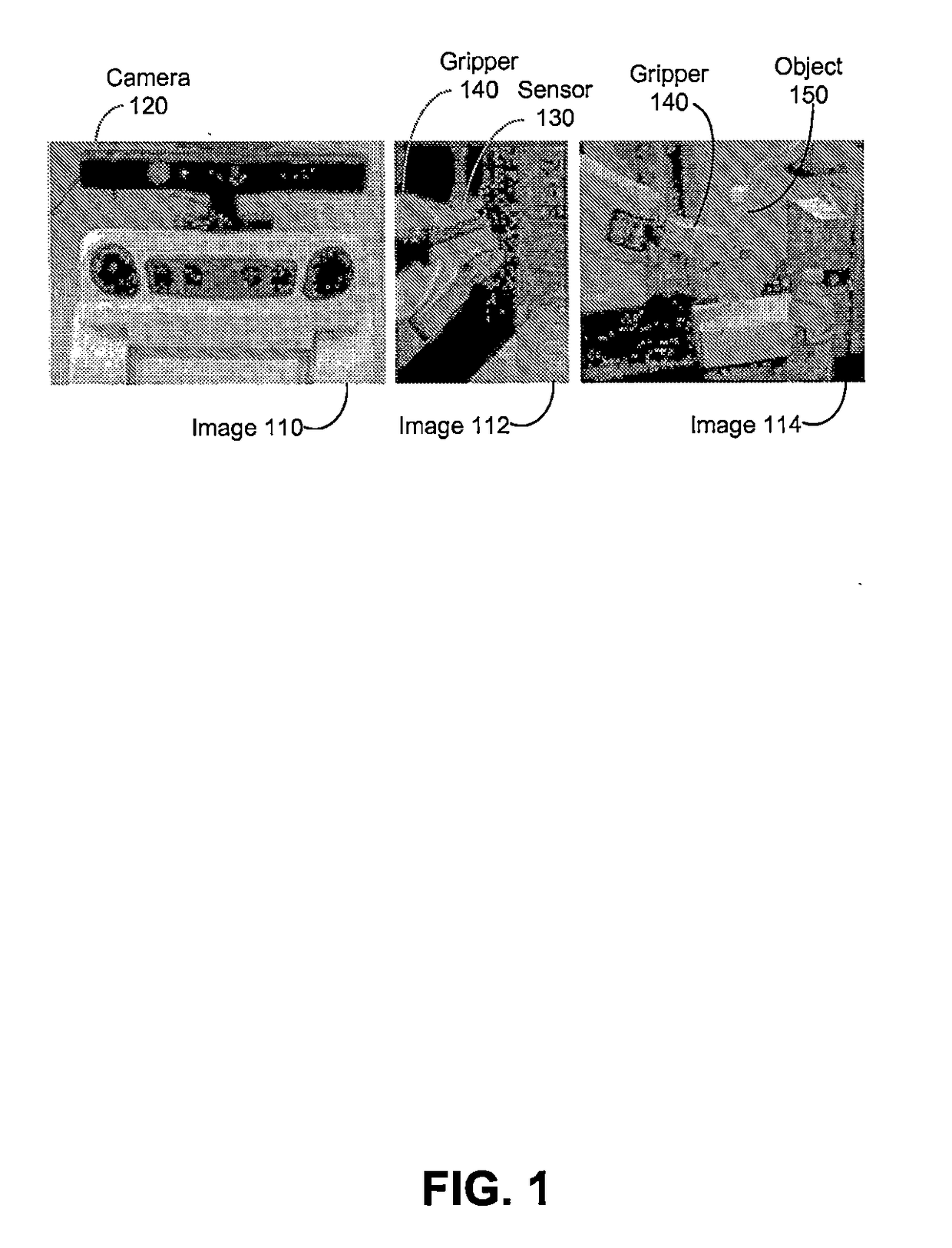

System and method for robot supervisory control with an augmented reality user interface

Described is a system for robot supervisory control. The system includes an operator device that receives camera imagery from a camera mounted on a robot and three-dimensional (3D) data from a 3D sensor mounted on the robot. The user interface displays a two-dimensional (2D) view of the scene from the camera and 3D sensor data. One or more object markers of objects in the scene are overlaid on the 2D view or 3D sensor data. Viewing the scene, the user can choose a robotic action from a library of actions, which generates a simulation of the robot performing the selected action. The simulation is then rendered and overlaid on top of the 3D sensor data. Moreover, the simulation shows the expected variability of the robot's action. Based on the simulation's outcome, the user can approve and trigger the execution of the action in the real robot.

Owner:HRL LAB

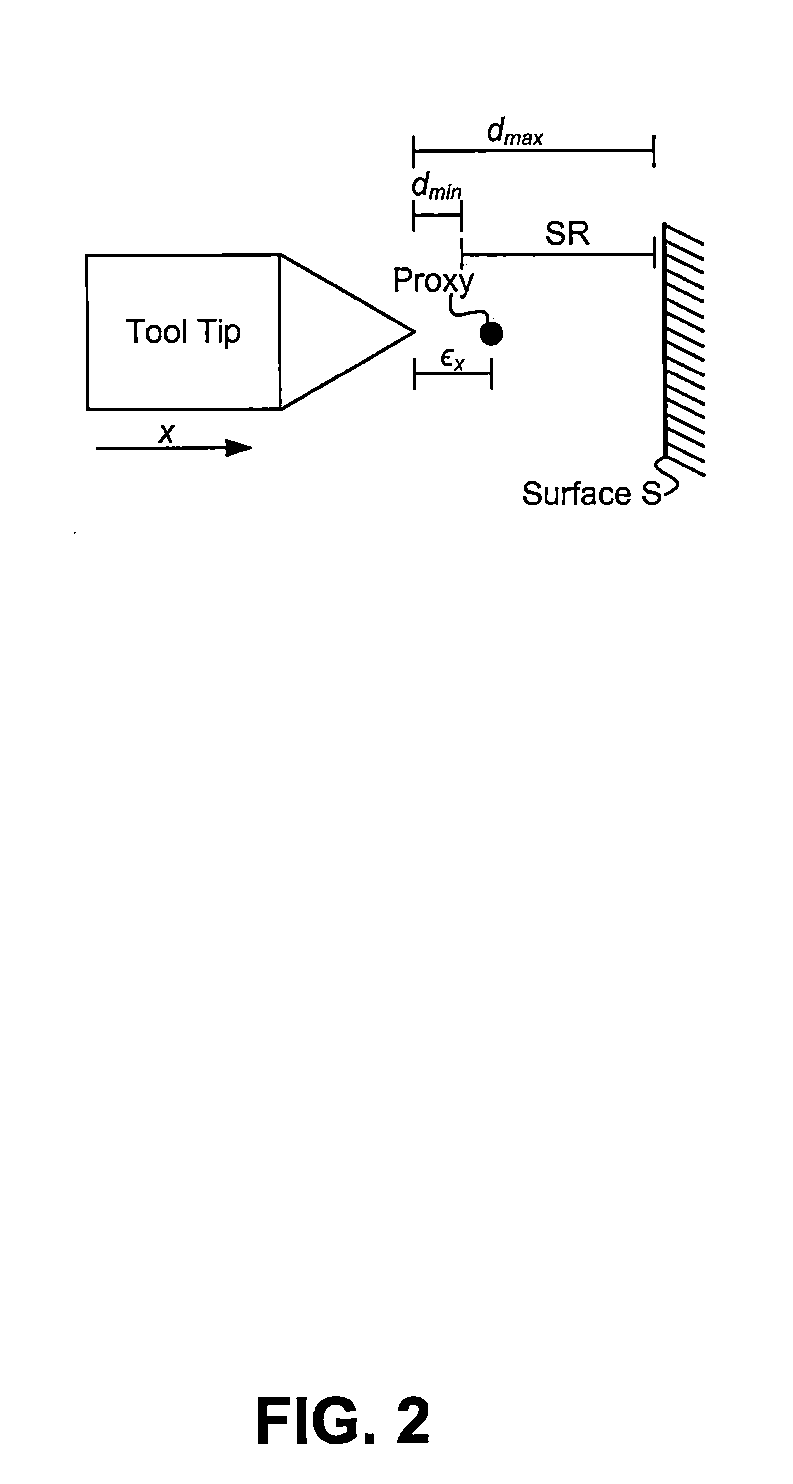

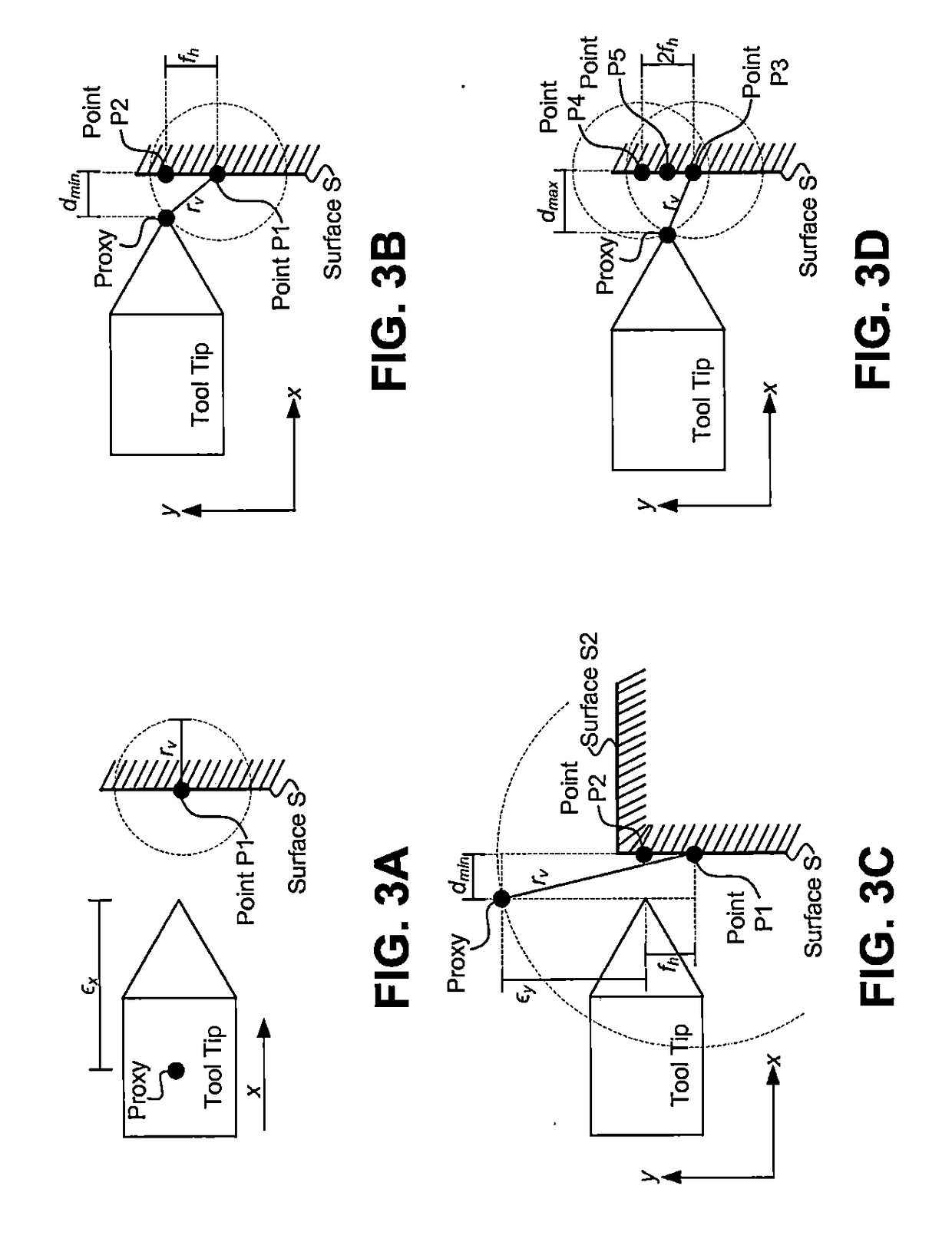

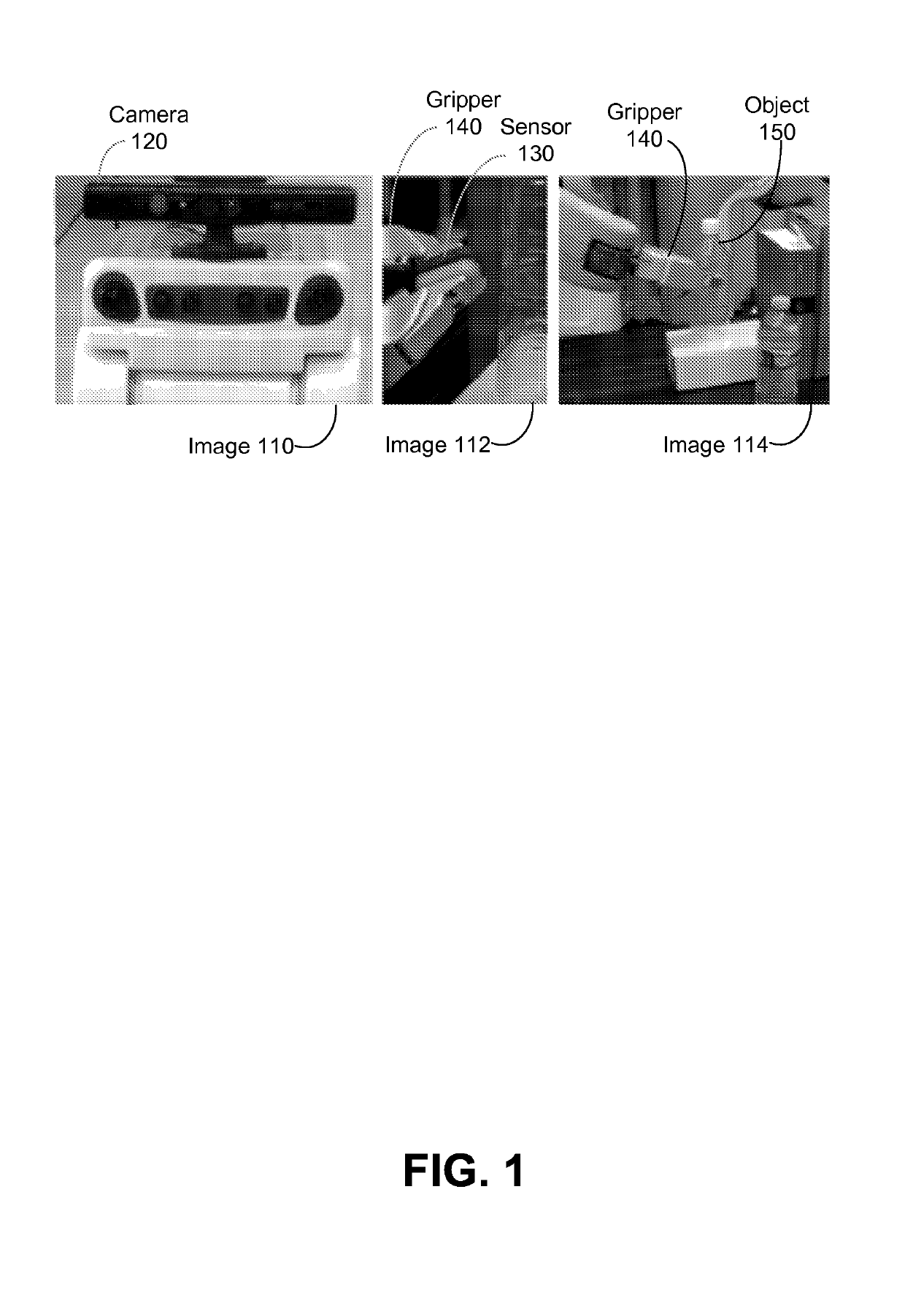

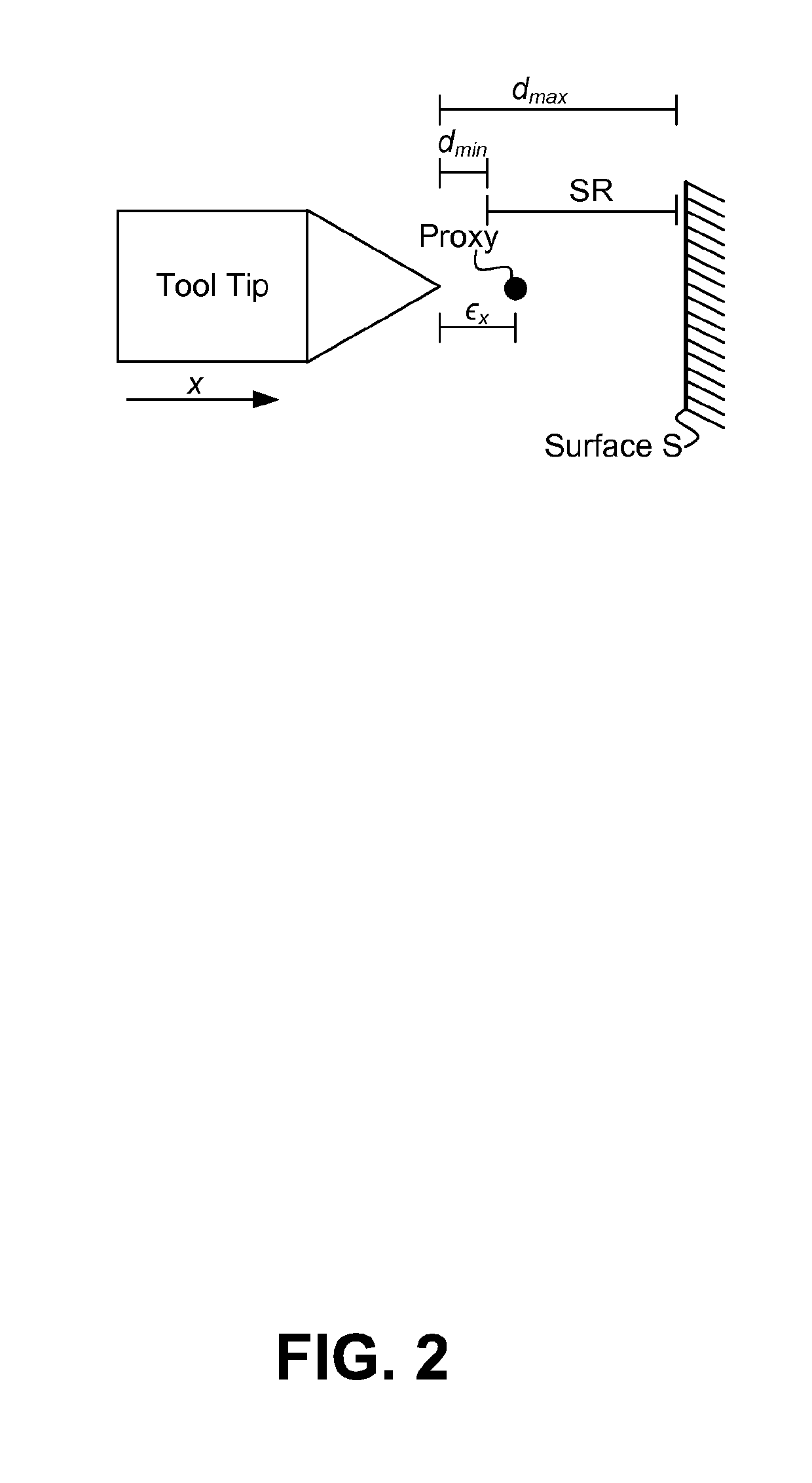

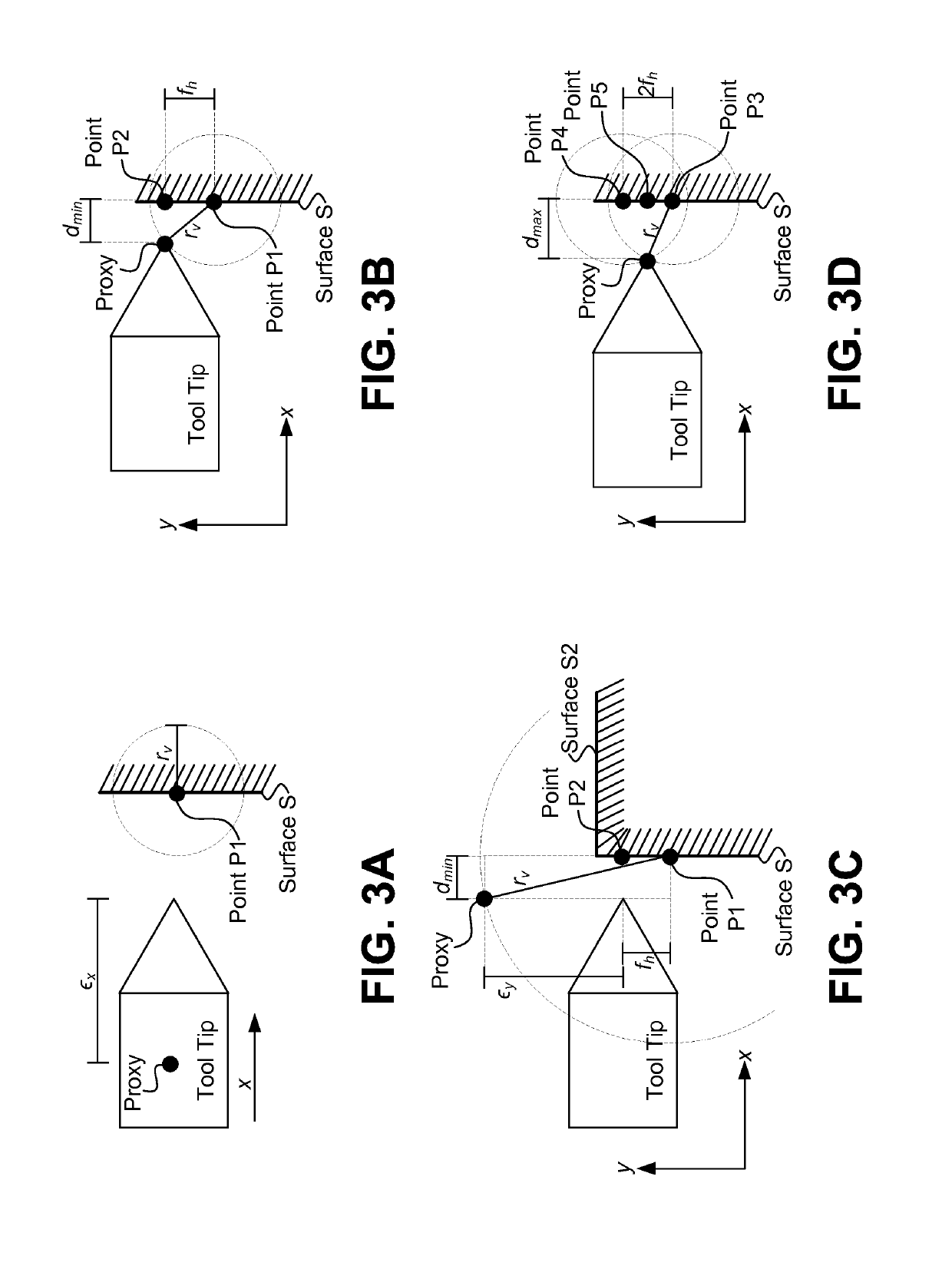

Integration of Auxiliary Sensors with Point Cloud-Based Haptic Rendering and Virtual Fixtures

ActiveUS20180232052A1Input/output for user-computer interactionImage analysisPoint cloudVirtual fixture

Owner:UNIV OF WASHINGTON

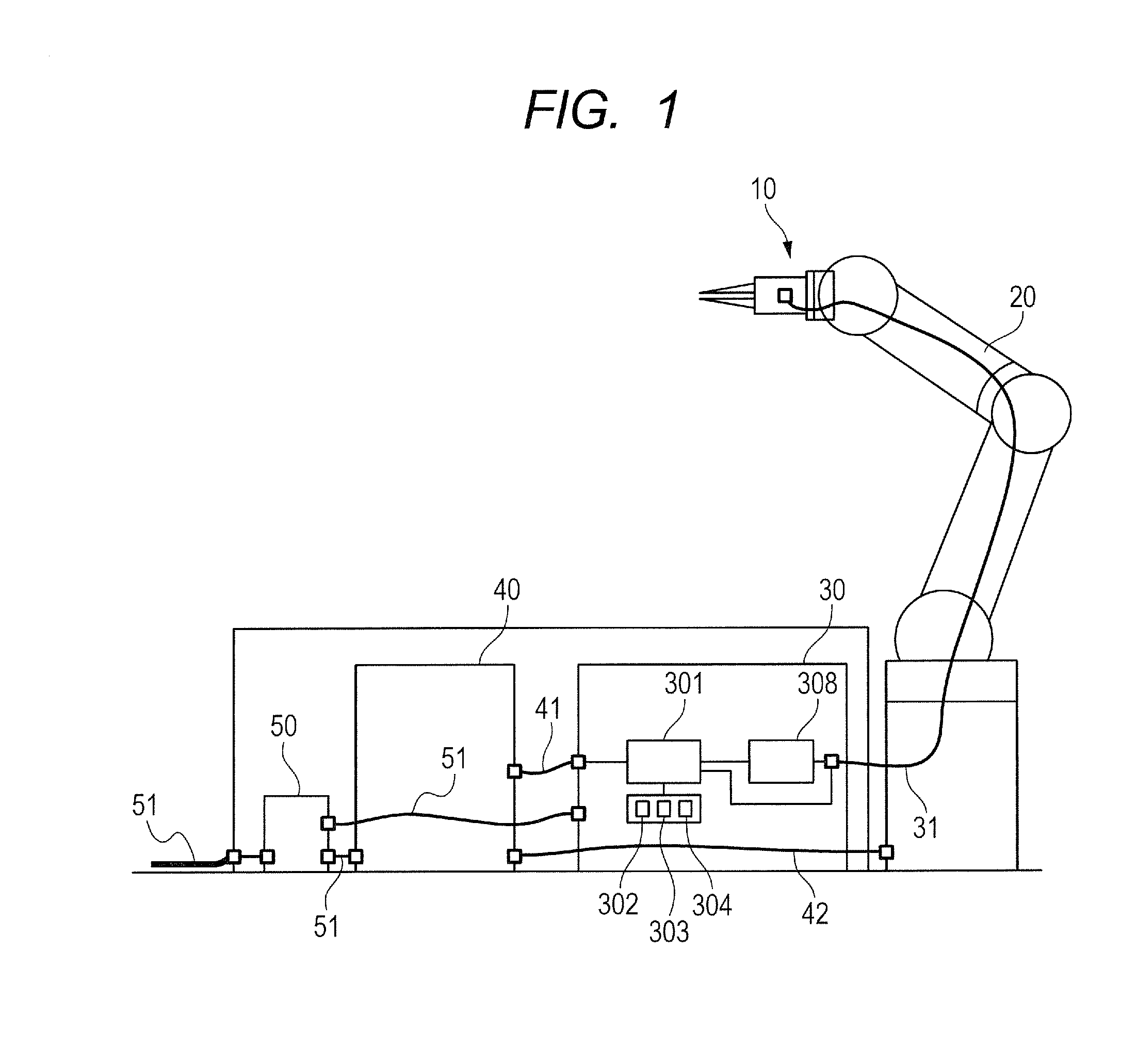

Robot hand controlling method and robotics device

ActiveUS20160221188A1Easy to adjustSimple configurationProgramme-controlled manipulatorRobotics systemsRoboticsRobot hand

Owner:CANON KK

Integration of auxiliary sensors with point cloud-based haptic rendering and virtual fixtures

ActiveUS10394327B2Input/output for user-computer interactionImage analysisPoint cloudVirtual fixture

Owner:UNIV OF WASHINGTON

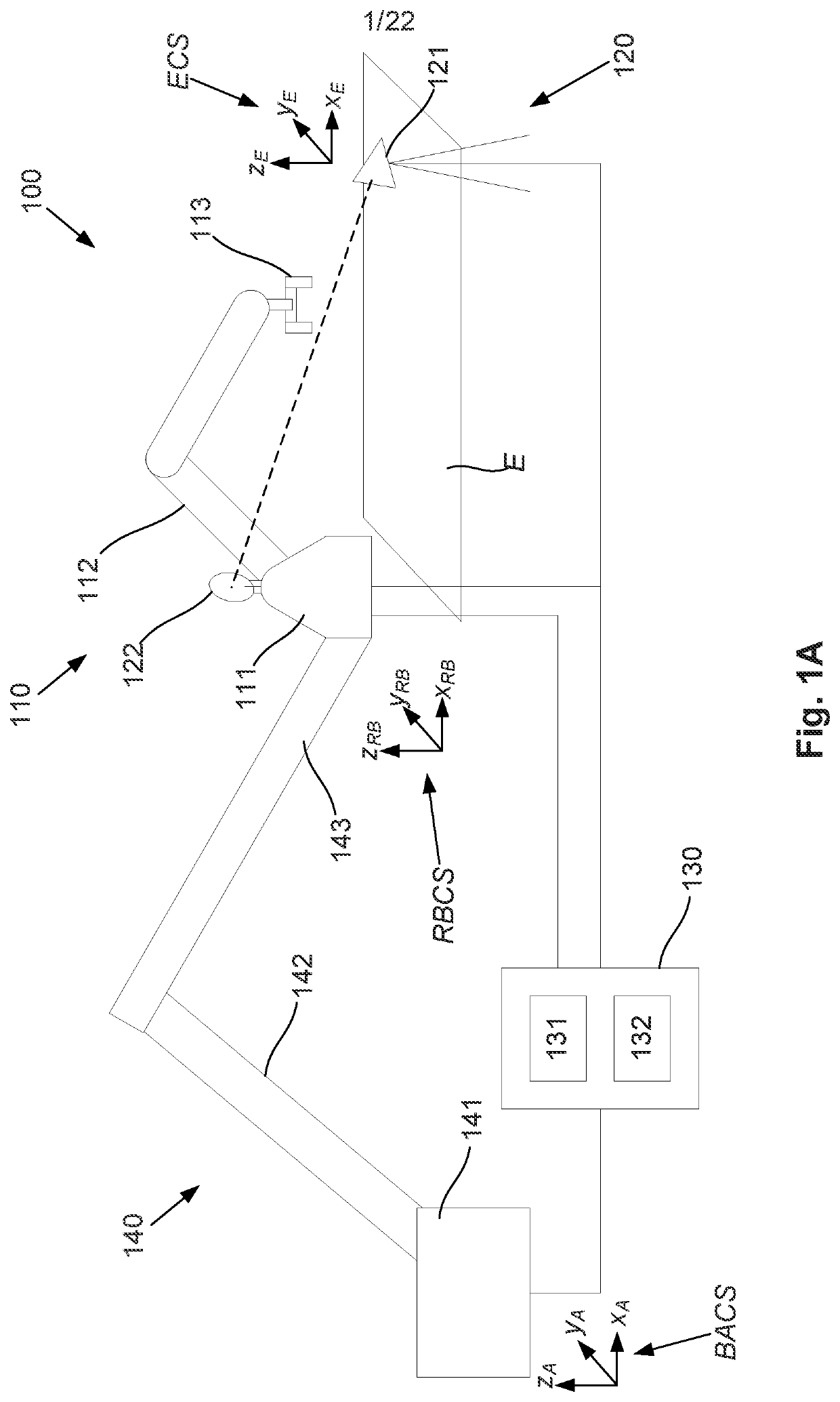

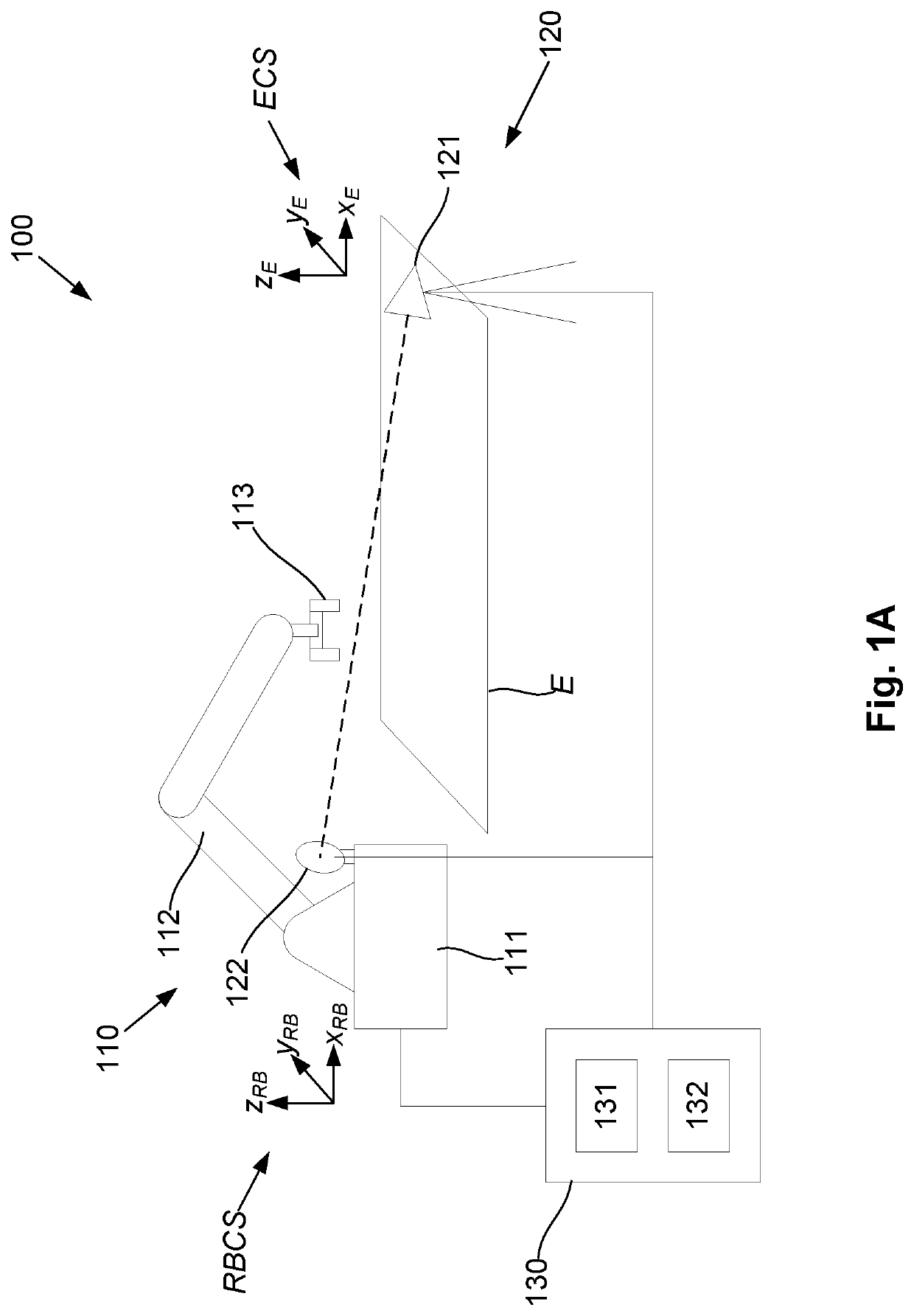

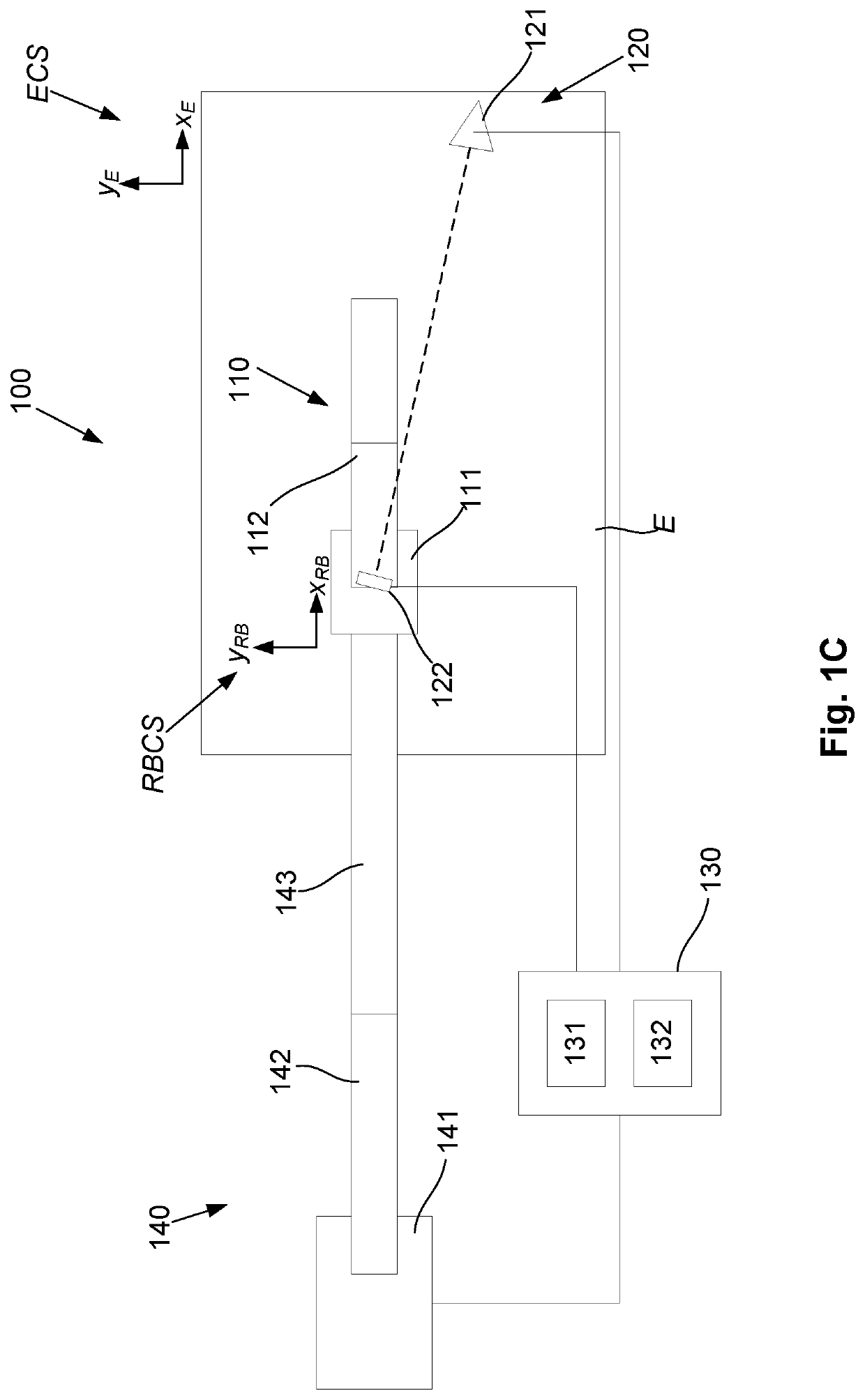

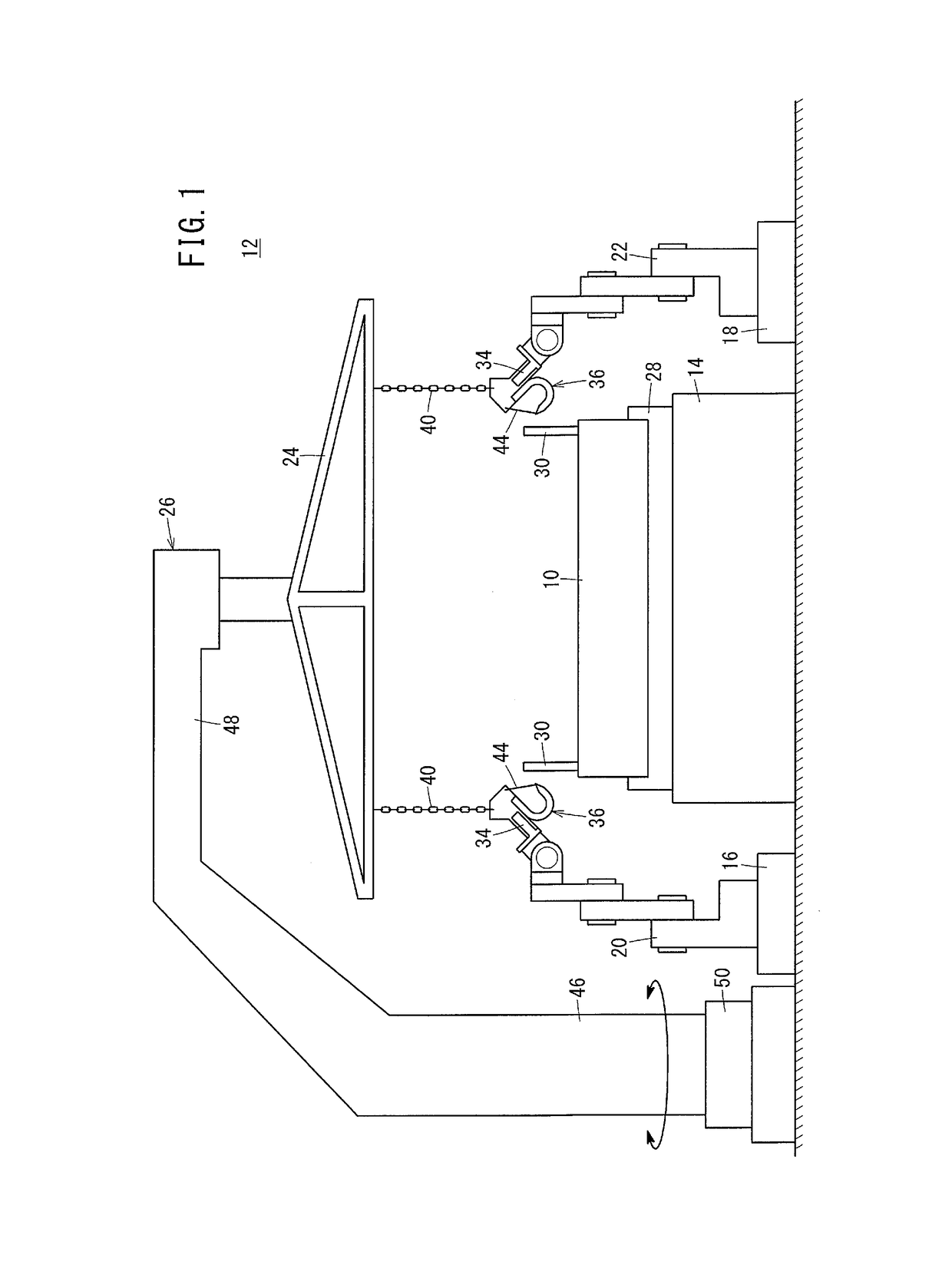

Active damping system

The present disclosure provides a system for performing interactions within a physical environment, the system including: (a) a robot base; (b) a robot base actuator that moves the robot base relative to the environment; (c) a robot arm mounted to the robot base, the robot arm including an end effector mounted thereon; (d) a tracking system that measures at least one of: (i) a robot base position indicative of a position of the robot base relative to the environment; and, (ii) a robot base movement indicative of a movement of the robot base relative to the environment; (e) an active damping system that actively damps movement of the robot base relative to the environment; and, (f) a control system that: (i) determines a movement correction in accordance with signals from the tracking system; and, (ii) controls the active damping system at least partially in accordance with the movement correction.

Owner:FASTBRICK IP PTY LTD

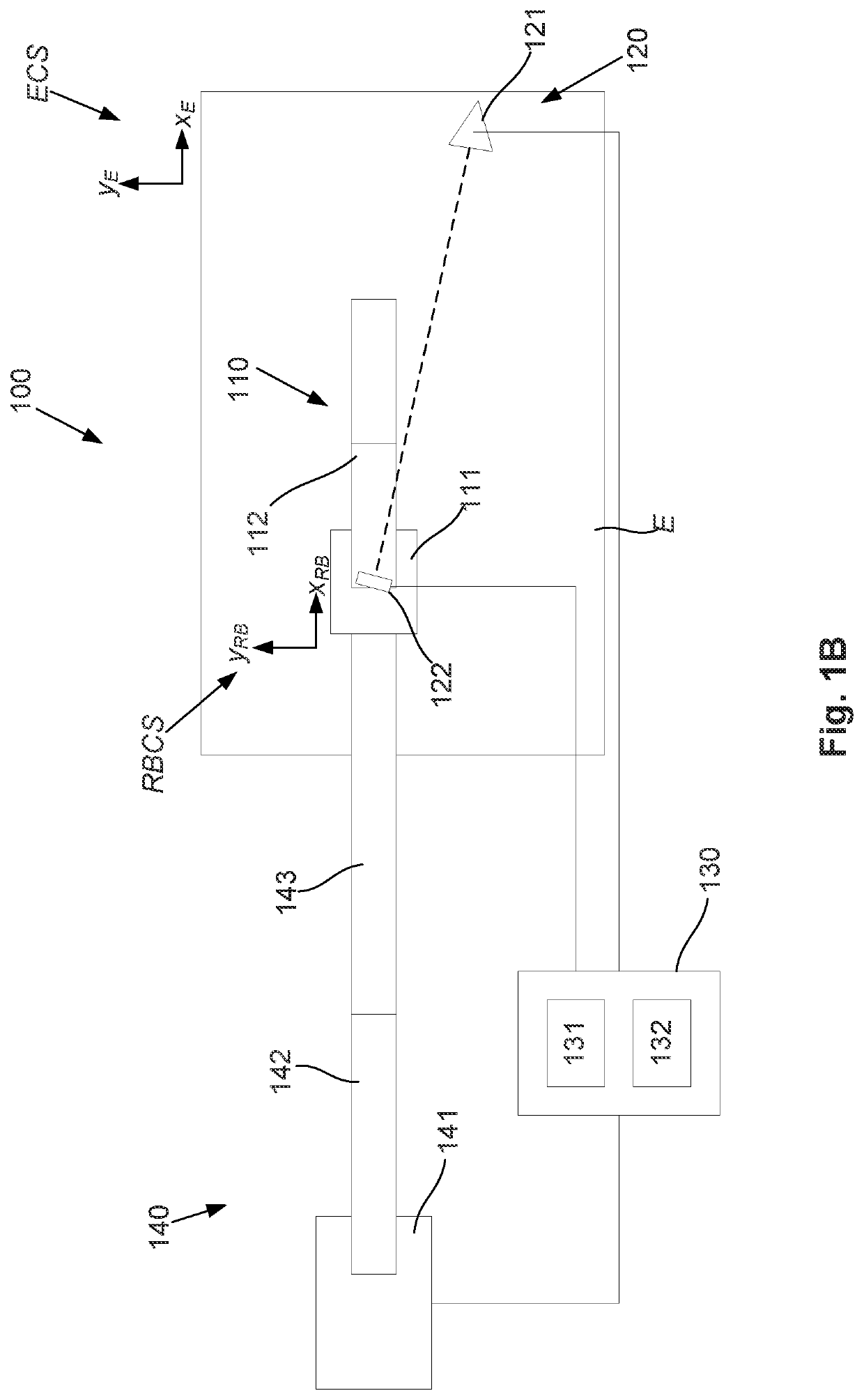

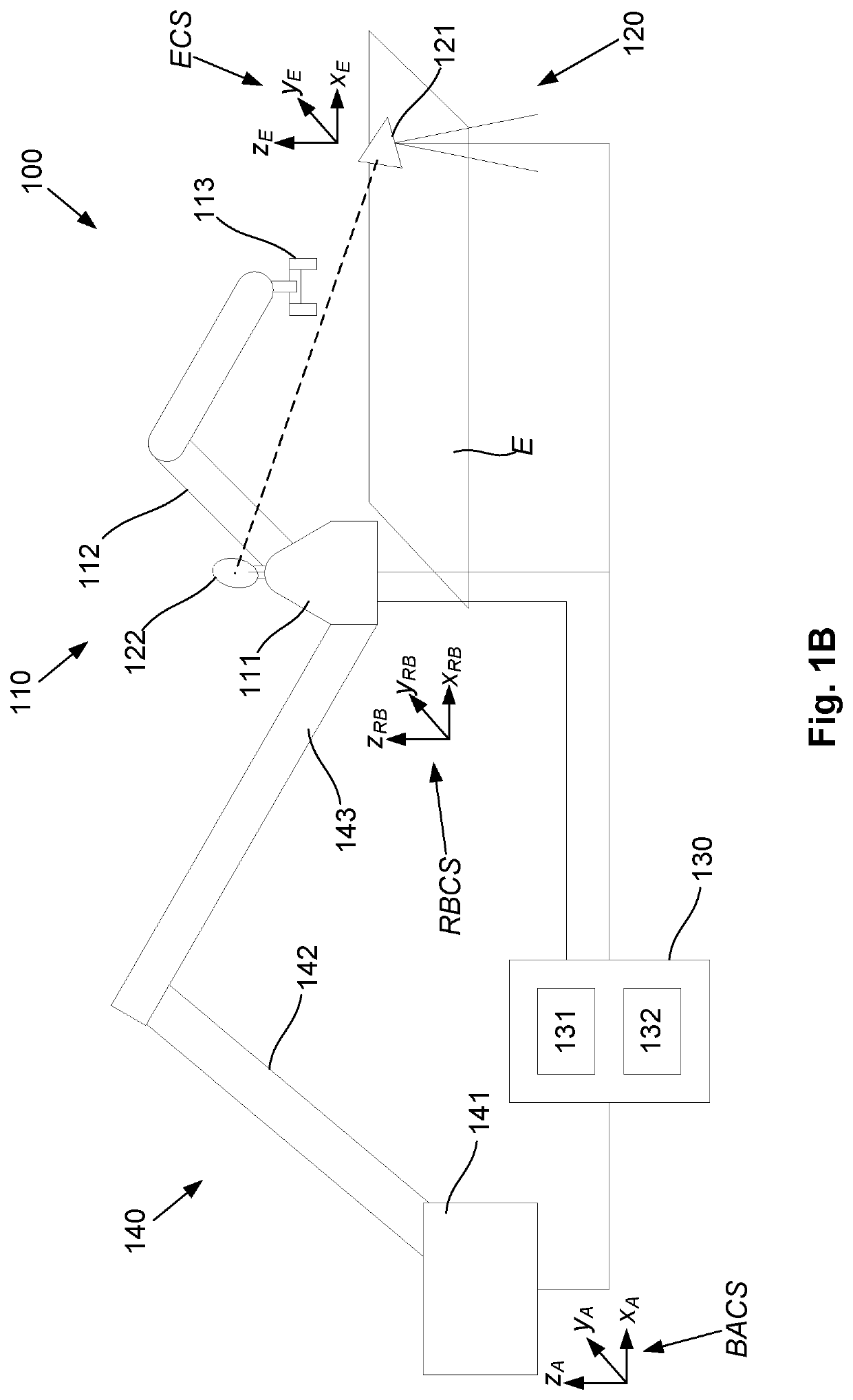

Backup tracking for an interaction system

PendingUS20210370509A1Reduces end effector speedShorten speedProgramme-controlled manipulatorRobotics systemsControl systemSimulation

A system for performing interactions within a physical environment including: a robot base that undergoes movement relative to the environment; a robot arm mounted to the robot base, the robot arm including an end effector mounted thereon; a first tracking system that measures a robot base position; a second tracking system that measures movement of the robot base; and, a control system that uses a robot base position to at least partially control the robot arm to move the end effector along an end effector path, wherein the control system: determines the robot base position at least in part using signals from the first tracking system; and, in the event of failure of the first tracking system: determines a robot base position using signals from the second tracking system; and, controls the robot arm to move the end effector along the end effector path at a reduced end effector speed.

Owner:FASTBRICK IP PTY LTD

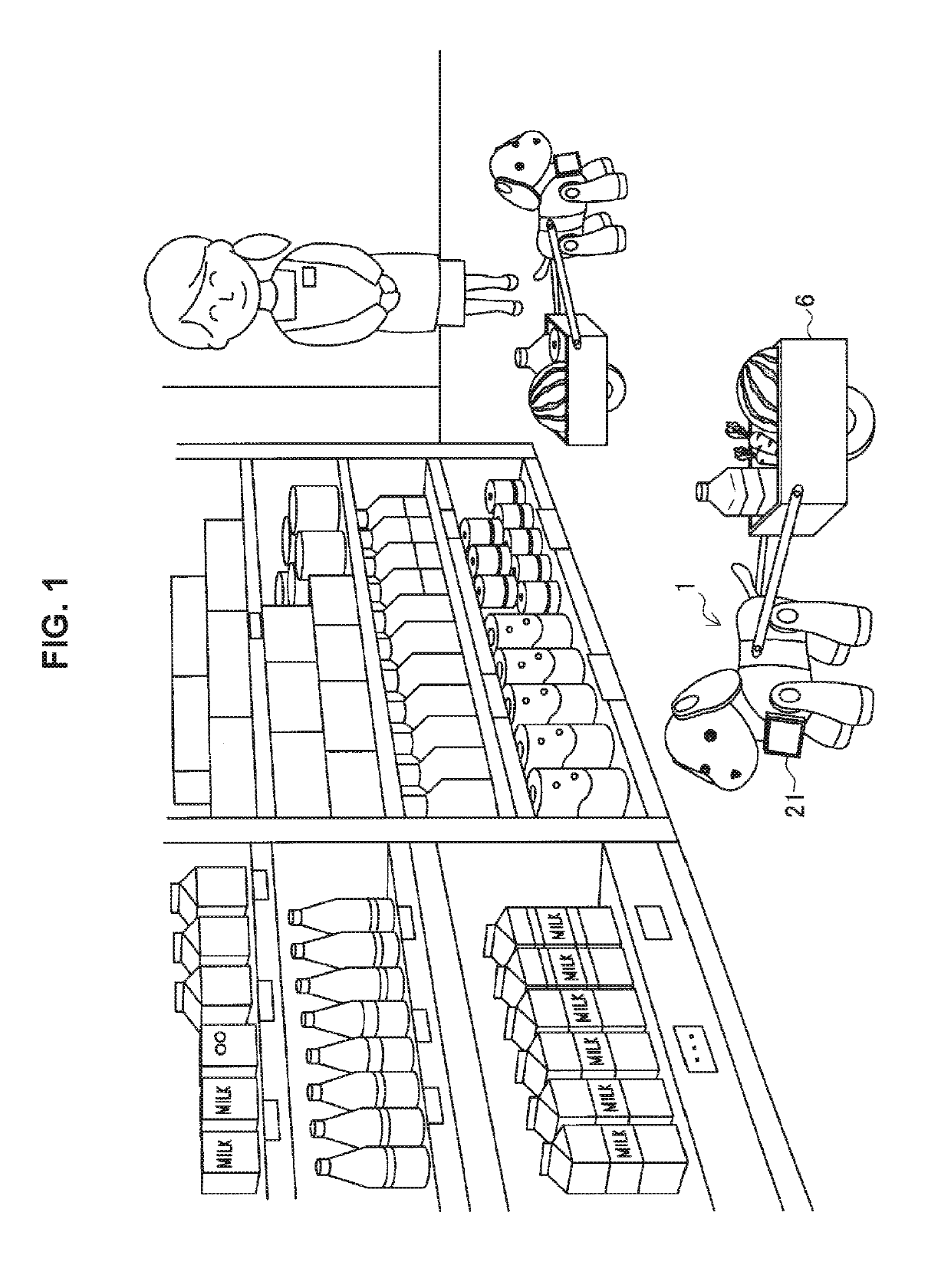

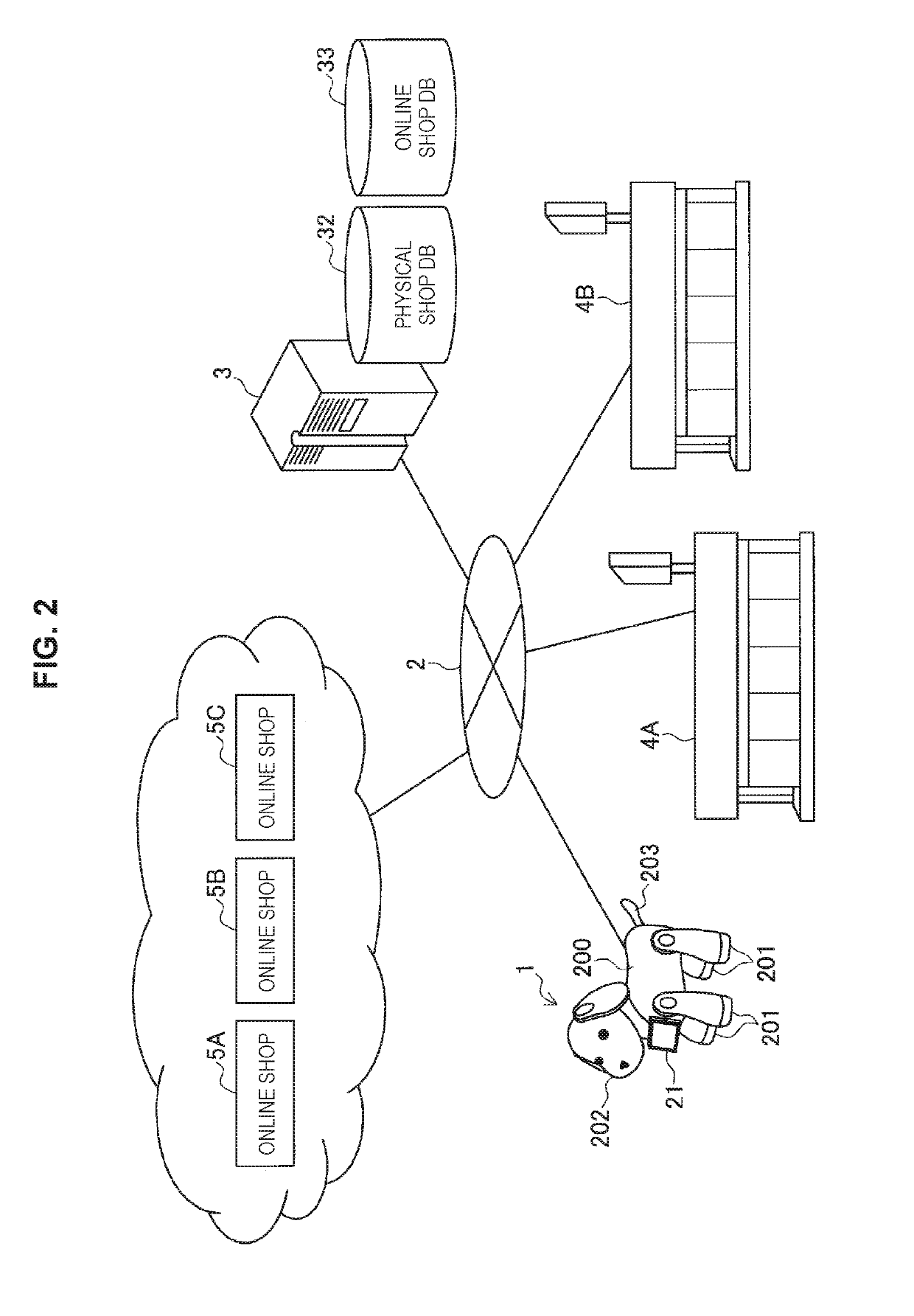

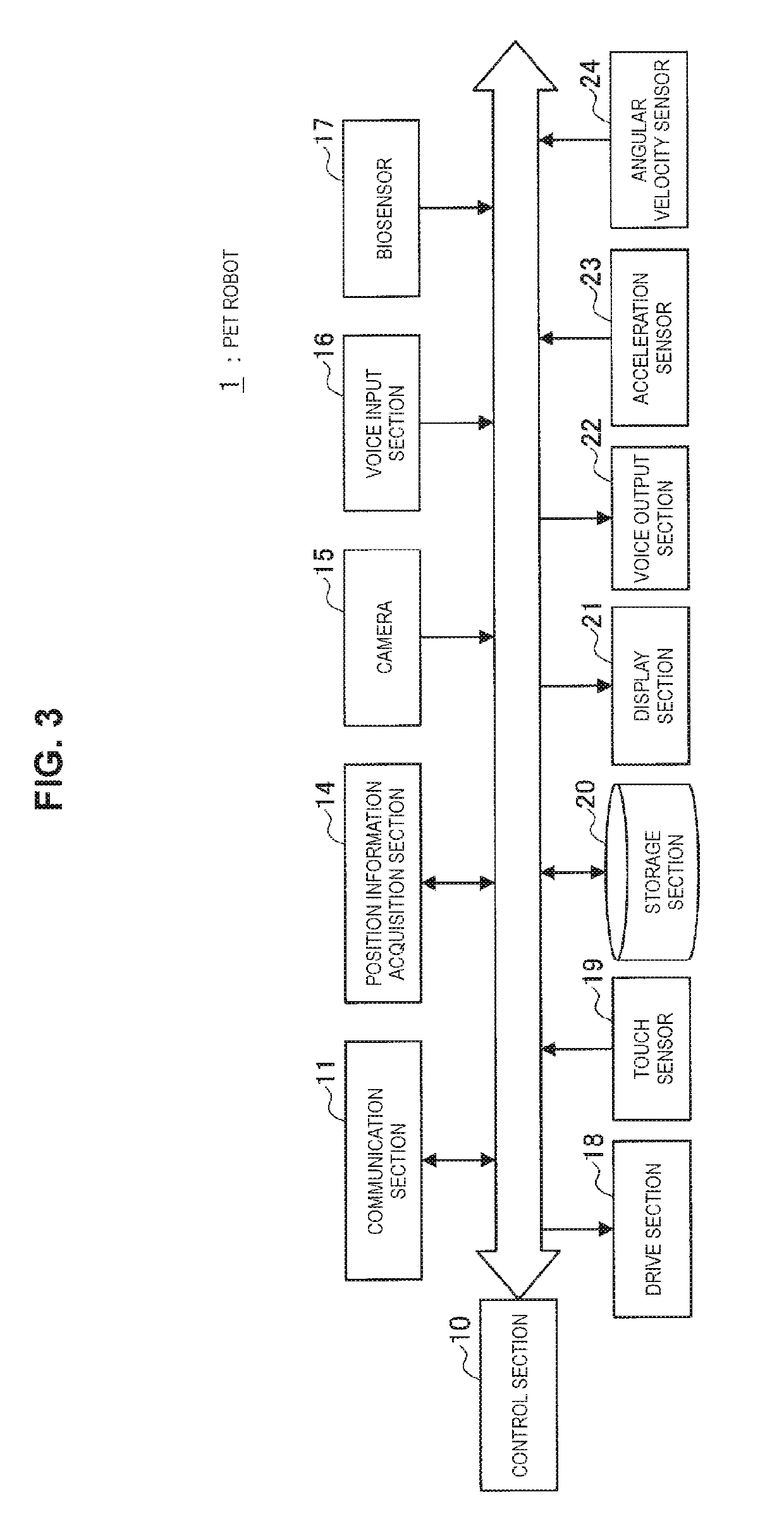

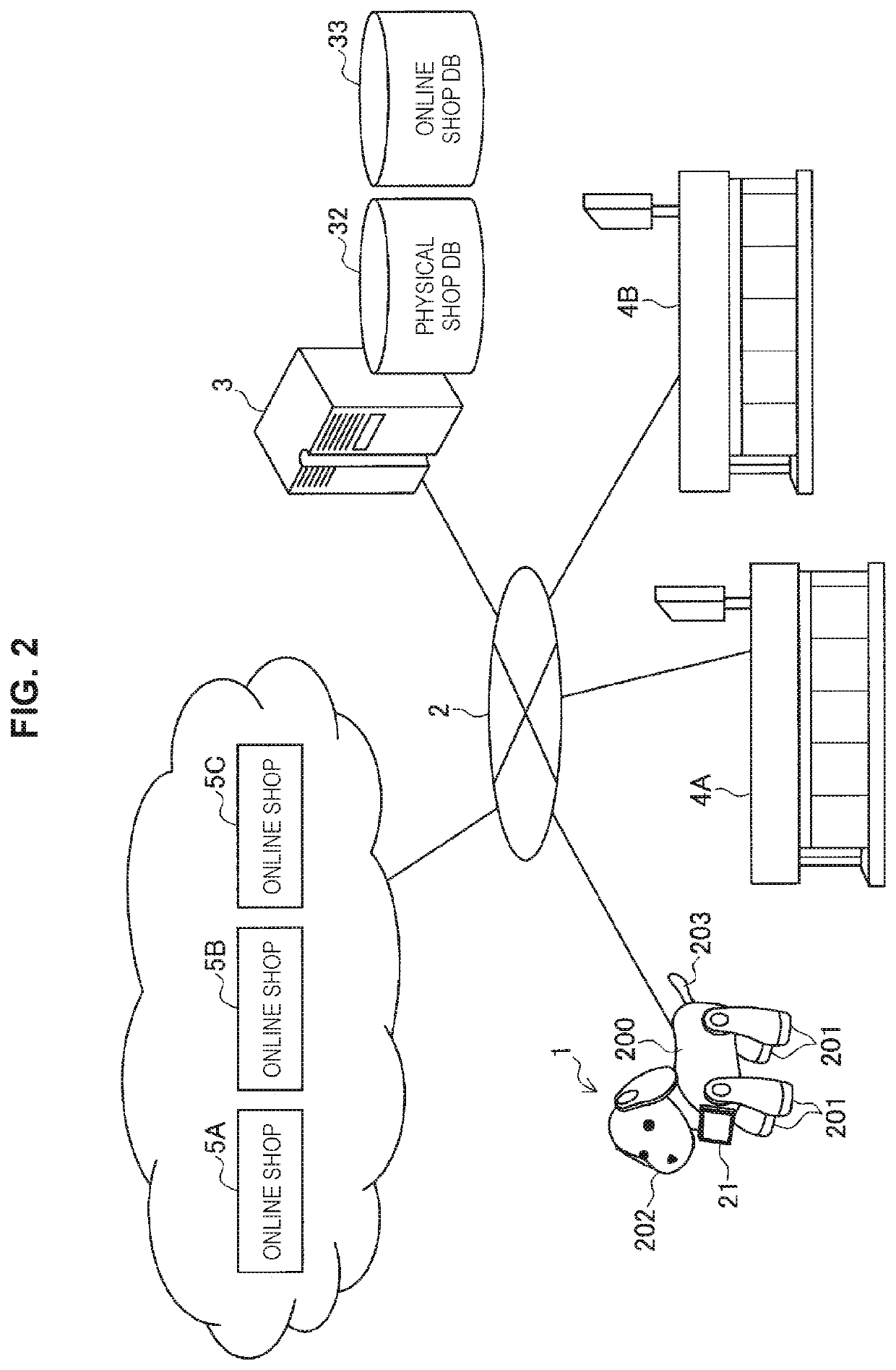

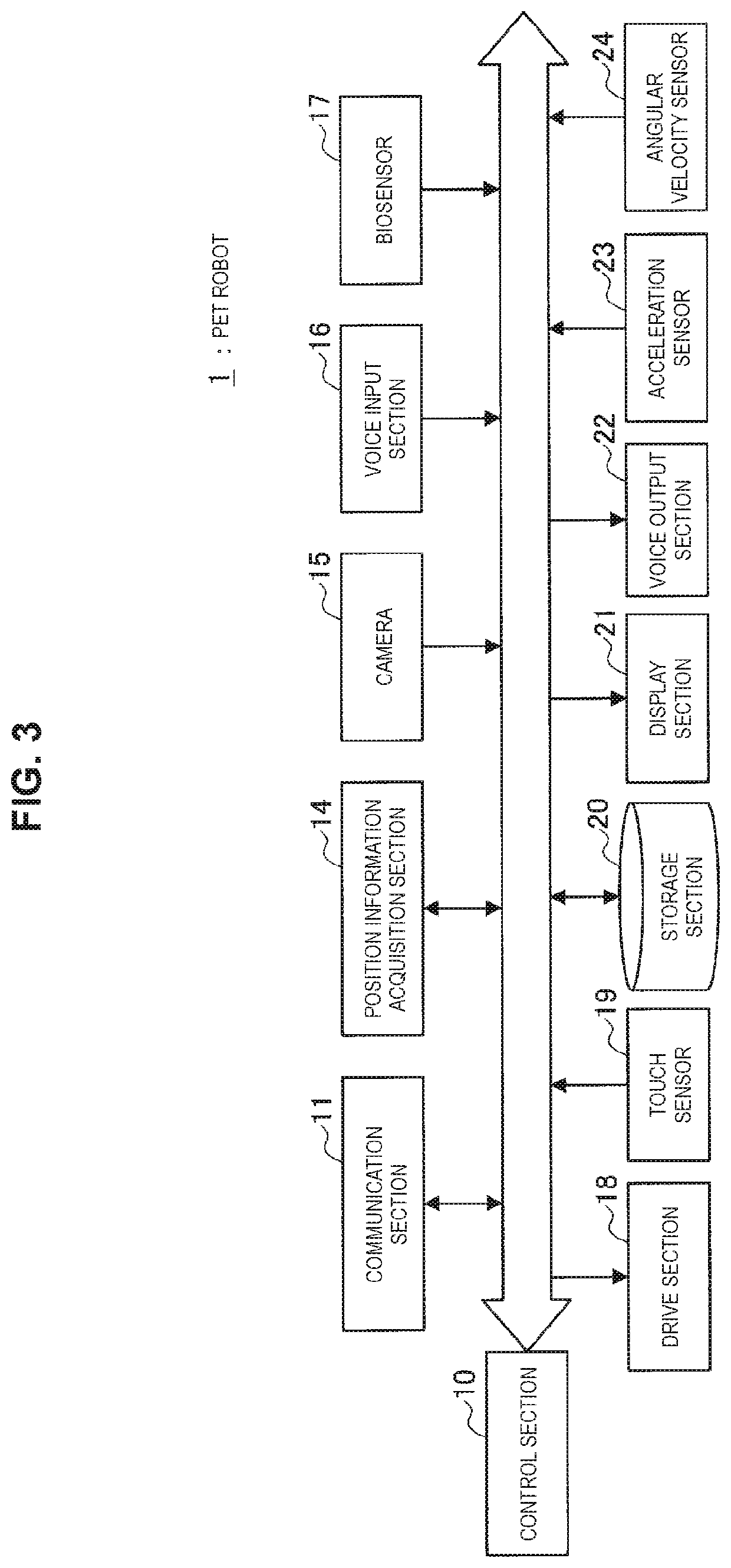

Agent robot control system, agent robot system, agent robot control method, and storage medium

ActiveUS20190164218A1Achieve effectProgramme-controlled manipulatorRobotics systemsControl systemSimulation

[Object] To provide an agent robot control system, an agent robot system, an agent robot control method, and a storage medium that can support optimum shopping in a physical shop and an online shop. [Solution] An agent robot control system including: an acquisition section configured to acquire a purchase master list indicating a candidate of a purchase commercial product of a user; and a control section configured to generate a purchase execution list for recommending purchase in a physical shop for a partial commercial product of the purchase master list, and recommending purchase in an online shop for another commercial product.

Owner:SONY CORP

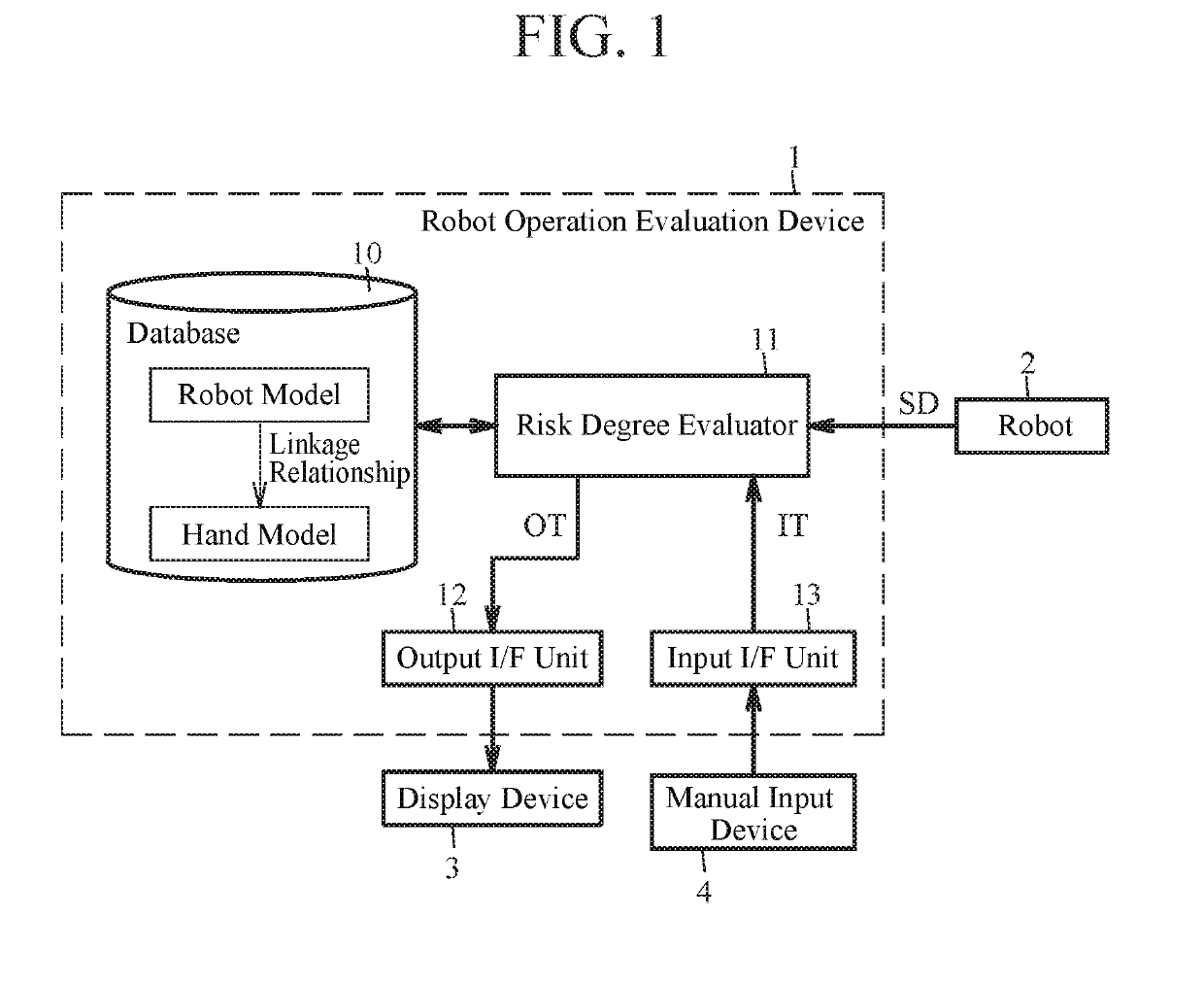

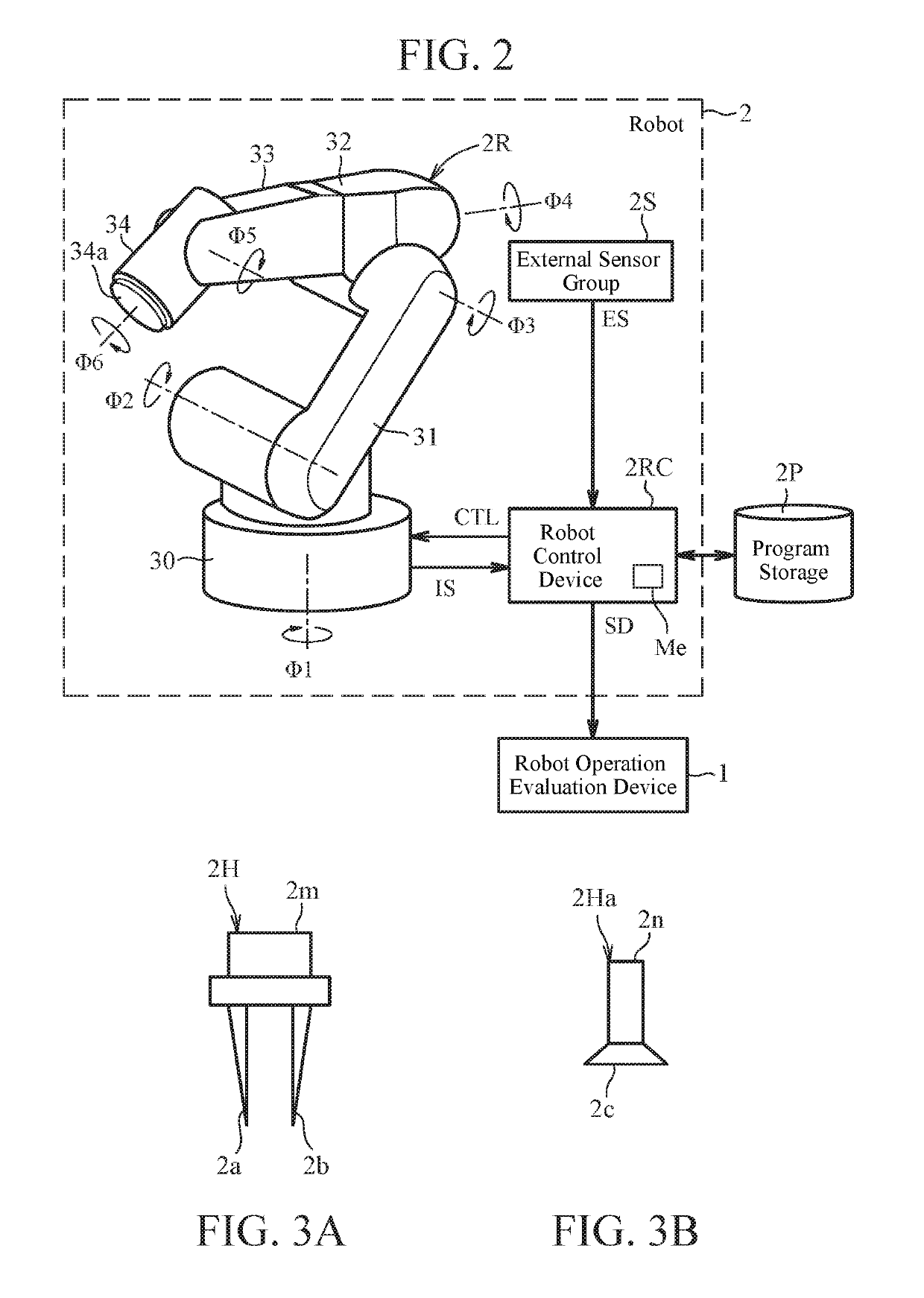

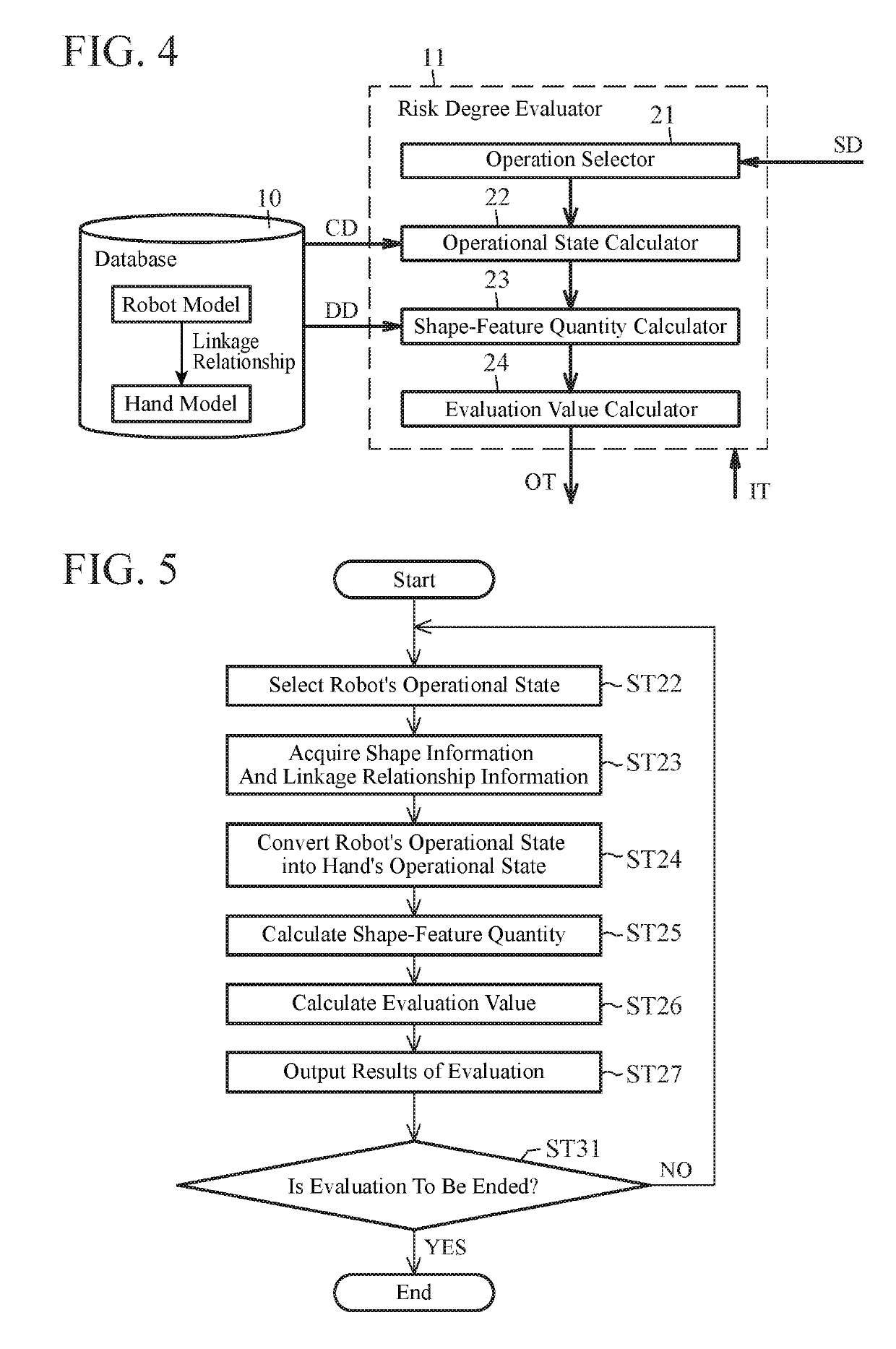

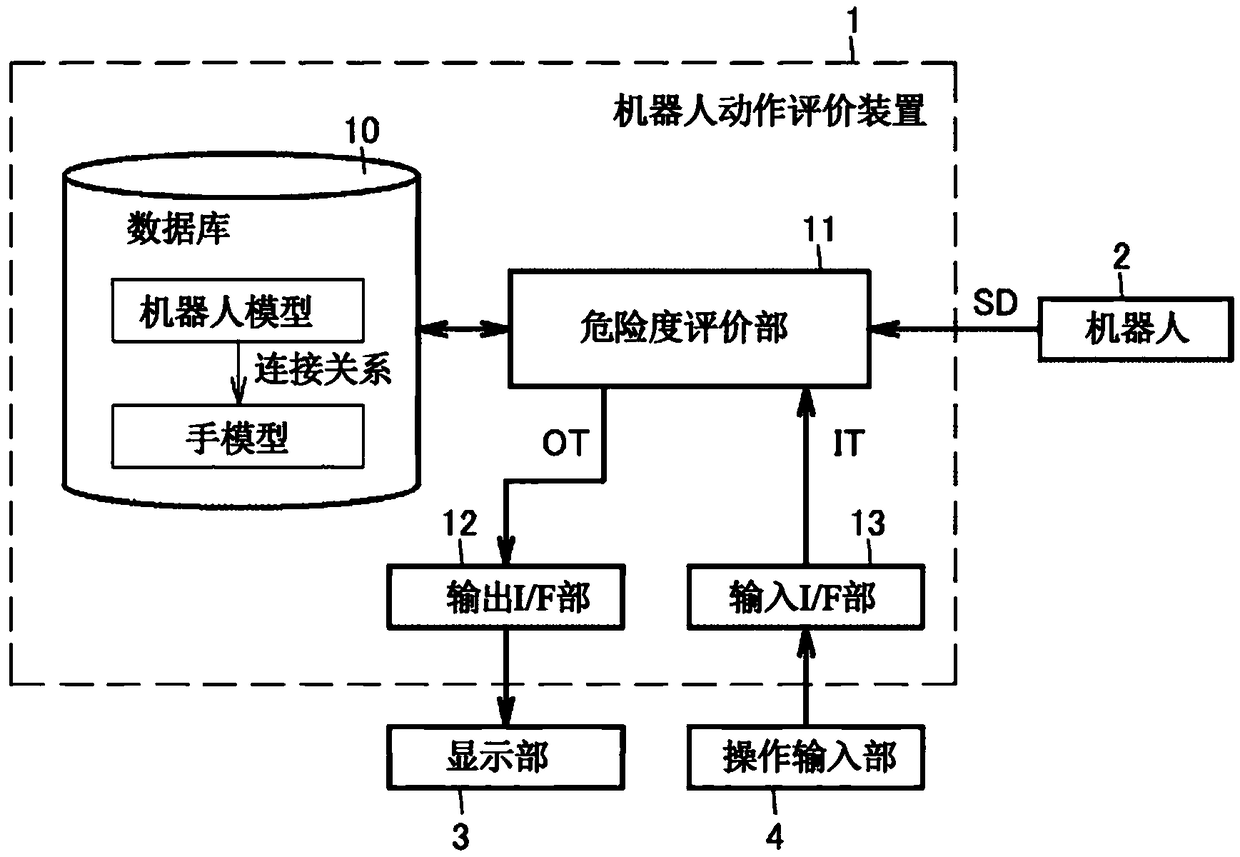

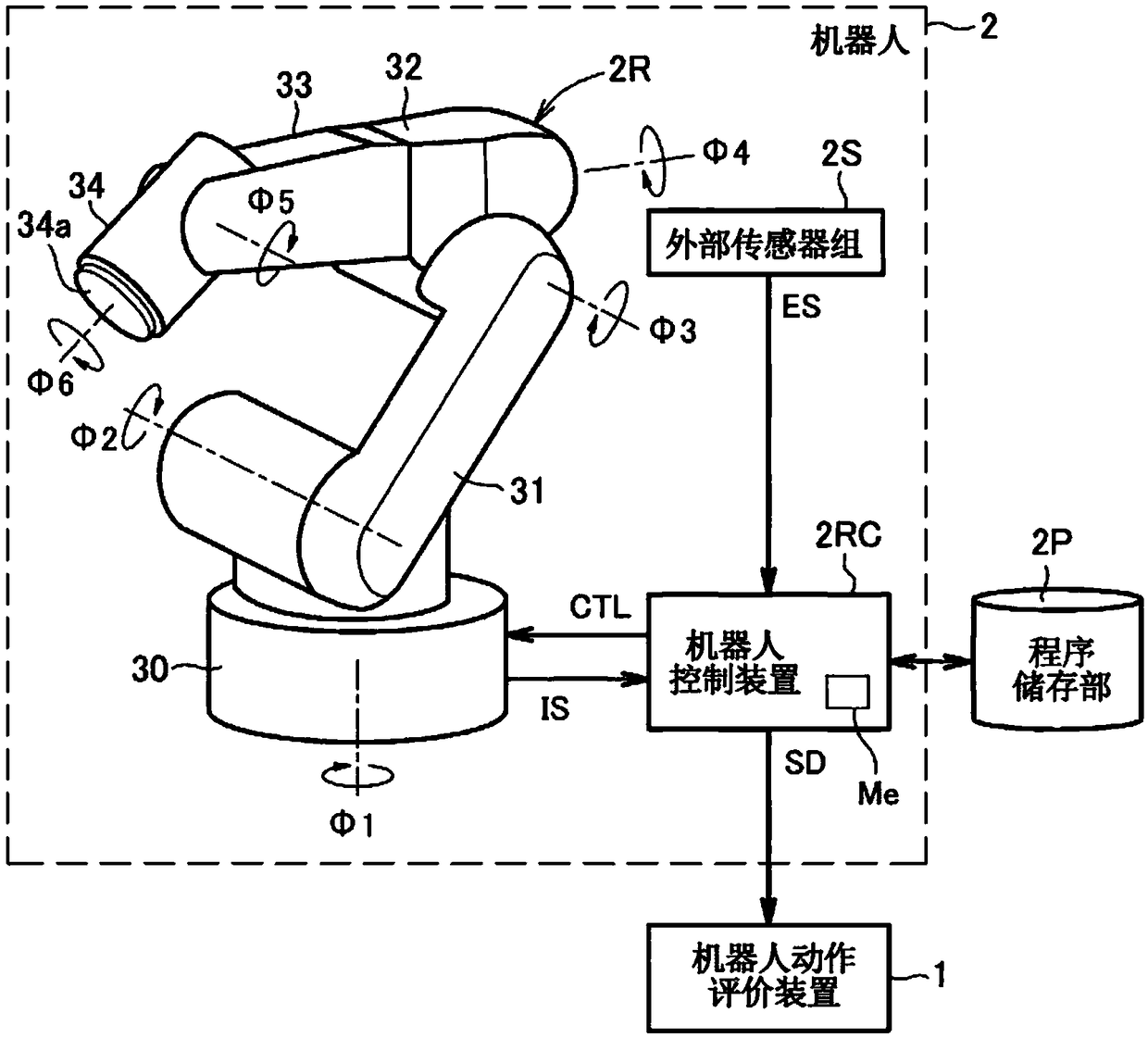

Robot operation evaluation device, robot operation evaluating method, and robot system

ActiveUS20190126475A1Ensure safetyProgramme-controlled manipulatorRobotics systemsRobotic systemsSimulation

A robot operation evaluation device includes: an operational state calculator for calculating an operational state of an evaluation region that is a movable region of a robot, based on an operational state of the robot; a shape-feature quantity calculator for calculating a shape-feature quantity depending on an operation direction of the evaluation region corresponding to the operational state calculated; and an evaluation value calculator for calculating an evaluation value representing a risk degree of the operational state of the evaluation region with respect to the operation direction, based on the shape-feature quantity.

Owner:MITSUBISHI ELECTRIC CORP

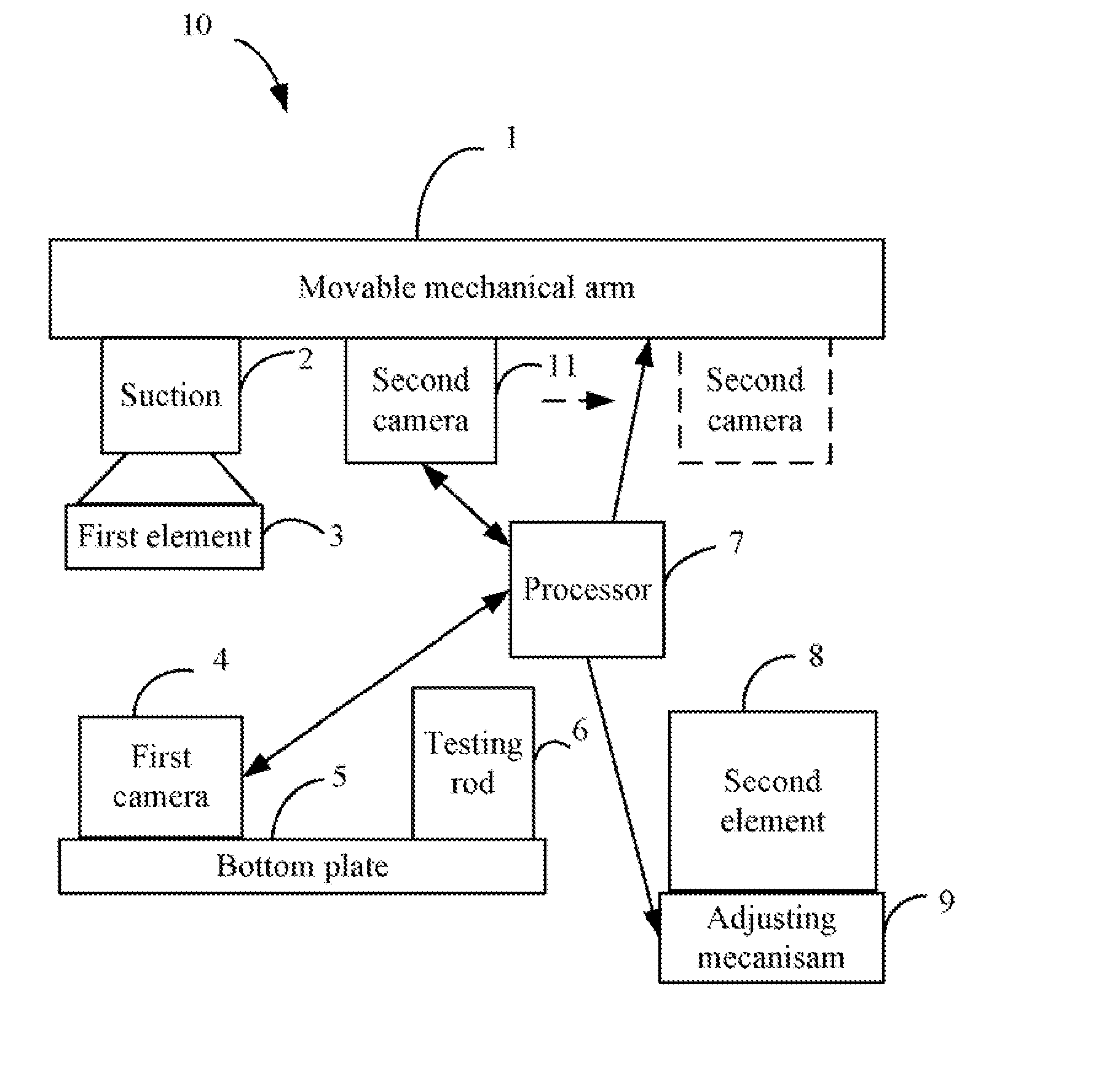

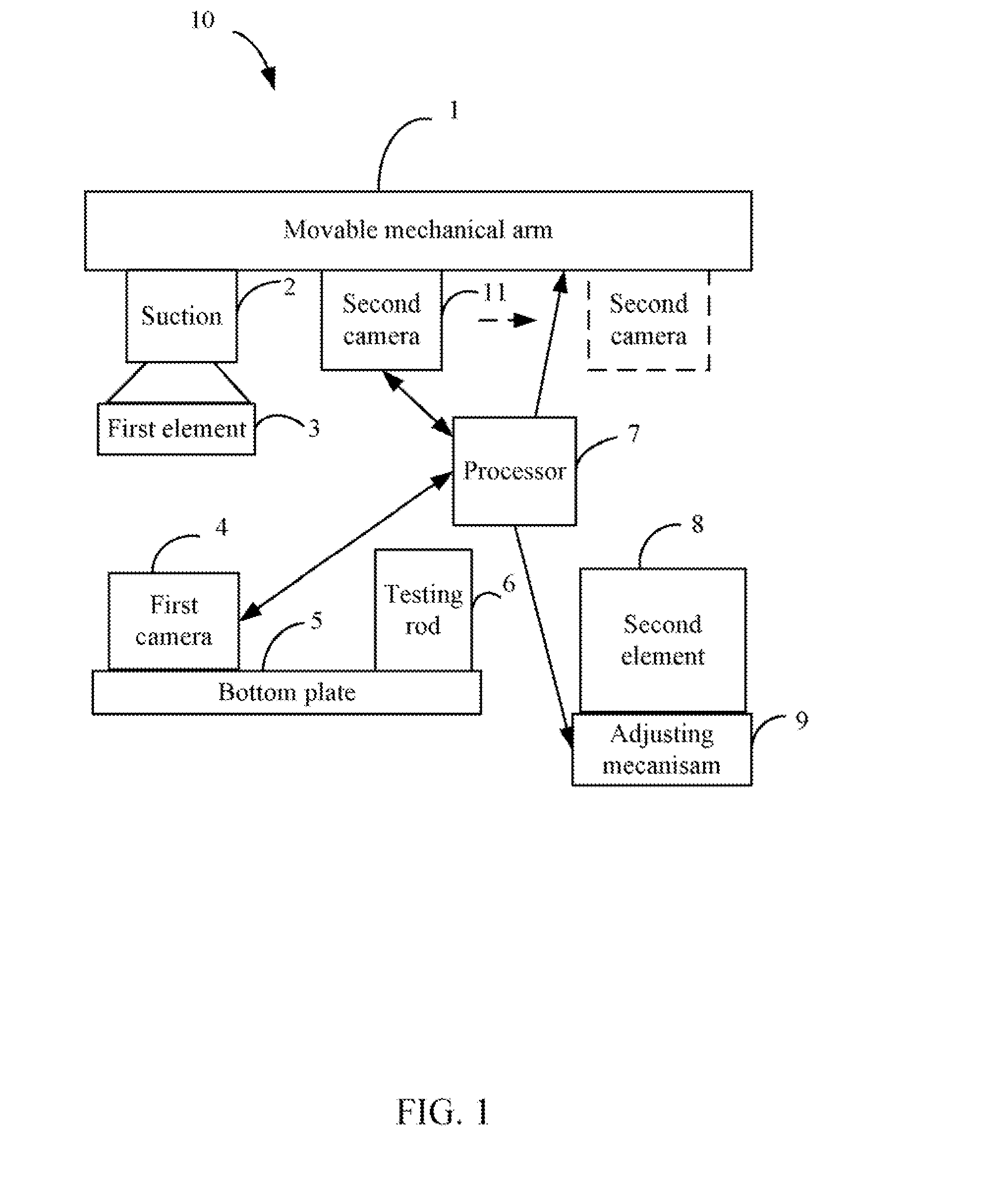

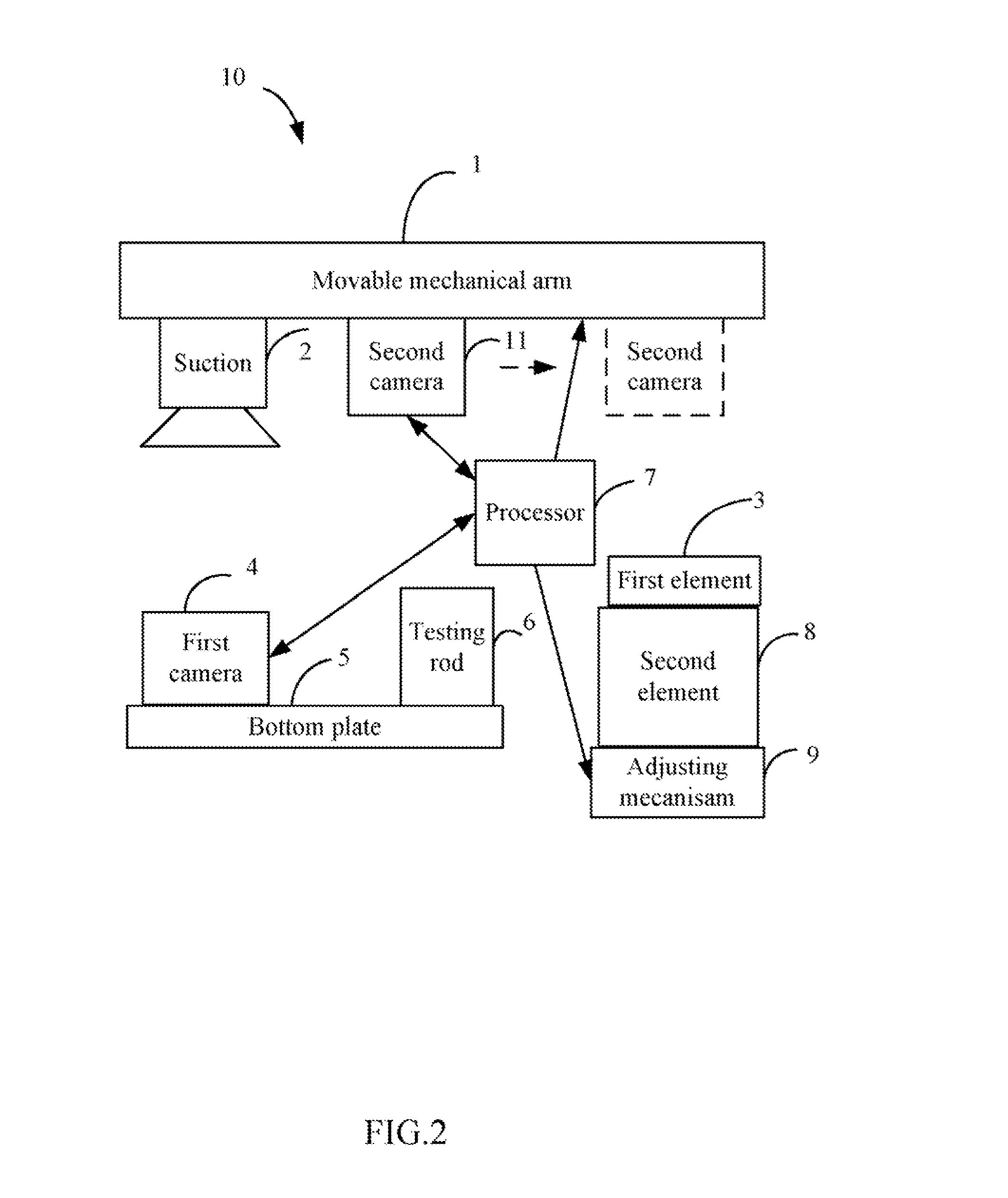

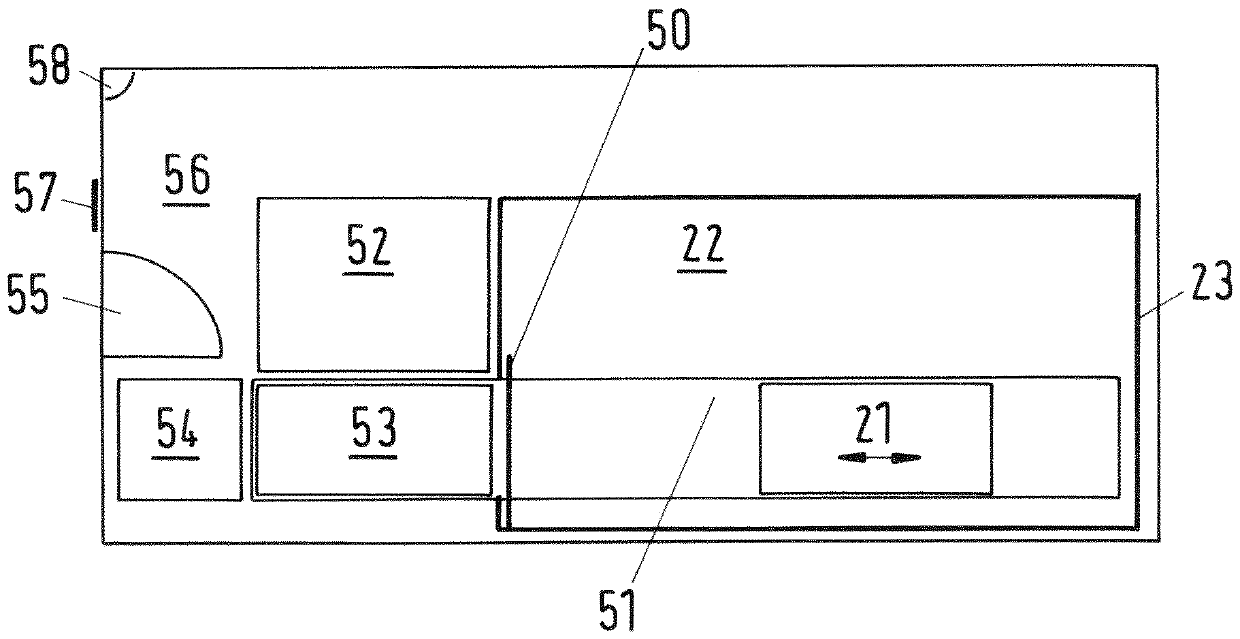

Position adjusting system and method

Owner:HON HAI PRECISION IND CO LTD

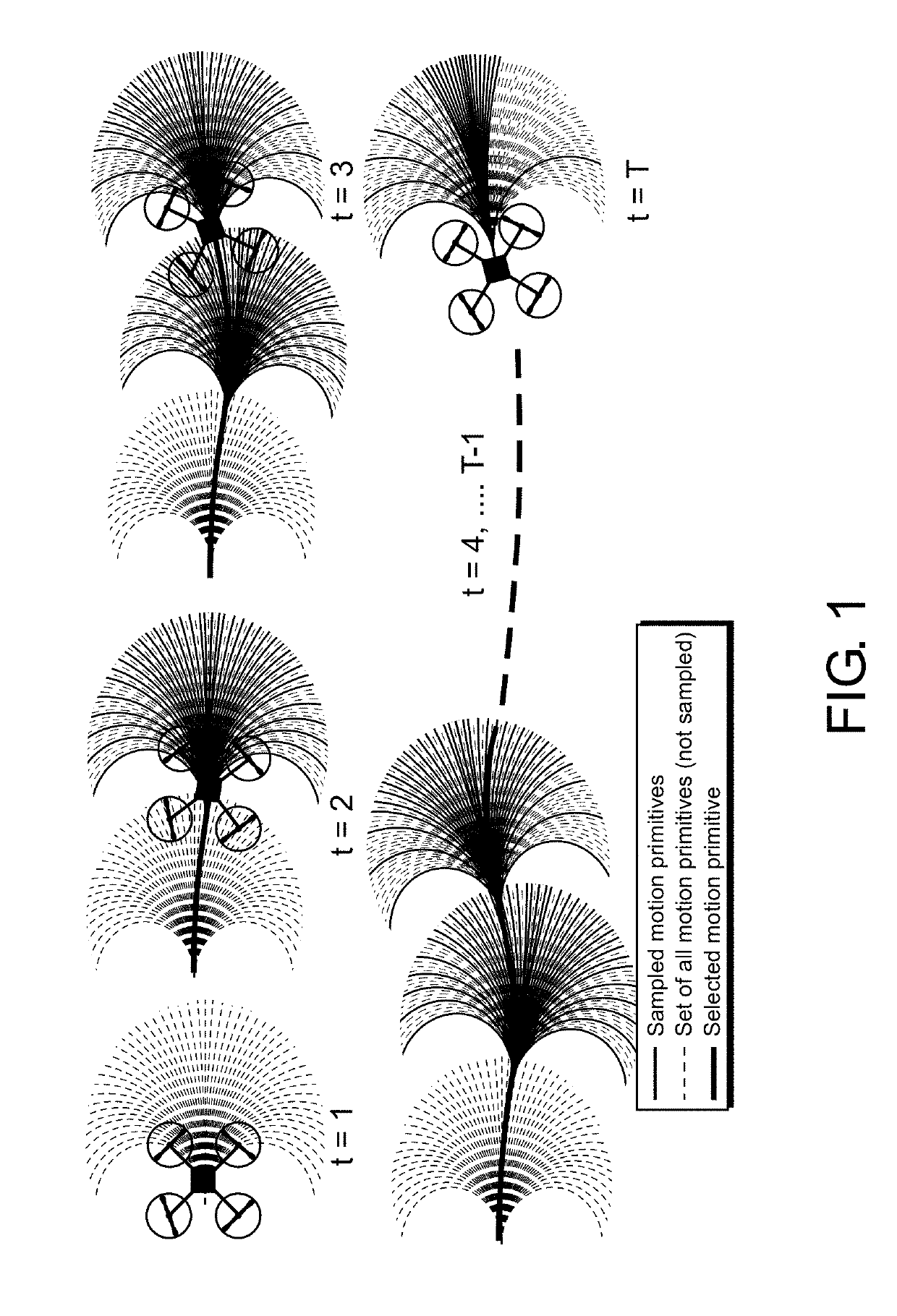

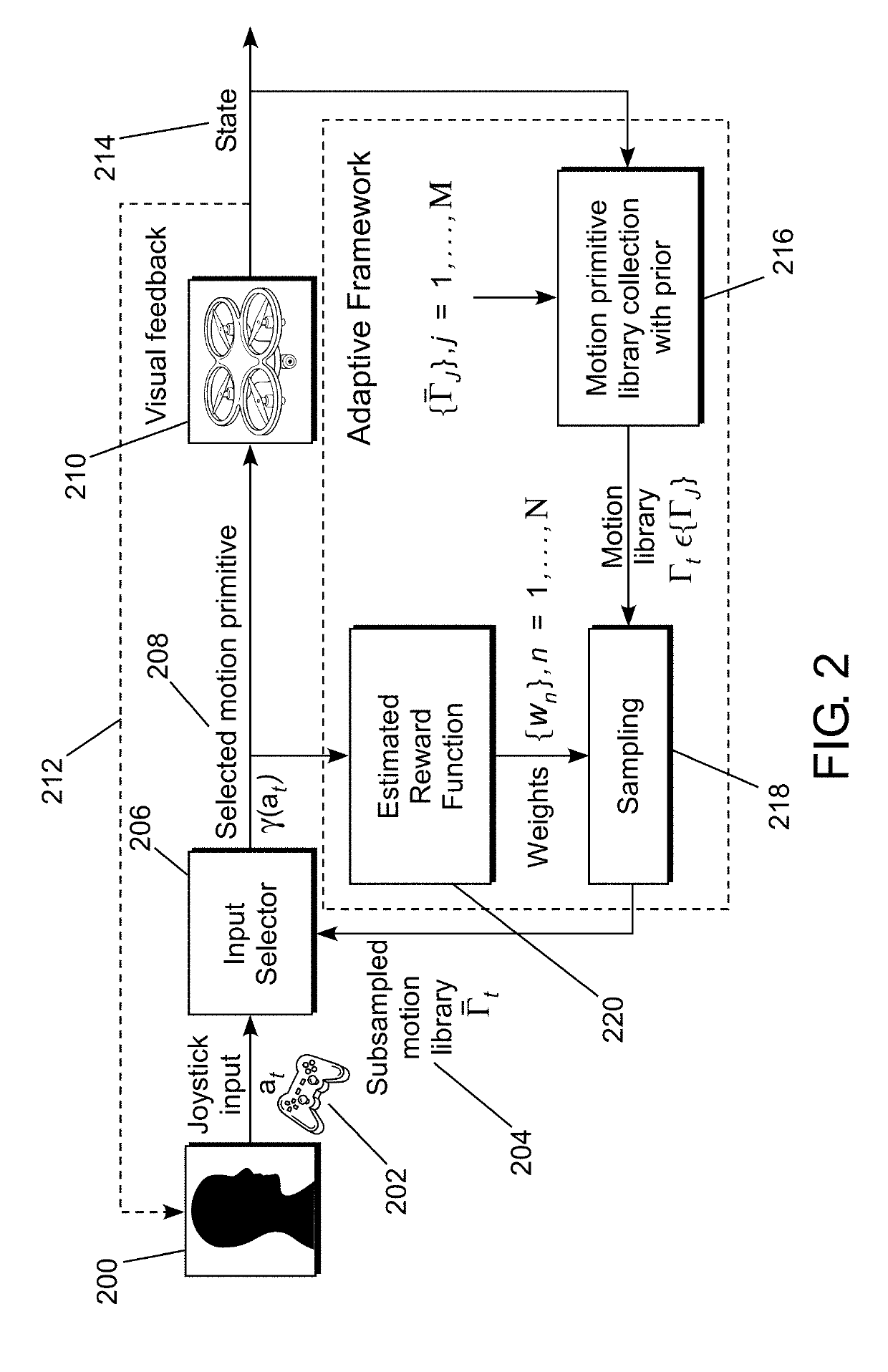

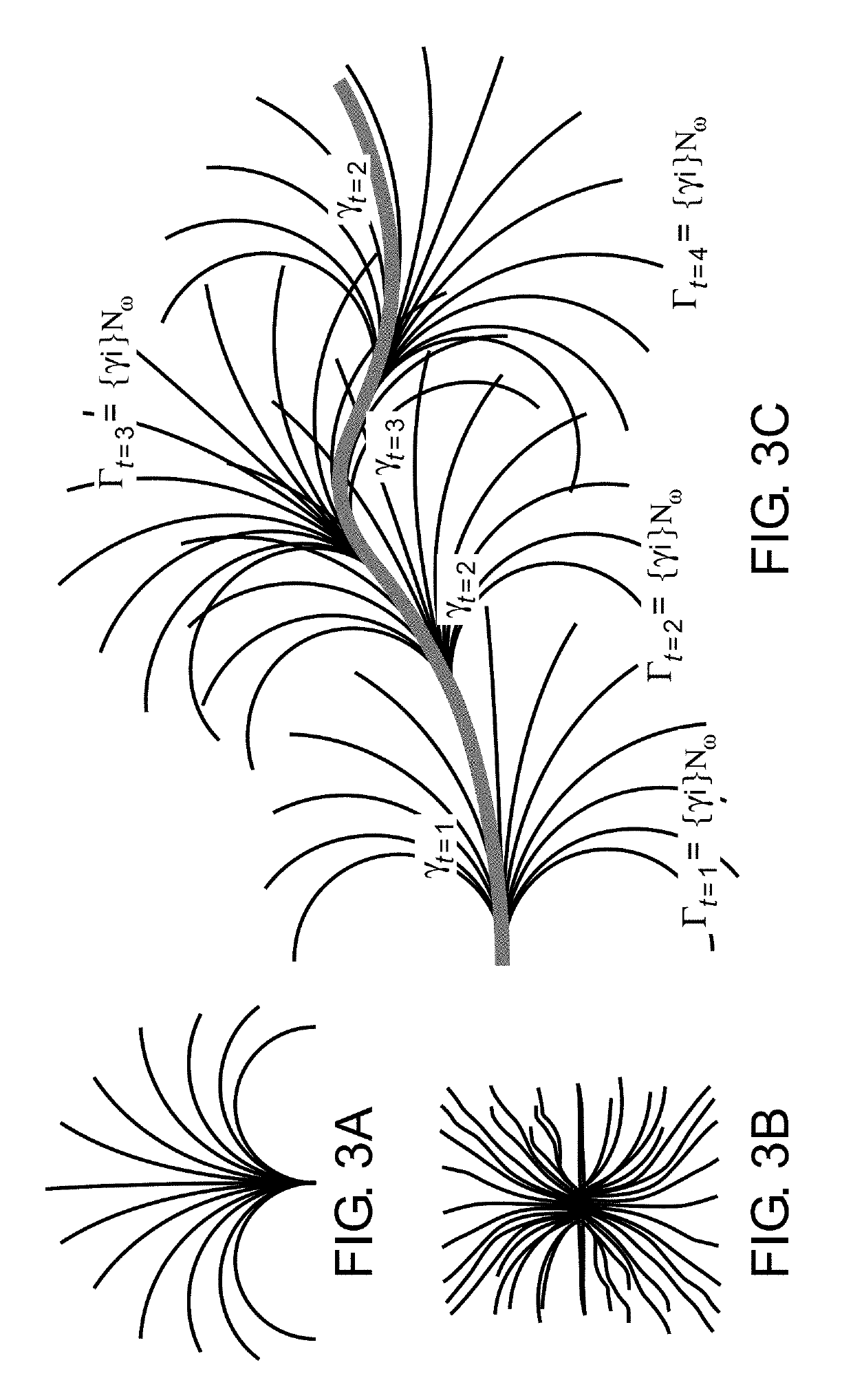

Efficient Teleoperation of Mobile Robots via Online Adaptation

ActiveUS20190271979A1Improve efficiencyAdapt effectivelyRobotics systemsVehicle position/course/altitude controlWatercraftEngineering

Described herein is a framework for efficient task-agnostic, user-independent adaptive teleoperation of mobile robots and remotely operated vehicles (ROV), including ground vehicles (including legged systems), aircraft, watercraft and spacecraft. The efficiency of a human operator is improved by minimizing the entropy of the control inputs, thereby minimizing operator energy and achieving higher performance in the form of smoother trajectories by concurrently estimating the user intent online and adaptively updating the action set available to the human operator.

Owner:CARNEGIE MELLON UNIV

Robot operation evaluation device, robot operation evaluation method, and robot system

ActiveCN109070366AAchieve securityProgramme-controlled manipulatorRobotics systemsRobotic systemsSimulation

A robot operation evaluation device (1) is provided with: an operation state calculator (22) for calculating the operation state of an evaluation portion, which is a movable portion of a robot, on thebasis of the operation state of the robot; a shape feature amount calculator (23) for calculating a shape feature amount, which is dependent on the operation direction of the evaluation portion corresponding to the calculated operation state; and an evaluation value calculator (24) for calculating, on the basis of the shape feature amount, an evaluation value representing the risk degree of the operation state of the evaluation portion with respect to the operation direction.

Owner:MITSUBISHI ELECTRIC CORP

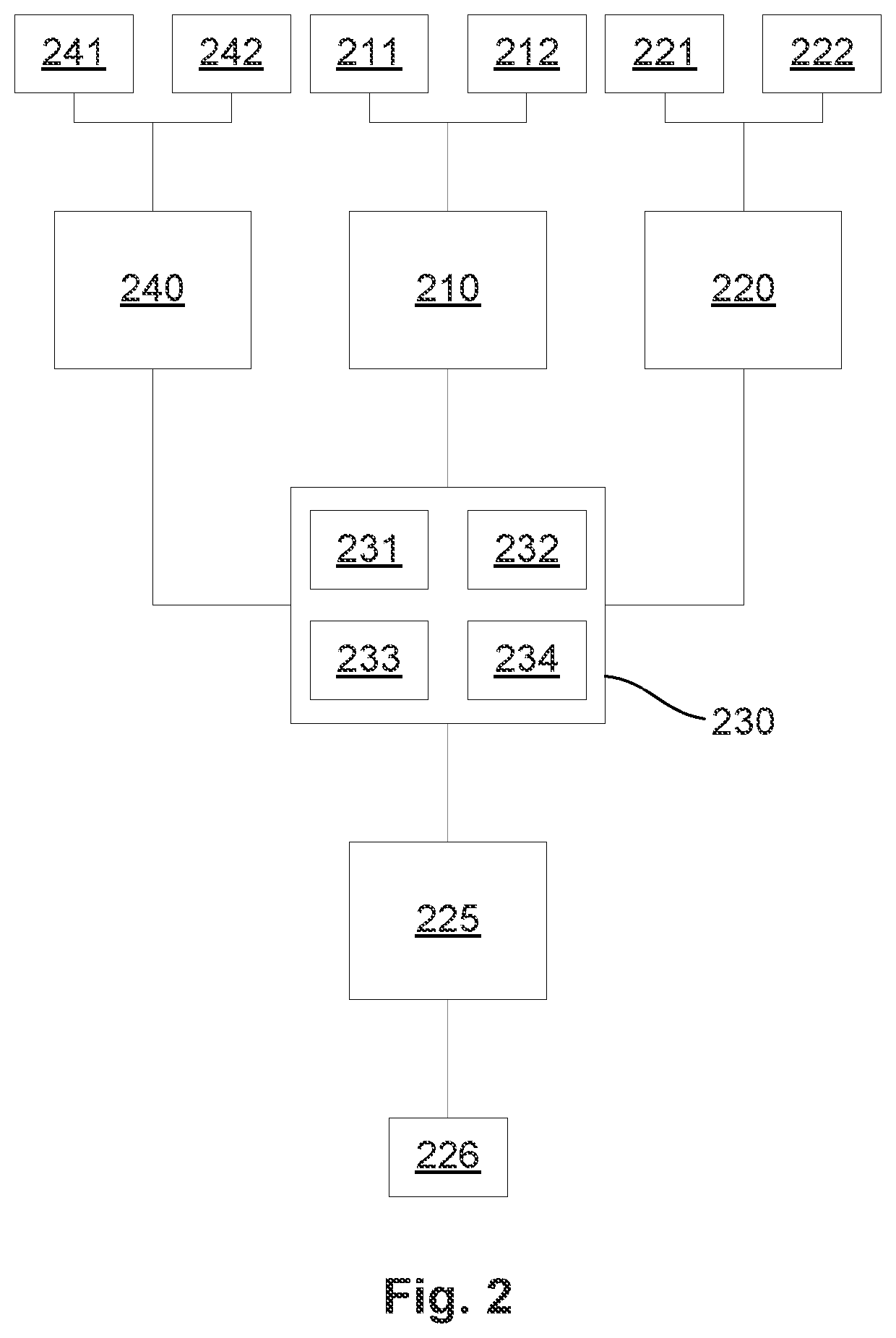

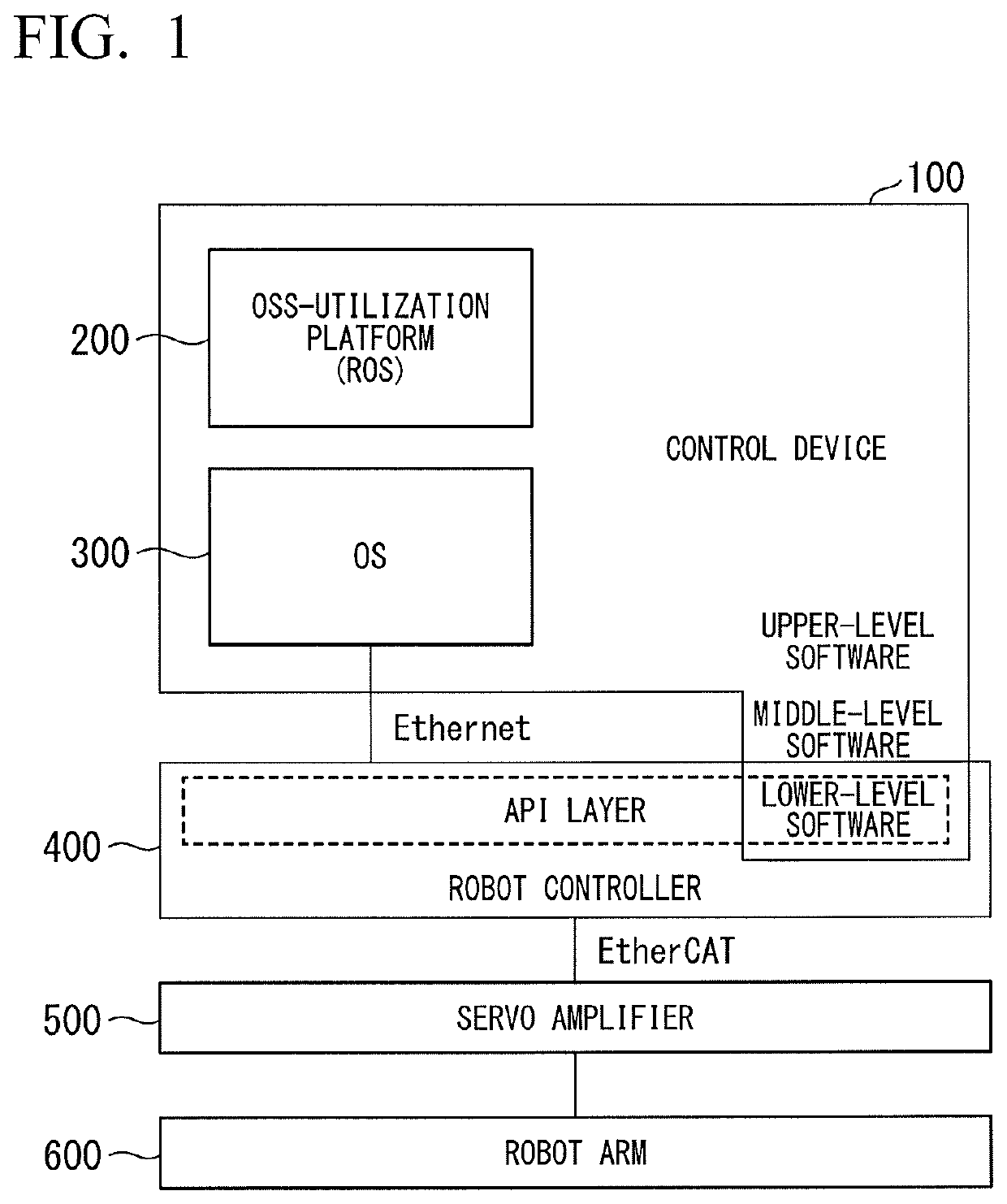

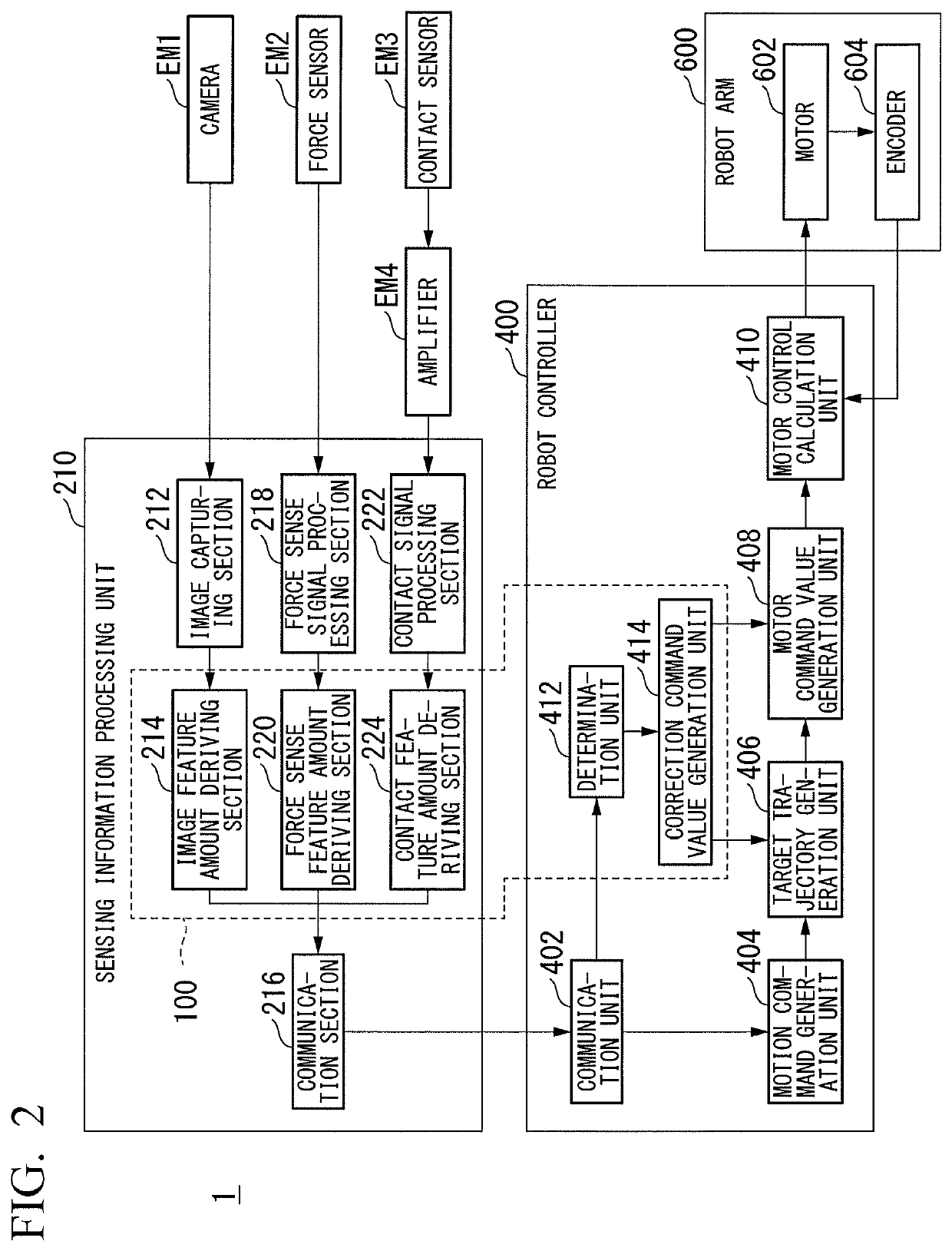

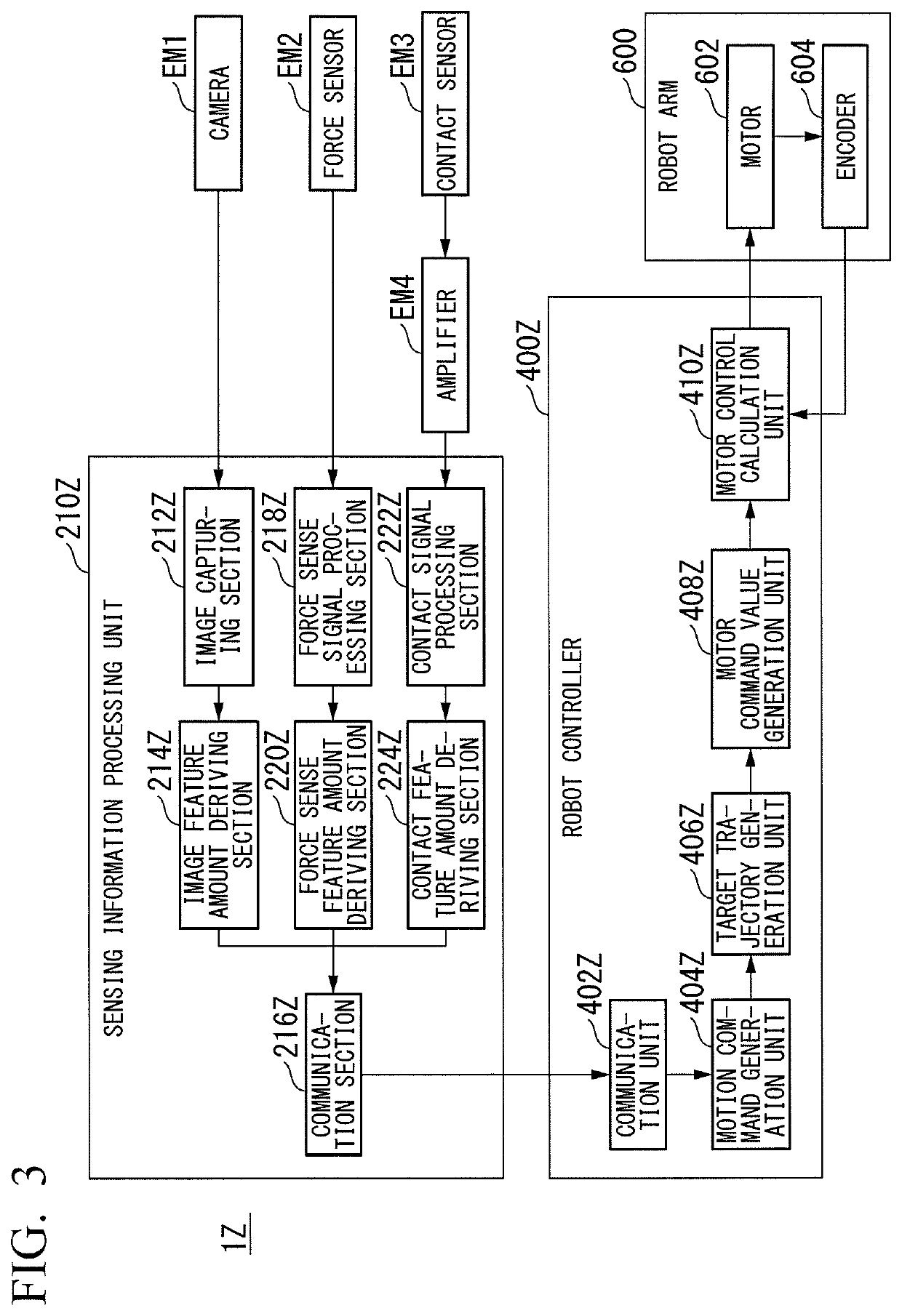

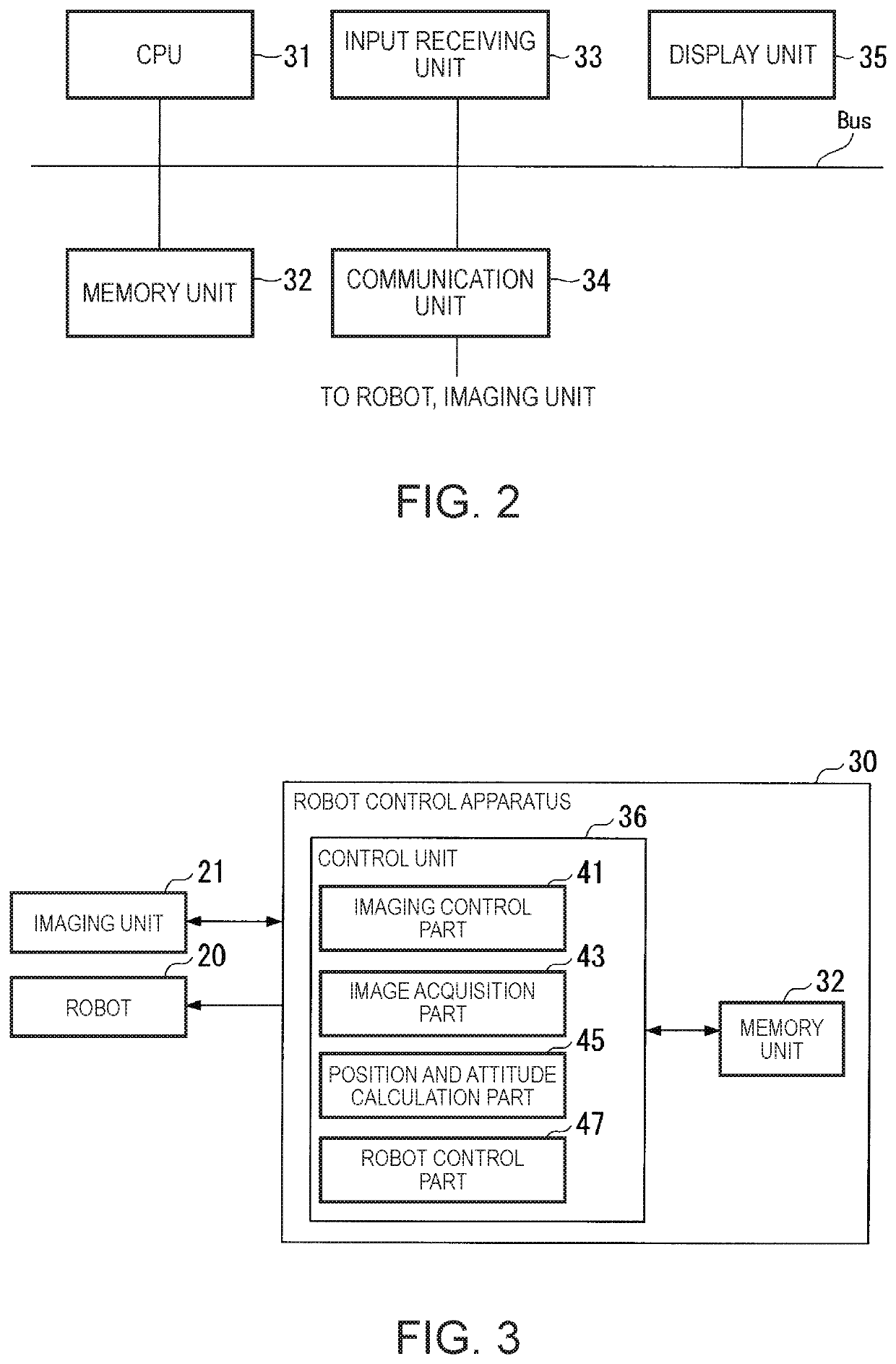

Control device, control method, and storage medium

ActiveUS20200061819A1Robust stabilityProgramme-controlled manipulatorRobotics systemsControl engineeringIdentification device

A control device includes at least two processors comprising at least a first processor and a second processor. The control device controls at least one autonomous motion mechanism on the basis of a recognition result received from a recognition device. A storage device of the control device stores upper-level software, middle-level software, and lower-level software. The upper-level software derives a feature amount representing a feature of the recognition result. The middle-level software generates a motion plan of the autonomous motion mechanism on the basis of the feature amount. The lower-level software outputs a command value for controlling the autonomous motion mechanism on the basis of the motion plan. The first processor executes at least the upper-level software, the second processor executes at least the lower-level software, and at least one processor included in the control device executes the middle-level software.

Owner:KK TOSHIBA

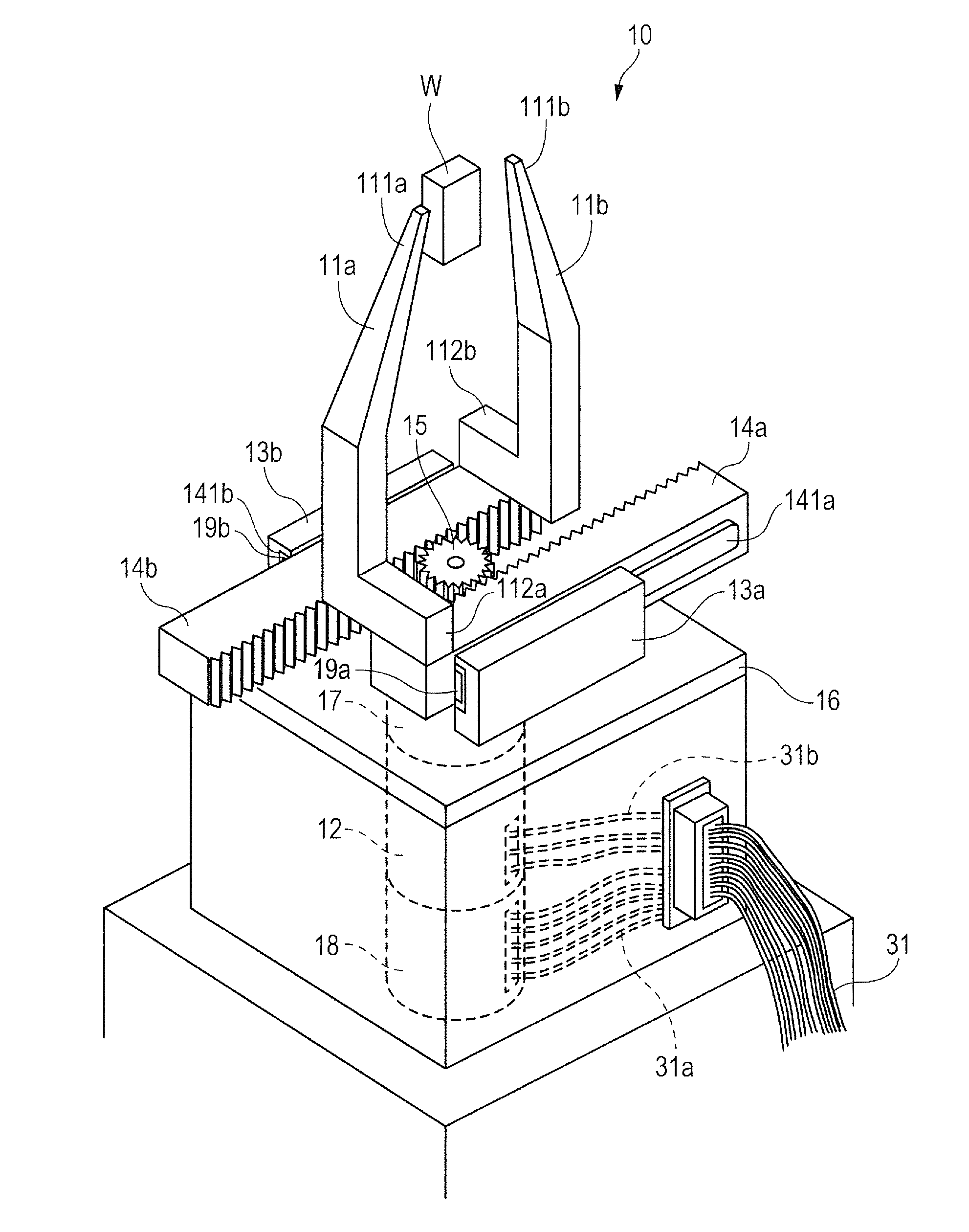

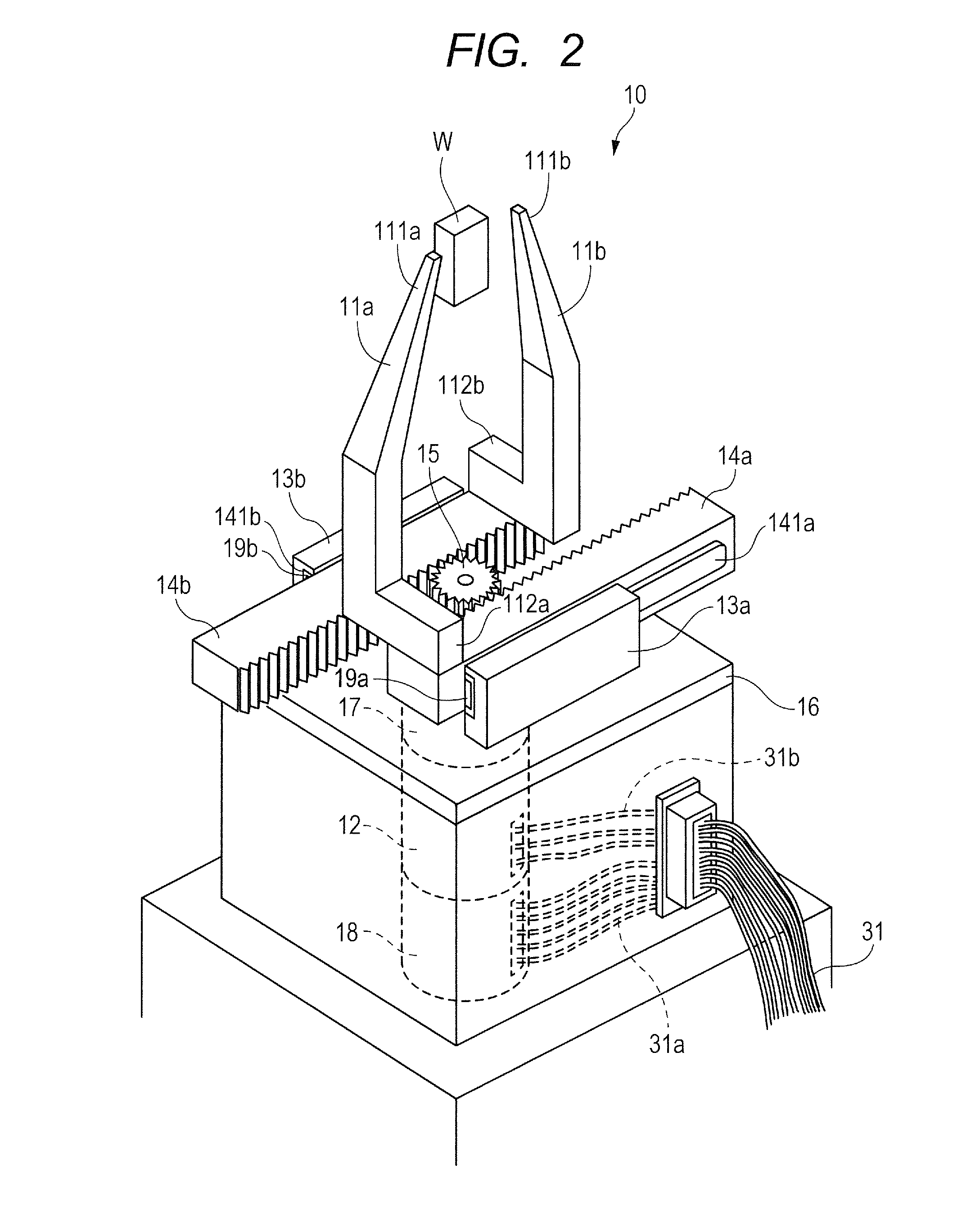

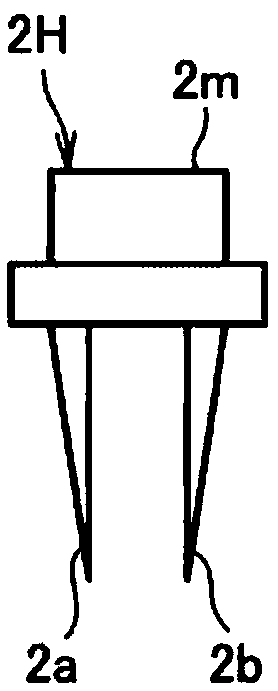

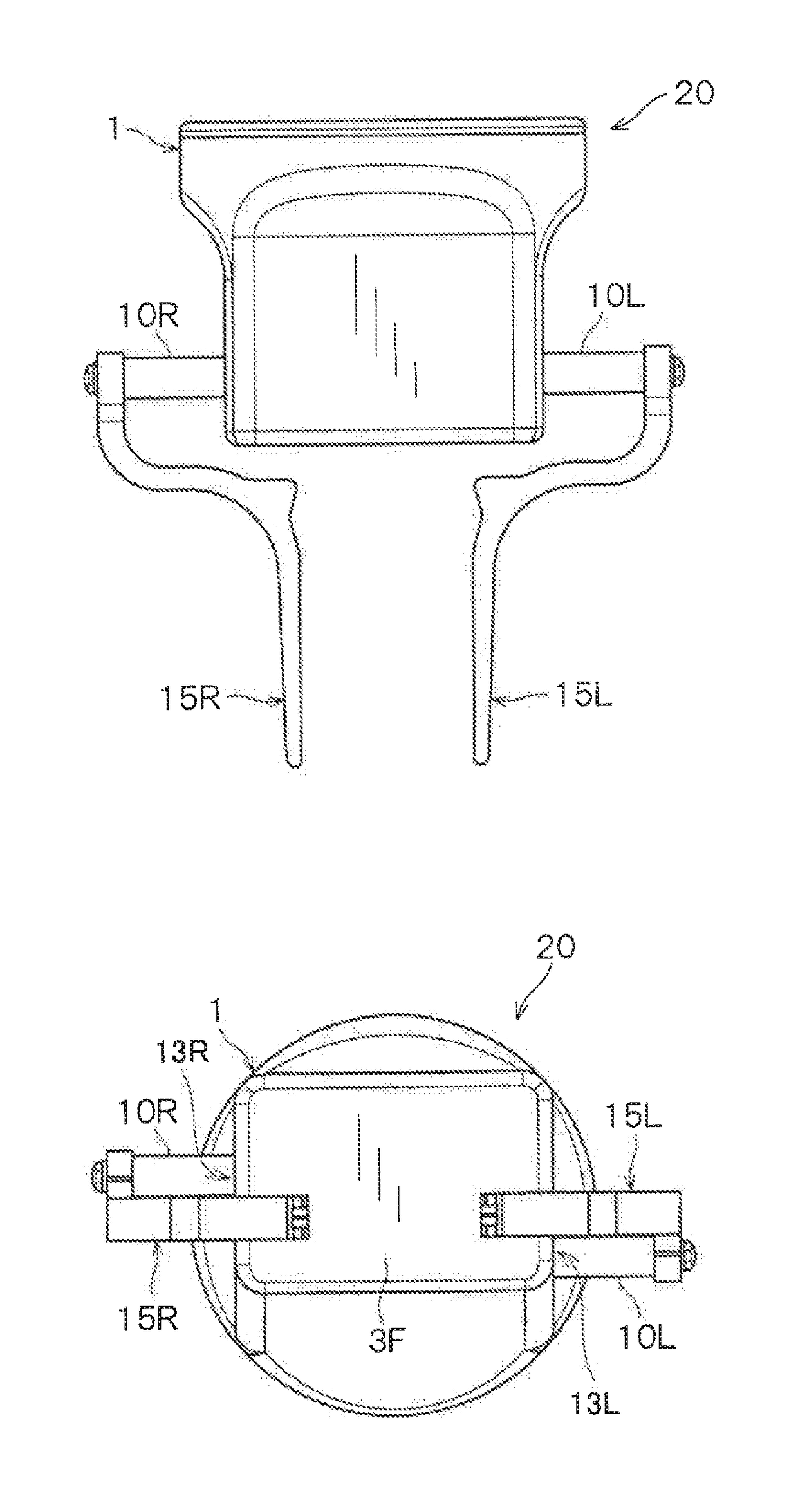

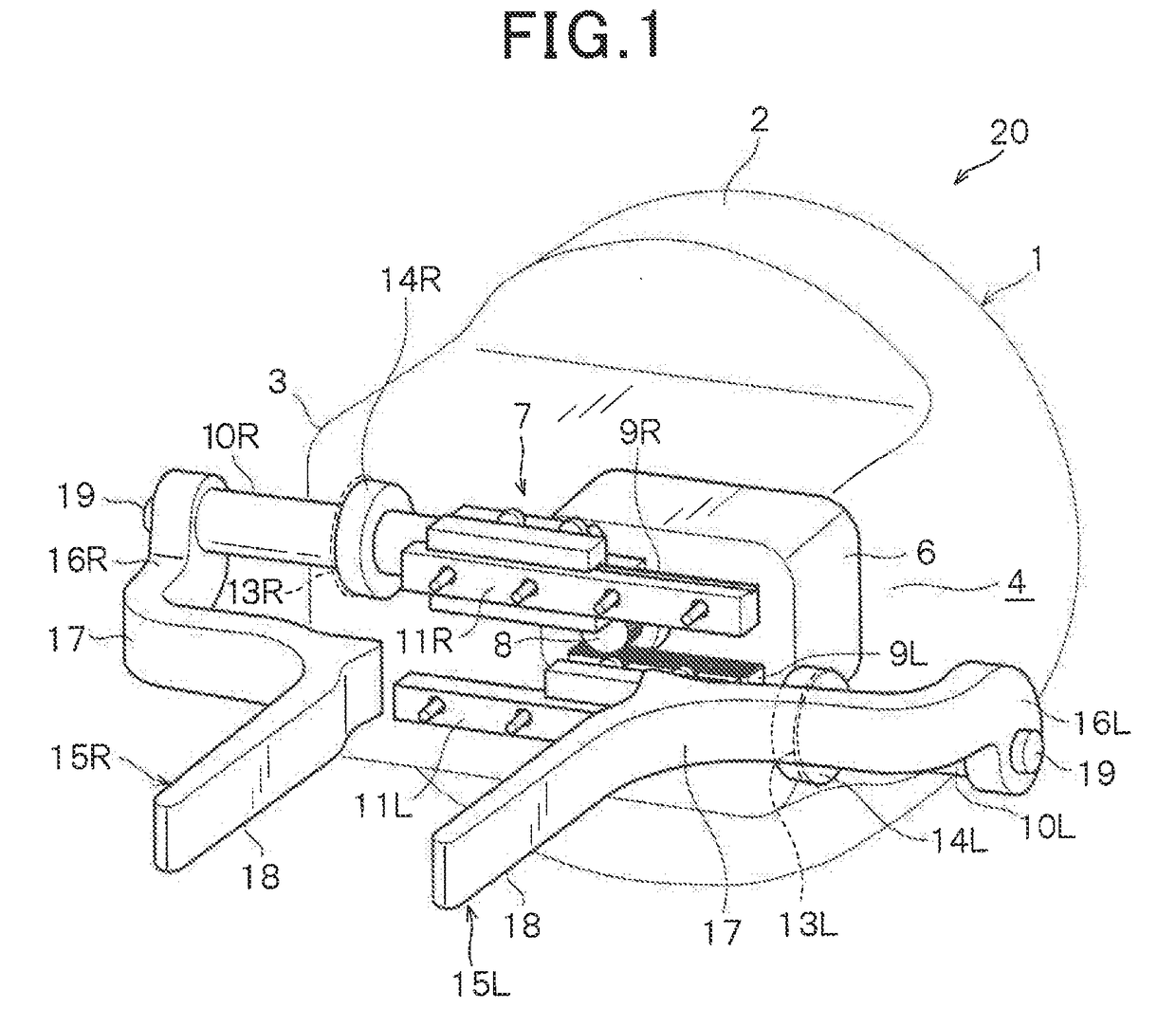

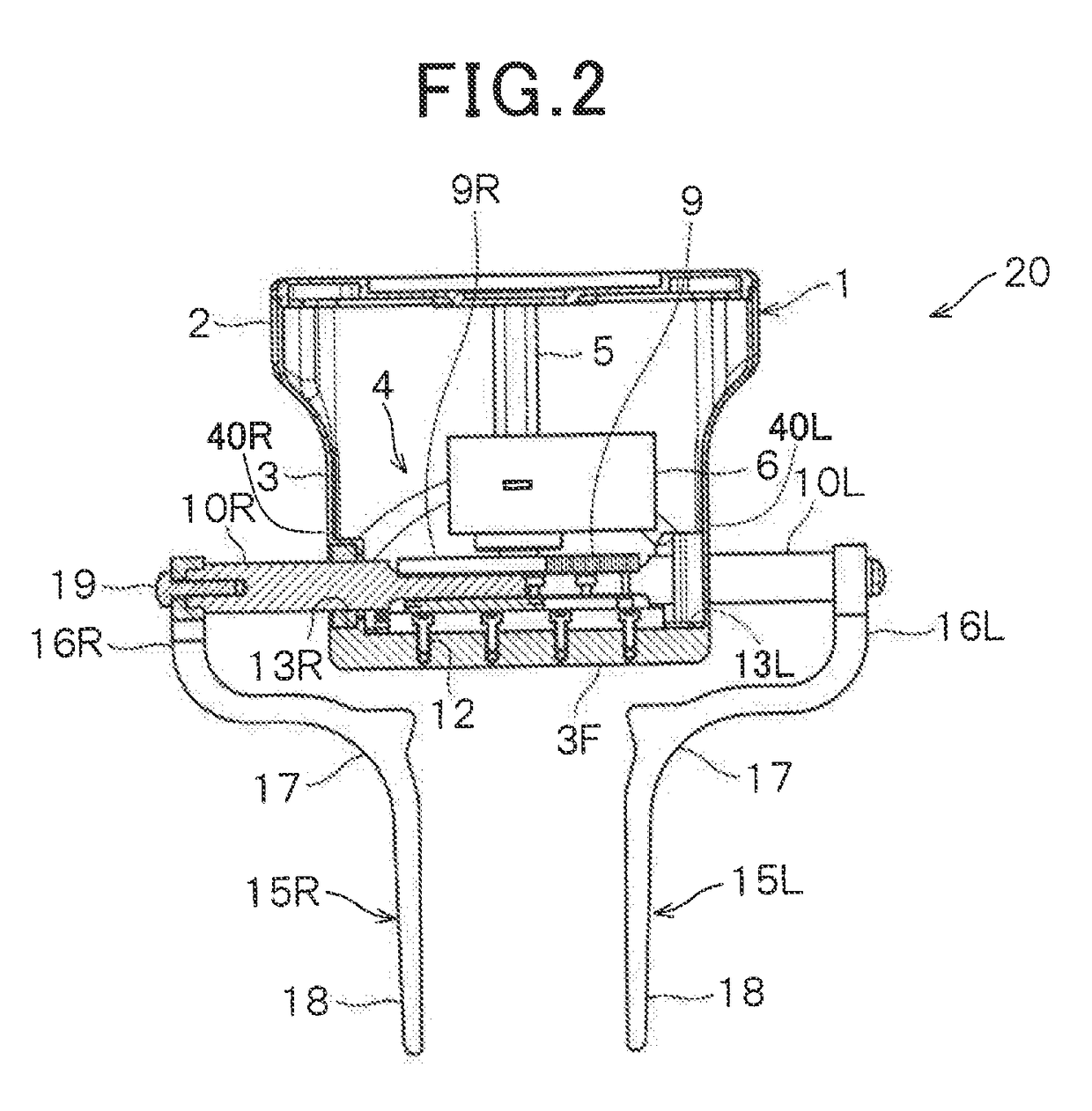

Robot hand

ActiveUS20170368694A1Improve the tightnessIncreased opening and closing strokeRobotics systemsGripping headsLinear motionRobot hand

A robot hand is designed to open or close fingers using a linear actuator disposed in a housing. The robot hand has linear motion shafts extending from inside to outside the housing through guide holes formed in a wall of the housing. Each of the fingers includes a base portion and a tip portion. The base portions are secured to the linear motion shafts outside the housing. The tip portions are bent inwardly from the base portions in directions in which they approach each other and then extend toward tips of the fingers. A sealing member is disposed between each of the linear motion shafts and a corresponding one of the guide holes to hermetically isolate the inside of the housing from the outside thereof. This structure achieves an increased degree of sealing of the housing and is capable of having an increased opening or closing stroke of the fingers.

Owner:DENSO WAVE INC

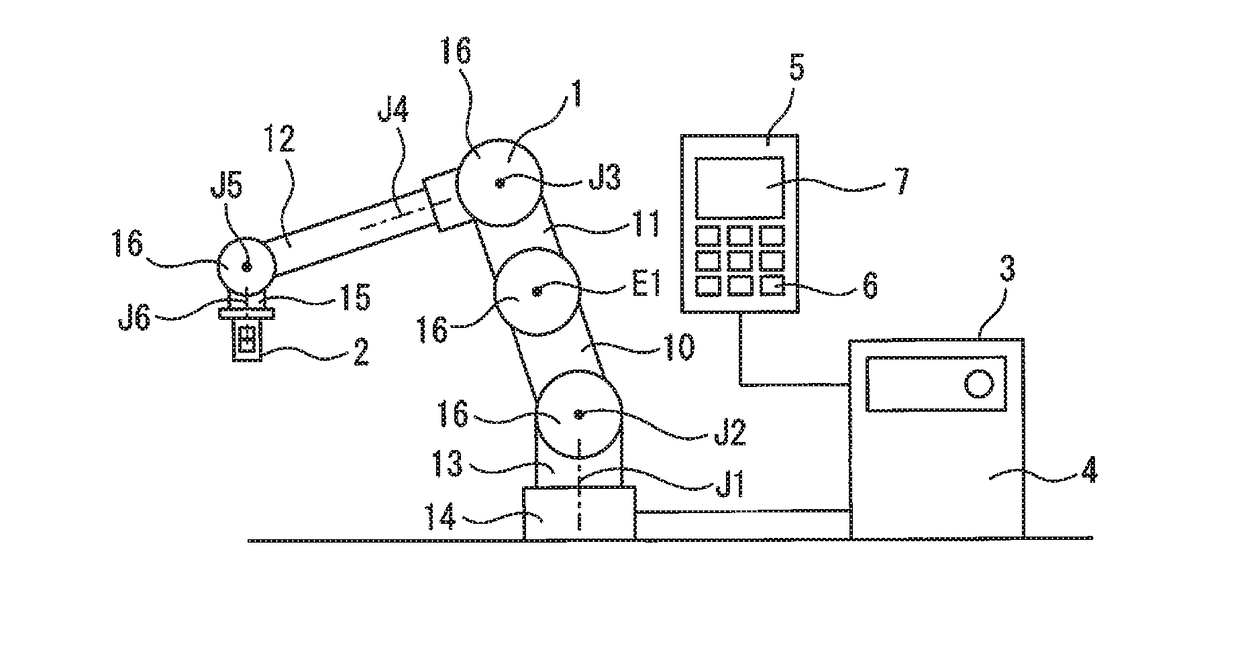

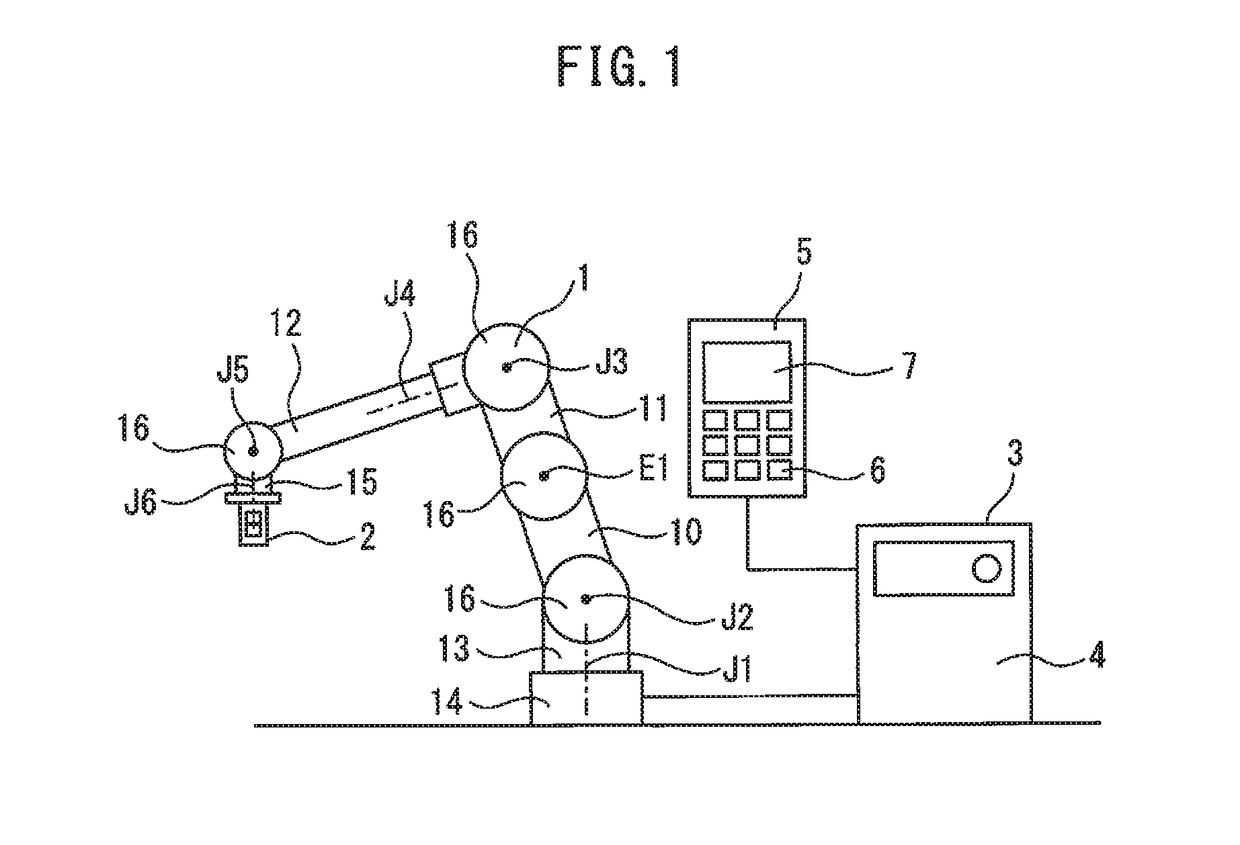

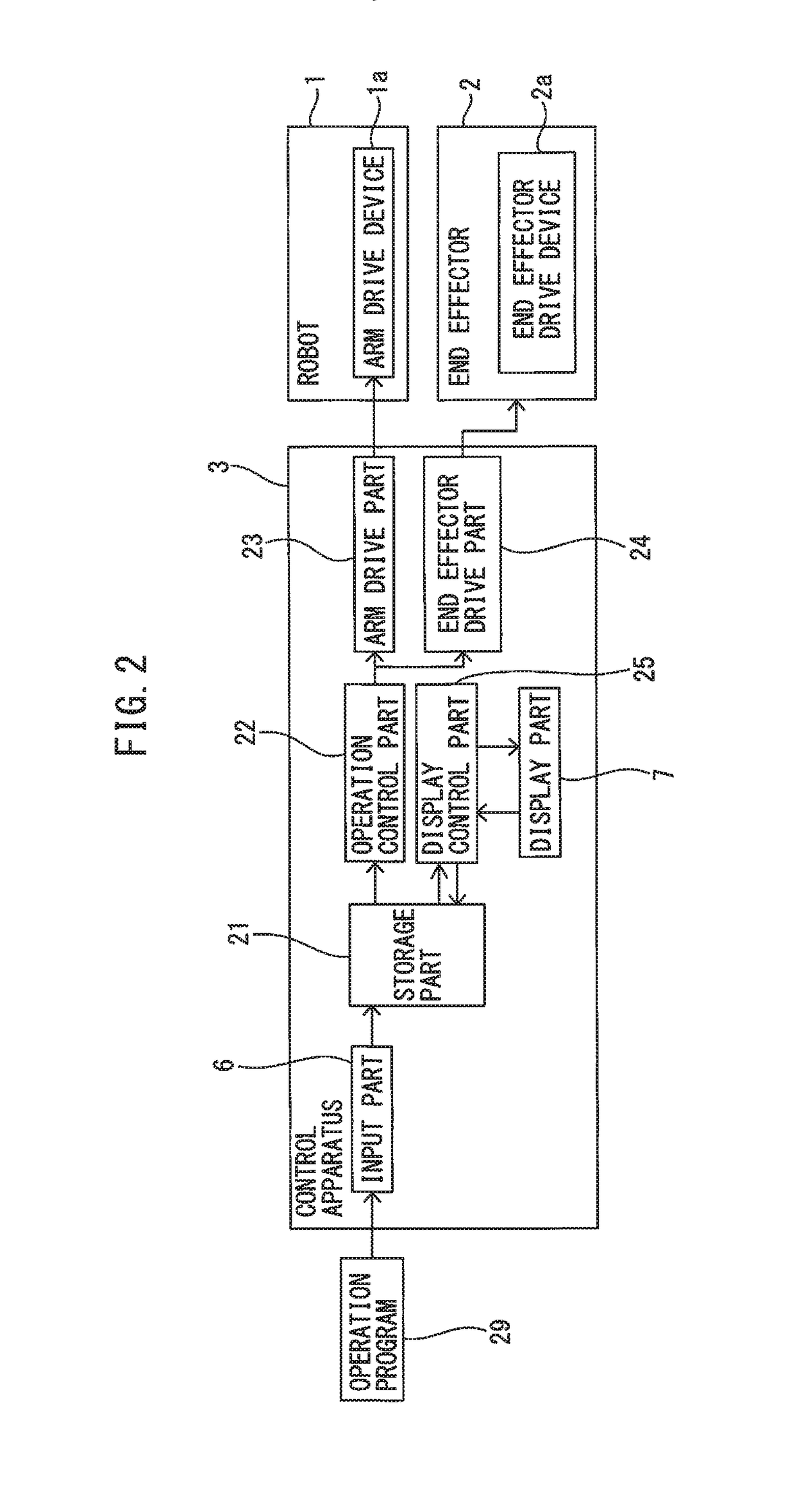

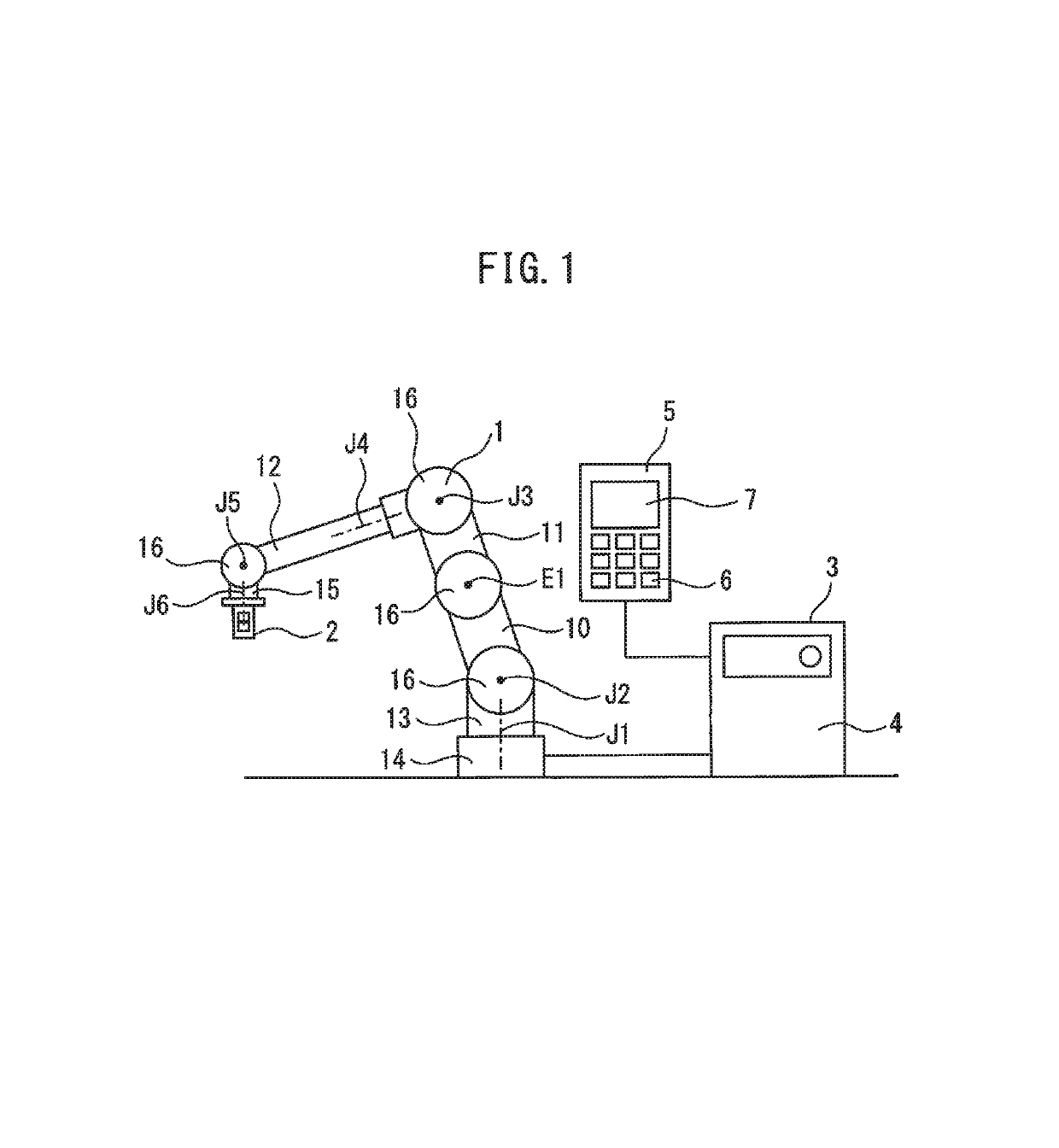

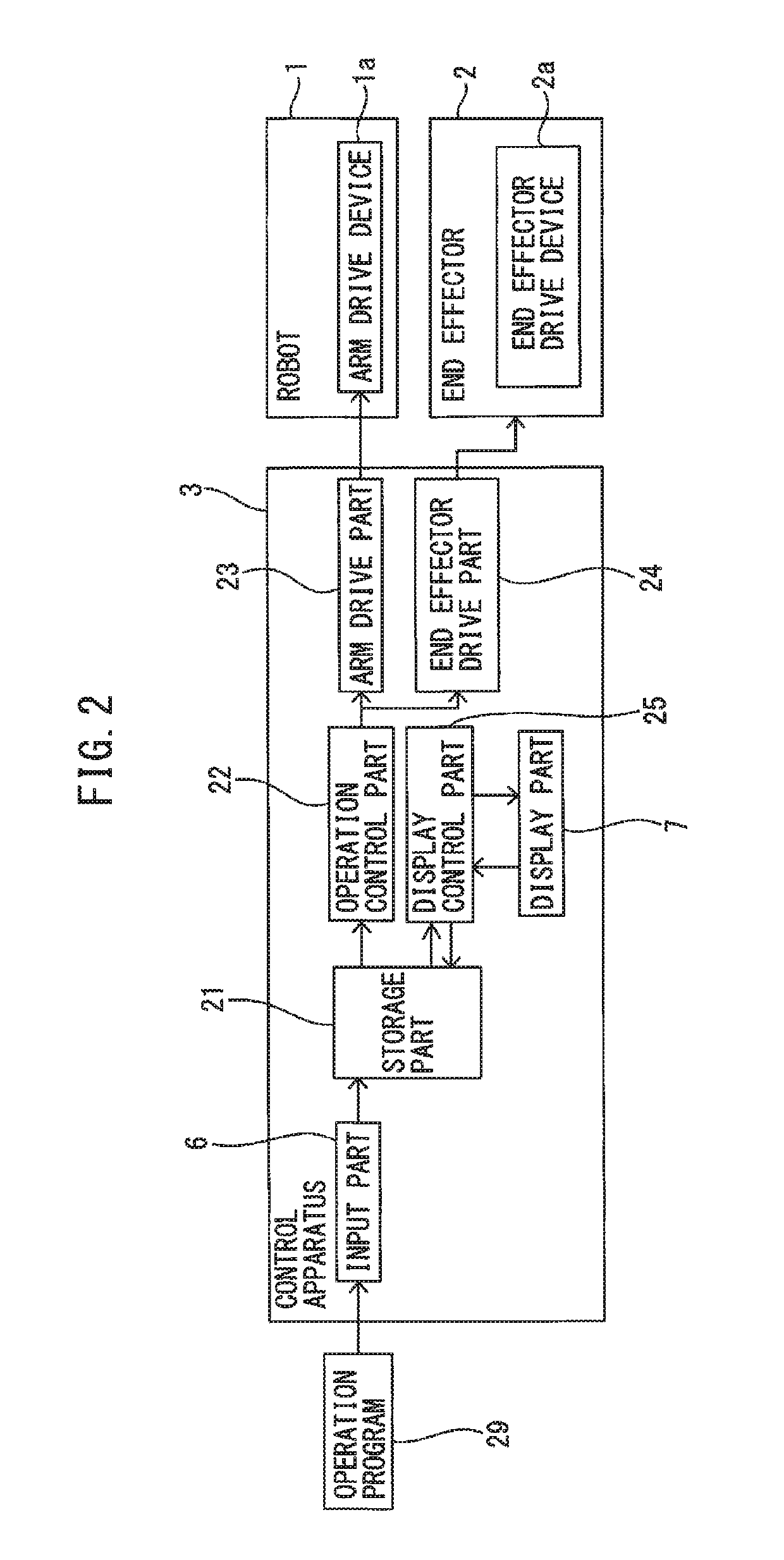

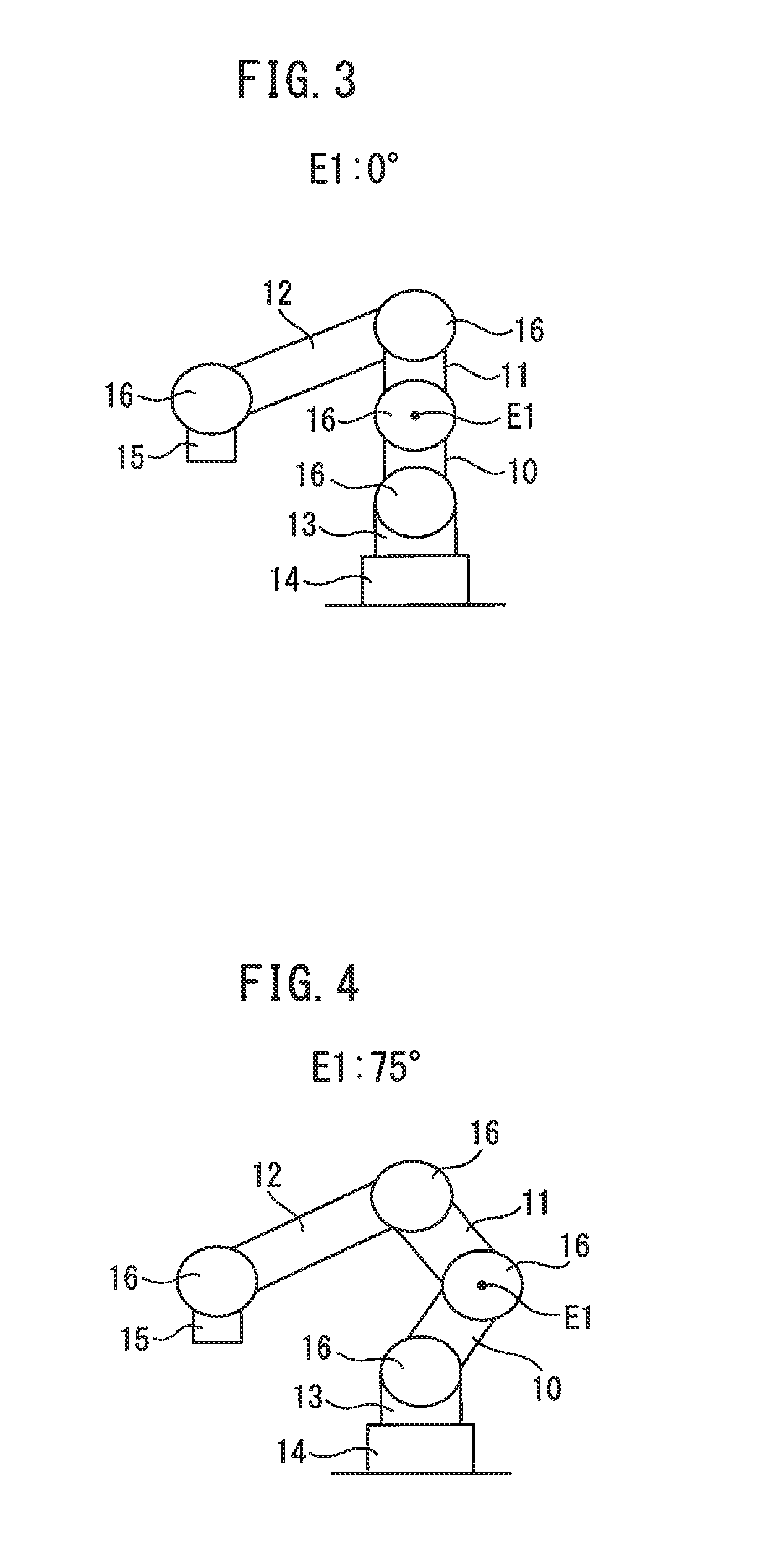

Robot control apparatus which displays operation program including state of additional axis

ActiveUS20170312912A1Easily estimate stateEasily estimate state and operationProgramme-controlled manipulatorRobotics systemsSimulationRobot control

A robot control apparatus controls a robot having six drive axes and a drive axis as an additional axis. The control apparatus includes a display control part which controls a display of a display part. The display control part displays, on the display part, a first picture which displays an operation program including an operation statement and a second picture which displays a state of the drive axes included in the operation statement. The display control part displays the operation statement including a state of the additional axis without including a state of the six drive axes in the first picture.

Owner:FANUC LTD

Agent robot control system, agent robot system, agent robot control method, and storage medium

Provided is an agent robot control system comprising an acquisition unit which acquires a purchasing master list which shows a user's purchase merchandise candidates, and a control unit which generates a purchasing execution list for recommending, from the purchasing master list, purchases for select merchandise to be performed at real storefronts and for recommending purchases for other merchandise to be performed at online storefronts.

Owner:SONY CORP

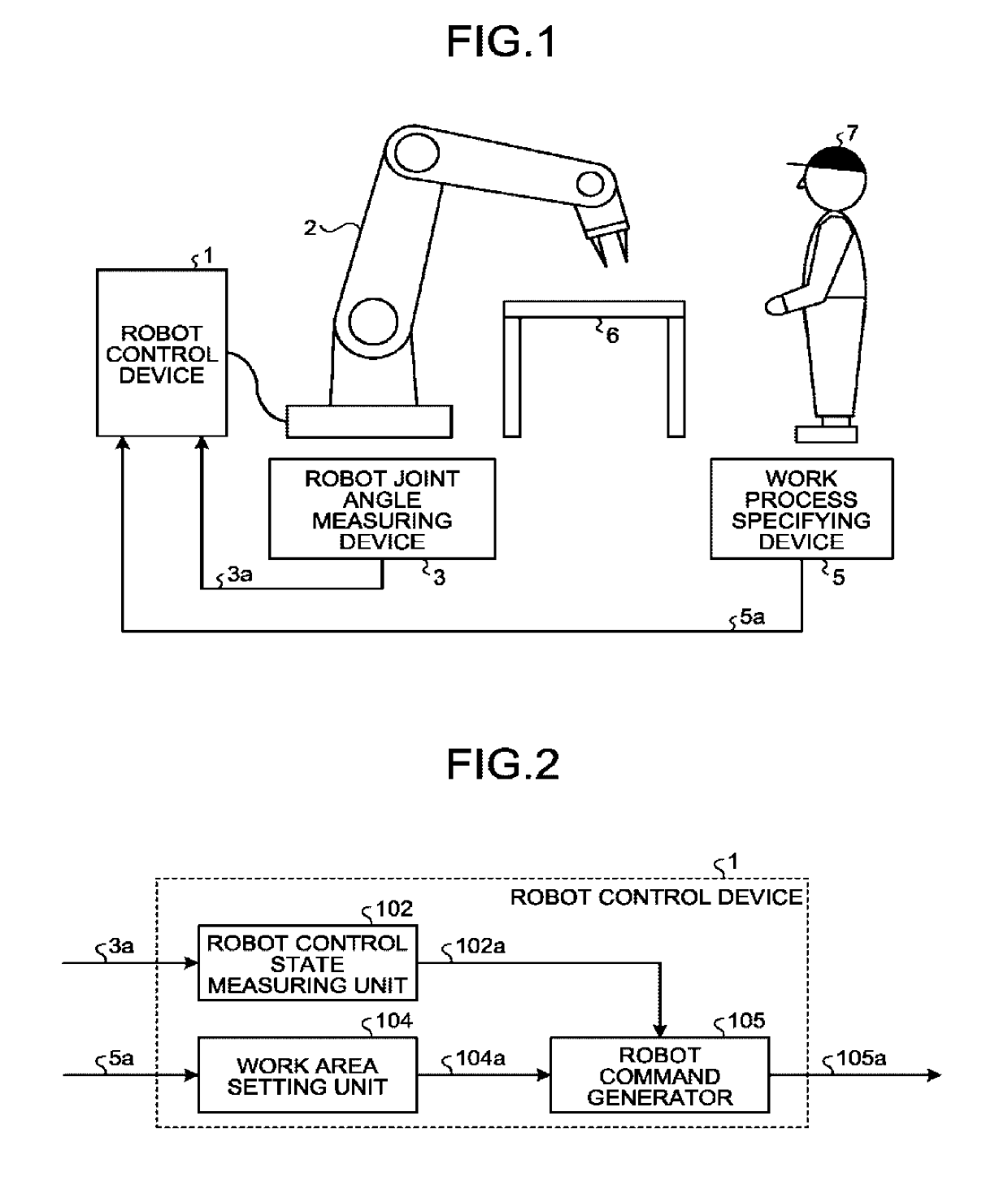

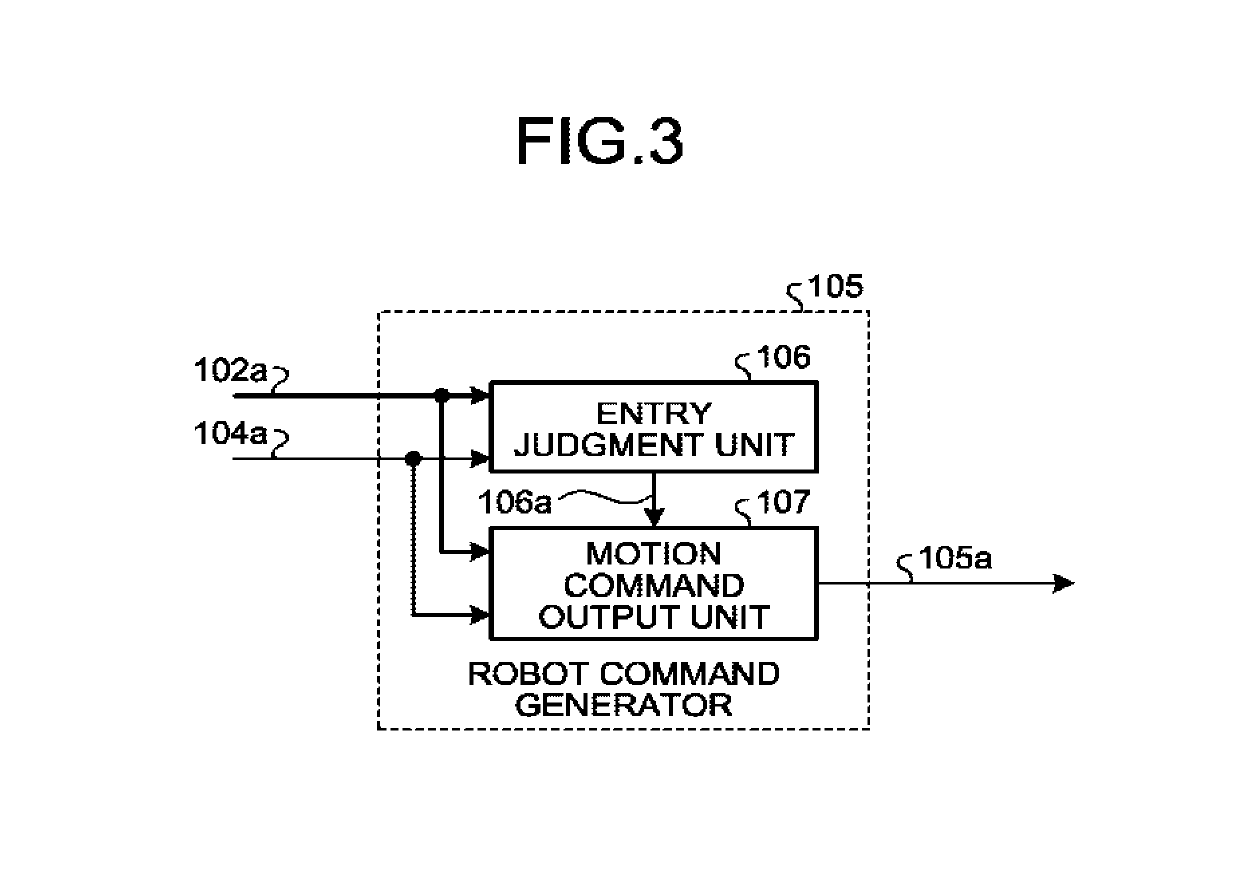

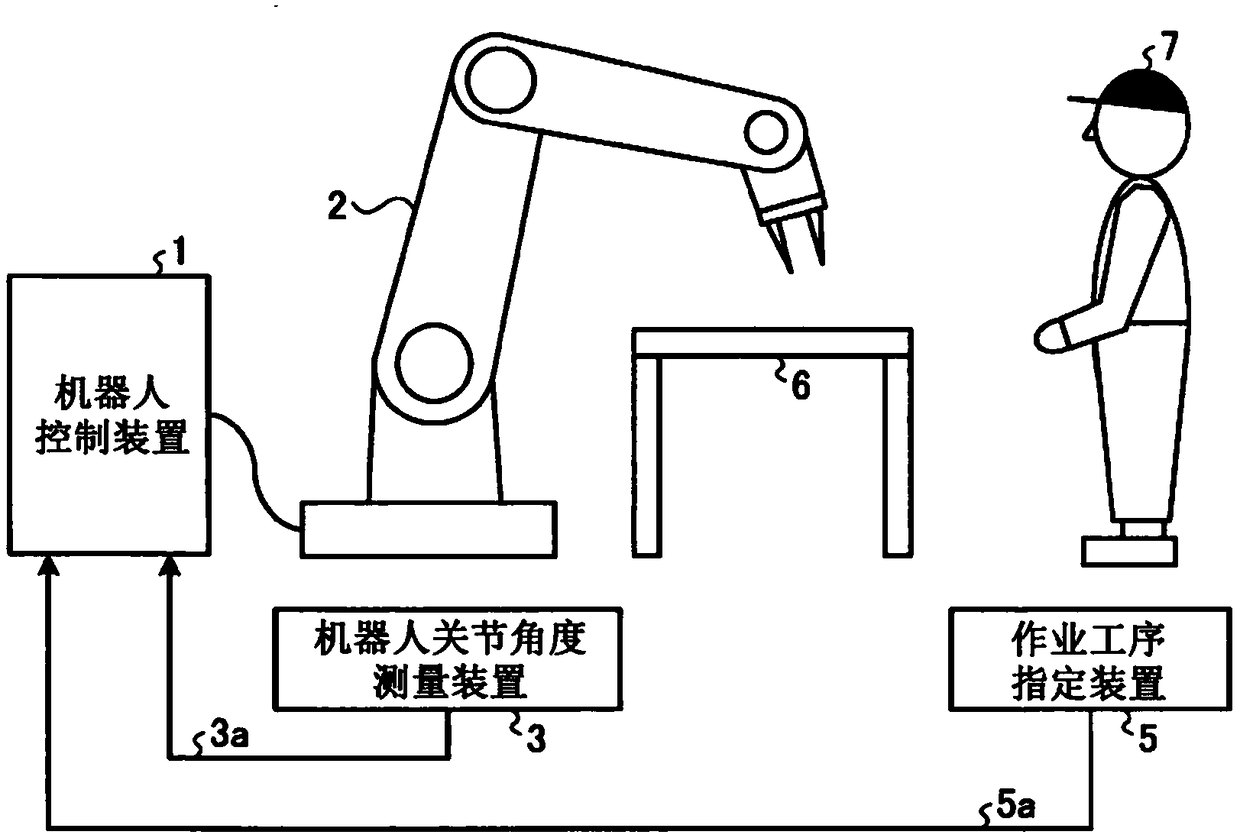

Robot control device

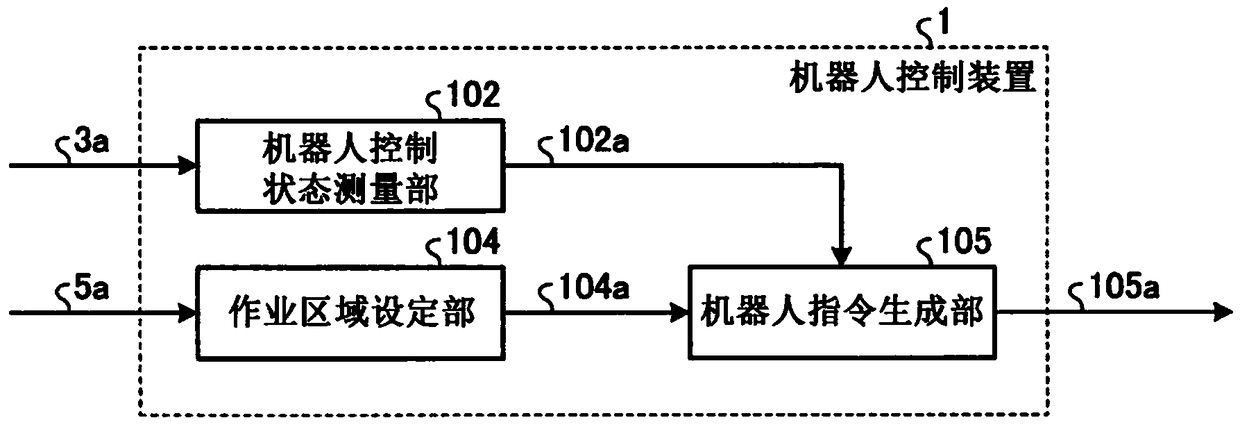

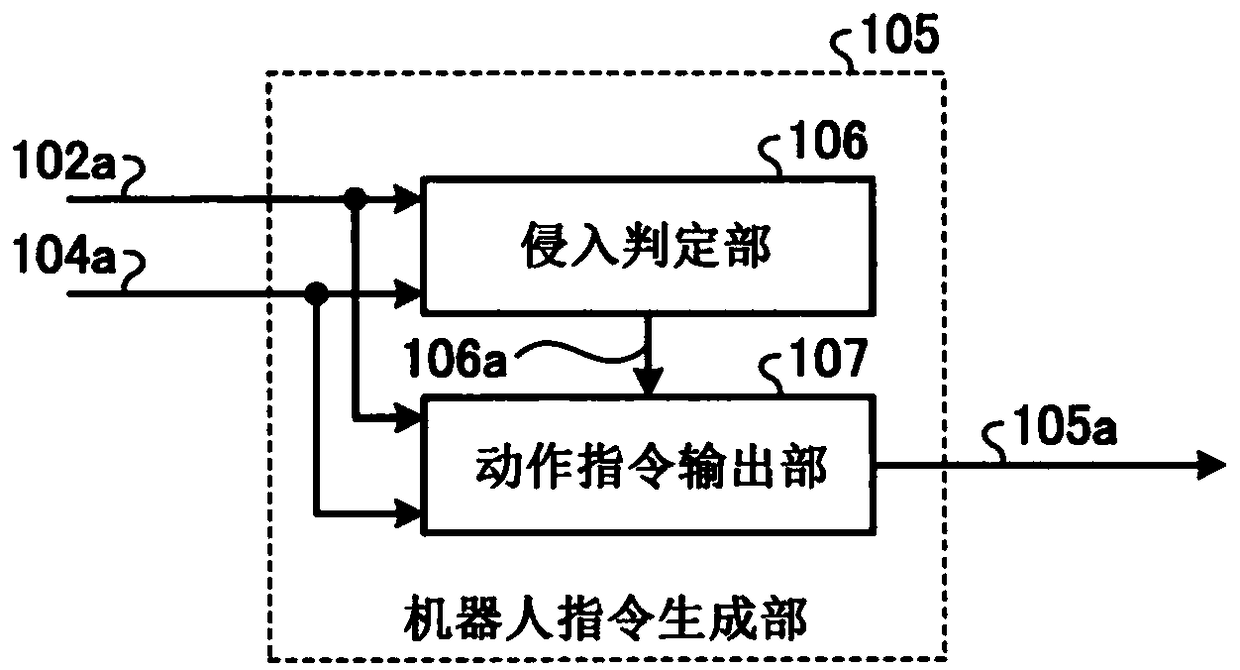

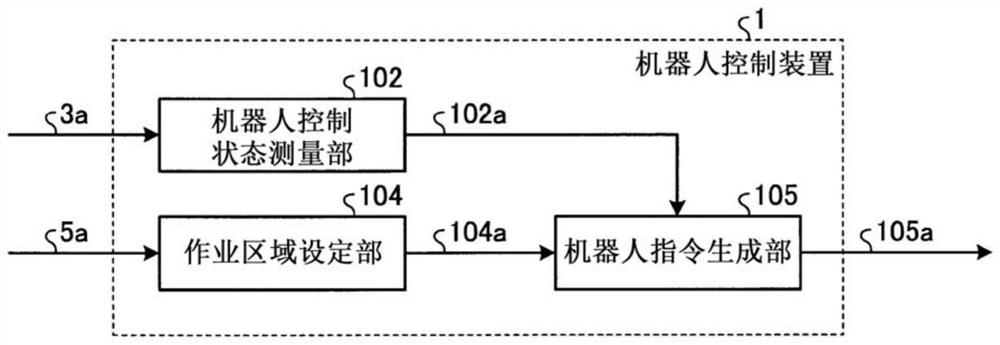

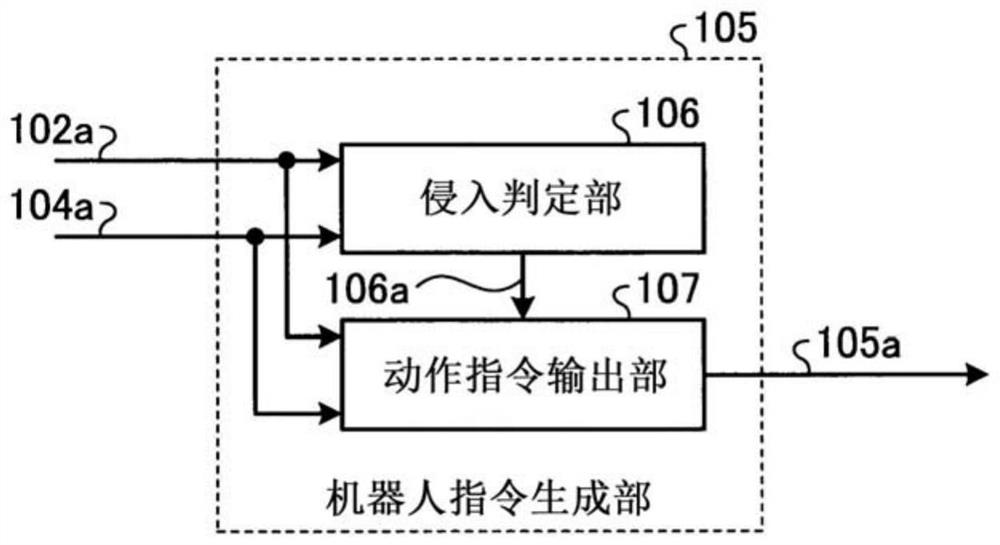

ActiveUS20190134819A1Reduce the likelihood of a collisionImprove working efficiencyProgramme-controlled manipulatorRobotics systemsSimulationEngineering

A robot control device includes: a measuring unit to measure a robot control state indicative of a position and a posture of the robot; a work area setting unit to store, for each of work processes, a work area that is defined by work movement of the worker between a start and an end of each of the work processes and includes a space a body of the worker occupies and to set the work area corresponding to the work process currently carried out by the worker based on a signal specifying the work process currently carried out by the worker; and a robot command generator to generate a motion command for the robot based on the work area and the robot control state. The generator varies the command for the robot based on whether the robot is present in the work area.

Owner:MITSUBISHI ELECTRIC CORP

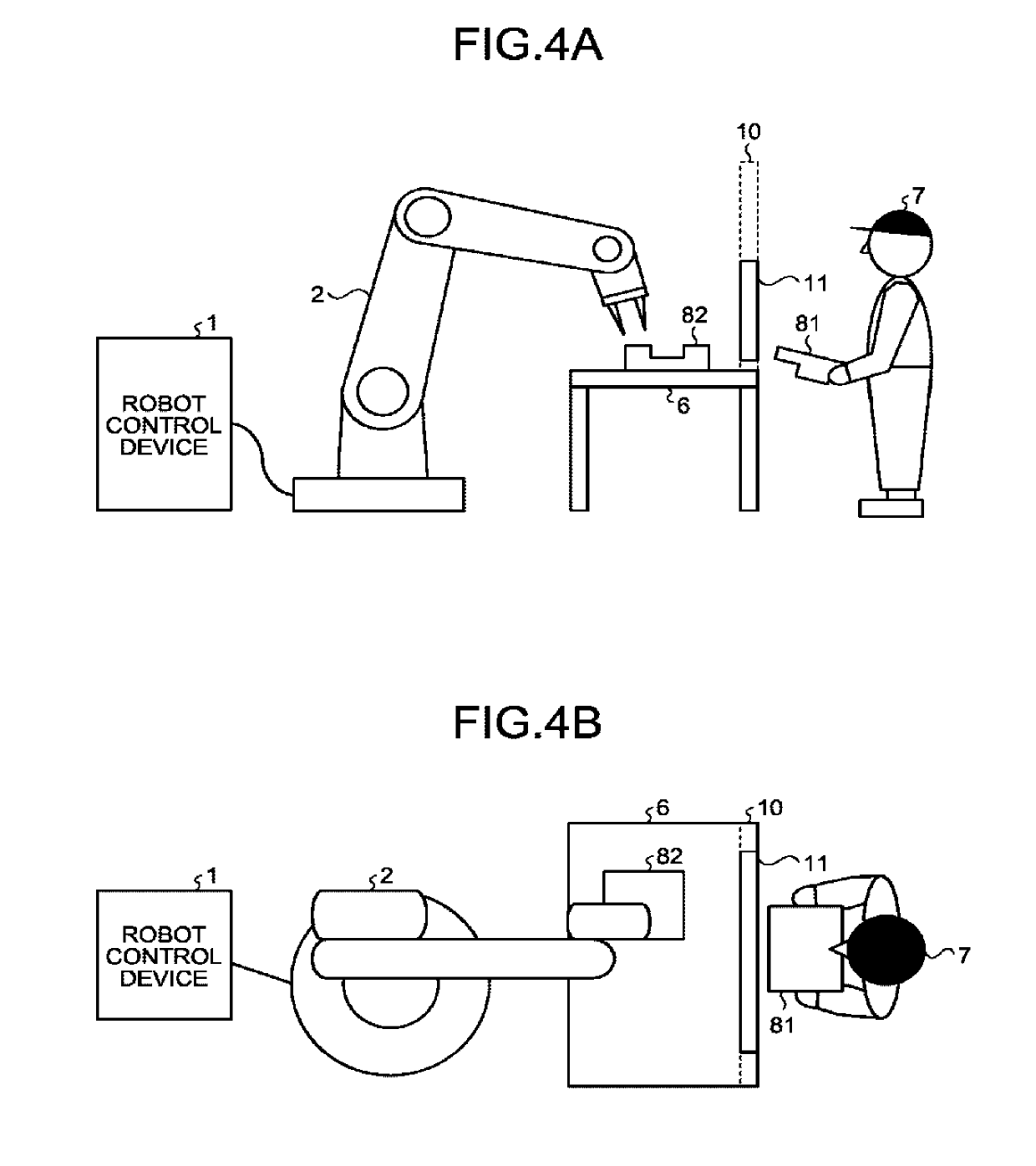

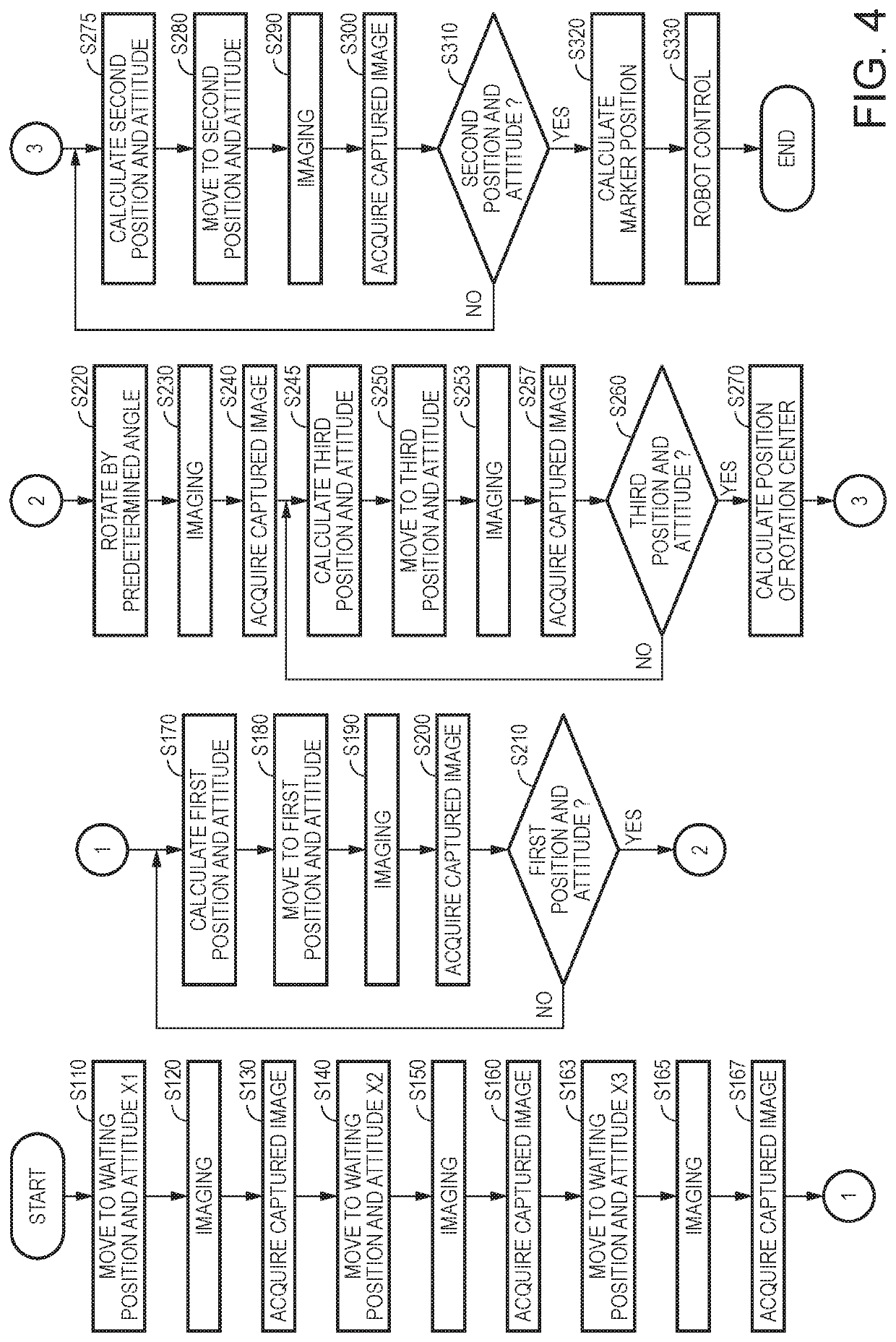

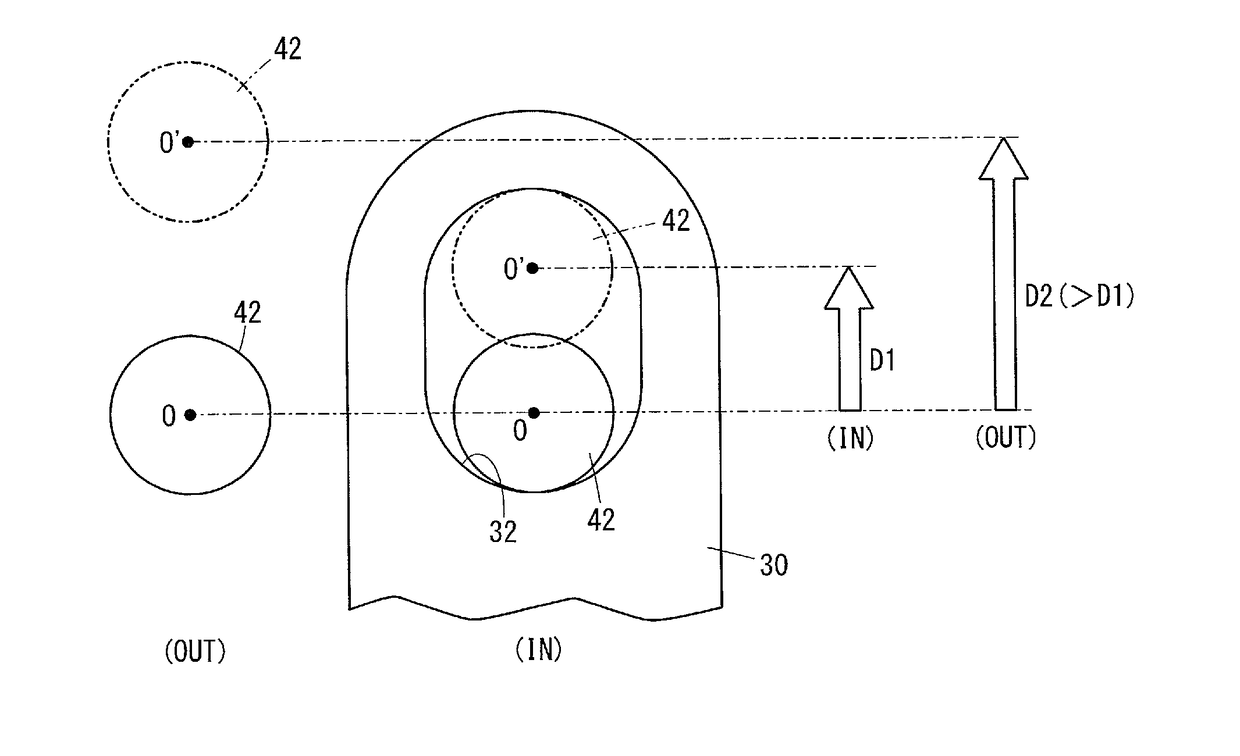

Robot, robot control apparatus and robot system

ActiveUS10551821B2Ensure correct executionEasy and accurate settingProgramme-controlled manipulatorRobotics systemsRobotic systemsEngineering

A robot includes a movable part, and the movable part performs an action based on a position of a first marker obtained using first position and attitude of the movable part when a first image containing the first marker is captured by an imaging unit provided in the movable part and second position and attitude of the movable part when a second image containing the first marker is captured by the imaging unit.

Owner:SEIKO EPSON CORP

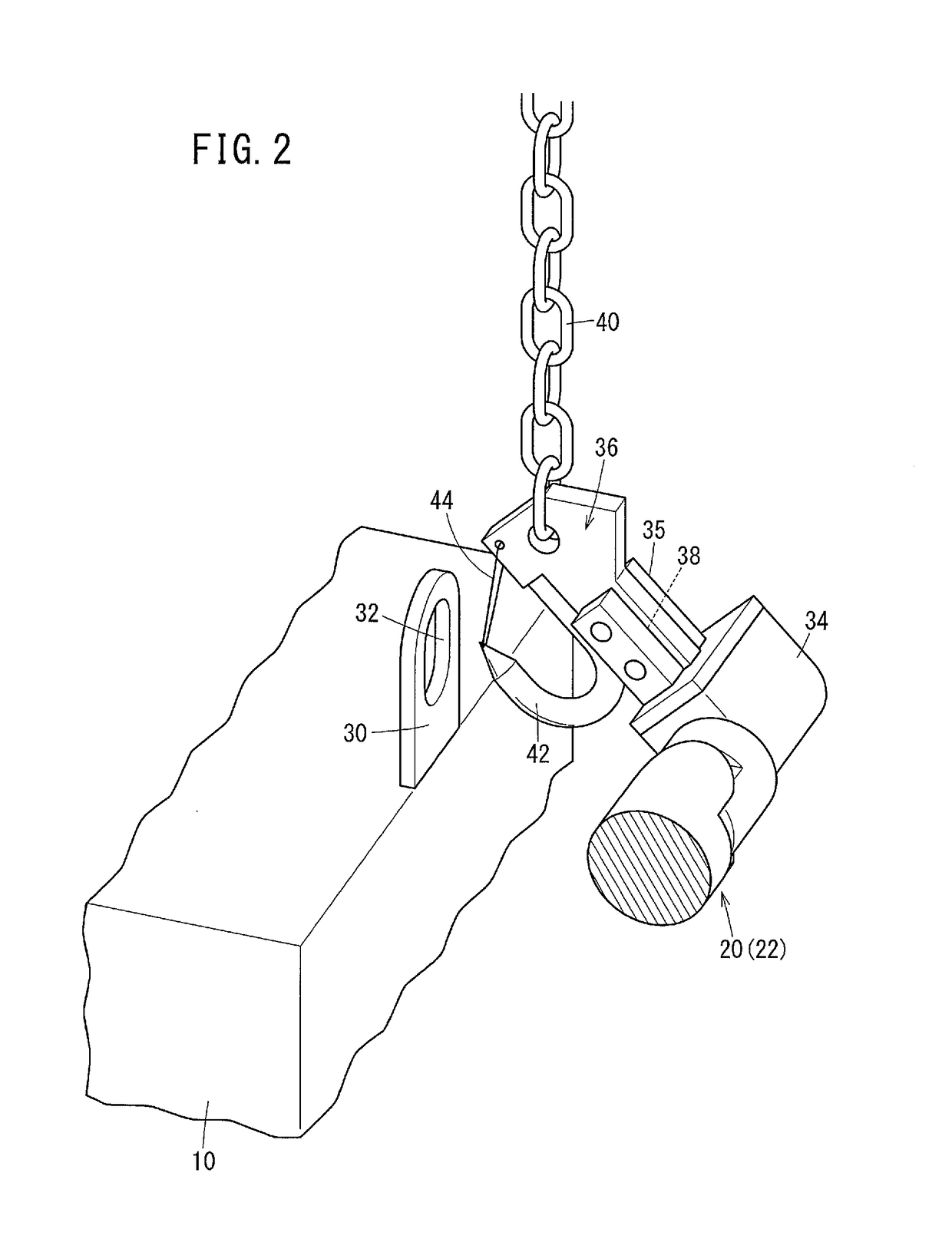

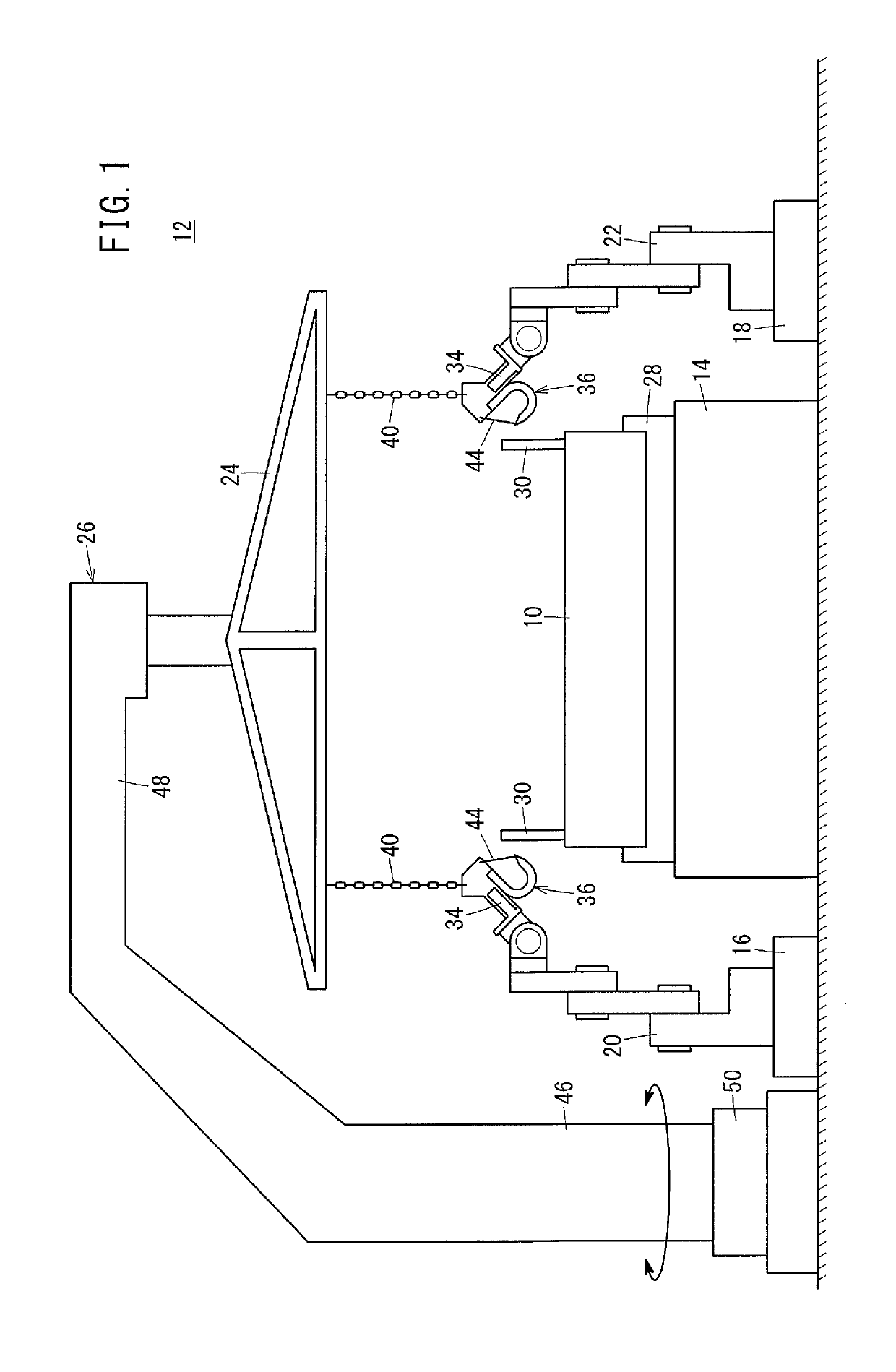

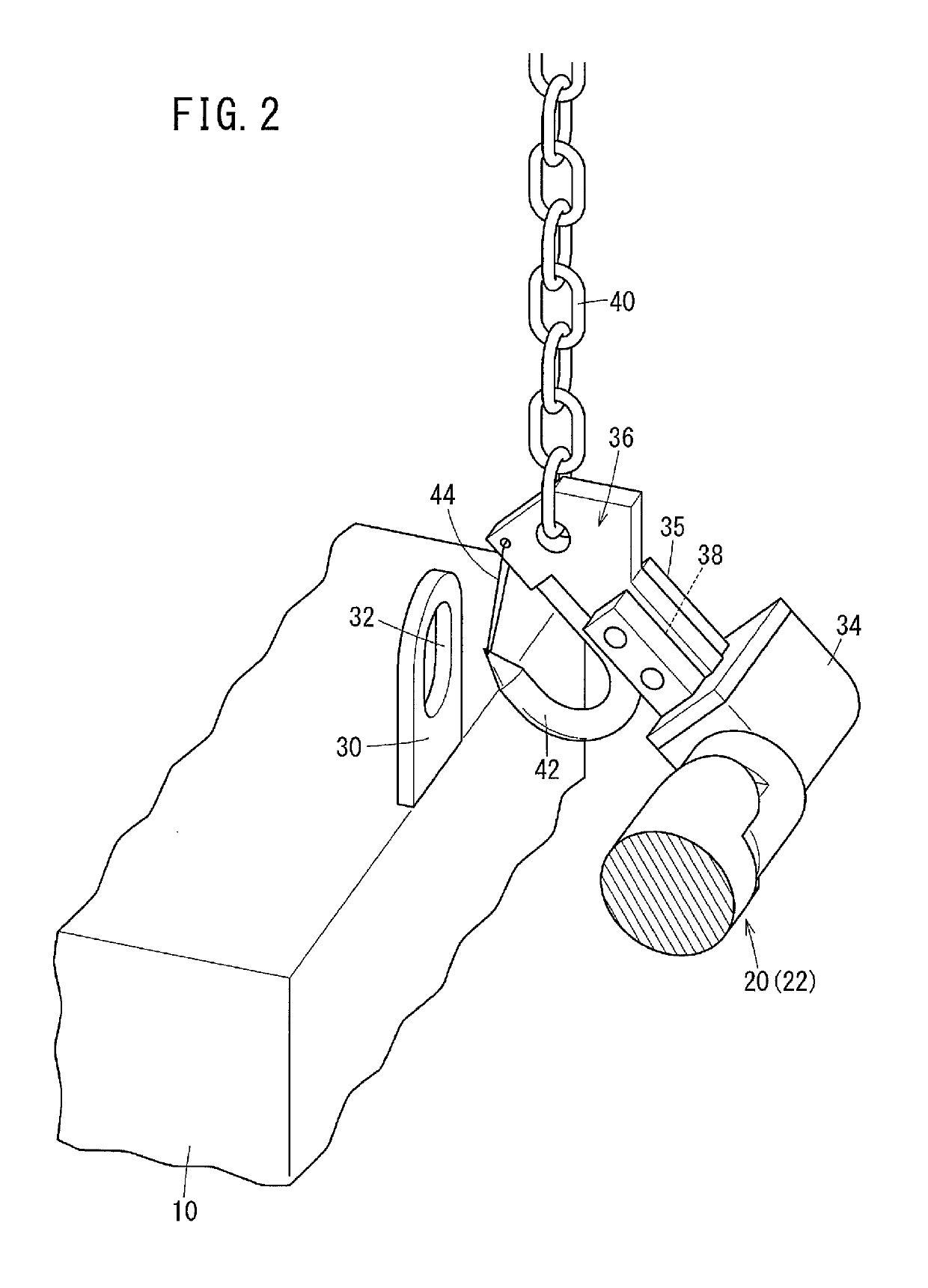

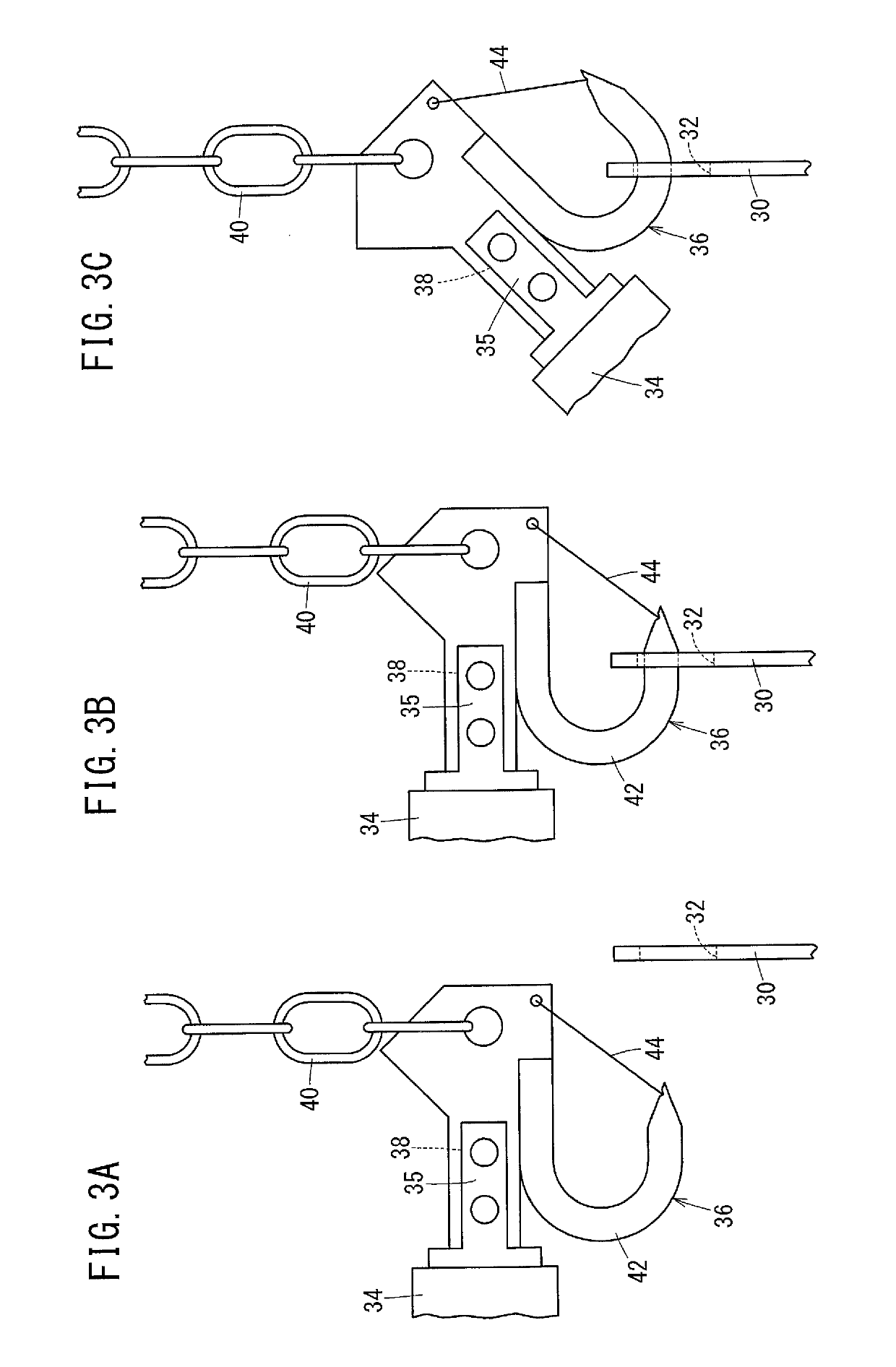

Engagement confirmation method performed by robot

ActiveUS20180016119A1Reduce the burden onSimple configurationProgramme-controlled manipulatorRobotics systemsHookingPosition control

A robot performs an appropriate operation in accordance with a position control, whereby an operation is carried out to pass a hook as a second engagement member through a hooking hole as a first engagement member. Thereafter, the robot is switched to a servo float control, and receives a command to raise the hook relatively with respect to the hooking hole. An amount of rising of the hook is compared with a maximum allowable amount of rising (threshold value) of the hook.

Owner:HONDA MOTOR CO LTD

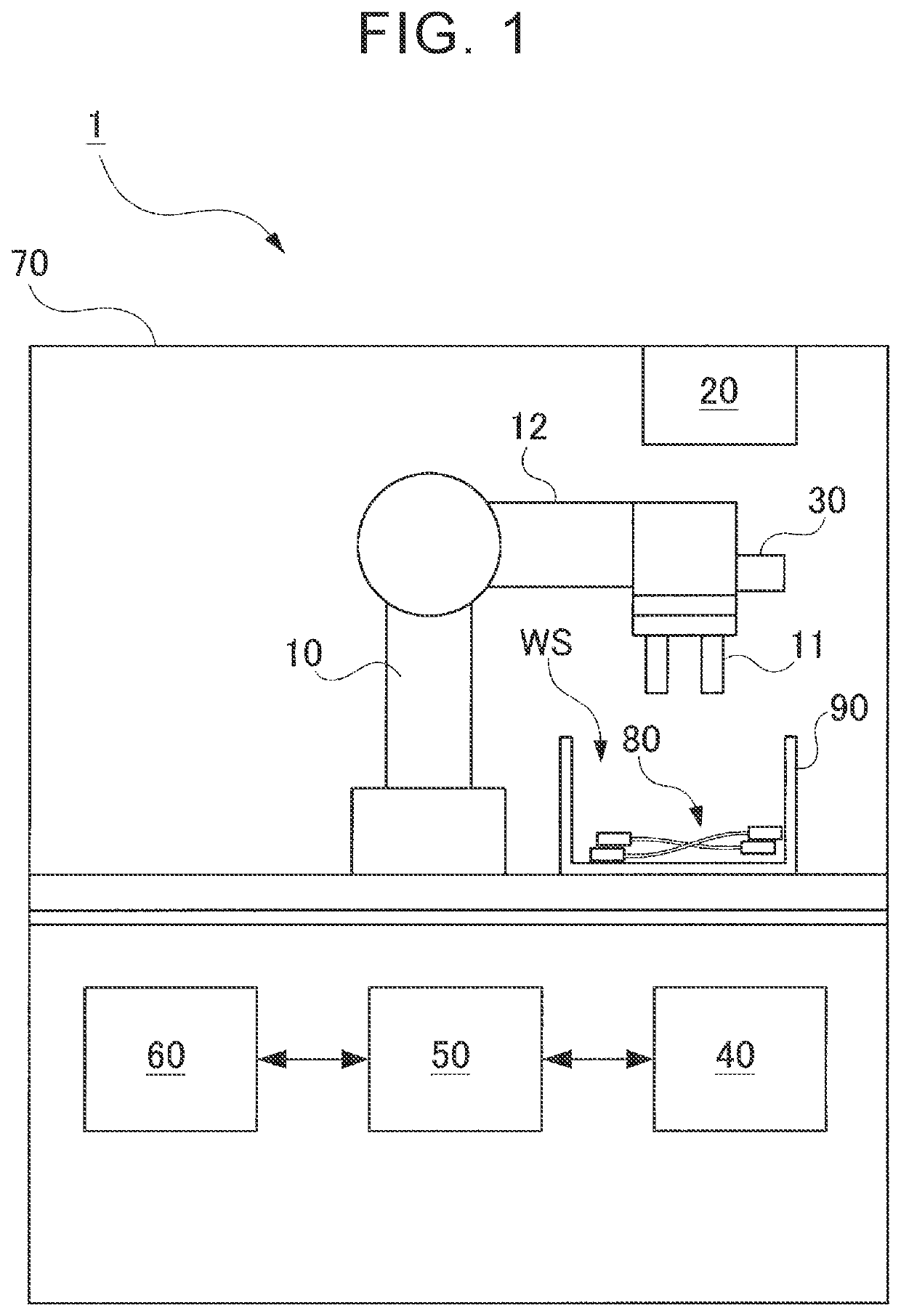

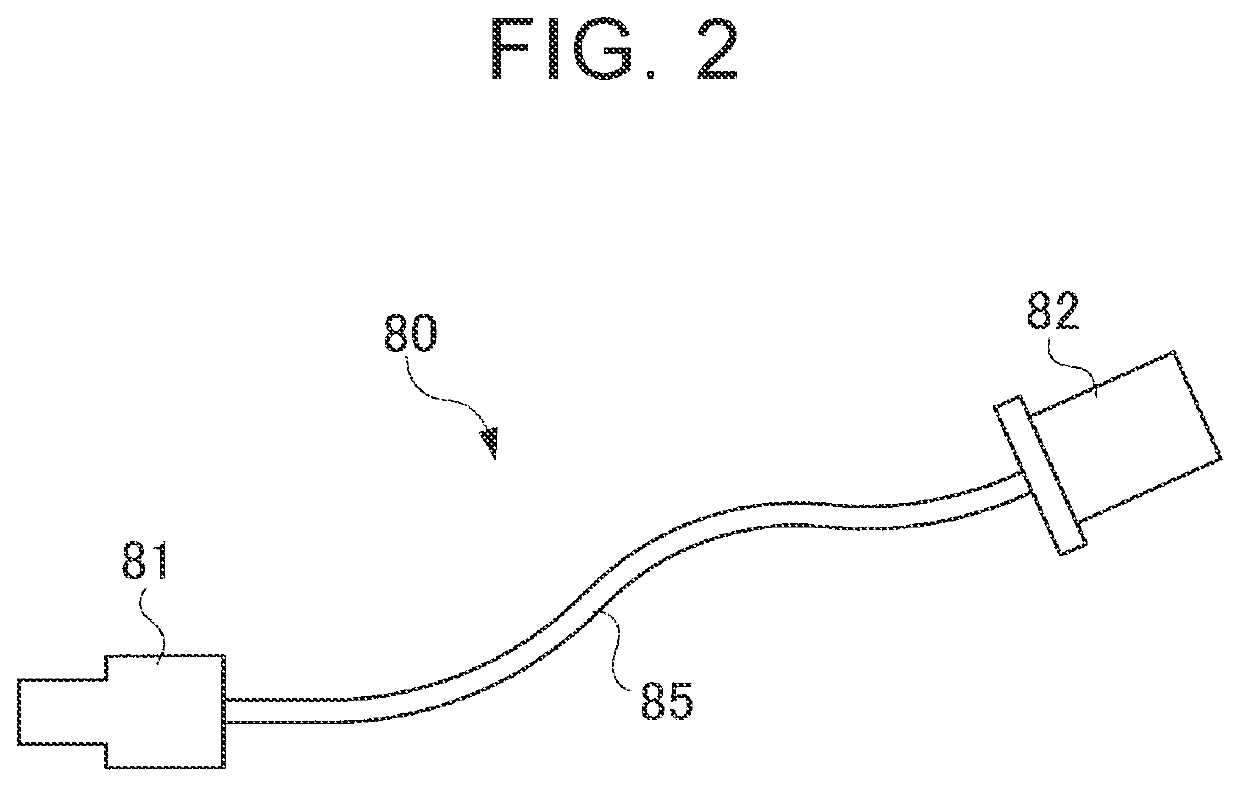

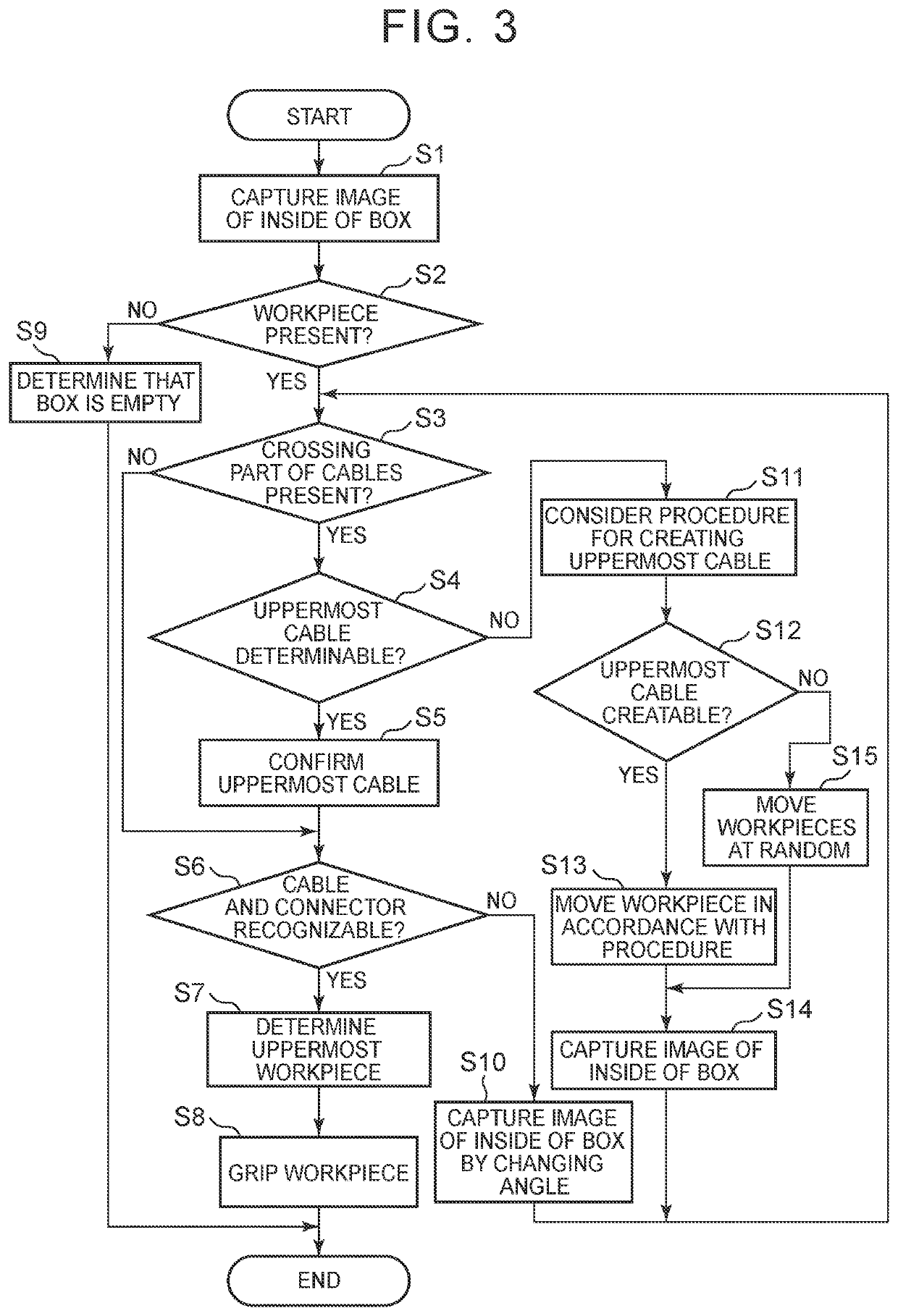

Workpiece identification method

ActiveUS11213954B2Programme-controlled manipulatorRobotics systemsComputer scienceMechanical engineering

Whether or not workpieces are present in a workpiece storage area is determined based on an image acquired by image capturing. When the workpieces are determined to be present, whether or not a crossing part is present in the workpiece storage area is determined based on the image, the crossing part being a part where soft body portions of a plurality of workpieces cross each other in an overlapping manner. When the crossing part is determined to be present, an uppermost soft body portion placed at an uppermost position among the soft body portions crossing each other is determined based on the image. A workpiece including the uppermost soft body portion thus determined is determined as an uppermost workpiece placed at an uppermost position.

Owner:TOYOTA JIDOSHA KK

Robot controller and method of controlling robot

PendingUS20200061834A1Programme-controlled manipulatorRobotics systemsSimulationReliability engineering

Owner:SEIKO EPSON CORP

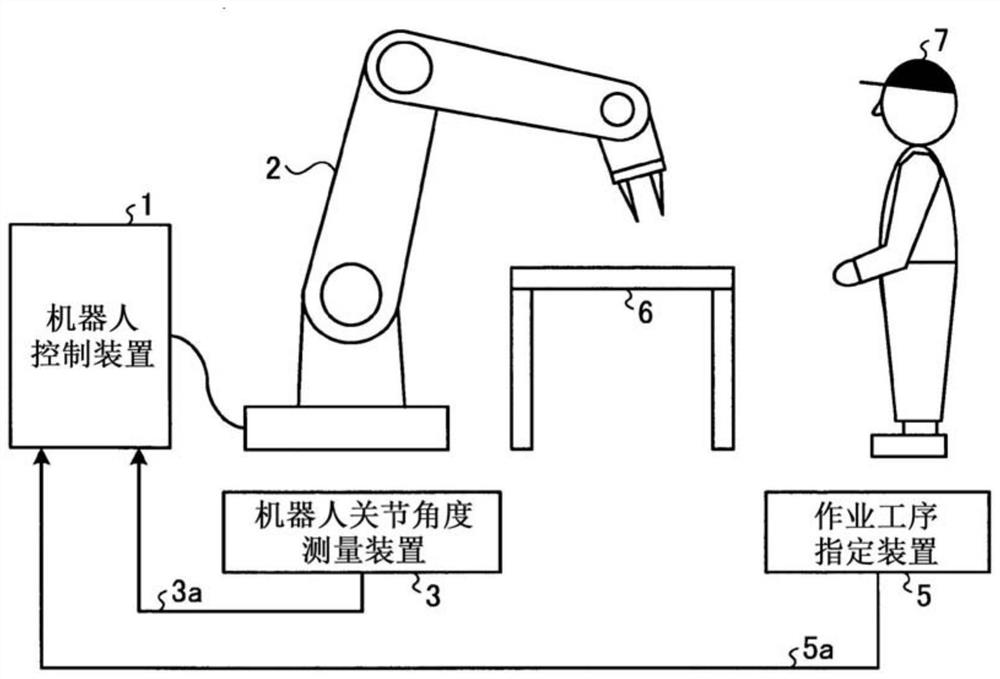

Robot control device

ActiveCN109153134AReduce the likelihood of a collisionImprove work efficiencyProgramme-controlled manipulatorRobotics systemsControl engineeringSimulation

The purpose of the present invention is to obtain a robot control device that reduces the risk of a collision occurring between a worker and a robot while maintaining high work efficiency when the worker and the robot work in a shared workspace. The present invention comprises: a robot control state measuring unit (102) that measures a robot control state that includes the position and the postureof a robot; a work area setting unit (104) that stores, for each work process, an area that contains the space occupied by the body of a worker in work actions performed by the worker from the startto the end of the work process, and that sets a work area corresponding to the current work process of the worker on the basis of a work process specifying signal that specifies the work process thatis currently being performed by the worker; and a robot command generating unit (105) that generates an operation command (105a) for the robot on the basis of the work area and the robot control state. The robot command generating unit (105) changes the operation command (105a) for the robot in accordance with whether the robot is inside the work area.

Owner:MITSUBISHI ELECTRIC CORP

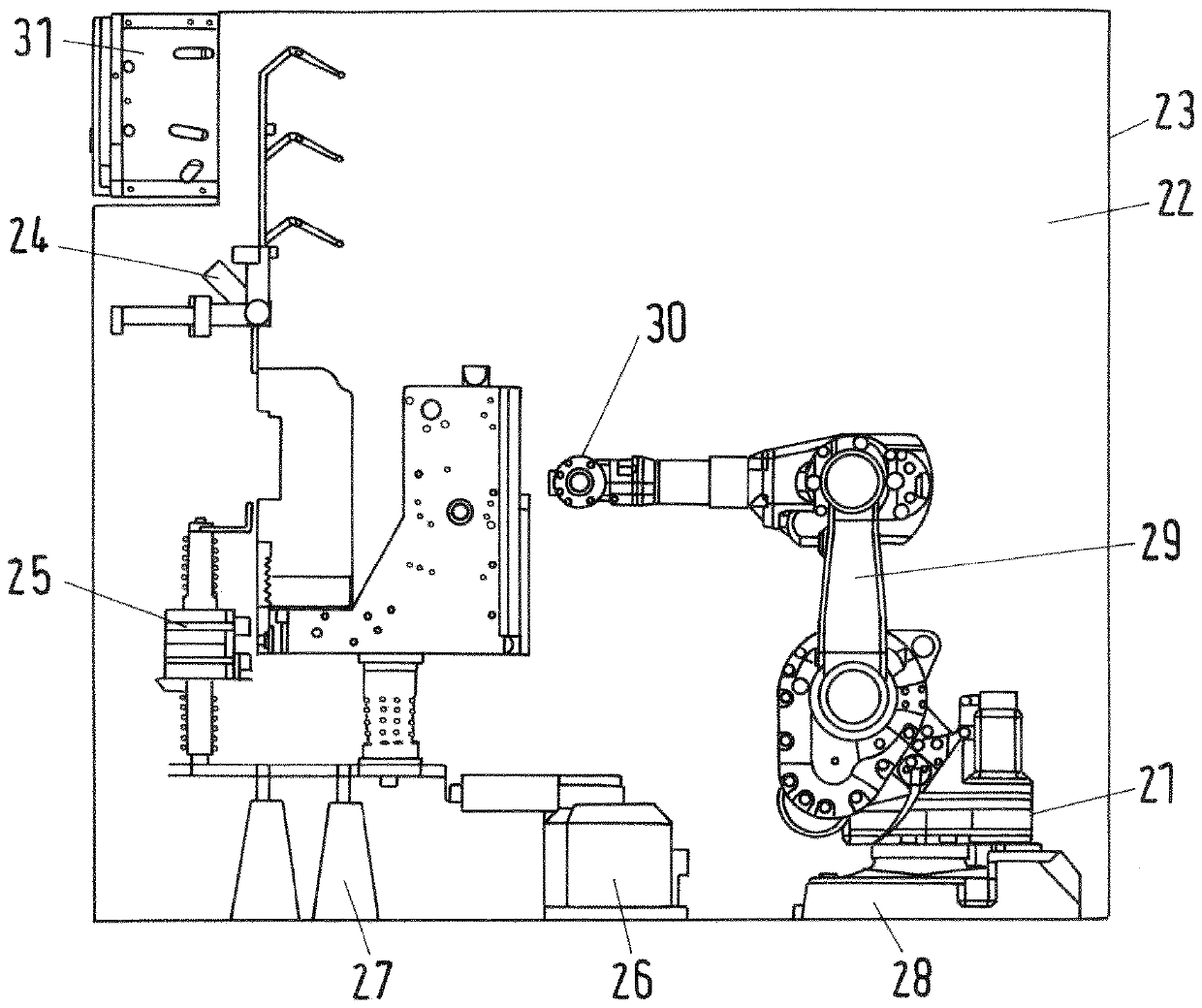

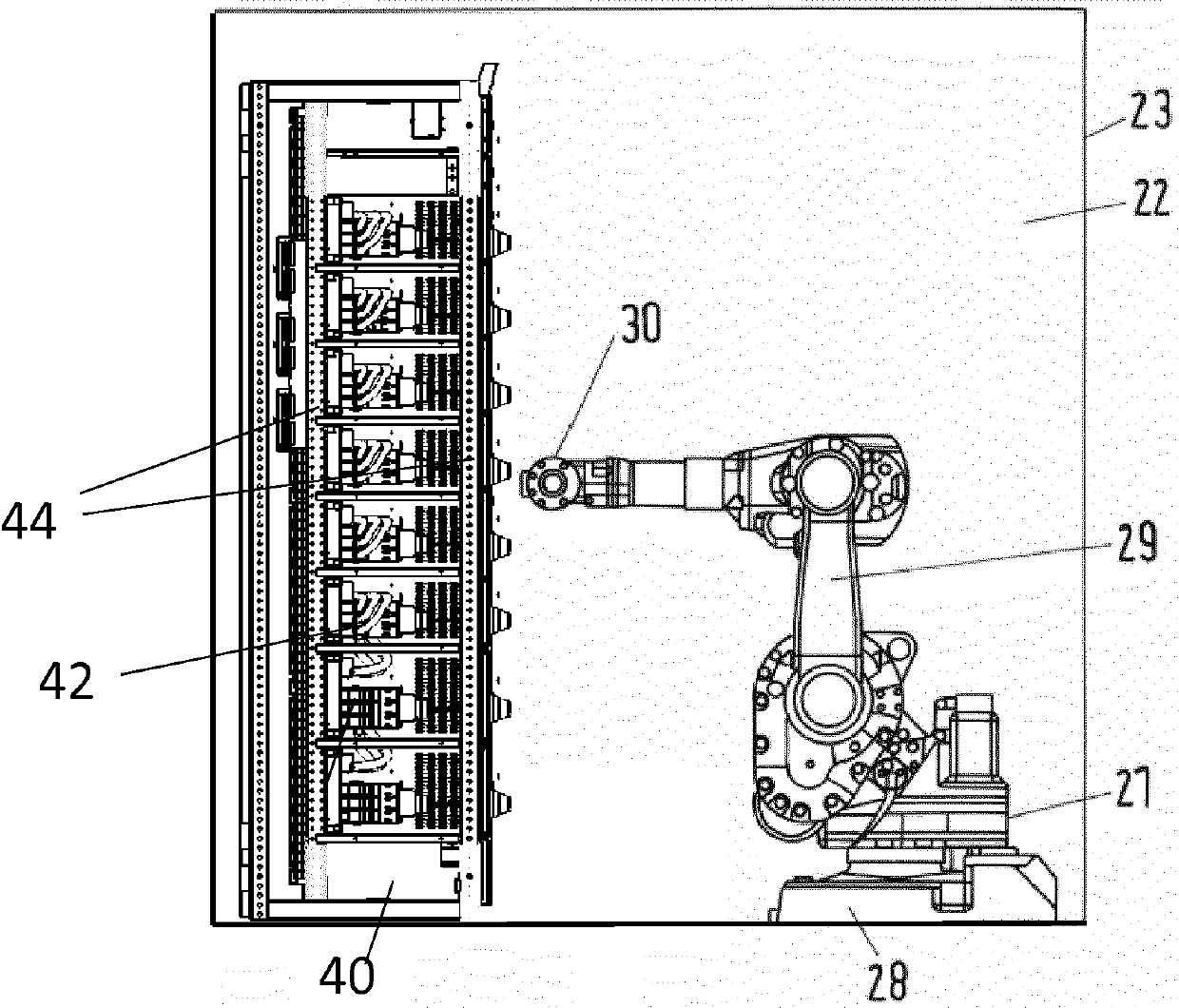

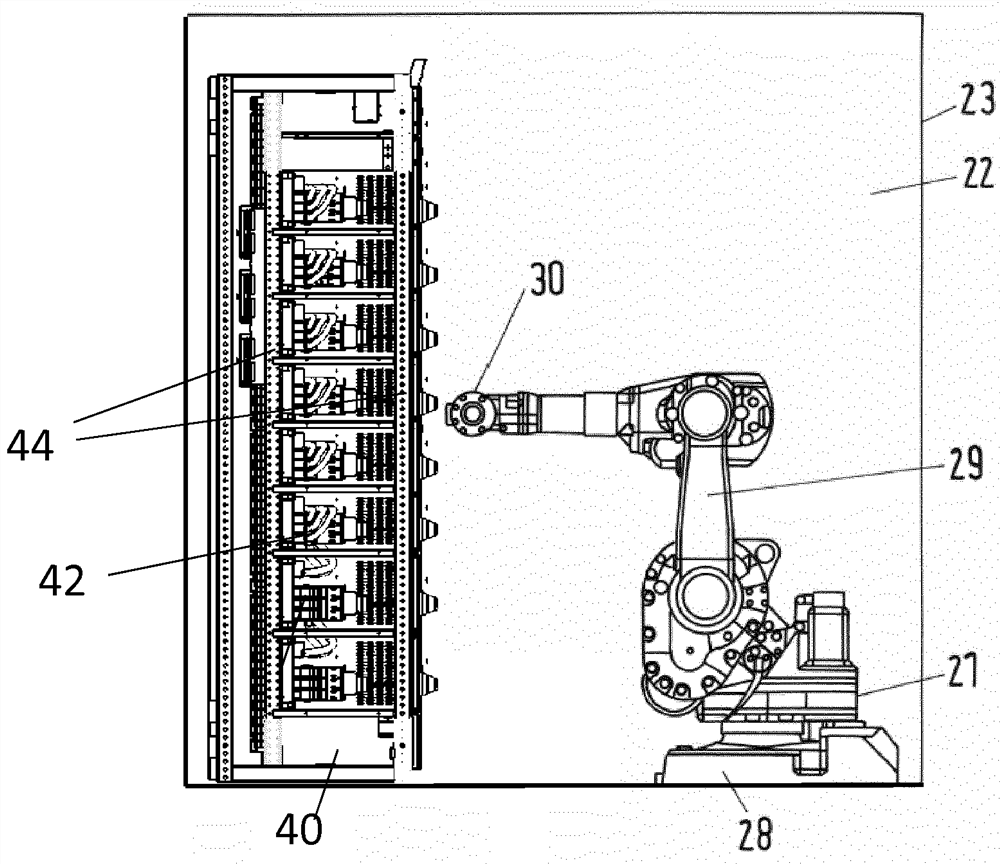

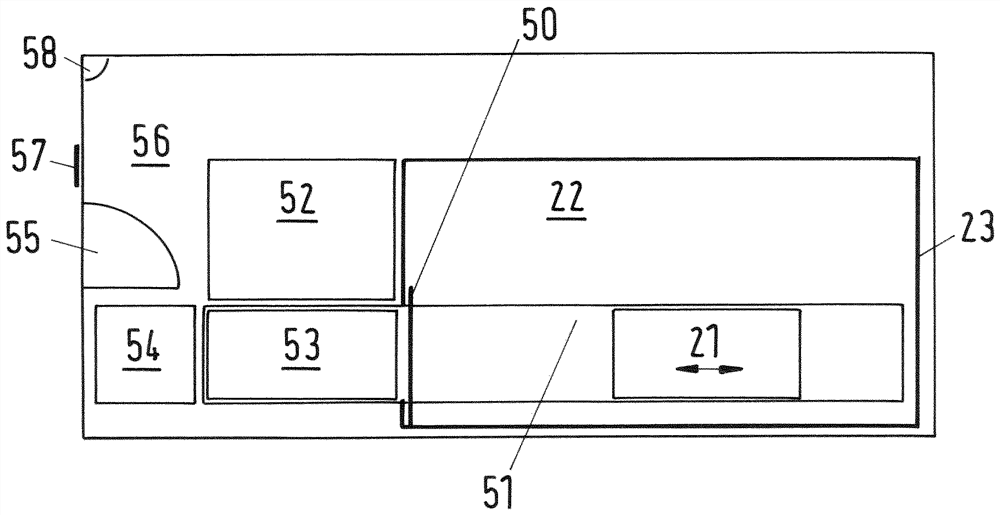

Substation containing switchgear or controlgear with unmanned operation and maintenance

ActiveCN110832720ACollect staticCollect visualProgramme-controlled manipulatorSwitchgear with horizontal withdrawalRobotic systemsSwitchgear

The invention relates to a substation containing switchgear or controlgear with unmanned operation and maintenance, according to the preamble of claim (1, 4), (0 and 12). In order to proceed the operating and / or maintenance of such substations in an automized way, and just in case of further need of human operator, to enhance security for the human operator, the invention is, that the inner room is locked against the outer housing by an inner, automatically operated door, that a robot system is implemented in such, that the robot systems acting area is extended form in the inner room, partly in the area outside the inner room, but inside the outer housing, where spare parts are stored in a spare parts hand over area, for maintenance.

Owner:ABB (SCHWEIZ) AG

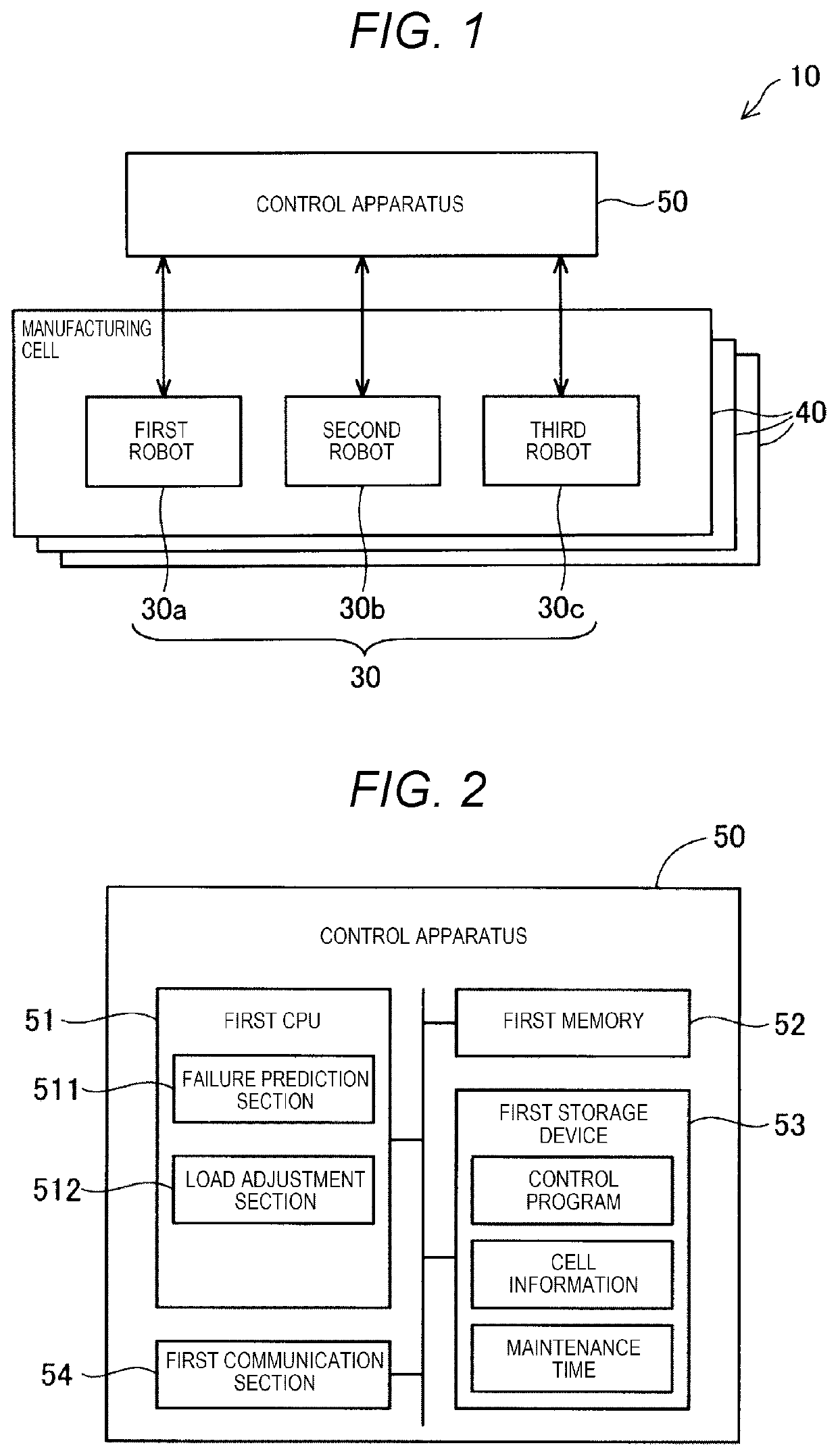

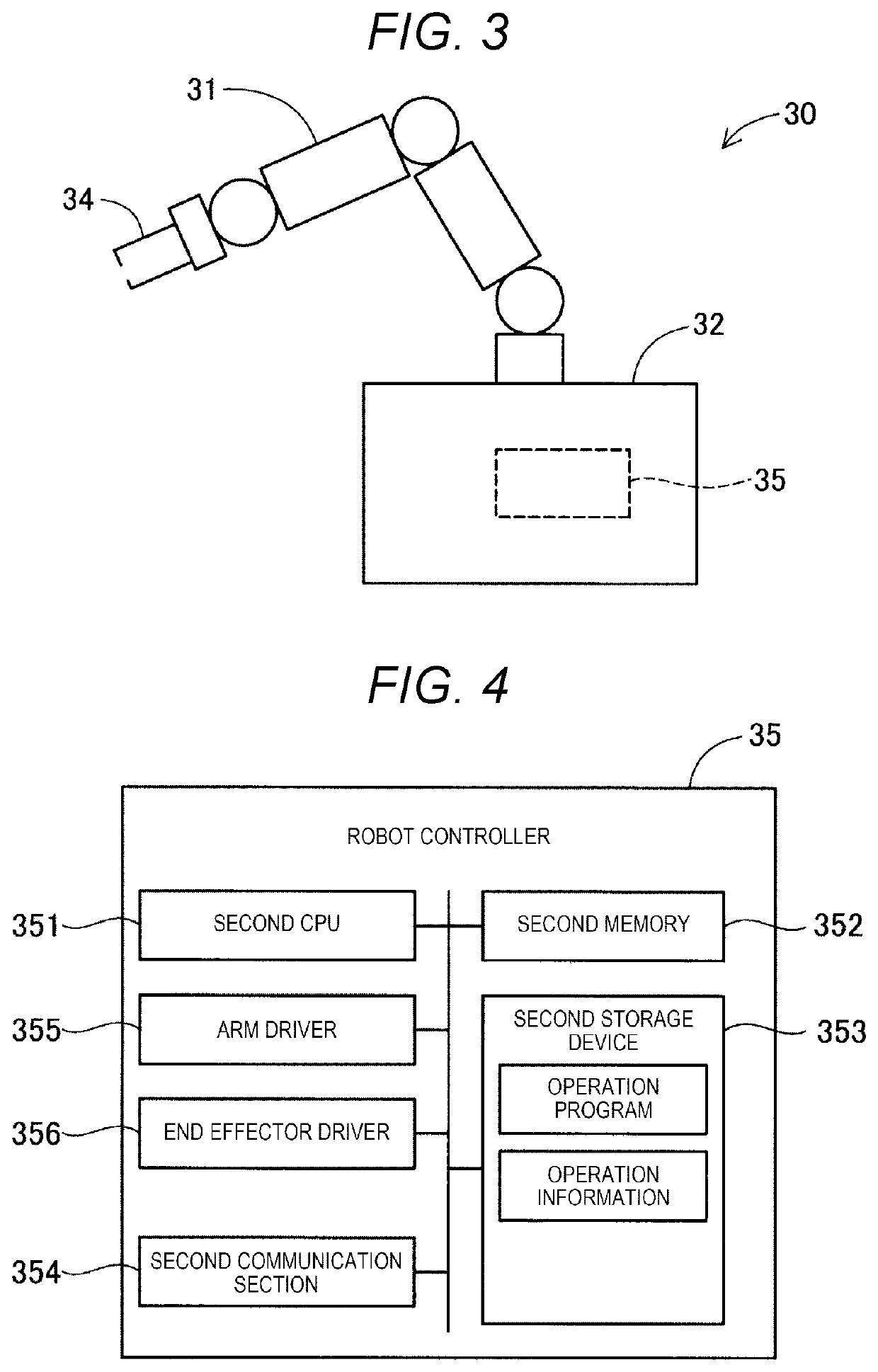

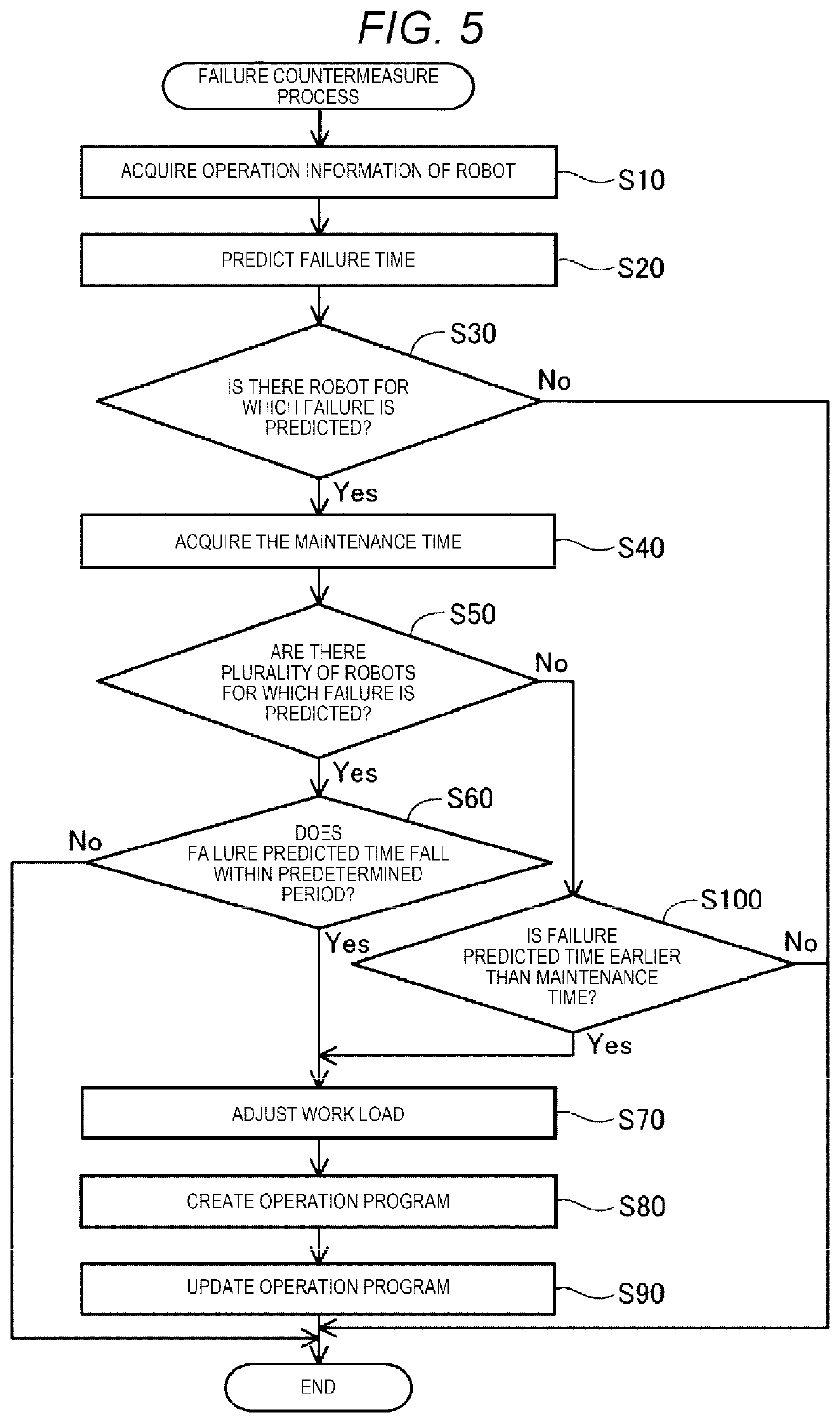

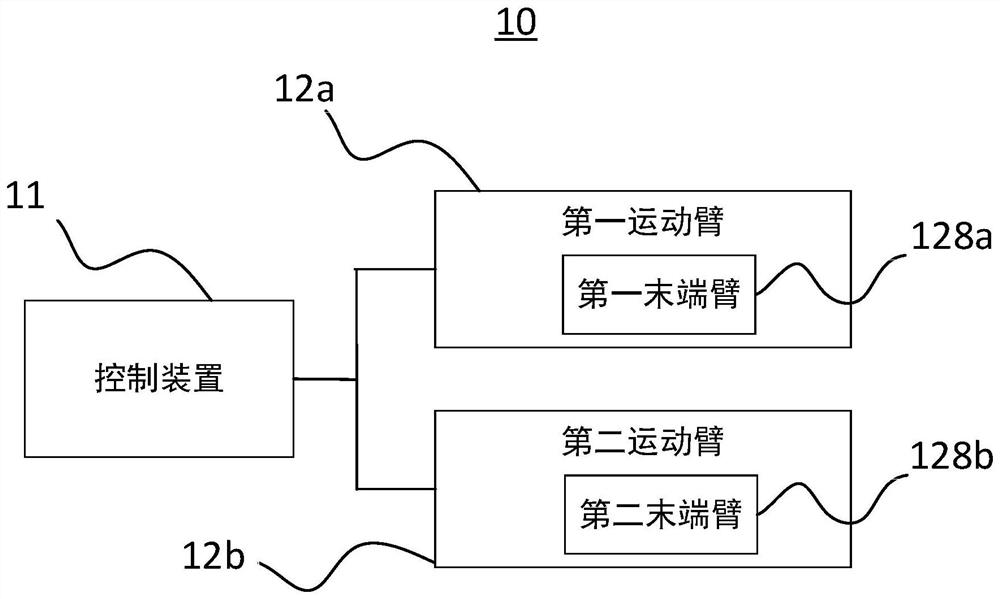

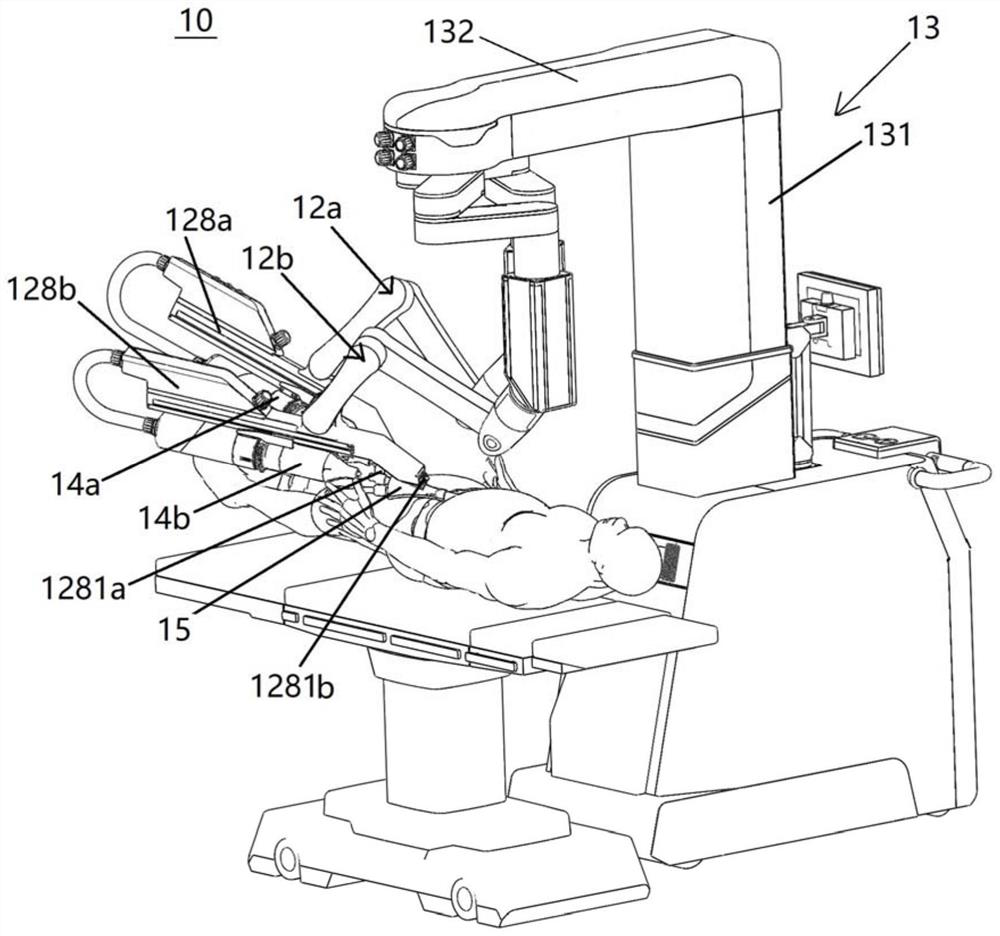

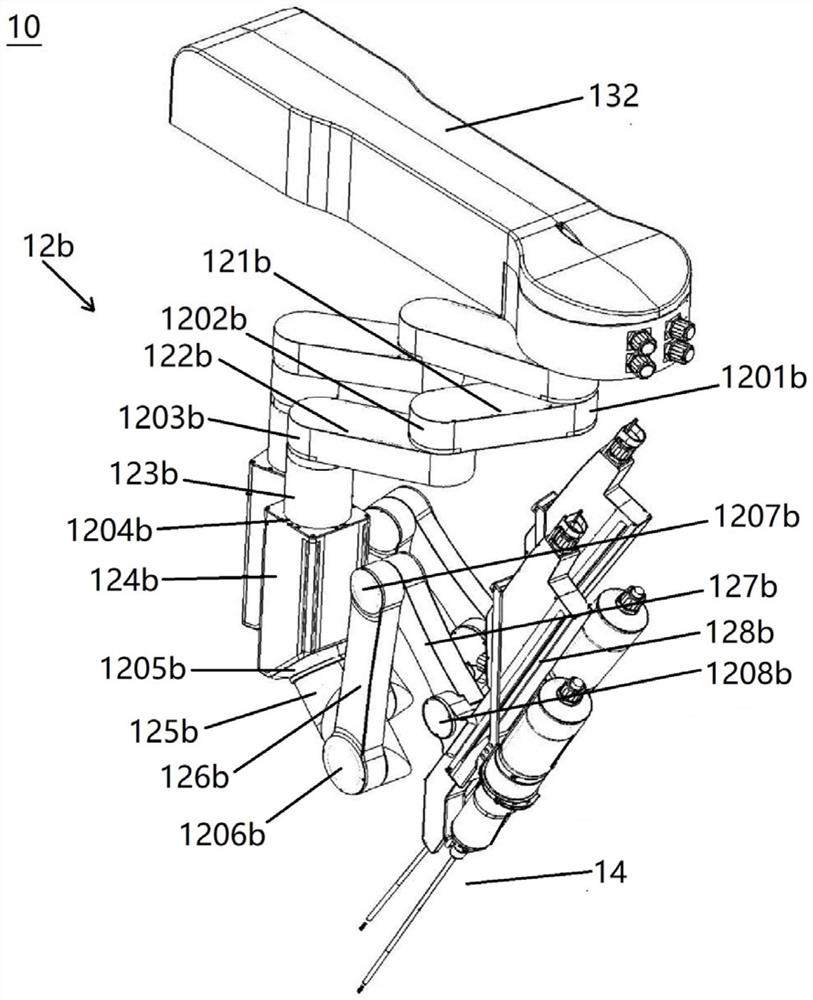

Robot system and control method

PendingCN114073589AProgramme-controlled manipulatorRobotics systemsRobotic systemsPhysical medicine and rehabilitation

The invention relates to the field of robots, and discloses a control method for a robot system, the robot system comprises a plurality of motion arms, and the control method comprises the following steps: determining the motion mode of one or more target motion arms in the plurality of motion arms based on an operation command; determining an initial pose of one or more target motion arms; performing one or more motion control cycles based on an initial pose of the one or more target motion arms and a motion step corresponding to the motion pattern, where for each motion control cycle, a target pose of the one or more target motion arms is determined; and controlling the one or more target motion arms to move towards the target pose. Therefore, the target motion arm can accurately, quickly and safely reach the target pose, and efficient and safe preoperative preparation is achieved.

Owner:BEIJING SURGERII TECH CO LTD

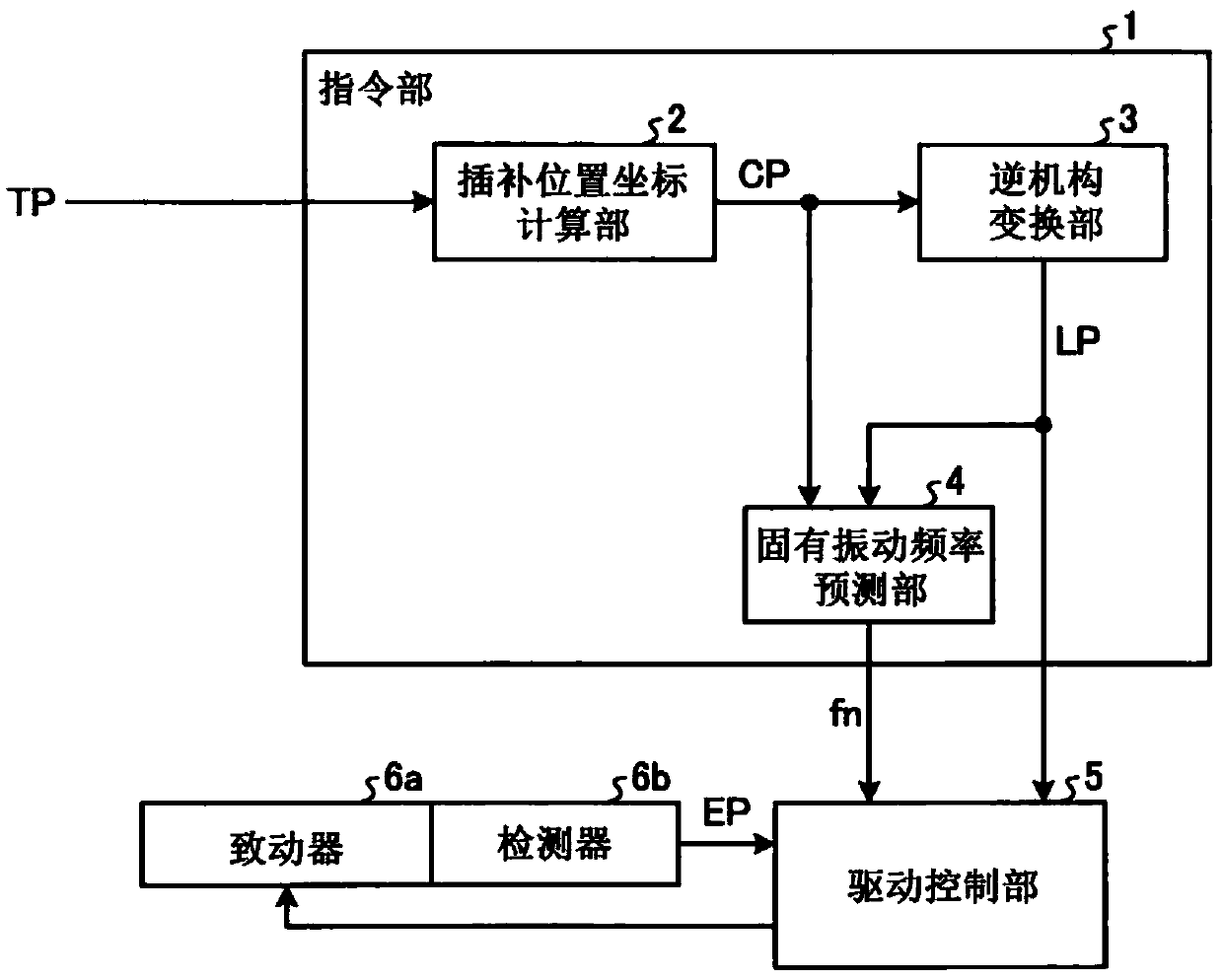

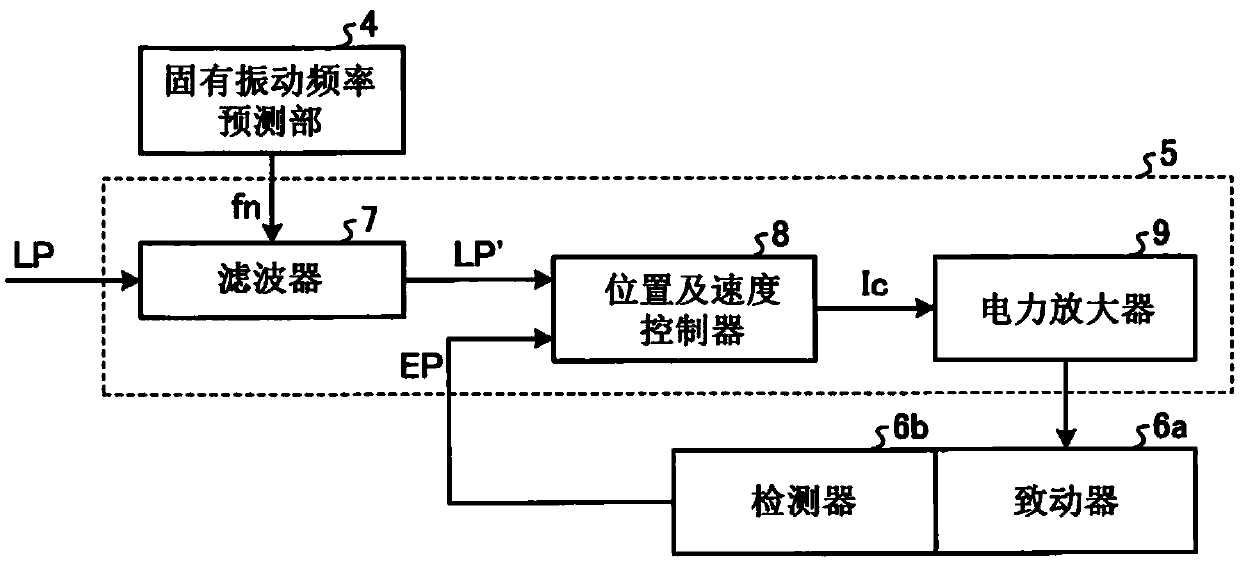

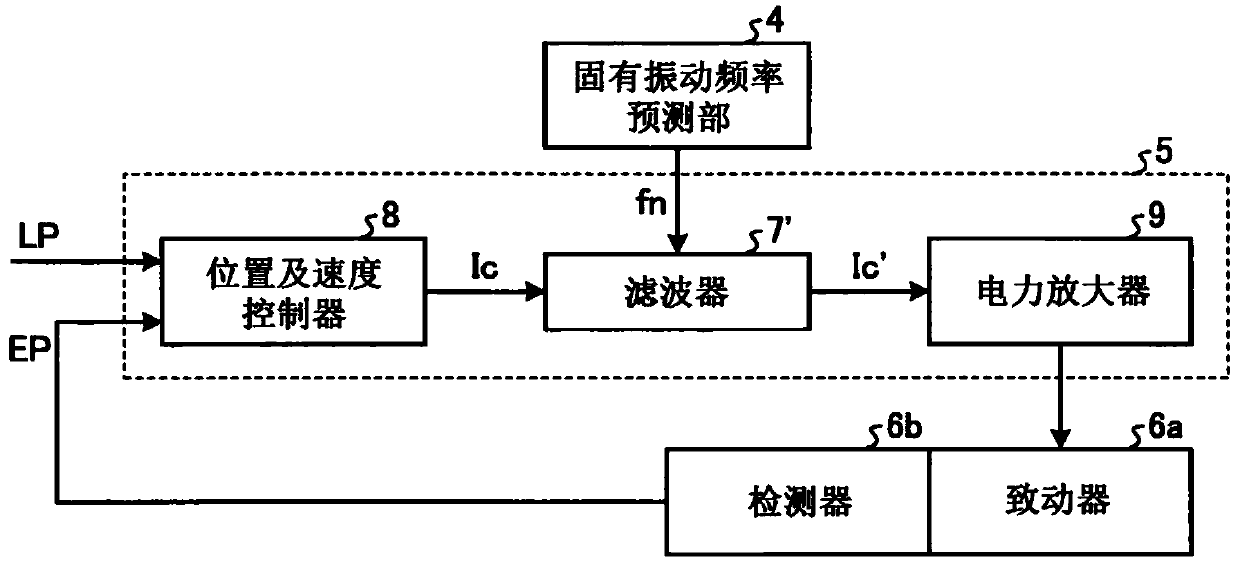

Device for controlling parallel link mechanism

ActiveCN109562518AReduce adjustment man-hoursReduce vibrationProgramme-controlled manipulatorRobotics systemsInstruction unitDynamic models

A device for controlling a parallel link mechanism comprises an instruction unit (1) in which instructions for controlling an actuator (6a) and a drive control unit (5) that control driving of the parallel link mechanism are issued to the drive control unit (5). The instruction unit (1) is provided with a natural frequency estimation unit (4) that calculates, for each interpolation position of anend effector, an estimated value of the natural frequency, which changes in response to the position of the end effector. The calculations are made according to a dynamic model obtained by simulatinga mechanical system from the base of the parallel link mechanism to a link joining part using a translation spring and simulating a mechanical system from the link joining part to the end effector using a single rigid body. The drive control unit (5) is provided with a filter that, for each interpolation position, changes a frequency component that is suppressed in accordance with an estimated value sequence for each interpolation position of the end effector calculated by the natural frequency estimation unit (4).

Owner:MITSUBISHI ELECTRIC CORP

robot controller

ActiveCN109153134BReduce the likelihood of a collisionImprove work efficiencyProgramme-controlled manipulatorRobotics systemsControl engineeringSimulation

An object of the present invention is to provide a robot control device that maintains high work efficiency and reduces the possibility of collision between the operator and the robot when they share the work space and perform work. It has a robot control state measurement unit (102 ), which measures the position and posture of the robot, that is, the robot control state; the work area setting part (104), which includes the body occupied by the operator in the operation action from the beginning to the end of the operation process. The area including the space is stored for each work process, and the work area corresponding to the current work process of the operator is set based on the work process specifying signal specifying the work process currently performed by the operator; and The robot instruction generating part (105), which generates an action instruction (105a) to the robot based on the operating area and the robot control state, and the robot instruction generating part (105) responds to the action instruction (105a) of the robot according to whether the robot exists in the operating area. ) to make changes.

Owner:MITSUBISHI ELECTRIC CORP

Engagement confirmation method performed by robot

ActiveUS10351393B2Reduce the burden onSimple configurationProgramme-controlled manipulatorRobotics systemsEngineeringHooking

A robot performs an appropriate operation in accordance with a position control, whereby an operation is carried out to pass a hook as a second engagement member through a hooking hole as a first engagement member. Thereafter, the robot is switched to a servo float control, and receives a command to raise the hook relatively with respect to the hooking hole. An amount of rising of the hook is compared with a maximum allowable amount of rising (threshold value) of the hook.

Owner:HONDA MOTOR CO LTD

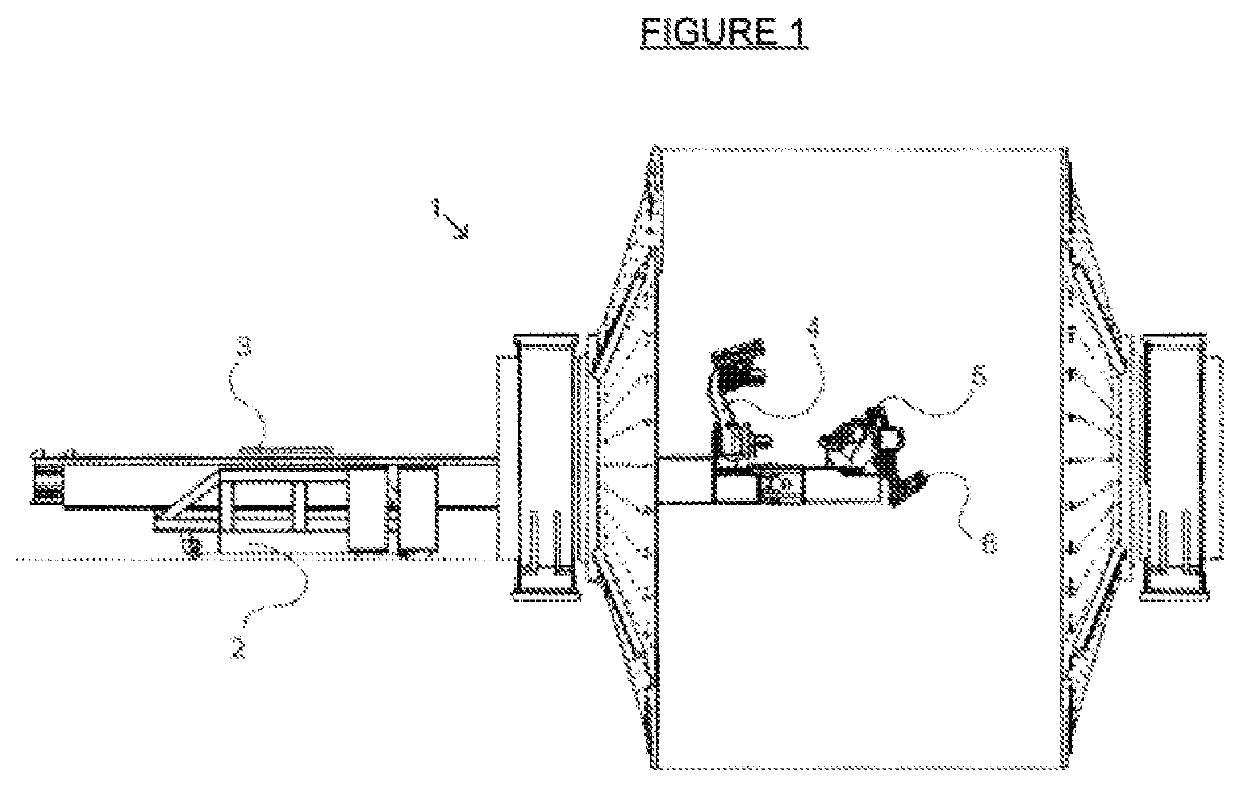

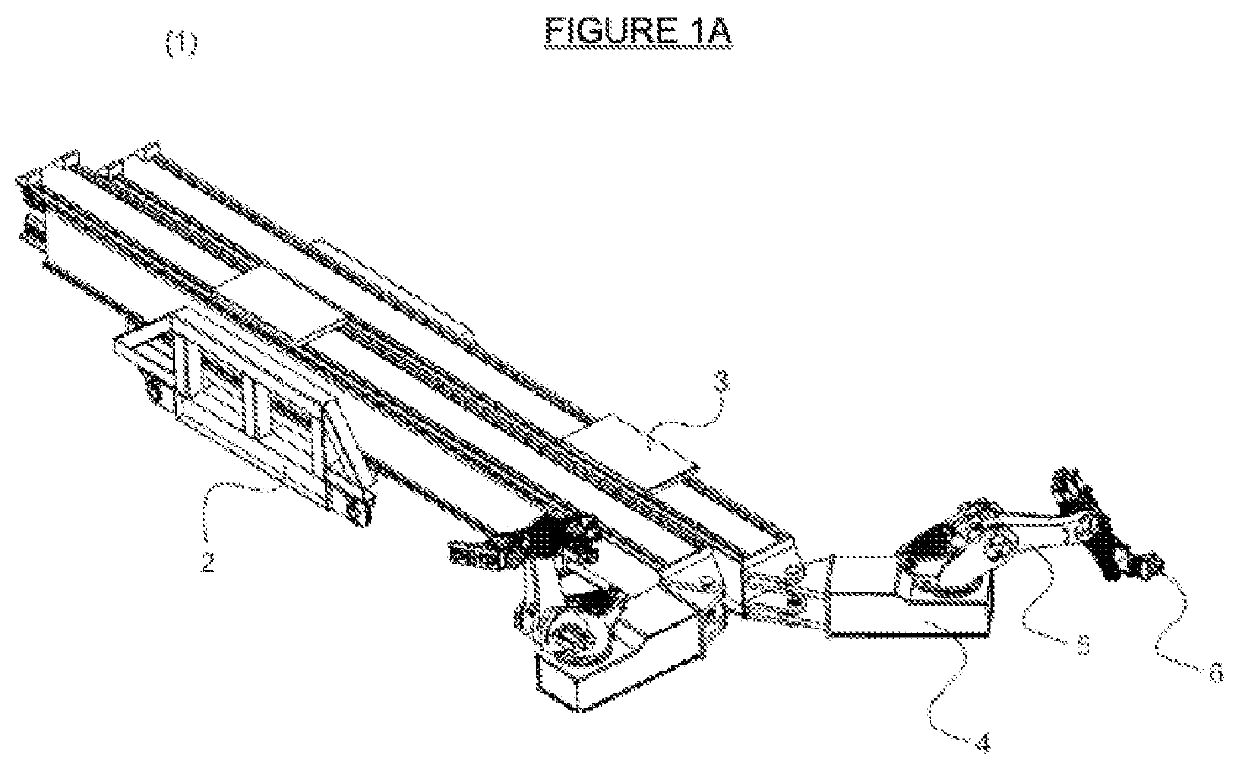

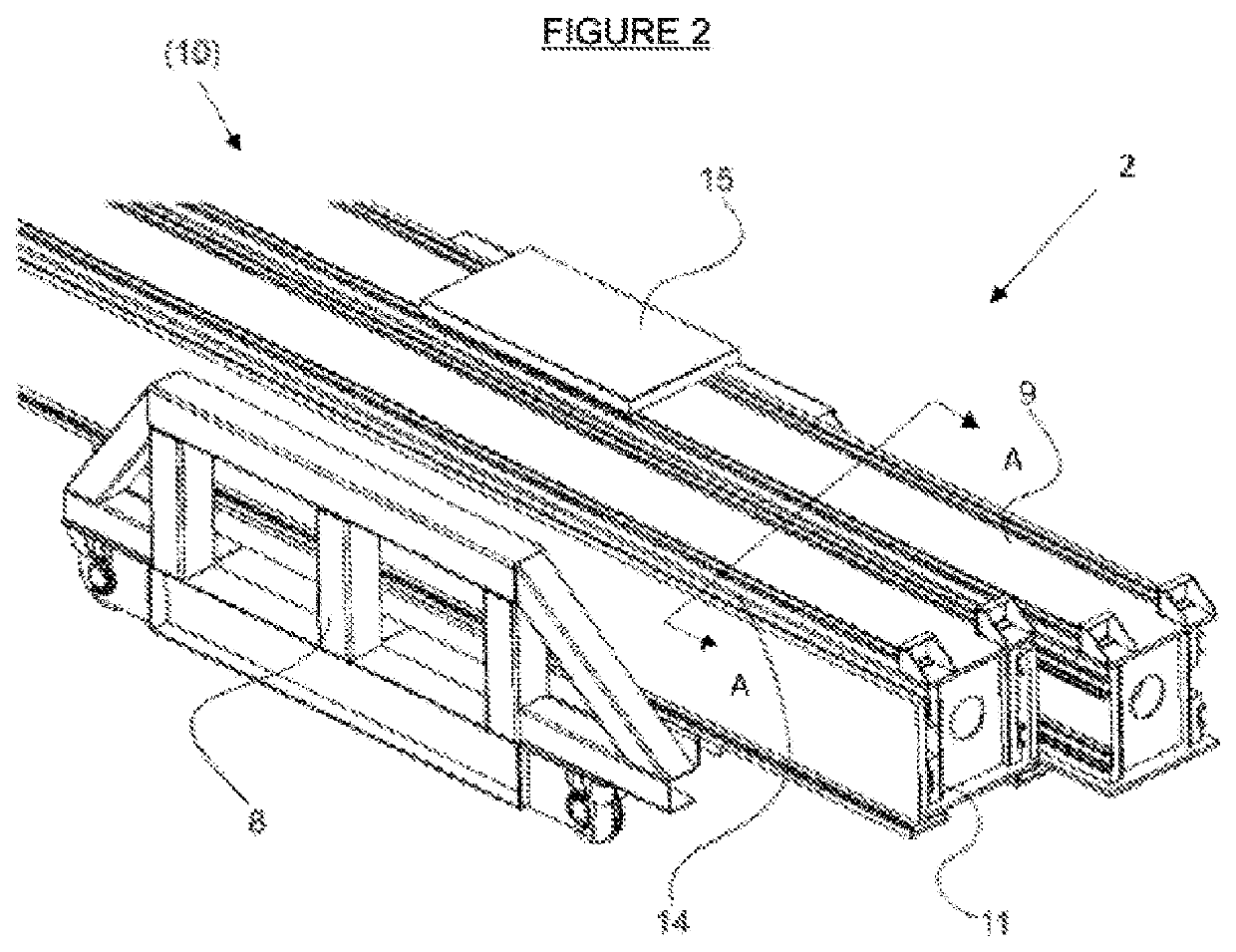

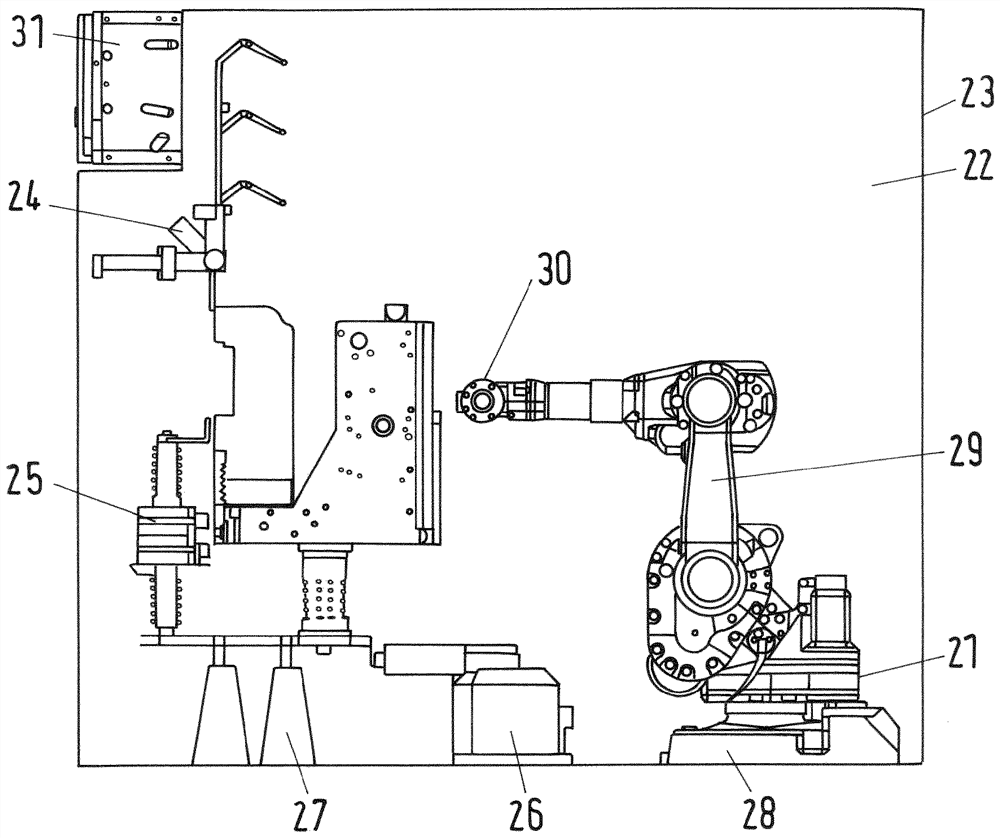

System and method for changing liners, the configuration of which allows the automated removal and insertion of liners of a mill used for ore grinding

PendingUS20220062915A1Great degree of certaintyGreat degree of efficiencyProgramme-controlled manipulatorRobotics systemsThermodynamicsControl system

The invention relates to a system and method for changing liners of a mill, the configuration of which allows the automated robotic manipulation of liners of mills for ore grinding in comminution processes. The configuration and operation of the system allows the task of manipulation to be improved, having a greater degree of freedom and / or flexibility in its movements, thereby providing a greater degree of certainty and efficiency to the method and thus optimising the time that the mill is halted for maintenance, and also preventing the risks to which maintenance staff may be exposed. The system comprises at least one support structure, at least one system for supplying and moving liners, at least one robotic manipulator system for manipulating the liners, at least one liner manipulation tool, at least one artificial vision system, and at least one control system.

Owner:MI ROBOTIC SOLUTIONS MIRS

Robot control apparatus which displays operation program including state of additional axis

ActiveUS10315305B2Easily estimate state and operationProgramme-controlled manipulatorRobotics systemsSimulationRobot control

A robot control apparatus controls a robot having six drive axes and a drive axis as an additional axis. The control apparatus includes a display control part which controls a display of a display part. The display control part displays, on the display part, a first picture which displays an operation program including an operation statement and a second picture which displays a state of the drive axes included in the operation statement. The display control part displays the operation statement including a state of the additional axis without including a state of the six drive axes in the first picture.

Owner:FANUC LTD

Substations containing unattended operation and maintenance of switchgear or controlgear

ActiveCN110832720BLocating and analyzing faultsProgramme-controlled manipulatorSwitchgear with horizontal withdrawalRobotic systemsControl engineering

The invention relates to a substation comprising switchgear or control gear for unmanned operation and maintenance. In order to carry out the operation and / or maintenance of such substations in an automated manner, and to increase the safety of the operators in the event that they are further required, the invention consists in separating the inner chamber relative to the outer casing by means of an automatically operated inner door Locking, realizing the robotic system such that the active area of the robotic system extends out of the inner chamber, partly in an area outside the inner chamber, but within the outer shell, wherein spare parts are stored in a spare part handover area for maintenance.

Owner:ABB (SCHWEIZ) AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com